The ceramic filter market for casting is growing fast around the world. I’ve noticed this growth is driven by the Metal casting industry. This industry serves automotive, aerospace, and electronics sectors.

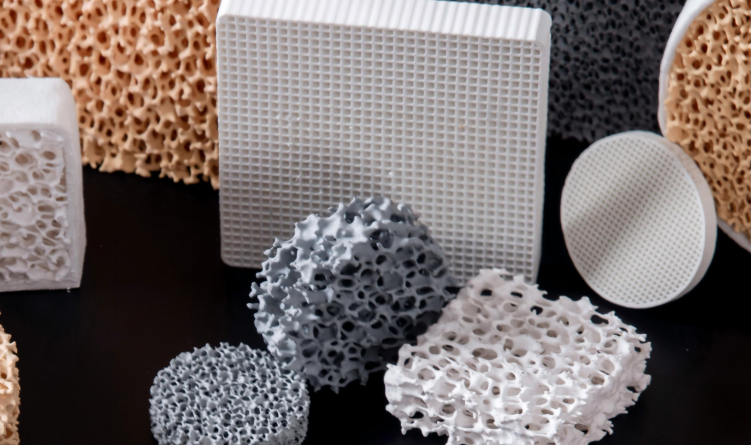

ceramic filters improve casting quality. Foam ceramic types like alumina, silicon carbide (SiC), and zirconia work best. Their porous structure removes impurities from molten metals. This ensures high flow rates and better contaminant capture.

I expect the ceramic filter market for casting to grow from USD 450 million in 2024 to USD 790.69 million by 2032. This means a compound annual growth rate (CAGR) between 7.2% and 13.5%. The rate varies by ceramic filter type and region.

Key industry drivers:

- High-quality cast parts are in demand for automotive and aerospace.

- Companies are using advanced tech like nanotechnology for better filtration.

- Automated manufacturing processes boost quality and productivity.

- Stricter environmental rules push companies to use emission-reducing and recyclable ceramic filters.

- Asia-Pacific regions are growing fast due to rapid industrialization.

Foundries use Ceramic filters the most. They manufacture defect-free automotive parts like engine blocks and transmission cases. Other industries use them too. These include electronics, pollution control, glass production, pharmaceuticals, chemicals, and petrochemicals.

Regional Highlights

- Asia-Pacific markets are expanding fast. China and India are growing quickly. Metal casting growth and new facility investments support this.

- North America will likely post the fastest CAGR. High innovation and strong industrial demand drive this growth.

- Europe focuses on sustainable, high-performance filter solutions. Germany leads in green manufacturing and waste management.

Major Manufacturers and Industry Developments

Key players include SELEE Corporation, LANIK, Vesuvius, SEFU, Drache, Protech Industries, Dynocast, Filtec, Induceramic, Pyrotek, Ferro-Term, FCRI Group. Many companies are investing in R&D. They focus on high-temperature, green products.

I suggest foundry industries adopt ceramic filters now. They improve product quality. They also reduce costs and help meet green regulations. This is a smart business move for the future.

SELEE Corporation: Industry Leader in Ceramic Foam Filters for Casting

SELEE Corporation is a pioneer in Ceramic foam filtration technology for the casting industry. I’ve seen their impact across aluminum, steel, iron, copper, and investment casting sectors. They truly lead the global market.

Key Innovations and Filter Technologies

Inventor of the PBA Ceramic Foam Filter: SELEE invented the phosphate-bonded alumina ceramic foam filter in 1973. Today, more than 98% of ceramic foam filters in the market use this structure or its variants.

Broad Product Range:

- CS-X® Aluminum Filter: This patented design works for aluminum cast houses. It delivers superior performance, safety, and environmental benefits.

- CS-T™ Lithium-Aluminum Filter: This filter is made for lithium-aluminum alloys. It reduces metal reactions and inclusion release.

- Zirconia PRZ Filter: This filter handles steel grade filtration well. It resists high thermal shock.

- MAX Copper Filter: I recommend this one—it cuts wire and rod breakage by up to 35%. It also reduces scrap from slag and nozzle blockage.

- Selee IC™ Aluminosilicate Filter: A silicon carbide-free solution. It meets the tough demands of investment casting.

Technical Superiority and Performance

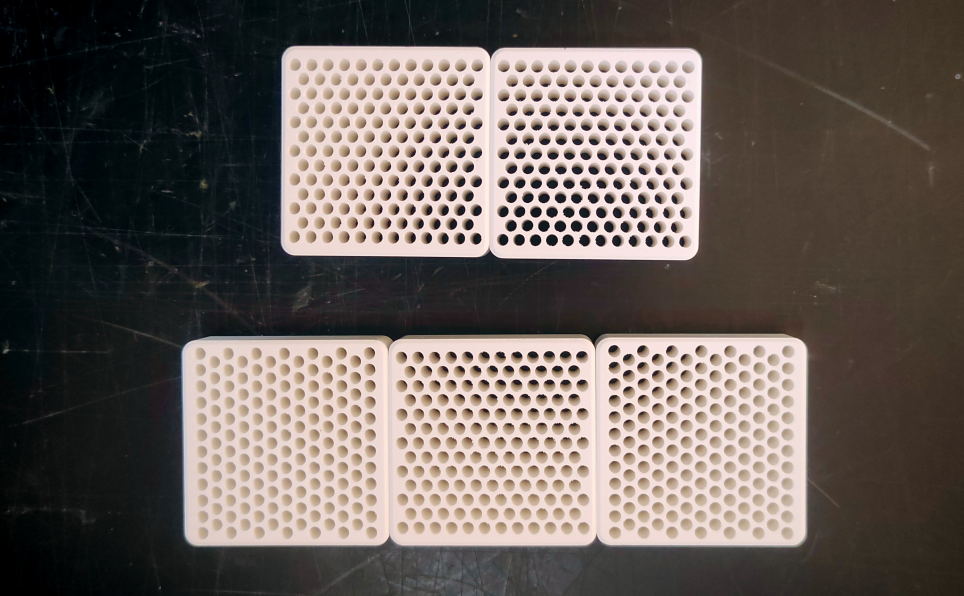

Precision and Efficiency: SELEE filters are cut after firing to keep tight size tolerances. The open-pore structure ensures deep-bed filtration. This is key for trapping dirt and cutting scrap.

Enhanced Casting Yields: Their products boost yield by catching inclusions during metal pouring. I’ve seen this support automotive, aerospace, and consumer product industries.

Proven Financial Benefits: SELEE’s metallurgical services have helped foundries save close to $100,000 in scrap costs on single casting projects. Based on my experience, that’s a major cost saver.

Application Highlights

Material Diversity: SELEE makes filters from phosphate-bonded alumina for aluminum. They use silicon carbide for iron, zirconia for steel, and aluminosilicate for investment casting.

Industry Applications: Their filters are trusted in automotive, aerospace, transportation, agriculture, and general manufacturing. They improve mechanical properties and surface quality.

Value Proposition

SELEE focuses on innovation and precision. This helps foundries aim for higher productivity, less scrap, and top-quality castings. Their global reach covers simple parts to high-complexity aerospace castings. I believe their commitment to quality makes them a smart choice for any foundry looking to improve results.

LANIK s.r.o.: Advanced Ceramic Filters for the Global Casting Market

LANIK s.r.o. is a top maker of ceramic foam filters. I see them as a leader in this industry through their VUKOPOR brand. They export more than 90% of their products to over 60 countries. This shows their strong reach worldwide. I believe their focus on technology sets them apart.

Key Product Features and Industry Applications

VUKOPOR ceramic foam filters: Foundries use these filters to clean molten metals. They work with aluminum, cast iron, and steel. Based on my experience, these filters also help in petrochemical plants, food processing, and building design. Their surface properties make them useful in many fields.

Performance in casting: The filters trap dirt during casting. This keeps the metal pure. They also make the mold-filling process smoother. This cuts down on defects. I suggest these for car and airplane makers who need quality parts.

LANIK works with Brno University of Technology on the LaBUT project. This research covers rapid prototyping and advanced filter tech. I believe these projects improve precision casting filters. They help LANIK stay ahead in the industry.

LANIK makes everything in-house. They serve many industries. They invest in research and development. I see them as a leading innovator in the global ceramic filter casting market.

Vesuvius plc: Leading Ceramic Filtration for Casting Markets

Vesuvius plc is a global leader in ceramic filtration. They serve the automotive, aerospace, and foundry industries. I’ve seen how their ceramic foam filters have changed molten metal purification. They deliver better casting quality and reduce defects.

Product Innovation and Technical Strengths

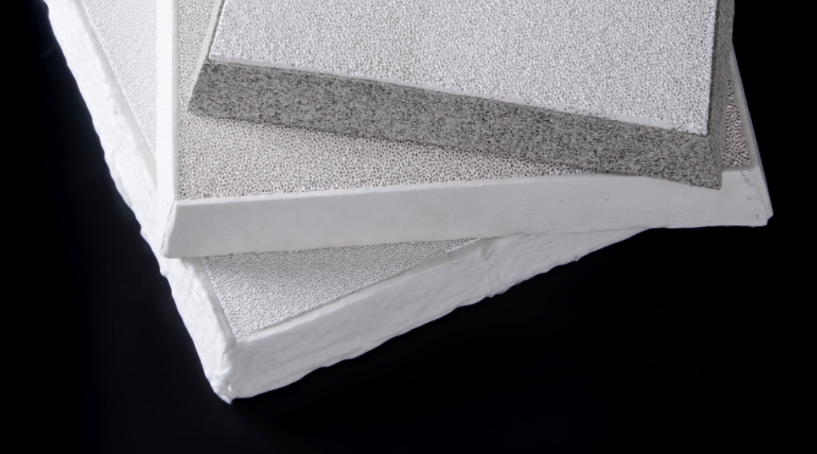

Advanced Filter Technologies: Vesuvius makes ceramic foam filters with better pore design and heat resistance. They test these filters at high temperatures. This ensures stable performance for aluminum, ferrous, and non-ferrous metal casting.

Material Engineering: The company puts major resources into new ceramic materials. These include alumina and zirconia. These materials resist chemicals better and reduce pressure drop during casting. I recommend this approach because it creates clean, efficient casting even in tough conditions.

Customization: They design filters for auto, aerospace, and industrial machinery makers. These customers need high-quality castings and low scrap rates.

Vesuvius wins by creating custom filtration solutions for specific alloys and casting needs. They make biodegradable and recyclable ceramic filters. Based on my experience, this matches what the market wants for sustainability. Their customers include automotive, aerospace, and industrial machinery foundries. Government bodies, investors, and consultants also buy their high-performance filters.

Drache GmbH: German Precision and Innovation in the Ceramic Filter Market for Casting

I consider Drache GmbH a top player in the ceramic foam filter market for casting. The company built its reputation on strong engineering and smart innovation. It started in 1984 in Diez, Germany. Since then, Drache has grown to supply products to over 50 countries. The company has operated in North America since 2003.

Drache makes all filters in Germany. This ensures quality stays consistent and traceable. They run warehouses near Frankfurt. They also have dedicated facilities in North America. These support fast global shipping and quick delivery. Their products work well for aluminum DC casting, iron, and steel foundries. Drache meets needs for both large-scale industry and specialized production.

Product Portfolio and Technical Innovation

-

Ceralu® Al₂O₃ Ceramic Foam Filters: These filters work for aluminum DC and continuous casting. You can get them in porosities from 10 to 70 PPI. Drache offers standard solutions and custom ones for tough foundry work.

-

Cerazirk® ZrO₂ Filters: These zirconia-based filters handle steel, superalloy, and large iron castings. They resist high heat and harsh chemicals.

-

Cerasic® NG Filters: These work great for small and medium iron casting. They handle non-ferrous metal temperatures up to 1500°C.

-

Engineering Ceramics: This line includes Silicon Nitride (SN) and Aluminum Titanate (ATi) parts. I recommend these for low-pressure Die casting processes.

I believe Drache GmbH leads in reliability, innovation, and technical service for ceramic filters in casting. The company helps the industry move toward better efficiency, cleaner metal, and superior finished products.

Protech Industries: High-Performance Ceramic Filter for Casting

Protech Industries ranks among the top manufacturers in the global ceramic foam filter market for casting applications. The company competes in an industry where the top 10 suppliers generate over $2 billion each year. These suppliers control around 60% of global market share.

It provides a wide range of ceramic foam filters for purification of molten aluminum, magnesium, copper, iron, and steel. Features optimized pore size distribution and higher porosity designs for better flow rates. These designs minimize pressure drop. Automotive and aerospace casting industries value these features.

Application Focus and Sector Demands

- Most demand comes from automotive and aerospace sectors. The aluminum purification filter market alone is projected to exceed $400 million in 2025.

- Growth accelerates in emerging economies. The Asia-Pacific region drives higher production volumes. More manufacturers in this region adopt advanced ceramic filters.

Protech Industries holds a leading position. The company focuses on innovation, sustainability, and advanced customization in ceramic filter technology for casting. Based on my experience, this strategy positions them well for future growth.

Dynocast: Precision Ceramic Foam Filters for High-Performance Casting

Dynocast is a key player in the global ceramic filter for casting market. Industry data shows the top 10 manufacturers, including Dynocast, hold around 60% of total market share. They generate annual revenues over $2 billion. The ceramic foam filters (CFFs) market alone is projected to reach $950 million in 2025. It shows a steady CAGR of about 7.5%. This growth comes from demand for quality. Advanced casting technology in automotive, aerospace, and heavy machinery drives it.

Key Characteristics and Market Impact

Dynocast’s success builds on high entry barriers. Making ceramic foam filters needs large capital. It also needs specialized engineering expertise. Their custom CFFs optimize filtration for specific metals and Casting methods. This improves metal purity. It reduces casting defects. It strengthens mechanical properties in finished products. Dynocast serves automotive, aerospace, and industrial machinery sectors. These markets need precise, low-defect metal castings.

Product Segmentation and Technological Innovation

Dynocast’s product range covers several ceramic material types:

- Alumina CFFs are popular for their cost-effectiveness and filtration performance. I recommend these for general applications.

- Zirconia-based filters work best in casting environments needing high chemical and thermal stability.

- Silicon carbide options complete their technical portfolio.

Filters come in various pore sizes and distributions. Dynocast customizes these to client needs. This supports different molten metal flows and final casting qualities. Product innovation is clear as they adapt to new trends in molten metal filtration. They develop higher porosity. They build greater strength. They create better thermal resistance.

Based on my experience, Dynocast’s position strengthens through ongoing innovation. They respond to market trends. They maintain a strong global reputation for high-quality ceramic foam filters in the casting industry.

Filtec: Ceramic Foam Filters for Casting

Filtec ranks as a top global maker of ceramic foam filters for casting. I often see it listed with big names like SELEE, Vesuvius, LANIK, Drache, Protech Industries, and Dynocast. Filtec makes three main types: alumina, silicon carbide (SiC), and zirconia ceramic foam filters. I recommend SiC filters. They resist heat and chemicals better than other types.

Product Innovation and Technology

Filtec company makes custom filters for specific alloys, casting shapes, and process needs. Based on my experience, this meets the strict quality standards of modern manufacturing.

Filtec leads in innovation. It makes filters with better durability. These resist high temperature and pressure. The company uses digital manufacturing for consistent quality. It also creates eco-friendly products that meet tough industry rules.

I see strong market growth in the Asia-Pacific (APAC) region. Manufacturing booms and industrialization drive this expansion. Filtec’s products beat alternatives like cloth filters. They work more efficiently and adapt to more uses.

Sustainability, Digital Tools, and Market Trends

Filtec invests in automation and digital tools for its manufacturing. This improves product quality. It cuts costs at scale. Filtec responds to environmental concerns. It makes filters that cut emissions and waste. This helps customers meet their sustainability goals. The company keeps developing new solutions. These fit stricter rules and changing industry needs.

Filtec in the Global Ceramic Filter Market: Quick View

| Aspect | Filtec’s Profile/Market Context |

|---|---|

| Market Share | Top 10, ~60% global market control |

| Product Range | High-porosity SiC, Alumina, Zirconia filters |

| Revenue Role | Part of $2B+ annual top-10 revenue group |

| Key Applications | Automotive, aerospace, electronics, precision |

| Innovation Strategy | Custom, durable, high-temp and sustainable lines |

| Regional Focus | Strong Asia-Pacific, global reach |

| Environmental Direction | Low-emission, sustainable products |

I believe Filtec stays ahead in the global ceramic foam filter market through constant innovation, quality filter design, and quick response to industry trends in metal casting.

Induceramic: Advanced Ceramic Filters for the Casting Market

Induceramic is a top provider of ceramic filters for casting. The market was valued at USD 650 million in 2023. I expect it to reach USD 1.2 billion by 2032. The company ranks among the global top 10. These top companies hold about 60% of market share. They generate over USD 2 billion each year.

Diverse Product Range and Technological Leadership

Induceramic makes alumina, zirconia, and silicon carbide ceramic foam filters. These filters deliver high filtration performance. The filters offer high porosity and custom pore sizes. 3D printing and additive manufacturing help create modular filter structures. These adapt to new casting requirements fast. Induceramic invests in automation and advanced digital design. This keeps quality consistent. It also controls production costs.

Global Presence and Growth Trends

Induceramic holds a strong position in the Asia-Pacific region. Industrial growth drives this. New foundry investments help too.

The company is growing in North America and Europe. Strict regulations push demand for top-quality casting. Reliable filtration solutions are required.

The ceramic foam filter market will grow at a CAGR of 7.5% between 2024 and 2033. This shows rising demand for Induceramic’s filter products.

Induceramic focuses on advanced materials and custom engineering. It uses green manufacturing. Based on my experience, these strengths make it a leader in the global ceramic foam filter market for casting.

Pyrotek: Ceramic Foam Filters for Casting

I recommend Pyrotek as a top maker of ceramic foam filters (CFFs) for the casting industry. They offer solutions for molten aluminium, copper-based alloys, and ferrous metals like steel and Ductile Iron.

Main Ceramic Foam Filter Products

Pyropore Ceramic Foam Filters:

- Work for sand casting, investment casting, shell casting, low-pressure casting, and permanent mould casting

- Also fit holding and transfer systems

- Give consistent cell size and high surface area

- This improves filtration of fine inclusions

SIVEX Ceramic Foam Filters:

- Built for aluminium processing (beverage can stock, aircraft alloys)

- Used in in-line filtration systems at casthouses

- Sizes range from 17.8–66 cm

- Grades span from 10 to 100 PPI

- Deliver high-purity filtration for sensitive and cost-driven uses

Product Features and Technical Benefits

- Made from high-strength ceramics or phosphate-bonded alumina

- This ensures high thermal resistance and durability

- You can get standard or custom sizes

- A wide range of pore sizes lets you match your needs

- They resist chemicals and heat from molten aluminium

- They filter inclusions much smaller than the pore size

- This improves metal cleanliness

- Easy to install and maintain

- They work with existing in-line and custom filtration systems

Key Drivers and Market Position

Based on my experience, Pyrotek’s strengths include custom engineering and expertise in special-purpose castings. They focus on the demanding needs of automotive and aerospace industries. They respond to environmental and efficiency demands. This keeps Pyrotek among the leading ceramic foam filter makers for the casting market.

Foundry Max: High-Performance Ceramic Filters for Foundries

I recommend Foundry Max for ceramic filters in casting operations. They focus on advanced, reliable filtration solutions for demanding foundry work.

Core Product Features and Technical Data

Ceramic foam filters remove solid particles and slag from molten metals before pouring. You get fewer inclusions, less trapped gas, cleaner surfaces, and higher yields without scrap. These filters work for many metals. They handle ferrous, aluminum, copper-based alloys, and steel. Temperature range is 900°C to 1700°C. The filters use open-cell 3D lattices (PPI 10–60). They capture fine impurities well. They also help metal flow smoothly. Higher PPI grades (40–60) catch inclusions smaller than 1 mm.

- Thermal performance: Zirconia variants resist heat up to 1700°C. This makes them perfect for ductile and gray iron.

- Mechanical strength: Filters resist thermal shock and work reliably. Zero failures reported under normal use.

Manufacturing and Customization

- Filters are customizable in shape and thickness. You can choose silicon carbide (SiC), alumina (Al₂O₃), or zirconia (ZrO₂) types. Each suits different casting needs.

- Advanced manufacturing uses top-grade PU sponge templates. Precise sintering creates uniform porosity and strength.

Market Position and Differentiators

I like Foundry Max for rapid delivery and hands-on technical support. They help with material selection. They offer filter life recommendations. Ceramic Filters provide high casting yield. They minimize production waste. They promote cost efficiency. Both low-volume and high-volume foundries benefit.

Application Examples

- Casting of steel engine blocks and aluminum automotive components

- Aerospace investment casting, such as turbine blades

- Filtration for petrochemical processing of molten materials

How to Choose the Best Ceramic Filter Companies for Casting

I recommend evaluating ceramic filter suppliers using specific criteria. These factors affect casting quality, efficiency, cost, and compliance.

- Your alloy or casting metal determines the best filter material. This choice affects both performance and how long the filter lasts.

- Based on my experience, top manufacturers deliver different pore sizes (10–40 PPI) to match your impurity type and cleanliness needs.

- Premium suppliers engineer ceramic filters that withstand operating temperatures up to 1700°C without breaking down.

- Best-in-class companies provide custom filter sizes, shapes, and compositions for specific molds, alloys, or casting systems.

In summary: The ceramic filter casting industry shows rapid market growth. Wide-ranging technological innovation marks the field. Asia-Pacific leads strongly. Rising demands for product quality, efficiency, and compliance shape a competitive global market.