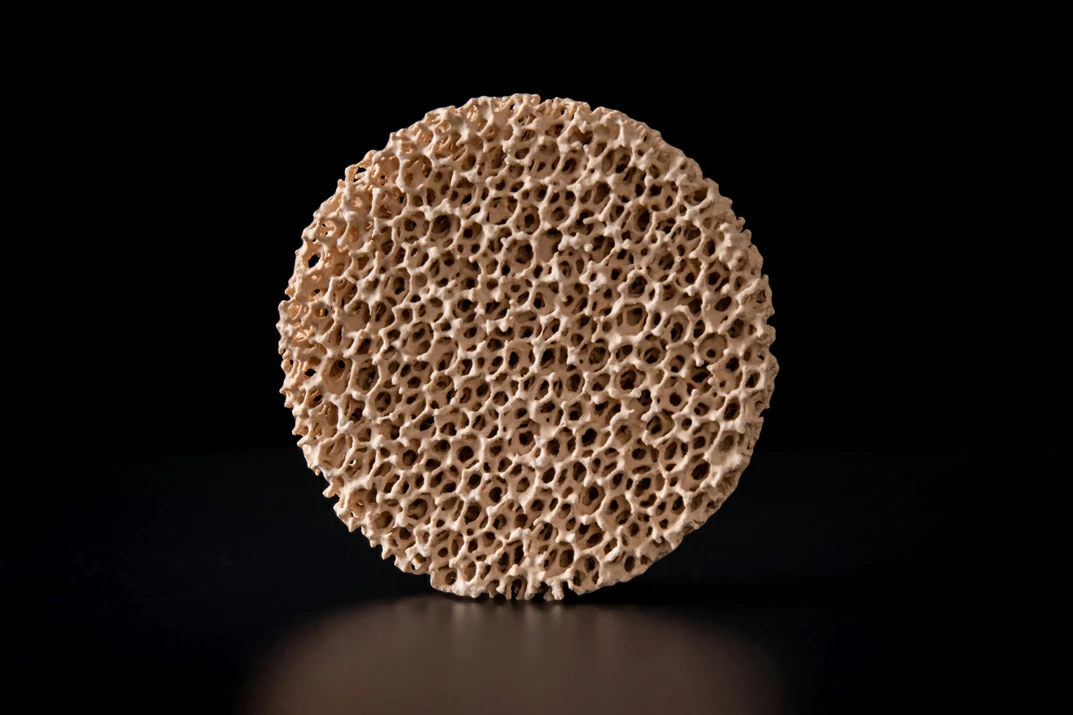

FM-08 High-Purity Magnesia Ceramic Foam Filter for Magnesium Alloy Melt Filtration

The FM-08 Magnesia Ceramic Foam Filter from FoundryMax revolutionizes magnesium alloy filtration with its ultra-pure composition and advanced 3D structure. Specially engineered for demanding magnesium casting environments, this filter effectively removes harmful impurities while maintaining optimal metal flow.

Ideal For:

High-precision magnesium alloy die casting

Aerospace and automotive magnesium components

Premium electronic housing production

Any application demanding ultra-clean magnesium melts

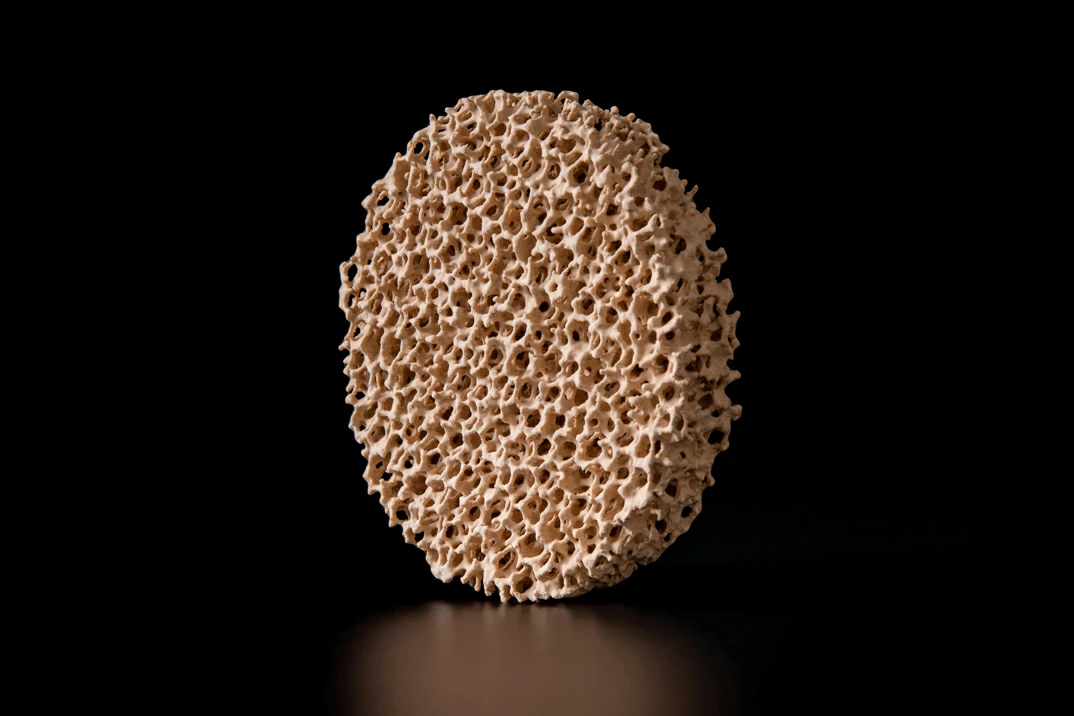

Three-dimensional mesh structure design provides optimal filtration efficiency and metal flowability.

Pore size options range from 10-60 PPI to meet varying filtration requirements.

High-temperature operation up to 1200°C meets the requirements of magnesium alloy casting processes.

High porosity of 80-90% reduces filtration pressure drop and improves production efficiency.

0.6 MPa room-temperature compressive strength ensures structural stability during use.

Excellent thermal shock resistance withstands multiple casting cycles.

Professional Ceramic Filter Manufacturer: Magnesia Ceramic Foam Filter for Magnesium Alloy Filtration

Specialized molten metal filter material for high-temperature magnesium alloy melts

Our magnesium oxide ceramic foam filters are specifically designed for magnesium alloy melt filtration. Made from 99% high-purity magnesium oxide, they offer excellent high-temperature stability and chemical compatibility. By effectively removing inclusions from molten magnesium, they significantly improve the surface quality and internal structure of castings, helping manufacturers reduce scrap rates and improve product performance.

Technical Specifications

| Main Composition | 99% Magnesium Oxide Material |

| Pore Size Range | 10-60 PPI |

| Maximum Operating Temperature | 1200°C |

| Through-Porosity | 80-90% |

| Compressive Strength at Room Temperature | 0.6 MPa |

Reduced Scrap Rate

Using this ceramic foam filter reduces scrap rates, directly improving production efficiency

Improved Casting Strength

Filtered magnesium alloy castings have increased tensile strength and more stable performance

Improved Surface Quality

Surface defects on magnesium alloys are reduced, reducing subsequent casting processing costs

What Can We Offer?

As a professional manufacturer, we offer magnesium oxide ceramic foam filters in a variety of sizes and shapes to meet the needs of diverse magnesium alloy casting applications. We can provide the most suitable product specifications based on your specific process parameters and quality requirements, ensuring optimal filtration performance and cost-effectiveness:

10-20 PPI foam filters: Large pore size and high flow capacity, suitable for high-flow rate and large-volume melt filtration, ideal for large casting production.

30-40 PPI foam filters: Comprehensively capture medium and large inclusions, maintain good flowability, and are widely applicable to most magnesium alloy casting processes.

50-60 PPI foam filters: Fine pore size and high filtration accuracy capture micro-inclusions, providing optimal filtration performance, suitable for high-precision and demanding casting production.

Custom Shape Series

Our magnesium oxide ceramic foam filters offer a comprehensive range of specifications and can be designed to meet your specific casting system needs. Custom shapes, including square, round, and special shapes, are available to perfectly fit your casting system.

Square: 20×20mm to 500×500mm, 15-50mm thickness

Round: 20mm to 300mm diameter, 15-50mm thickness

Special Shapes: Customizable according to your CAD drawings.

Our magnesia ceramic foam filters are designed for easy installation into existing casting systems.

Our ceramic filters are available in a wide range of sizes and can be directly installed into the filter housing or gate of existing casting systems. For non-standard systems, we offer custom-shaped filters and corresponding mounting adapters to ensure a perfect fit.

The filter design takes into account the unique process requirements of magnesium alloy casting. We provide detailed process parameter recommendations to help customers integrate the filters into their existing production processes.

Applicable Metals: Suitable for all types of magnesium and magnesium alloy molten metals

Gating System: Compatible with all types of pouring cups, filter holders, and filter chambers

Foundry Equipment: Compatible with all major foundry equipment and melting furnaces

High-Purity Magnesia Ceramic Foam Filter

Magnesium Alloy Filter Material

Our Magnesia Ceramic Foam Filters provide a one-stop melt purification solution for magnesium alloy foundries. Their 99% high-purity magnesium oxide material and innovative gradient filtration structure maintain stability even at temperatures up to 1200°C, effectively removing over 95% of inclusions. This helps customers improve product quality, reduce scrap rates, and save production costs. Our customized services ensure each customer receives the filtration solution best suited to their specific process.

Through this holistic solution approach, our magnesia ceramic foam filters are not just a standalone product, but a key component of a comprehensive system for improving magnesium alloy casting quality, helping customers achieve a leap in overall process performance.

Filter Application

After using our ceramic foam filters for magnesium alloy filtration, customers have seen a reduction in internal porosity and inclusion defects in magnesium alloy castings, resulting in lower foundry scrap rates and direct savings in production costs. After filtration, the tensile strength of magnesium alloy castings increased by 15-20%, while ductility also improved. With less rework and post-processing, production cycle times are shortened and productivity is increased.

Frequently Asked Questions

What are the advantages of magnesia ceramic foam filters compared to other filter materials?

The primary advantage of magnesia ceramic foam filters is their excellent chemical compatibility with magnesium alloy melts. Traditional alumina or silicon carbide filters may react in high-temperature magnesium liquid environments, resulting in reduced filtration effectiveness or contamination of the liquid metal. Our product is made of 99% high-purity magnesium oxide, which remains chemically stable at magnesium alloy casting temperatures and does not react with the melt. Furthermore, its three-dimensional network structure provides deep filtration capabilities, achieving filtration efficiencies exceeding 95%, far exceeding the 60-70% of traditional metal mesh filters.

How to Choose a PPI?

The following factors should be considered when selecting the appropriate pore density:

- Inclusion Size: Generally speaking, smaller inclusions require a higher pore density.

- Metal Flow Rate: At higher flow rates, a lower PPI is recommended to reduce resistance.

- Casting Quality Requirements: High-precision castings typically require a 50-60 PPI, while general castings can require a 30-40 PPI.

- Alloy Type: Different magnesium alloys may have specific requirements.

Can magnesia ceramic foam filters be reused?

Our magnesia ceramic foam filters are designed for single use. After a single use, the filter may have trapped a significant amount of inclusions, partially blocking the pores and significantly reducing filtration efficiency. Furthermore, the filter may have undergone trace reactions with the melt, potentially compromising its structural stability. For quality control and safety reasons, we strongly recommend using a new filter for each pour to ensure optimal filtration and casting quality.

Can you provide custom specifications? What is the custom process?

Yes, we specialize in providing customized products. The customization process is as follows:

- Request Submission: Provide specific requirements such as size, shape, and pore density.

- Technical Evaluation: Our engineers will assess feasibility and provide recommendations.

- Solution Confirmation: Both parties agree on the final technical proposal and quote.

- Sample Production: For first-time orders, we typically provide sample confirmation.

- Mass Production: Mass production begins after sample confirmation.

- Quality Inspection: Inspection is conducted according to agreed standards.

- Delivery: Complete technical documentation and user instructions are provided.

Custom lead times typically range from 10-15 days for samples and 15-30 days for mass production. We can customize parameters, including size, shape, and pore size, to meet your specific needs.

Related Casting Filter Products

As an experienced filter manufacturer, we craft durable and efficient molten metal filters tailored for foundry needs

Contact us for magnesia ceramic foam filter samples and expert application advice. Our engineers will provide the most suitable product and filtration solution based on your specific casting process parameters, helping you reduce scrap and improve product performance. Inquire now!

Discover Your Optimal Filtration Solution

Request a free consultation with our filtration specialists to identify the ideal industrial filter technology.

CONTACT US

Let's Connect

Our Engineers Will Analyze Your Needs & Offer the Perfect Filter Design – Contact Us Today.

Address

Guanting Industrial Park, Cangzhou City,

Hebei Province, China