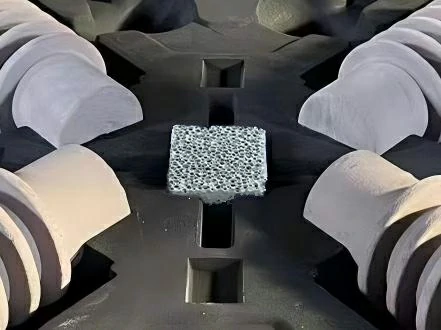

FM-01 Silicon Carbide Ceramic Foam Filter for Metal Filtration

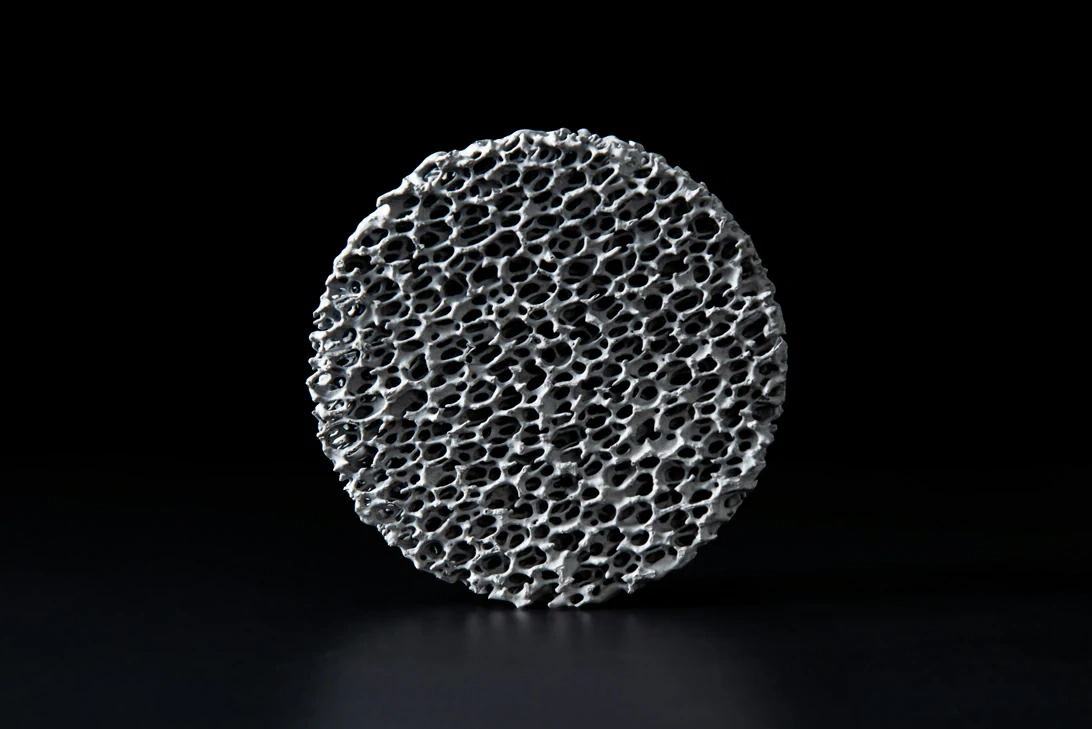

The FM-01 silicon carbide ceramic foam filters are designed for high-performance molten metal filtration. These advanced SiC filters feature

unique 3D reticulated structure that effectively traps oxides and inclusions while ensuring smooth metal flow. These foam filters help foundries reduce defects by up to 85% and improve casting yields.

Key Features:

High-temperature resistance – Works reliably up to 1500°C for iron, copper, and aluminum casting applications

3D foam structure – Captures impurities efficiently for cleaner metal

Strong & durable – Handles molten metal pressure without breaking

Chemical resistance – Withstands metal oxides and slag

Even filtration – Uniform pores for consistent results

Smoother metal flow – Reduces turbulence for better casting quality

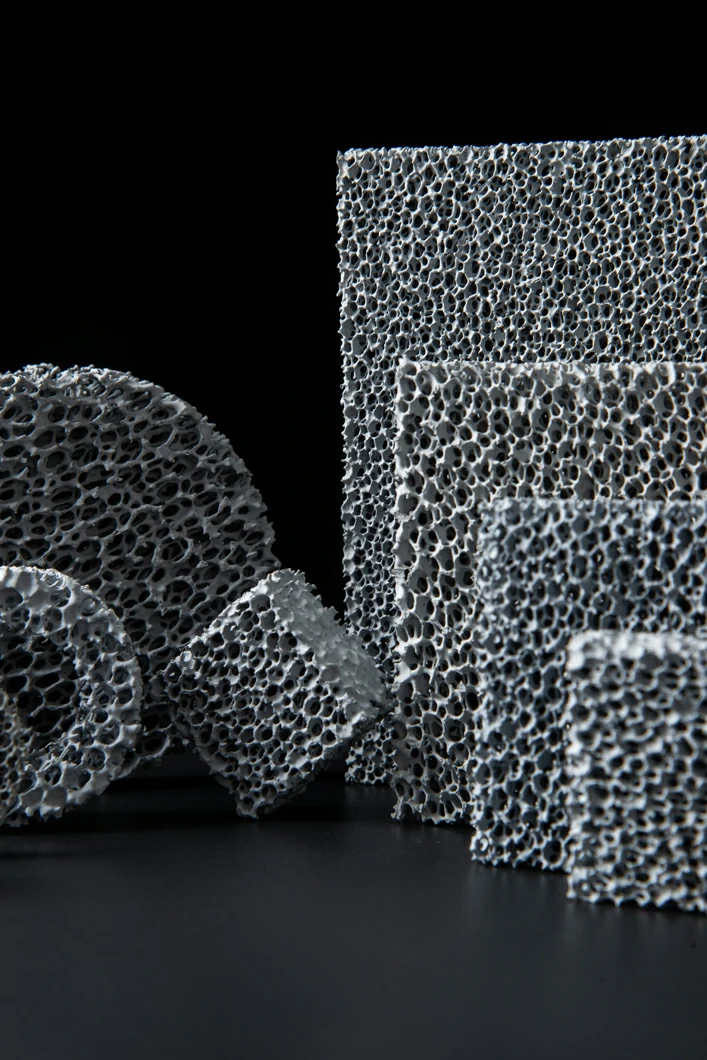

Custom sizes & shapes – Fits any foundry gating system

Why Choose FM-01 Silicon Carbide Ceramic Filters?

Made from high-quality silicon carbide materials – tough and long-lasting

Proven to cut defects and boost production yields

Trusted by professional foundries worldwide

Advanced SiC Filtration Technology For Superior Metal Casting Results

FoundryMax silicon carbide ceramic filters offer exceptional high-temperature performance, superior mechanical strength, and optimized filtration efficiency to significantly reduce inclusions, improve metal flow, and enhance quality in cast iron, copper, and aluminum applications.

Technical Specifications

| Material | Silicon Carbide (SIC) | |

| Operating Temperature (°C) | ≤1500 | |

| Pore Size (PPi) | 10-40 | |

| Compressive Strength (MPa) | ≥1.0 | |

| Density (g/cm³) | ≤0.5 | |

| Thermal Stability (1100°C/times) | 6 | |

| Composition | Al₂O₃ (%) | 30-35 |

| SiO₂ (%) | 0-5 | |

| SiC (%) | 60-65 | |

| ZrO₂ (%) | / | |

| Other (%) | 0-5 | |

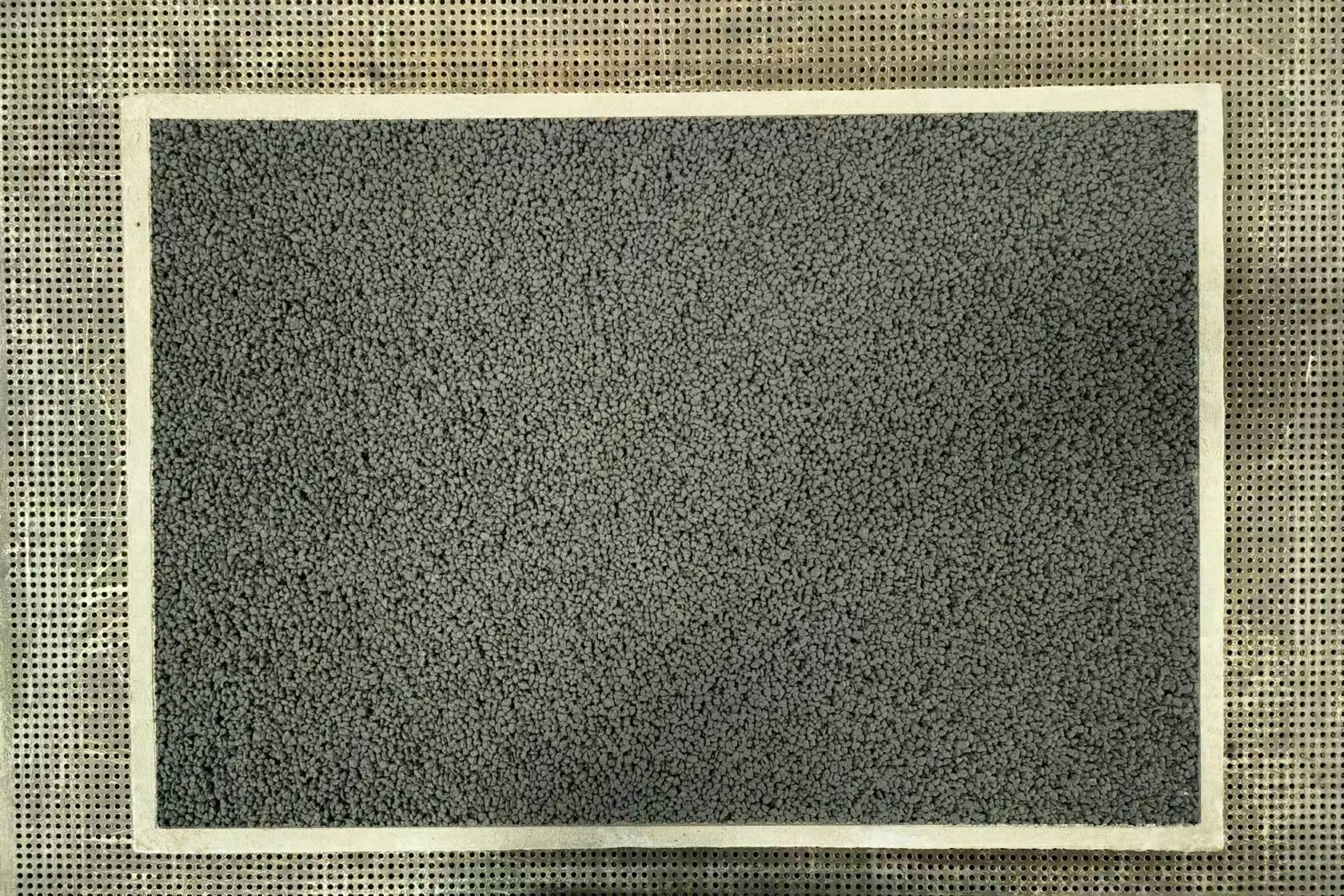

As a professional ceramic filter manufacturer with extensive industry experience, our porous silicon carbide filters are available in a full range of sizes to fit into existing foundry gating systems.

Custom Sizes

Foam filters can be manufactured to precise specifications with tolerances of ±0.5mm

Shape Variations

Beyond standard rectangular, round, and trapezoid options, custom shapes are available.

Pore Size Options

Filters are available in specific pore sizes from 10 PPI to 40 PPI to accommodate specific casting flow.

What Can We Offer?

Our silicon carbide foam filters combine unmatched thermal performance, superior mechanical strength, and exceptional filtration capabilities into customizable solutions that seamlessly integrate with your existing casting processes, significantly improving casting quality and production efficiency. Our silicon carbide filter technology enables you to produce higher-quality castings with fewer defects while reducing production costs and increasing manufacturing capabilities.

Compatible with all standard gating systems

Suitable for gravity, low-pressure, and continuous casting processes

Suitable for ferrous metals (gray iron, ductile iron) up to 1500°C

Suitable for non-ferrous metals such as copper, bronze, brass, and aluminum alloys

Compatible with all standard casting equipment and pouring methods

Can be integrated with automatic pouring systems

Compatible with horizontal and vertical casting orientations

Compatible with a variety of molding materials, including green sand and resin sand

Porous Ceramic Filter

10 PPI (Porosity Per Inch) – Suitable for applications requiring high flow rates, providing primary filtration of larger inclusions and ideal for large castings and initial filtration.

20 PPI Foam Filter – Balanced filtration, effectively removing inclusions while maintaining flow rate, suitable for most general casting applications.

30 PPI Foam Filter – Enhanced filtration capacity while maintaining adequate flow rate, recommended for parts with stringent quality requirements.

40 PPI Foam Filter – High-efficiency filtration, suitable for applications requiring the highest metal cleanliness, ideal for thin-walled and pressure-resistant parts.

FM-02 Reinforced Silicon Carbide Filter for Metal Casting Filtration

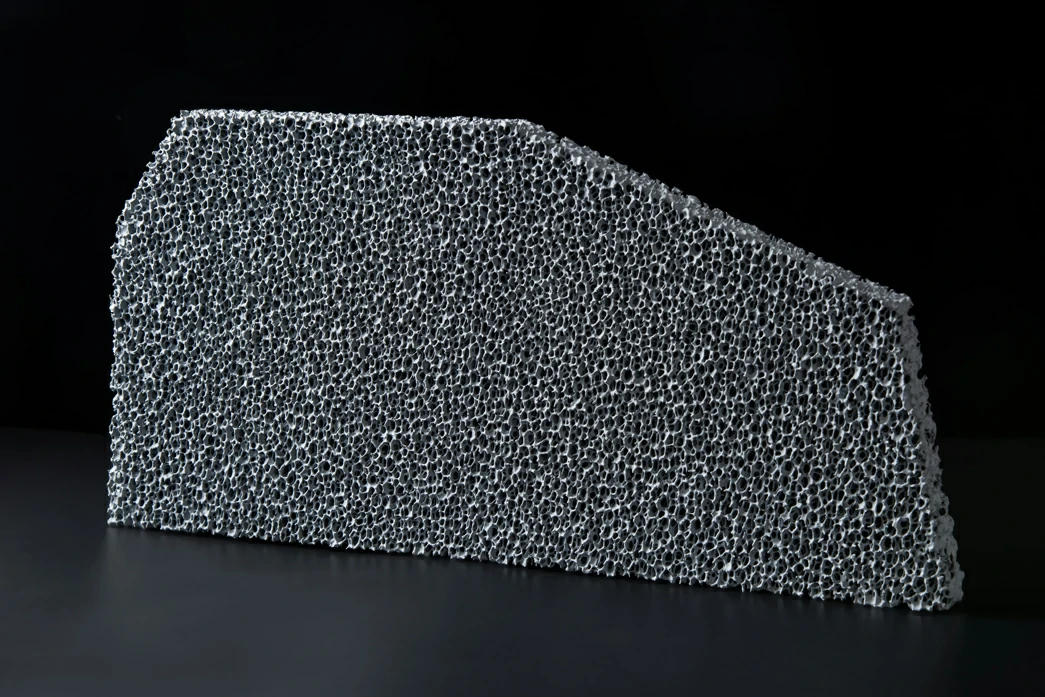

FM-02 reinforced silicon carbide filter, the new SIC foam filter, made from special silicon carbide materials and ceramic filter manufacturing process, offers superior strength and temperature resistance to standard ceramic foam filters.

Designed for tough casting conditions, it handles heavy pouring weights and extreme temperatures – perfect for large industrial castings like wind turbines and machine tools.

Key Features:

Extra strength – Handles heavier castings without breaking

Higher temperature resistance – Performs in extreme heat

Ideal for demanding applications – Works best for high-weight casting processes

Cleaner metal flow – Reduces defects for better quality castings

Longer lasting – Reinforced design improves durability

Upgrade your foundry’s efficiency with our premium reinforced silicon carbide ceramic filters.

SiC Filter Application

Upgrade your casting quality with our high-performance silicon carbide foam filters. Designed for sand, permanent mold, and other casting processes, these foam filters effectively remove impurities from molten iron, steel, and aluminum when placed in your pouring cup or runners – delivering cleaner castings with fewer defects.

Frequently Asked Questions

How do I determine the correct filter size for my application?

The optimal filter size depends on several factors, including metal type, pour weight, and flow rate requirements. Our technical team can provide specific recommendations based on your casting parameters. For most applications, the filter cross-sectional area should be 2-4 times the most restrictive in your gating system to ensure minimal flow restriction.

How do I properly store unused filters?

Our Silicon Carbide Ceramic Foam Filters should be stored in a clean, dry environment away from sources of contamination or physical damage. While the filters do not degrade over time when properly stored, we recommend avoiding exposure to moisture, oils, or chemicals that could contaminate the ceramic structure. There is no specific shelf life limitation when proper storage conditions are maintained. For optimal handling, we recommend using clean gloves when removing filters from packaging for installation.

Are custom shapes and sizes available for specialized applications?

Yes, we offer extensive customization capabilities for specialized applications. Our manufacturing process can accommodate virtually any shape, including round, square, rectangular, hexagonal, trapezoidal, and irregular geometries to fit specific gating systems. Custom dimensions are available with tight tolerances (±0.5mm).

More Foundry Filters

As a filter manufacturer with decades of experience in the foundry industry, we produce and supply a wide range of molten metal filter materials.

Request your custom SiC filter specification today for a detailed quotation tailored to your specific application requirements. Our technical team will analyze your metal type to recommend the optimal filtration solution for immediate quality improvements.

Discover Your Optimal Filtration Solution

Request a free consultation with our filtration specialists to identify the ideal industrial filter technology.

CONTACT US

Let's Connect

Our Engineers Will Analyze Your Needs & Offer the Perfect Filter Design – Contact Us Today.

Address

Guanting Industrial Park, Cangzhou City,

Hebei Province, China