Cloudy tap water or gritty residue? You face a common problem: finding a filtration system that gives you clean, safe water. You don’t want to spend a fortune. You don’t want constant maintenance either.

Sediment filters versus ceramic filters—this choice goes beyond just removing particles. You need to match the right technology to your water quality problems, your budget, and how you live.

Sediment filter vs ceramic filter pros and cons require looking past marketing hype. Check real-world performance. Look at maintenance needs. Compare long-term costs.

Got well water full of sand and silt? Maybe you have municipal water with rust particles. Or you want pathogen protection for your household. Each filter type brings different benefits and drawbacks.

These technologies work in unique ways at the microscopic level. Combining both filters can create your strongest defense against water contamination. This approach helps you avoid expensive mistakes. Every glass of water will meet your standards.

What Is a Sediment Filter and How Does It Work

Sediment filters trap physical particles using mechanical barriers. Water passes through filter media—sand, synthetic materials, or wound strings. Dirt, rust, and debris get caught. Clean water flows out the other side.

The filtration process uses graded density structures. Most sediment filters force water through tighter and tighter layers. Large particles stick to the outer surface. Smaller particles travel deeper into the media. Then they get trapped. This layered approach removes multiple particle sizes in one pass.

Types of Sediment Filter Technologies

Pleated filters use synthetic folded material with uniform pore sizes. The pleated design creates broad surface area for capturing sediment. You can wash and reuse these filters. They work best for larger particles. Trapped dirt forms a layer. This layer improves filtration over time.

Melt-blown filters have layered polymer fibers. These fibers are created by blasting molten material with high-velocity gas. The inner core is denser than the outer layers. This graduated structure catches particles below 10 microns. Perfect for fine sediment like silt and clay.

String-wound filters wrap cotton, polyester, or polypropylene string around a core. The wrapping is tight. They filter varying micron sizes through graded density. Watch for overloading though. Clogged strings can loosen and shift. Debris then flows back into your water. Time for replacement.

Spin-down filters use centrifugal force instead of disposable cartridges. Water enters the clear chamber and spins fast. Heavy sediment slams against the bowl wall. It drops to the bottom collection area. A mesh screen filters (100-15 microns) remaining particles as water moves to the center core. Manual flushing through the base valve clears collected sediment.

Performance Metrics That Matter

Beta ratio measures filtration effectiveness. The formula: particles entering ÷ particles passing through. A beta ratio of 1000 means 1 particle per 1000 escapes the filter. Higher numbers equal better performance.

Differential pressure tracks the pressure difference between water entering and leaving the filter. Low initial differential pressure means minimal flow resistance. That’s what you want for residential systems. Rising pressure signals filter clogging.

Advanced Filtration Methods

Electro-kinetic adsorption technology uses charged filter media. It attracts charged contaminants. These filters grab microorganisms and colloidal matter smaller than their rated pore size. A 2-micron electro-kinetic filter can capture particles much smaller than 2 microns. It does this through electrical attraction.

Radial flow cartridges push water through the cartridge wall into an inner hollow core. This design uses the entire length and circumference as filtering surface. Not just the ends. Pleated radial cartridges increase the available surface area even more.

Large commercial systems use beds of natural media like sand, garnet, and anthracite. Some use manufactured materials—Filter Ag, ChemSorb, Micro Z. These systems backwash by reversing water flow through the media bed. Trapped particles flush down the drain. The clean media bed is ready for another filtration cycle.

Protecting Your Water Treatment System

Sediment filters serve as critical pretreatment for reverse osmosis systems. They protect the flow restrictor from clogging with particles. Standard RO prefilters use 5-micron wound string cartridges. You can swap to melt-blown or pleated versions. 10-micron filters work for clean water. 1-micron options suit contaminated sources. Match the micron rating to your actual water conditions.

Sediment Filter: Advantages You Should Know

Sediment filters protect you from physical contaminants. They catch sand, silt, and rust. These particles can damage your water treatment system. This simple tech saves money and makes equipment last longer.

Protection for Your Entire Filtration System

Sediment filters protect parts downstream from early failure. Carbon filters work best with chemicals—not physical debris. A sediment pre-filter removes large particles first. Your carbon filter then handles chlorine, VOCs, and dissolved contaminants. This split workload makes carbon filters last much longer.

The Aquasana EQ-1000 whole-house system shows this principle. The sediment pre-filter catches large particles. Sub-micron and carbon stages work downstream. They don’t clog. The system maintains 1,000,000 gallons total capacity. You replace filters much less often.

Real Cost Savings Through Smart Pre-Filtration

Multi-stage systems with sediment pre-filters cut your yearly maintenance costs. You spend less replacing delicate filters. Carbon cartridges cost £30-£50 each. Sediment pre-filters cost £8-£15. Protecting the expensive carbon stage means fewer replacements.

Your plumbing and appliances get protection too. Sediment filters stop particle buildup in water heaters, dishwashers, and washing machines. Less mineral buildup means lower energy use. Repairs happen less often. Equipment lasts years longer.

Performance Specs That Deliver Results

Flow rate decides if a sediment filter meets household needs. The Aquasana EQ-1000 delivers 7 GPM without pressure loss. Large families get good water pressure at multiple fixtures at once.

Micron ratings show filtration precision. Standard sediment filters remove particles above 5-20 microns—sand, silt, visible rust. Advanced nanofiltration models capture particles down to 0.001 microns. Balance your micron rating against flow needs. Tighter ratings slow water flow.

Pleated surface filters trap particles on the outer layer. Depth filters catch contaminants through the entire media thickness. Both designs handle different sediment loads with little maintenance.

Simple Installation and Maintenance

Replacement takes minutes in well-designed systems like the EQ-1000. No special tools needed. Homeowners do the swap themselves. Long filter life means you do this task rarely—systems rated for 1,000,000 gallons need changes every few years, not months.

High-sediment areas benefit most. Well water with sand or city systems with old pipes create tough conditions. Sediment filters stop infrastructure damage. Water clarity and taste improve right away as cloudiness disappears.

Sediment Filter: What It Can’t Do

Sediment filters catch visible particles. But they miss invisible dangers in your water. Dissolved chemicals, heavy metals, and germs pass right through.

Chemicals and Heavy Metals Get Through

Sediment filters can’t remove dissolved pollutants. The tiny holes—usually 5 to 20 microns—block particles bigger than their size. But dissolved stuff like nitrates, pesticides, and trihalomethanes? They go right through. These chemicals are at the molecular level. Physical filtering can’t catch them.

Heavy metals create serious health problems. Lead, mercury, and arsenic leak from old pipes. They damage your brain and kidneys. Sediment filters have no way to absorb them. These toxins flow through without stopping.

Hard water minerals cause problems too. Calcium and magnesium pass through sediment filters. Limescale builds up. Your appliances lose 20-30% efficiency. Energy bills go up each month.

Chlorine, chloramines, and VOCs remain in your water. These chemicals make water taste and smell bad. They form harmful byproducts. Hydrogen sulfide makes your water smell like rotten eggs. A sediment filter won’t fix any of this.

Germs Can Get Through

Most sediment filters can’t stop germs. Standard filters have holes bigger than 1 micron. Bacteria, viruses, and parasites slip through these openings. E. coli gets through if the holes aren’t small enough.

Clogged filters turn into germ factories. Trapped organic matter feeds bacteria. The filter becomes a breeding ground. Water picks up more germs than it had before. Mold grows in wet cartridges. Your “clean” water now carries new health risks.

Fine particles escape too. Clay particles and “flour sand” are smaller than 5 microns. They pass right by standard filters. You get about 99.9% removal for the right particle sizes. Everything smaller ends up in your glass.

You Need to Replace Them Often

Replace your sediment filter every 3-6 months. Miss this schedule and things go bad. Clogged filters reduce water flow by 50-100%. Pressure drops up to 30 psi. Your faucets slow to a drip. Shower pressure gets weak.

No alarm tells you about clogging. You find out when water slows to a crawl. Dirty cartridges grow mold between changes. The contamination risk grows each day.

You Need Multiple Filters

Sediment filters are just the first step. You need carbon filters for chemicals. Add reverse osmosis for heavy metals and germs. This protection costs more money.

A full multi-stage setup costs £200-500 upfront. Replacement cartridges cost £50-150 per year. The sediment pre-filter does save money though. It stops your expensive RO membrane from clogging too soon. This protection saves £100-300 per year in early replacements.

Some systems waste water during backwashing. Used cartridges need special disposal—they contain concentrated pollutants. These practical problems add up fast if you use sediment filtration alone.

What Is a Ceramic Filter and How Does It Work

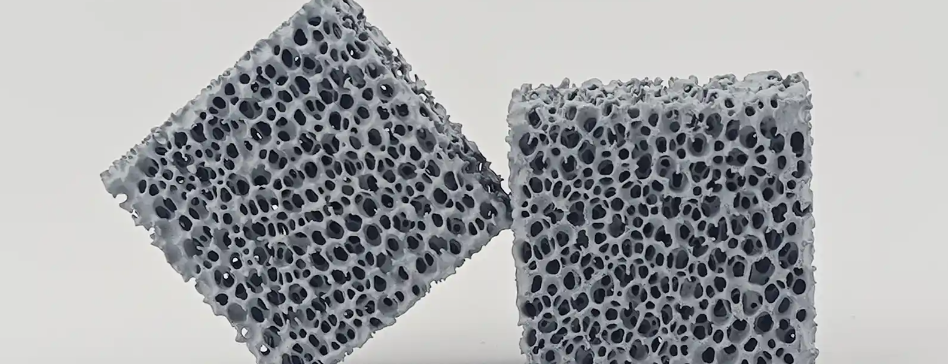

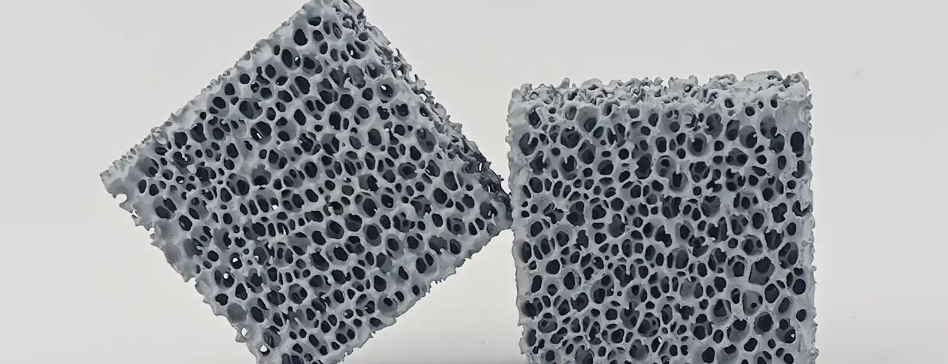

Natural clay forms the core of ceramic filters. Makers shape this clay into porous structures with tiny openings. These small holes work like gates—they block contaminants while water passes through.

The ceramic structure has three layers. The rough outer layer gives strength against pressure and impact. The middle layer holds the filtering membrane. The inner layer has uniform pores that trap particles by size.

Water flows through these tiny pores two ways. Gravity-fed systems let water drip through the ceramic into a bottom container. Pressure-based systems push water faster through the material. The pressure traps toxic compounds, ammonia nitrogen, germs, bacteria, and pathogens. Clean water comes out the other side.

How Ceramic Filtration Removes Contaminants

Physical blocking comes first. The tiny pores stop particles bigger than the openings. Think of a fine mesh catching debris while water slips through.

Adsorption boosts performance. Many ceramic filters have activated carbon or treated materials inside. These materials bond with dissolved contaminants that physical pores miss. Chlorine, heavy metals, and organic compounds stick to these surfaces.

The porous design creates huge surface area. More surface means better filtration power. Ceramic filters trap suspended solids, bacteria, pathogens, and germs through this combined physical-chemical process.

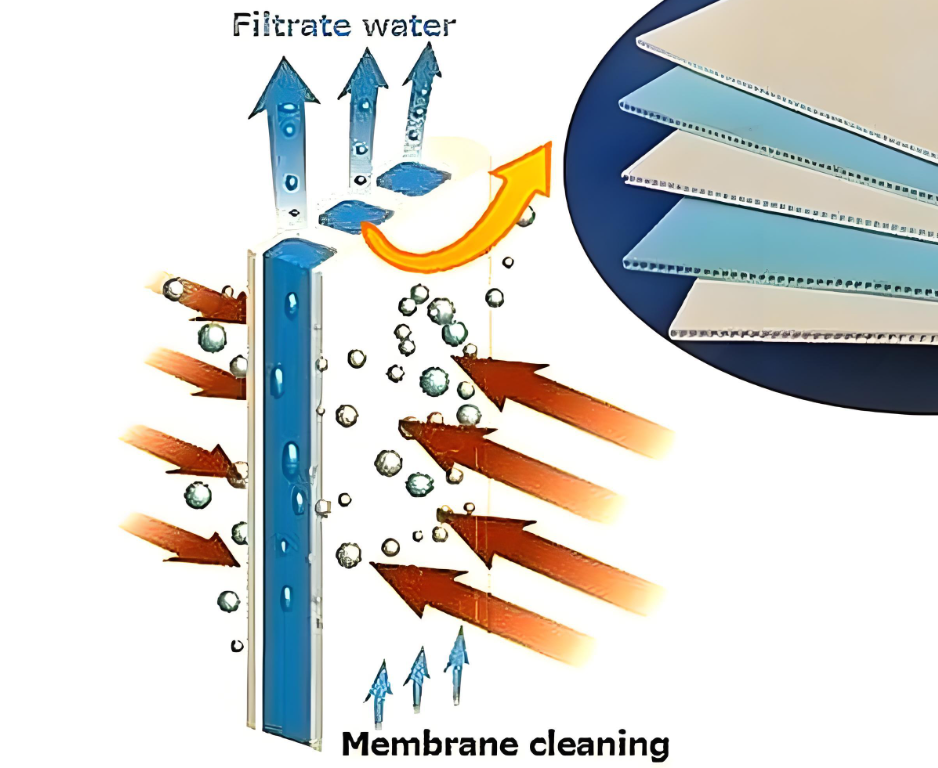

Regular flushing with clean water brings back filtering power. Back-flushing clears leftover filter cake from the surface. This cleanable design means one ceramic element lasts years, not months.

Ceramic Filter: Key Benefits and Advantages

Ceramic filters last years instead of months. You clean them with a brush. No need to throw them away every few weeks like disposable cartridges.

Washable Design Cuts Long-Term Costs

Ceramic elements handle tough cleaning without breaking down. The material has strong mechanical strength and chemical stability. This lets you scrub away buildup. Brush the surface. Rinse it off. Flow rate comes right back. Polymer filters fall apart under this treatment. High-solid loads destroy them fast.

Industrial ceramic membranes prove this durability every day. Nanostone Water’s ultrafiltration systems achieved 70% year-over-year revenue growth in 2024. Why? Their ceramic filters get cleaned and reused. Replacement costs drop hard. Corning’s ceramic filtration products generated $382 million in Q3 2024 net sales alone. Businesses pick durable components over disposables.

The numbers tell the story:

|

Segment |

2024 Market Size |

Growth Rate |

Core Benefit |

|---|---|---|---|

|

Overall Ceramic Filters |

$1.69 billion |

6.4% CAGR to 2030 |

Sustainable residential filtration |

|

$0.982 billion (2025) |

4.28% CAGR to 2031 |

Chemical-resistant cleaning |

|

|

Ceramic Membranes |

$10.21 billion (2023) |

10.87% CAGR to 2032 |

High efficiency across applications |

Residential users grab 41.8% of the 2024 market share. Families want clean water without constant filter replacements. One ceramic element saves £50-150 per year compared to disposable cartridge systems.

Superior Germ Removal Without Chemicals

Ceramic filters beat polymer options for removing germs. The tiny pore structure blocks bacteria, cysts, and pathogens. No chemicals needed. Drinking water and wastewater both get cleaned. Performance stays strong even in harsh conditions. Conventional membranes fail where ceramic keeps working.

Silicon carbide foam variants combine excellent filtration with chemical resistance. Metallurgy and wastewater plants use these for removing impurities. The filters meet strict rules. They keep working after other materials break down.

Works Anywhere—No Electricity Needed

Gravity does the work. Fill the top chamber. Water drips through the ceramic. Clean water collects below. Point-of-use ceramic filters work great in homes. Urban households with stressed municipal systems get easy installation. No power connection required. No pump noise.

Remote areas and outdoor locations benefit most. Camping trips. Rural homes. Emergency kits. A gravity-fed ceramic system gives you safe drinking water anywhere. Industrial settings use the same idea. The 6.6% CAGR growth rate in industrial applications proves ceramic’s versatility.

Minerals Stay—Contaminants Go

Ceramic filtration targets dirt while keeping good minerals. Calcium and magnesium pass through. Heavy metals and pathogens get trapped. Your water tastes better. Your body gets the minerals it needs. Residential use focuses on this balanced approach—clean water that’s still healthy to drink.

Fast Recovery After Clogging

Surface clogging slows any filter over time. Ceramic fights back better than alternatives. Brush away the buildup. The strong material handles rough scrubbing. Hybrid ceramic designs restore flow rates fast. Chemical resistance means you can use stronger cleaning agents if needed.

SiC foam filters show this advantage well. Easy maintenance in tough environments. One quick cleaning session brings performance back to normal. Compare this to disposable cartridges—those just get tossed after clogging.

Ceramic Filter: Problems and Limits

Ceramic filters need patience and gentle care. The tiny pores that clean water also cause problems in use.

Slow Water Flow Creates Delays

Gravity-fed ceramic systems produce water drop by drop. No pressure pushes the water through. You wait much longer to fill one glass than turning on a tap. A family needs several liters for cooking or drinking. These waits add up fast.

The numbers tell the story. Compliance rates drop from 100% to 0%. Water quality shifts hard. Mean colony counts jump from 242.7 to 624.3 CFU/100mL. Over three years, mean quality worsens from 72.0 to 268.5 CFU/100mL. Fine particles clog the pores bit by bit. Flow gets slower and slower.

Scrubbing hard to restore flow creates new risks. Push too hard and you break the delicate ceramic. The material stops filtering. You’ve just wasted a £50-100 filter element.

Fragile Material Cracks Fast

Ceramic cracks from pressure or impact. Drop the filter candle while cleaning? It breaks. Use too much force during setup? Thin cracks form. These breaks ruin the whole filter barrier.

Stats show breakage happens at random. Any day over two years has equal risk. This random failure explains why ceramic filters fail so often outside the lab. Handle each cleaning with care. Use soft brushes. Accidents still happen.

Chemicals and Heavy Metals Pass Through

Pore size stops bacteria but lets smaller dangers through. Chlorine flows right through. Heavy metals like copper and lead enter your glass untouched. Viruses slip between the ceramic pores.

You need extra treatment steps. Activated carbon pulls out chlorine and fixes taste. Ion exchange or KDF media catch heavy metals. A sediment pre-filter stops rapid clogging. Each part makes the system more complex. Total costs rise £100-300 above the basic ceramic piece.

Water with lots of sediment needs that pre-filter. Skip it and your ceramic clogs in days, not months. Now you care for two filter types.

Sediment Filter vs Ceramic Filter: Head-to-Head Comparison

Both filters remove particles from water. But their internal designs create different performance profiles.

Sediment filters use simple mechanical straining. Water flows through a physical barrier. This could be wound string, pleated material, or melt-blown layers. The barrier catches particles larger than its micron rating. Simple. Direct. Particles pile up on the surface or through the media depth. Clean water exits the other side.

Ceramic filters force water through a maze. The ceramic structure has countless tiny holes. These connect through twists, turns, and sharp angles. Particles get trapped deep inside this pathway. The physical blocking happens throughout the entire ceramic element. Not just the surface.

Performance Capabilities Show Clear Differences

Sediment filters do one job well. They remove physical particles. Sand, dirt, rust, and turbidity from wells and surface water get stopped cold. Match the micron rating to your sediment level. Light sediment? A 20-micron filter works fine. Heavy sediment loads? Drop to 5-micron. Or add backwashing capability for high water volumes. Special membrane variants tackle ultra-fine sediments. Think shale rock flour and colloidal clays.

Ceramic filters handle a broader threat range. The ceramic outer shell blocks bacteria and cysts. This gives you microbiological protection that sediment filters can’t match. Lab testing proves impressive results: 100% removal of aluminum, copper, uranium, chloroform, and total THMs. Chlorine, molybdenum, and barium got reduced to zero. Nitrates dropped 70%.

Ceramic systems with internal treatment media expand protection further. Cysts, lead, asbestos, and various chemicals get trapped. This broad approach tackles both physical particles and dissolved contaminants. All in one filter element.

Flow Rate and Maintenance Requirements

Hollow fiber alternatives deliver very high flow rates. Ceramic filters can’t match this speed. Less surface area means slower water movement through the ceramic structure. Families notice this difference right away. Filling a pitcher takes longer with ceramic.

The cleaning advantage tilts toward ceramic though. Heavy clogging ruins most filters. Ceramic surfaces bounce back through simple scrubbing. Flow rate returns to normal in minutes. No replacement needed yet. Sediment cartridges just get tossed once clogged.

Conclusion

Sediment filter vs ceramic filter? You don’t have to pick just one. Each works best in different situations. Sediment filters handle large particles and debris at low cost with high flow rates. Ceramic filters remove bacteria better and last longer for health-focused needs.

The smart move? Use both types together. These technologies work well as a team. Set up a multi-stage system. Put a sediment filter first to catch heavy particles. Add a ceramic filter after it for germ protection. This gives you complete water treatment with less maintenance hassle.

Your next step: Check your water quality issues. Got sand, rust, or sediment? Start with a sediment filter. Worried about bacteria? Want a long-lasting, sustainable choice? Go ceramic. Want full protection? Install both.

The right water filtration system matches your specific needs. There’s no single “best” filter for everyone. What’s your biggest water concern?