Ever struggled with ceramics that turn out weaker than expected? Or they soak up water like a sponge? Porosity is to blame. Those tiny, hidden holes mess with performance. I’ve seen this problem in filters, insulators, and tough parts. Managing porosity is key for all of them.

So, what’s the trick? How do you get dense, reliable ceramics without spending too much on high heat or expensive additives?

Sintering Methods with Process Parameters

I recommend optimizing sintering methods to reduce porosity in ceramics. This approach improves mechanical performance. Here are the key process parameters and strategies:

Sintering Temperature and Cycle

Higher sintering temperatures lead to better densification and lower porosity. But temperatures over 1200 °C increase energy costs. They also cause unwanted grain growth.

For aluminosilicate ceramics, I suggest sintering at 1150 °C with additives like MnO₂. This matches the flexural strength of undoped ceramics sintered at 1200 °C. It also cuts water absorption significantly.

Sintering Aids and Additives

Add sintering aids such as MgO, ZrO₂, SiO₂, CaO, or MnO₂. These help grain boundaries diffuse better. They fill pores more effectively. They also stop excessive grain growth.

Example: I tested 0.3 wt.% MnO₂ at 1150 °C. Water absorption dropped to just 0.05%. That’s one-tenth of undoped ceramics at higher temperatures.

Pressure-Assisted Sintering

I like techniques like hot pressing and isostatic pressing. They use high pressure to speed up densification. They often achieve densities greater than 99%. Porosity drops to near theoretical limits.

Powder Properties

Start with ultra-fine powders. They boost atomic diffusion rates. This helps eliminate pores quickly. Key factors include initial grain size, size distribution, and particle shape. All these affect how well pores are removed.

Porosity Measurement and Control

I use the Archimedes method to track open and closed porosity during sintering. As the process moves forward, open porosity decreases. Isolated closed pores replace it.

Porosity type and distribution (open vs. closed, thin vs. equiaxed) can vary across different ceramic layers. This matters for specialized uses like filtration or catalysis.

Key Process Parameters to Monitor

- Temperature profile: Monitor the heat-up rate, peak temperature, soaking period, and controlled cooling. All these are vital.

- Atmosphere: Choose between oxygen, inert, or other reactive gases. Your choice impacts surface reactions.

- Applied pressure: This is needed for hot or isostatic pressing. It pushes densification forward.

- Additive concentration: Dose sintering aids precisely. This ensures the best microstructure forms.

Powder Preparation Techniques for Porosity Control in Ceramics

I believe powder preparation is key to managing porosity in ceramics. The methods below show how to shape ceramic structures for reduced or controlled porosity.

Ball Milling and Particle Size Optimization

- Start by mixing powders like zirconium silicate or alumina using a ball mill. I recommend a ratio of corundum ball: powder: water at 10:5:3.

- Mill at 250 rpm for 4 hours. This ensures uniform particle size and homogeneity.

- This step reduces clumps. It creates a foundation for denser, more consistent green bodies.

Drying, Sieving, and Solid Content Management

- After milling, dry the slurry at 120°C to a constant weight.

- Pass the dried powder through a 100-mesh sieve for optimal distribution.

- Control the solid content. For example, maintain 52 vol% to achieve suitable green body density.

- Proper control here improves densification. It also minimizes pore formation during sintering.

Use of Porosity Control Agents

Add sacrificial materials to adjust porosity:

- Synthetic: polymer beads, organic fibers

- Natural: potato starch, cellulose

- Inorganic: nickel, carbon, ash

The level of porosity relates to the amount of agent you add. For instance, adding more than 6% yeast increases brittleness in alumina ceramics.

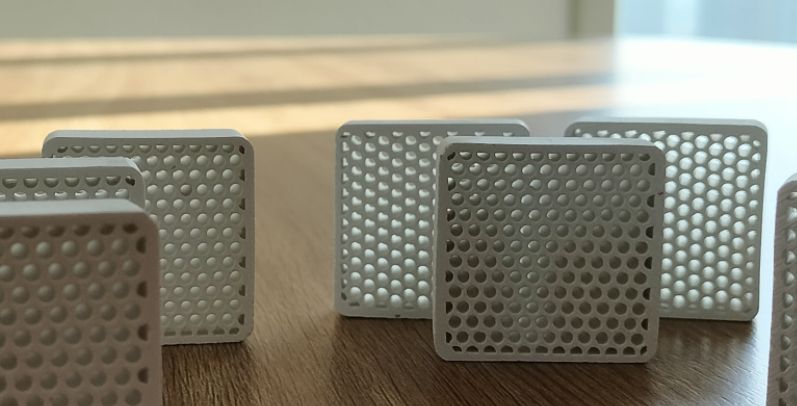

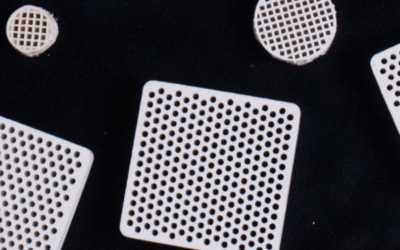

Template and Replica Methods

Use organic foam impregnation. Submerge a 3D foam in ceramic slurry, then dry and sinter.

Example: Sintering α-Al2O3 with organic foam at 1200°C for 2 hours achieves up to 93% porosity.

Alternative: Use sponges as sacrificial templates. This introduces controlled large-scale porosity.

Partial Sintering Approach

- Mix alumina powder with a binder (e.g., polyvinyl alcohol).

- Compact using 1 MPa for 2 minutes in a mold (20mm diameter).

- Dry at 100°C for 24 hours.

- Sinter at 1100°C for 1 hour.

Based on my experience, this technique achieves specific pore size and distribution. It often results in better mechanical properties than replica or sacrificial methods.

Additives and Stabilizers

I suggest adding materials such as CeO2 or MgO/CeO2 during powder preparation. These promote high-temperature phase stability. They reduce shrinkage and help with densification.

Measurement and Outcome Analysis

- Measure apparent porosity using the Archimedes method.

- Match pore diameter and total number with template features. This gives predictable results.

- Use lauryl sulfate triethanolamine (0.2–1 vol%) as a foaming agent. It creates uniform pore distribution.

Key Data and Practical Figures

- Ball milling: 250 rpm for 4 hours, 10:5:3 ratio

- Drying temp: 120°C

- Sieving: 100-mesh

- Solid content: 52 vol%

- Porosity via template: up to 93% at 1200°C/2h

- Partial sintering compaction: 1 MPa for 2 min

All these preparation steps and controls matter. From milling to using sacrificial templates, they determine ceramic grain connectivity. They shape pore distribution, final mechanical strength, and overall heat-mechanical properties.

Pressing and Forming Methods to Reduce Porosity in Ceramics

Different pressing and forming techniques help lower porosity in ceramics. I recommend choosing the right method based on your needs. The selection and parameters impact density, pore structure, and the final ceramic product’s strength.

Dry Pressing for Controlled Shapes

- Process: Ceramic powder is compressed with a die and punch.

- Features: Suitable for complex shapes and mass production.

- Porosity Impact: This method is quick and scalable. But non-uniform compaction can leave some residual porosity. I suggest combining dry pressing with secondary processing steps. This helps increase density.

Isostatic Pressing for Uniform Density

- Mechanism: Pressure is applied from all directions at once. The powder sits in a sealed, flexible mold. It is compacted under liquid or gas pressure.

- Porosity Results: This uniform compaction reduces air pockets. It leads to more uniform and denser green bodies.

- Material Examples: Alumina and zirconia show big gains in mechanical performance after isostatic processing.

Cold Isostatic Pressing (CIP) for Low-Porosity Green Bodies

How It Works: Very high, uniform pressure is used at room temperature. This overcomes particle bridging. It ensures even structure throughout the compact.

Advantages: CIP delivers green ceramics with almost no density gradient. Initial porosity is very low. This cuts down defects and residual voids after sintering. You get stronger, more reliable parts.

Hot Isostatic Pressing (HIP) for Near-Zero Porosity

Process Details: This method combines very high gas pressure with high temperatures. It speeds up atomic diffusion and complete pore closure. Grain growth stays controlled.

Applications: I recommend HIP for aerospace and defense components. It is key when ceramics must reach near-theoretical density and exceptional strength.

Technique Comparison: Efficiency and Applications

| Technique | Core Principle | Key Advantages | Applications/Outcomes |

|---|---|---|---|

| Dry Pressing | Compacting with die/punch | High output, complex forms | Electronic ceramics, tools |

| Isostatic Pressing | Pressure from all directions | Uniform green density, less porosity | Medium volume, complex parts |

| Cold Isostatic Pressing (CIP) | Very high pressure from all sides | Best structural uniformity, low porosity | High-density, strong ceramics |

| Hot Isostatic Pressing (HIP) | High-pressure, high-temperature gas environment | Densities near theoretical, closed porosity | High-performance, critical applications |

Based on my experience, these pressing and forming strategies are foundational for achieving ceramics with low porosity. They are necessary for advanced technology. They offer precise control over microstructure and physical properties.

Additive Materials and Their Functions for Porosity Control in Ceramics

I believe additive materials are vital for reducing and controlling porosity in ceramics. Each type affects pore structure, size, and ceramic performance.

Types of Additive Materials

Organic Pore Formers

- Examples: Starch (potato, corn, wheat), cellulose derivatives (methylcellulose, carboxymethylcellulose), polymer microspheres (PEG, PMMA, polystyrene spheres)

- Burnout Range: 200°C–500°C for polymers, 250°C–400°C for starch, and 300°C–450°C for cellulose derivatives

These additives burn out during firing. They create connected or elongated pores. The additive particles determine the size and shape. They give you high control over pore size and distribution. This makes them perfect for filters and insulators. But overuse can weaken mechanical strength.

Inorganic Additives

- Examples: Calcium carbonate (CaCO₃), silicon carbide (SiC)

At high temperatures, these additives release gases or react. This creates smaller, uniform, and stable pores. They make ceramics stronger and more heat-stable. I recommend them for high-strength, high-temperature uses.

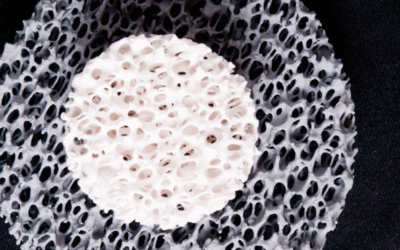

Fugitive Materials

- Examples: Paraffin wax, expandable polystyrene beads, sublimable terpenes (camphene, TBA)

These additives melt or sublimate during firing or freeze-casting. The result is a macro-porous network with unique shapes. Based on my experience, these work well for lightweight, permeable ceramic products.

Performance Data and Effect of Additives

- Porosity Levels: You can achieve up to 85% porosity with high concentrations of foaming agents.

- Thermal Conductivity: Porous silica ceramics (with polymer additives) can reach ultra-low values, such as 19.1 mW/m·K. This is key for insulation.

- Mechanical Strength: With polymer additives, compressive strength ranges from 0.2 to 1.4 MPa.

- Compression Recovery: Porous ceramics with polymers can show a recovery strain of up to 85%. This is useful in applications that need resilience.

Advanced Porosity Engineering and Dual-Scale Pores

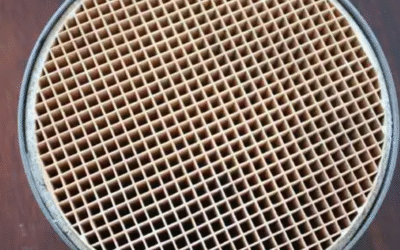

- Additive Manufacturing: Methods like 3D printing (robocasting, extrusion) create ceramics with both micro- and macro-scale pores.

- Benefits: Dual-scale designs improve fluid flow. They increase surface area. They boost mechanical and biological performance.

- Precision: I suggest using techniques such as two-photon polymerization with functionalized colloidal additives. These control pore diameter and achieve features below 200 nm.

Comparison Table: Additive Effects and Applications

| Additive type | Main function | Pore size/shape | Application areas |

|---|---|---|---|

| Starch (organic) | Burnout forming | Connected, tunable | Filters, insulation |

| Polymer beads | Burnout forming | Spherical, uniform | Porous supports, catalyst carriers |

| CaCO₃ (inorganic) | Gas release | Fine, uniform pores | High-strength ceramic parts |

| Paraffin/polystyrene | Melting out | Large, open pores | Lightweight components |

| Terpenes | Sublimation/freeze | Dendritic structures | Biomedical scaffolds |

Key Selection Factors

- Chemical match with the ceramic matrix

- Burnout or reaction temperature matched to the firing cycle

- Ability to balance mechanical strength, insulation, and permeability needs

Your additive material choice directly impacts final porosity. This makes it crucial for best ceramic performance across industrial, filtration, catalytic, and thermal insulation applications. I recommend choosing carefully based on your specific needs.

How to Reduce Porosity in Ceramics After Processing

Post-processing methods help you minimize porosity in ceramics. I recommend using these techniques to boost density and improve mechanical properties. They also fix problems like cracks and uneven pores.

Sintering: The Main Densification Step

Sintering is the top method for reducing porosity. You manage the heat cycle to make ceramic green bodies denser through solid-state diffusion. Case studies in ceramic extrusion additive manufacturing show this: optimized sintering gets final porosity below 1%. Sintering removes vertical porosity gaps. It makes the void size and shape uniform. You get smoother surfaces and better dimensions.

Data point: Volume shrinkage and densification during debinding and sintering can produce less than 1% porosity. This was measured by 2D image analysis.

Infiltration Processes: Sealing Leftover Pores

Infiltration adds materials like polymers, metals, or glass into open pores after initial sintering. This process seals any leftover porosity. It improves mechanical strength and toughness. Studies show that using infiltration after sintering cuts porosity and cracking by over 20% in 3D-printed ceramic parts.

Photonic Sintering and Curing: Fast Porosity Control

Photonic sintering (or photonic curing) uses high-intensity light bursts for fast, selective densification. It works great for thin films and bulk ceramics. This method cuts down on pore formation. It keeps substrate heating low.

Example: Photonic sintering processes ceramics in layers as thin as <1 μm in milliseconds. You can fabricate directly without long thermal post-processing.

Hydrothermal Treatments: Changing Ceramics Before Sintering

Hydrothermal treatment modifies the surface of ceramic powders before sintering. It adjusts chemical bonds for better densification. Alumina powders treated with phosphoric acid under hydrothermal conditions saw condensation temperatures drop from 165 °C to 150 °C. This created denser, stronger 3D-printed ceramic parts with lower final porosity.

Outcome: You see clear gains in both density and strength from these pre-sintering changes.

Test Results and Data Points

Advanced post-processing brings real improvements:

- Porosity reduction: Over 20% with infiltration plus sintering on 3D-printed ceramics.

- Leftover porosity after optimal sintering (extrusion AM): Less than 1%.

- Hydrothermal treatment: Lowers condensation temperature. This causes a clear drop in porosity.

X-ray μ-CT studies show uneven pore distribution in green ceramic parts. Sintering makes it uniform.

Alumina parts from extrusion additive manufacturing go through full post-processing (debinding then precision sintering). They show <1% porosity and better flexural strength.

I suggest these post-processing techniques—sintering, infiltration, photonic curing, and hydrothermal treatments—for low-porosity ceramics. Based on my experience, each step has strong data and real cases. They lead to better microstructure, performance, and product reliability across different ceramic technologies.

Equipment and Process Control Methods for Reducing Porosity in Ceramics

I recommend using the right mix of equipment and tight process control to optimize ceramic porosity. Special machines and controlled environments can cut down open and closed pore content. This boosts both density and mechanical performance.

Vacuum Hot Press Machines

Vacuum hot press machines work well for cutting ceramic porosity. These machines apply heat and pressure in a vacuum. They consolidate material and push porosity levels below 1%. Standard methods often give about 8% porosity. The vacuum removes almost all trapped air. This creates a very dense structure.

Mechanical and Ultrasound Mixing Equipment

Good mixing is key in the preparation phase. Mechanical mixing equipment blends powder and additives evenly. This cuts the risk of air pockets forming. I suggest using ultrasound mixing apparatus with mechanical mixers. Ultrasound waves break up clumps. This lowers porosity more and prepares the slurry or paste for forming.

Here’s what I’ve seen: hand mixing gives ~8% porosity. Mechanical mixing does better. Vacuum mixing can cut porosity to below 1%.

Pressurization and Centrifugation Systems

Pressurization systems push external pressure onto ceramic bodies. They force out air, compact material, and boost density. These systems suit high-density or tough industrial uses.

Centrifugation equipment uses centrifugal force to separate and remove air. It works based on density differences. This method does well for advanced ceramics and specialty metal-ceramic products.

Advanced Foaming and Molding Technologies

The foaming-injection molding method works with reaction sintering. This allows fine tuning of pore structure. For example, zirconia-reinforced mullite ceramics made this way achieved 66.4% porosity, 14.3 MPa flexural strength, and 36.3 MPa compressive strength. You must set foaming parameters with care for even pore distribution.

Direct foaming equipment creates very high porosity ceramics. It reaches over 95% porosity. This process controls gas addition and keeps the foam structure stable.

Foam Stabilization and Process Parameters

Ceramic foam stability depends on surfactant adsorption. With proper surfactant use, foam lifetimes extend from minutes to days or weeks.

Colloidal particle adsorption at air bubble surfaces boosts foam stability more. It reduces collapse and gives exact pore design.

Temperature and Time Controls in Sintering

You need exact temperature control in the sintering process. Based on my experience, sintering alumina at 1200°C for 2 hours produced ceramics with up to 93% porosity. This shows how sintering temperature and duration control final pore structure and shape.

Temperature changes porosity. It also changes linear shrinkage, grain growth, and phase composition.

Summary Table of Porosity Outcomes by Mixing and Pressing Method

| Method | Typical Porosity Achieved |

|---|---|

| Hand Mixing | ~8% |

| Mechanical Mixing | Lower than hand mixing |

| Vacuum Mixing/Hot Pressing | Below 1% |

| Foaming-Injection with Sinter | Up to 66.4% (tailored) |

| Direct Foaming | Above 95% (tailored) |

I recommend careful choice of these equipment types. Proper process controls are vital for tuning the porosity, structure, and performance of ceramic materials in industrial and high-tech uses.

Examples and Material Specifications for Reducing Porosity in Ceramics

I’ve found that real-world cases show how you can control porosity in ceramics. Material choice, additives, and fabrication techniques all play a role.

Red Clay Ceramic Membranes: Carbonate Removal

Removing carbonate from Moroccan red clay increases density. It also lowers open porosity.

At 900 °C:

- With carbonate: 48.51% open porosity, 1.39 g/cm³ density

- Carbonate-free: 41.82% porosity, 1.47 g/cm³ density

At 1100 °C:

- With carbonate: 39.35% porosity, 1.55 g/cm³ density

- Carbonate-free: 33.15% porosity, 1.59 g/cm³ density

My take: Carbonate removal works well for denser, less porous red clay ceramics. I recommend this for membrane and filtration uses.

Organic Foam Impregnation and Porous Ceramics

Materials used: α-Al₂O₃, zirconia (ZrO₂), mullite, with MgO, CeO₂ as stabilizers.

Porous Alumina Example:

- Sinter α-Al₂O₃ with gum arabic and organic foam template at 1200 °C for 2 hours.

- This achieves 93% porosity. You get a lightweight, open-structured ceramic.

Zirconia-Reinforced Mullite Ceramics:

- Mullite + 6 wt% AlF₃·3H₂O → 68.6% porosity, 11.3 MPa flexural strength, 29.4 MPa compressive strength.

- Add 8 wt% Y₂O₃ to ZrO₂-mullite: 66.4% porosity, 14.3 MPa flexural, 36.3 MPa compressive strength.

- Strength gains: +20.5% flexural, +19% compressive over standard porous ZrO₂.

Unidirectional Pore Ceramics via Templating and Evaporation-Freezing (EF)

Mullite ceramics with aligned pores created using the EF method.

Performance:

- Capillary rise: up to 1.29 m

- Effective pore radius: 4 μm

- Contact angle: θ = 69.5°

Applications: Better water transport and passive cooling. Surface temperature drops by ~10 °C (from >40 °C to about 30 °C under wetting).

Hierarchical Porous Ceramics via 3D Printing

3D-printed ceramic lattices:

- Porosity: 73.7%–79.3%

- Compressive strength: 1.53–9.61 MPa

Feature: You can tune architecture and mechanical strength by design. Based on my experience, these work well for advanced filters, scaffolds, and insulators.

Porosity Control in Silica Ceramics: Freeze-Casting with Camphene

Silica ceramics shaped by freeze-casting in one direction. Camphene acts as a pore-forming agent.

Result: You get controlled microstructure and porosity. The full-factorial process design allows customization.

Material Specification Summary

I suggest looking at these key materials:

- Red clay (carbonate-modified, optimized for density)

- α-Al₂O₃ (with gum arabic, organic foam templates, sintered at 1200 °C)

- Mullite + ZrO₂/Y₂O₃ or MgO/CeO₂ stabilized systems

- Silica (with camphene, freeze-casting)

- 3D-printed ceramic lattices for porous architectures with different layers

Summary

Looking back at all these methods and materials, I’ve learned something important. Reducing porosity isn’t about one magic fix. It’s about matching the right technique to your specific needs.

Are you pressing powders? Choosing additives? Fine-tuning sintering cycles? Each decision shapes your final product.

I suggest you experiment with these approaches. Start small. Measure with precision. Build on what works.

Creating dense, reliable ceramics takes patience. Based on my experience, the results are worth the effort.