Porous alumina ceramic versus zirconia ceramic—your choice affects both project performance and budget. Both materials lead in advanced industrial and biomedical uses. But they give you different results in strength, porosity, biocompatibility, and cost.

Engineers and researchers face this choice often: Do you need zirconia’s exceptional toughness? Or do you need alumina’s controlled porosity and thermal stability? The answer depends on your specific needs. Dental implants need different properties than bone scaffolds. Filtration systems differ from wear-resistant parts.

This comparison shows you when each material works best. You’ll see where they fall short. Plus, we cover how new hybrid solutions are changing the ceramic field. Designing medical devices? Improving industrial processes? Just exploring material options? You’ll find the performance metrics and real-world insights to make a confident, cost-effective choice.

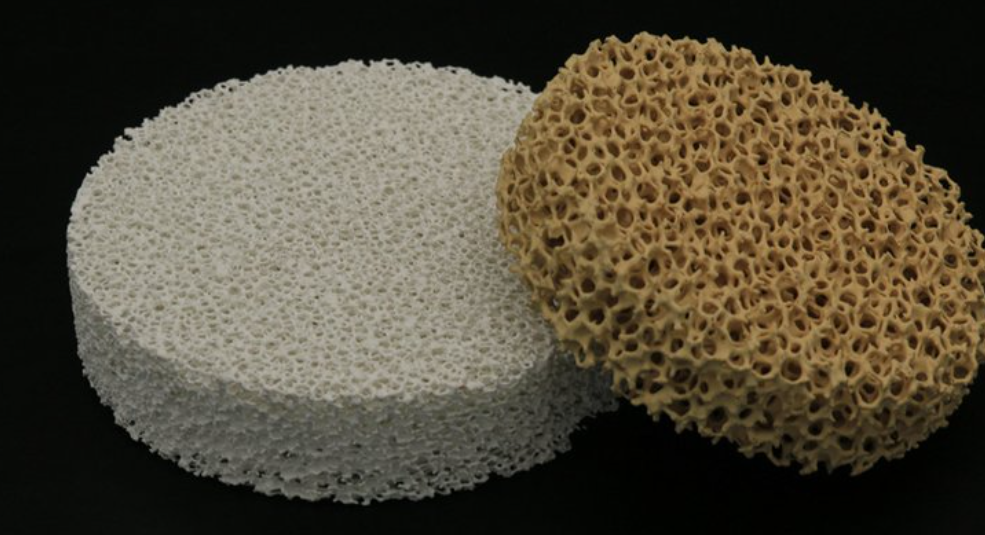

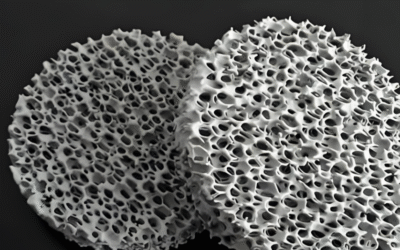

What Is Porous Alumina Ceramic? Core Properties and Applications

Porous alumina ceramic is aluminum oxide (Al₂O₃) built with controlled pore networks. This material blends alumina’s natural hardness and heat stability with designed void spaces. These spaces enable filtration, permeation, and lightweight uses.

Material Composition and Purity Levels

The composition ranges from 91% to 99.999% Al₂O₃. Industrial-grade types contain 91-99% alumina. High-purity versions reach 99.999% aluminum oxide. This cuts contamination risks in sensitive uses like semiconductor processing or medical devices.

Porosity Architecture

Porosity levels span 6.2% to 57%. Manufacturing techniques determine this range. Common industrial grades operate at 11.8-55% porosity. You control pore traits through pore-forming agents:

-

PS50 agent (20 wt.%) creates 11.8% porosity at 3.2 g/cm³ density. It gives you optimal strength-to-weight balance at 150.4 MPa bending strength.

-

40 wt.% starch produces 57% porosity with 60 MPa compressive strength. This works for high-flow filtration.

-

Core-shell microspheres generate closed porosity from 5.82% to 14.5%. Flexural strength sits between 97 and 292 MPa.

Pore sizes vary widely. You get 0.055 μm (55 nanometers) for ultra-fine filtration. Gas permeation systems use up to 50 μm. Grade N-99SP hits 0.055 μm median pore diameter at 99.9% purity. Perfect for precision membrane applications.

Mechanical Performance

Bending strength ranges from 69 to 291 MPa. High-purity grades hit 379 MPa flexural strength (Weibull average, 4-point testing). Water absorption links with porosity: 14% at lower porosity levels, rising to 35% at 55% porosity.

Industrial Applications

Porous alumina plays key roles in gas and liquid filtration systems. It works in vacuum chucks for semiconductor wafer handling. Air bearing surfaces use it too. You can customize membranes with pore diameters from 0.1 to 50 μm. The material handles temperatures up to 1100°C. Structural integrity stays intact.

What Is Zirconia Ceramic? Key Properties and Uses

Zirconia ceramic (ZrO₂) works best where you can’t afford failure. This ceramic breaks at up to 17 MPa·m¹/², beating most other advanced ceramics. Agents like yttria, magnesia, or ceria keep the crystal structure stable. This stops harmful changes during heat cycles.

Strong Mechanical Performance

You get flexural strength from 800-1400 MPa across different types. Ultra Tough versions hit 1000 MPa. Nano HIP processing pushes this to 1400 MPa. Compressive strength reaches 2000-2500 MPa. So zirconia works well under heavy loads in dental crowns and cutting tools.

Fracture toughness gives zirconia its edge. Standard types deliver 8-10 MPa·m¹/². Ultra Tough HIP versions hit 17 MPa·m¹/². Compare this to alumina at 4-5 MPa·m¹/². Zirconia stops cracks through transformation toughening. Stressed areas trigger a phase change that soaks up energy.

Hardness goes from 13-14.5 GPa (1200-1300 kg/mm² Knoop scale). Surface hardness hits 91 HRA on the Rockwell scale. Dense grain structures—down to 0.2 µm in YSZ types—give this strong wear resistance.

Heat and Electric Properties

You can run this at 1500°C in inert atmospheres. Air limits this to 800-1000°C based on stabilization type. Heat moves through slowly at 2-3 W/m·K. That’s less than one-tenth of other structural ceramics. Thermal expansion sits at 9-10.3 × 10⁻⁶/K. It handles 250-400°C temperature swings without breaking.

Dielectric constant measures 28-29 at 1 MHz. Dielectric strength hits 18 kV/mm. This makes it great for high-voltage insulation and electronic bases.

Stabilized Types and Mixed Solutions

-

3YSZ (3 mol% yttria): Fine-grain structure gives 1200 MPa flexural strength. Works up to 1000°C.

-

YTZP (Yttria-Stabilized Tetragonal): Strong wear resistance with >800 MPa flexural strength. Very stable in chemicals.

-

ZTA (Zirconia-Toughened Alumina): Gets alumina’s cost benefit plus 20-30% more strength. Toughness and hardness beat pure alumina.

-

Zircalon 30: Balanced at 1200 MPa flexural and 1600 MPa compressive strength. Toughness hits 15 MPa·m¹/².

Mechanical Strength and Toughness: Head-to-Head Comparison

Strength alone doesn’t tell the full story. Toughness shows whether your ceramic survives real-world stress.

Porous zirconia ceramic beats porous alumina in both bending strength and crack resistance. Standard zirconia delivers 800-1400 MPa bending strength. Porous alumina sits at 69-291 MPa. The porosity level makes the difference. Higher porosity creates weaker structure. At 57% porosity, strength drops to around 60 MPa under pressure. Dense alumina reaches 379 MPa bending strength. That’s still half of zirconia’s baseline.

Crack Resistance: The Key Difference

Crack resistance measures how well material stops cracks from spreading. Zirconia wins here. Standard grades hit 8-10 MPa·m¹/². Ultra Tough HIP versions reach 17 MPa·m¹/². Alumina-based ceramics max out at 3.6-4.4 MPa·m¹/². In-Ceram Alumina (slip-pressed) achieves 4.4 MPa·m¹/² with 594 MPa pulling strength. That’s the highest among alumina types. Zirconia’s special toughening process absorbs stress energy. This same energy would break alumina apart.

Compare this to structural steel. AerMet® 100 alloy scores a toughness index of 103. It balances crack resistance (120 ksi√in) and impact energy (35 ft-lb). Ceramics can’t match how metals bend. But zirconia’s 17 MPa·m¹/² crack resistance gets close to the reliability you need for heavy-duty uses.

How Porosity Changes Things

Porous alumina trades strength for function. At 11.8% porosity, you get 150.4 MPa bending strength with great filtering ability. Add 40 wt.% starch and porosity jumps to 57%. Strength drops, but liquid flow shoots up. Zirconia doesn’t give you this choice. It’s dense or nothing.

Impact Resistance in Real Use

Zirconia handles sudden impacts better. Its hardness (13-14.5 GPa) and toughness work together. This stops chipping in dental work and cutting tools. Porous alumina has connected empty spaces. These make it break easily under shock. Water soaks in (14-35%). This weakens the structure more as moisture fills the pores.

Pick zirconia for uses where failure isn’t an option. Surgical tools, aerospace seals, high-stress bearings. Pick porous alumina for jobs where controlled liquid flow beats pure strength. Membrane filters, supports for chemical reactions, heat barriers under moderate weight.

Biomedical Performance: Porosity Effects on Cell Growth

Cell behavior in bone scaffolds depends on pore architecture. Pore size, porosity percentage, and surface area create different biological responses in tissue engineering.

Optimal Pore Ranges for Bone Regeneration

Porous alumina ceramic scaffolds need specific pore sizes for bone tissue engineering. Initial cell attachment works best at 96–150 µm pore diameter. Bone growth itself requires larger channels: 300–800 µm. Studies confirm the minimum viable pore size sits at 75–100 µm. The sweet spot? 100–135 µm for balanced cell infiltration and nutrient flow.

Vascularization demands pores above 300 µm. Blood vessels can’t form in smaller spaces. Pores below 300 µm push tissue toward osteochondral ossification instead. This is a different bone formation pathway. It limits full integration.

Cell Attachment Versus Proliferation Trade-offs

Testing on collagen-glycosaminoglycan scaffolds (85–325 µm range) reveals a surprising pattern. Cell adhesion drops as pore size increases. The 96 µm scaffolds achieve the highest initial attachment. Why? Surface area-to-volume ratio equals 0.718/d (d = pore diameter). Smaller pores pack more surface area per unit volume.

Proliferation tells a different story. MC3T3-E1 pre-osteoblast cells grown for 7 days show highest numbers on 325 µm pores at all time points. A temporary peak appears at 120 µm during 24–48 hours. It disappears by day seven. Smaller pores (85–190 µm) retain higher percentages of seeded cells due to surface area. Absolute cell growth favors larger pores.

Porosity Effects Beyond Bone Applications

Cancer research and wound healing show porosity drives cell fate in ways pore size alone doesn’t. Porous zirconia ceramic membranes at 0.849 µm pore diameter with 30% porosity boost metabolic activity and proliferation. Increase porosity to 39% at 0.896 µm. Cells shift toward aggregation and differentiation instead.

Macroporous alginate hydrogels at 30% porosity show mechanical advantages too. Stress relaxation happens 10 times faster than bulk materials. Young’s modulus stays stable. Bulk versions lose about 50% stiffness after one week. Cell density climbs much higher in porous structures. Migration fraction and distance both scale with porosity volume.

Angiogenesis—new blood vessel formation—speeds up in 160–270 µm pores. Tantalum scaffold studies (days 3 and 5) confirm Ta T70 and T80 groups outperform Ta T60 in cell growth metrics.

For implant integration with minimal scarring, aim for ~26 µm pores. This diameter matches twice the size of rodent macrophages (13 µm) and fibroblasts (18 µm). It reduces fibrous capsule formation. Plus, it encourages vessel infiltration.

Cost and Production Factors

Material choice isn’t just about performance—budget and time matter too. Porous alumina ceramic costs 40-60% less than zirconia per kilogram for standard grades. High-purity alumina (99.9%) closes this gap. But it still costs 20-30% less than zirconia in bulk orders.

Production methods create the real cost gap. Porous alumina uses simpler heating at 1400-1600°C. You control the holes using added agents (starch, tiny spheres, polymer beads) mixed before heating. Scaling up is straightforward. Custom orders take 2-4 weeks.

Zirconia ceramic needs exact steps throughout. Adding yttria requires precise ratios (3-8 mol%). Heating temps reach 1500-1550°C. HIP (Hot Isostatic Pressing) after heating adds 30-50% to costs. This gives you that strong 17 MPa·m¹/² toughness. But orders take 6-10 weeks.

Manufacturers face pressure from many sides. Raw material prices jumped 5.4% in 2025. Forecasts show 4.4% more for 2026. Labor and benefit costs climb 2.5% in factories. Ceramic production spending rose 3% despite these challenges. Right now 86% of ceramic makers pass some costs to buyers—32% pass all of it.

Better processing raises costs more. Factories using AI quality checks (50% adoption rate) and process upgrades (42%) lower defects by 15-25%. Robot systems (37% use) cut labor needs. These upgrades explain higher prices for zirconia parts.

Go with porous alumina for tight budgets and quick needs. Good for filters, catalyst bases, or heat barriers. Go with zirconia for parts where breakdown means huge losses—medical implants, exact bearings, cutting tools. Reliability covers the extra cost.

Wear Resistance and Durability in Industrial Applications

Industrial equipment battles constant friction, impact, and corrosion. Your ceramic choice shapes your maintenance budget and uptime. The global wear-resistant materials sector hits USD 8.5B in 2024. It’s growing at 7% CAGR through 2030. Mining and construction companies spend hundreds of millions USD each year replacing worn parts.

Zirconia ceramic wins where extreme wear meets heavy loads. Its hardness (13-14.5 GPa) and fracture toughness (8-17 MPa·m¹/²) deliver strong durability in grinding media, ball mill liners, and crusher parts. Mining operations report 20x longer service life versus quenched steel in skirt liners and chutes. This means fewer technician calls and less downtime cost.

Testing shows zirconia’s edge under constant stress. Ball-on-disc tests (5N load, 3Hz frequency, 100Cr6 steel ball) prove ceramic-based ZA200 coatings reach 465.56 cycles to failure (trimmed mean). Standard steel coatings (S220GD) fail at 214.64 cycles—less than half. The layered ceramic structure absorbs harsh forces that quickly break down metal options.

Porous alumina ceramic handles different wear situations. Filtration systems moving rough slurries use controlled porosity (11.8-55%). The pore network catches particles and stays strong at moderate loads. Chemical processing equipment relies on porous alumina for catalyst supports and membrane reactors. Here, wear stems from chemical attack, not mechanical friction. Alumina’s chemical stability (working temperature up to 1100°C) stops breakdown that ruins polymer options within months.

Load intensity drives the choice. Excavator buckets, conveyor impact zones, and drilling equipment need zirconia’s top-level toughness. These uses justify the 40-60% cost premium over alumina through longer replacement cycles. Filtration membranes, air bearing surfaces, and vacuum chucks face lower mechanical stress. Porous alumina gives enough wear resistance at lower cost. Plus, production is faster (2-4 weeks versus 6-10 weeks for zirconia).

Industry 4.0 monitoring systems track real-time wear through embedded sensors. This data guides ceramic selection. High-wear zones get zirconia composites or ZTA (Zirconia-Toughened Alumina) blends. These hybrids boost strength 20-30% above pure alumina. They also maintain better cost efficiency than full zirconia parts. Lower-stress areas keep using porous alumina types. This balances performance against budget.

Material choice shapes maintenance timing too. Zirconia parts in oil & gas drilling equipment resist harsh environments and extreme heat. Steel alternatives need replacement every three months. Zirconia extends this to annual cycles. Porous alumina filters in semiconductor manufacturing hold precision (0.055 μm pore diameter) through thousands of process cycles before fouling needs replacement. Both materials cut downtime—just through different paths.

Application Guide: Picking Between Porous Alumina and Zirconia Ceramic

You need to pick the right ceramic material. Start by ranking factors based on failure risk and performance needs. For porous alumina ceramic vs zirconia ceramic, ask yourself three key questions first:

-

Does failure create safety risks?

-

What temperatures will this handle?

-

Do you need controlled permeability or dense structure?

Medical Implants: Toughness Matters Most

Dental crowns, surgical tools, and load-bearing implants need zirconia. Make fracture toughness your top priority. Failure here means patient injury.

Zirconia handles 8-17 MPa·m¹/² toughness. This stops major cracking. Alumina breaks at just 3.6-4.4 MPa·m¹/². Both materials meet biocompatibility rules. But zirconia stands up to 10+ years of chewing forces (800N average bite pressure). Alumina can’t match that.

Bone scaffolds work differently. Porous alumina ceramic wins here. Cell growth matters more than strength. Go for 100-325 µm pores with 30-55% porosity. Tests show 325 µm pores give the best MC3T3-E1 cell growth over 7 days. Blood vessels need at least 300 µm channels. Zirconia can’t create this structure. It’s built to be dense.

Filtration Systems: Porosity Comes First

Chemical plants, chip makers, and water treatment facilities use porous alumina. Here’s how properties rank:

– Permeability: 0.40 weight

– Chemical resistance: 0.25 weight

– Cost: 0.25 weight

– Strength: 0.10 weight

Alumina membranes hit 0.055-50 µm pore sizes with precision. They work at 1100°C. Filter accuracy stays consistent through thousands of cycles.

Zirconia fits ultra-high-pressure filtration (>10 bar). That’s where you need serious structural strength. But the 40-60% price jump doesn’t pay off in standard separation work.

Heavy-Duty Industrial Parts: Load Strength Decides

Mining gear, ball mill liners, and crusher parts call for zirconia. Put hardness (13-14.5 GPa) and wear resistance at the top. Field tests show 20x longer life than steel options. Ball-on-disc tests hit 465.56 cycles before failure. That’s twice what steel coatings deliver.

Catalyst supports, air bearings, and heat shields match porous alumina’s mid-level stress needs. Cost factor (0.30-0.40) makes alumina the smart pick. This works for replacement cycles over 12 months and loads under 150 MPa bending stress.

Test prototypes in real conditions before placing bulk orders. Lab tests don’t catch real-world chemical exposure and heat cycling. These factors decide how long your parts last.

Hybrid Solutions and Future Trends

Material science keeps moving forward. Zirconia-Toughened Alumina (ZTA) gives you 20-30% higher strength than pure alumina. Plus, it costs less than full zirconia parts. This mix solves the old problem between porous alumina ceramic vs zirconia ceramic. You get balanced toughness, controlled porosity, and good pricing all together.

Manufacturers now layer materials in smart ways. Dense zirconia forms the outer shell for impact zones. Porous alumina fills the core. This cuts weight and manages heat better. Medical device makers use this in custom implants. The zirconia surface handles bite forces. The alumina interior helps bone grow in through controlled porosity.

Market Growth Signals Industry Direction

Global hybrid power solutions hit USD 11.8 Bn in 2023. The forecast shows USD 25.6 Bn by 2033 at 9.0% CAGR. Related hybrid markets grow even faster. Hybrid devices jump from USD 61.78 Bn (2026) to USD 264.03 Bn (2035) at 17.56% CAGR. These numbers show a big industrial shift toward mix solutions.

AI-driven manufacturing changes how we make ceramics. Real-time systems (now used by 50% of manufacturers) adjust heat and pressure on their own. This creates gradient porosity structures. Dense surfaces resist wear. Porous cores handle filtration. All in one production run. Custom orders that took 6-10 weeks? They now ship in 3-5 weeks.

Battery storage keeps getting tougher. Ceramic envelope seals and barriers face harsher conditions. Hybrid alumina-zirconia mixes can handle >1200°C. They control ion flow too. Support from 130+ countries speeds up funding. Expect ceramics built for specific loads within 2-3 years.

Conclusion

Porous alumina ceramic or zirconia ceramic? Your application needs will decide.

Porous alumina works best in medical scaffolds and filtration systems. Controlled porosity drives its performance. Plus, it costs less for high-volume production.

Zirconia shines where you need extreme toughness and wear resistance. Think dental implants and precision cutting tools. Its transformation toughening process makes the higher price worth it.

Here’s the good news: You don’t have to pick just one. Hybrid composites now combine alumina’s heat stability with zirconia’s mechanical strength. This mix creates performance you can’t get from either material alone.

Your next step: List your key needs—porosity level, load capacity, budget, and operating conditions. Match these against the selection matrix we’ve outlined.

Working on biomedical projects? Check the material biocompatibility data for your tissue engineering goals.

Running industrial operations? Request sample testing under real operating conditions before ordering production volumes.

The better material isn’t about which one ranks higher. It’s about which one fits your engineering needs and business goals.