In aluminum casting, filters vary in quality. Picking the right aluminum filtration product affects your final casting product. I’ve seen how a smoother finish or stronger casting depends on small details in your filtration setup. Ceramic foam and bonded particle filters each have unique benefits.

Ceramic Foam Filters

Ceramic foam filters are key in aluminum casting. They clean molten aluminum. They improve the final casting quality. Their unique structure reduces non-metallic dirt. This leads to smoother metal flow.

Materials, Composition, and Structure

- Made from alumina (Al₂O₃). Composition: 85% Al₂O₃, 6% SiO₂, and 9% other oxides.

- Sizes range from 7″ to 26″ square. Dimensional tolerance: ±3 mm.

- Porosity levels: 80–90%. This allows effective filtration.

- Pore size (PPI: pores per inch) varies from 10 to 60. Higher PPI means finer filtration.

- Compression strength: ≥1.0 MPa. Volume density: ≤0.5 g/cm³.

- Alumina filters work up to 1200°C. Zirconia filters handle even higher temperatures.

Production and Technical Features

Made using organic foam coating method. Ceramic slurry coats a foam template. Then it’s heated at high temperature. The 3D pore network provides large surface area. It blocks dirt and traps inclusions.

Filtration Performance and Key Data

Finer pore sizes improve filtration:

| Pore Size (PPI) | Inclusion Size Filtered (μm) | Filtration Rate (%) |

|---|---|---|

| 20 | 80 | 78 |

| 30 | 40 | 85 |

| 40 | 20 | 88 |

| 50 | 10 | 92 |

| 60 | 5 | 95 |

A 12-inch filter offers up to 80% effective filtration area.

Flow rates for aluminum alloys vary by filter size:

- 7-inch: 22–56 kg/min

- 9-inch: 25–80 kg/min

- 12-inch: 50–156 kg/min

Advantages and Performance Benefits

- Removes large and fine dirt. Results in much cleaner molten aluminum.

- Improves surface quality. You get better ingots, rods, and coils.

- Great thermal shock resistance. Can handle shifts between 800°C and room temperature at least 5 times.

- High strength and erosion resistance. Stays durable under harsh metal flow and stress.

Practical Applications

Must-have for high-spec parts. I recommend them for aviation, transportation, and electronics (like computer hard disks and jet turbine blades). Foundries install these filters in a filter box. This is standard for precision alloys.

Operational and Selection Guidelines

- Pick filter material based on alloy type and casting temperature.

- Choose mesh or PPI based on cleanliness needs and metal flow. Higher PPI gives finer results. Lower PPI gives higher output.

- You can mount filters flat or upright. Most use an expansion seal for tight fit.

Impact on Casting Quality

Ceramic foam filters cut defect and scrap rates. This improves yields. You’ll see clear improvements in appearance. Mechanical performance of high-value aluminum parts gets better too.

Varieties and Temperature Ranges

- Alumina filters: work at ≤1200°C. Suited for aluminum and aluminum alloys.

- Zirconia filters: handle up to 1700°C. Good for steel and superalloy work.

- Silicon carbide filters: used for iron and non-ferrous alloys.

Key Data Summary

- Pore sizes: 10–60 PPI standard. Up to 90 PPI available.

- Porosity: 80–90%.

- Compression strength: ≥1.0 MPa.

- Filtration rate: up to 95% for finest filters.

- Flow rate: 22–156 kg/min. Depends on filter size.

- Used often in aerospace, electronics, and casting of high-tech aluminum alloys.

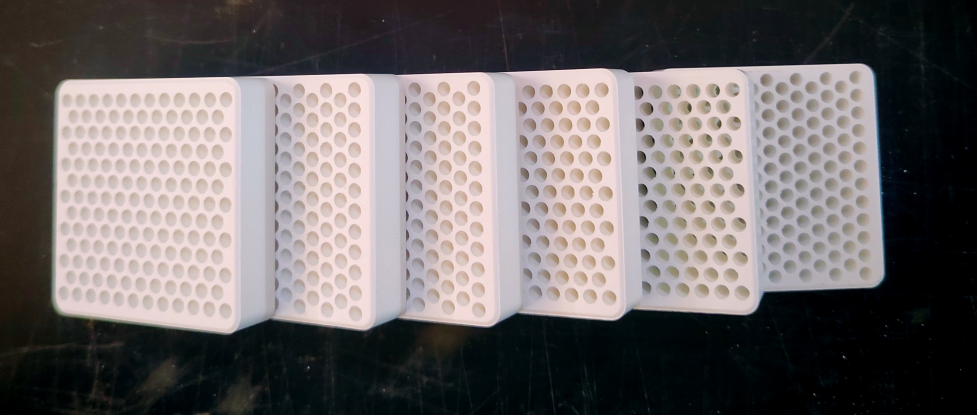

Ceramic Honeycomb Filters

Ceramic honeycomb filters are vital in metallurgy and aluminum casting. They remove impurities from molten metal. This boosts the quality and stability of aluminum castings.

Key Features and Technical Specifications

- Large surface area with straight channel honeycomb structure. This increases contact area between molten aluminum and the filter.

- High mechanical strength and thermal shock resistance. The filter can withstand harsh casting conditions.

- Temperature resistance up to 1390°C.

- Standard sizes include: 178×178×50mm, 230×230×50mm, 305×305×50mm, 381×381×50mm, 432×432×50mm, 508×508×50mm, 584×584×50mm.

- Through-hole ratio (light transmittance): 95% or higher.

- Thermal shock resistance: Withstands repeated cycling at 800°C with water cooling, tested for over 5 cycles.

- Thermal expansion coefficient: Less than 5 (10⁻⁶/k) between 20–1000°C.

- Made from inert extruded ceramics. This provides high corrosion and chemical resistance.

Filtration Performance and Benefits

- Molten aluminum mobility increases by 25–30% with honeycomb filters.

- Casting rejection rate drops by 85%. This means far fewer defective products.

- Strength of castings improves by 10–20%. Fewer inclusions and better metal purity make this possible.

- Laminar flow design ensures steady, splash-free flow. This reduces pore defects and voids in castings.

- Machining performance of castings improves.

- Eliminates a high percentage of non-metallic inclusions, slag, and trapped gases.

Comparison and Application Advantages

- More consistent flow rates than ceramic foam filters. This enables precise control over the casting process.

- Minimizes splash effect. This protects casting integrity and reduces chances of air entrapment or surface defects.

- Proven in aerospace and automotive casting. Also works well in general machinery and non-ferrous foundry applications.

Cost and Operational Benefits

- Reduced casting costs through fewer rejections and less scrap.

- Improves labor productivity. This happens by decreasing the need for secondary finishing and defect corrections.

- Industrial prices vary by size and quantity. Prices range from $2 to $15 per unit for standard dimensions and specifications.

My Recommendations and Practical Use

I recommend these filters for high-quality aluminum casting lines. Use them where consistency, low rejection rates, and clean surface finish matter most.

These work well for filtration of molten aluminum and various non-ferrous alloys. Foam filters may not meet high throughput or stability needs in these cases.

I believe ceramic honeycomb filters are a top choice in the aluminum and non-ferrous casting industry. They combine excellent thermal properties with operational efficiency and reliability.

Fiberglass Filter Mesh / Filter Pouches

Fiberglass filter mesh and filter pouches are key filtration tools in aluminum casting. They remove slag, oxides, and tiny impurities from molten aluminum. This keeps casting quality high while controlling costs.

Technical Specifications and Materials

- Material: Alkali-free, high-purity glass fiber. We often add phenolic resin coating for extra strength.

- Mesh density: Standard is 300 g/m². This gives strong filtration.

- Mesh size: Most use 0.8 mm. You can customize as needed.

- Thickness: Ranges from 0.18 mm to 0.35 mm. Different casting processes need different thickness.

- Operating temperature: Works at 700–800°C. This suits most aluminum molten handling.

- Softening point: 900°C.

- Heat resistance: Advanced types handle up to 1700°C.

Product Types and Application Flexibility

We offer fiberglass mesh filters in three main types. Each type fits specific needs:

– Standard: General filtration for typical aluminum castings.

– Smokeless: Cuts smoke and harmful emissions during casting. I recommend this for cleaner production environments.

– Carbonized: Built for specialty molten metal handling and tough filtration tasks.

Shape and formats give you more options:

– Sheet and roll: For wide area coverage or custom cutting.

– Cap-style mesh: Made for die-casting. It fits tightly to stop metal bypass and maximize filter contact.

– Filter pouches: Enclose molten aluminum for targeted impurity removal.

Performance Data and Operational Examples

- Mesh size: Standard 0.8 mm. Custom options available.

- Thickness: 0.18–0.35 mm.

- Temperature: Handles 700–800°C for routine work. Specialty versions work up to 1700°C.

- Density: 300 g/m². This balances strength and filtration well.

- Material structure: Alkali-free, high-twist fiberglass yarn. We often add phenolic resin coating for extra durability.

Industry Use Cases:

– LPDC (Low Pressure Die Casting) sand casting: Many plants use smokeless mesh. This improves quality and cuts environmental impact.

– Die-casting lines: Cap-shaped filters stop unfiltered aluminum from bypassing. This ensures complete impurity removal.

Key Advantages

- Effective impurity removal: Filters out slag, oxides, and other tiny bits.

- Economic and disposable: Costs much less than ceramic filters. I suggest them for single-use, high-volume production.

- Customizable design: Shapes (flat, cap, pouch) and mesh specs match various aluminum casting needs.

- Reduced emissions: Smokeless products cut harmful gases. This supports safer, cleaner plant operations.

Data and Feature Summary

- Material: High-purity, alkali-free fiberglass

- Mesh size: 0.8 mm (customizable)

- Thickness: 0.18–0.35 mm

- Operating temp: 700–800°C, up to 1700°C max (for advanced types)

- Soft-point: 900°C

- Types: Standard, smokeless, carbonized

- Shapes: Flat mesh, cap-style, filter pouch

Fiberglass filter mesh and filter pouches are versatile, cost-effective solutions. They remove impurities and boost yield in modern aluminum casting. Based on my experience, their flexibility and low cost make them a smart choice for foundries. I like them because they prioritize both quality and operational efficiency.

Reticulated Alumina In-Line Filters

We often call these filters alumina ceramic foam filters. They play a key role in modern aluminum casting. These filters remove inclusions and impurities from molten aluminum. This improves the cleanliness and quality of cast products.

Technical Specifications and Material Features

- Material composition: Made of 85–87% Al₂O₃ (alumina). Works at up to 1200°C without stopping.

- Porosity: Keeps open porosity at 80–90%. This means strong filtration without slowing metal flow.

- Strength: Compression strength ranges from 1.0 to 3.5 MPa. Flexural strength reaches up to 1.91 MPa.

- Thermal shock resistance: Survives at least five rapid cycles from 800°C to room temperature. This ensures durability for repeated casting.

Pore Size Options and Filtration Accuracy

PPI Range (Pores Per Inch):

- 10–40 PPI: Standard choice for everyday aluminum casting jobs.

- 30–60 PPI: I recommend this for aerospace and precision-grade aluminum castings.

Available filter sizes: Standard dimensions from 660×660×50 mm (26″) down to 178×178×50 mm (7″). These fit a wide range of filtration systems.

Filtration Performance and Casting Impact

Effective inclusion removal: Traps both larger contaminants and fine micron-sized impurities. This is critical for producing flawless aluminum products.

Improved mechanical and visual properties: Boosts the surface finish. Also improves mechanical strength, ductility, and machinability of aluminum alloys.

Promotes laminar flow: Reduces turbulence and gas entrainment. This minimizes gas pockets, shrinkage, and crack defects. I’ve seen this work well in valuable alloys like A356 and 6082.

Key Industry Applications

Aerospace: Filters like EXACTFLO work well for aerospace structural and engine components. These require maximum cleanliness and strength.

Automotive and Electronics: Used to manufacture high-purity aluminum parts for cars, PCB base boards, and electronics. These have strict impurity limits.

General Industrial Casting: Foundries seeking higher casting yields and fewer rejections use these filters.

Examples and Case Highlights

Aerospace castings: I suggest using sintered reticulated alumina filters. They lead to defect-free components and consistent high mechanical properties.

Automotive foundries: Plants report higher yields. They also see improved machinability on complex castings. This means proven reduction in scrap.

Additional Operation and Selection Benefits

No slag generation: The strong alumina structure resists degradation during use. This prevents the introduction of filter-derived slag or particles.

Customizable: Offered in many shapes, edge coatings, and gasket materials (fiber paper, cotton, expanded cotton). These suit diverse production setups.

Yield improvements: Drop in defect and scrap rates. This achieves better process efficiency and lower environmental impact.

Typical Technical Data Snapshot

- Porosity: 86.8% (by volume)

- Compressive strength: Up to 3.50 MPa

- Flexural strength: 1.91 MPa

- Density: ≤0.5 g/cm³

- Thermal resilience: Withstands drastic, repeated temperature cycles without failure

Core Benefits at a Glance

- High removal of inclusions and slag for superior casting cleanliness

- Maintains stable aluminum flow rate. Limits turbulence and casting issues.

- Trusted for both routine and high-specification aluminum alloy castings

- Delivers higher yield, reduced environmental impact, and better final part quality

Based on my experience, reticulated alumina in-line filters are essential for foundries. They help you achieve top-tier casting quality and operational consistency. I recommend them for sectors where product reliability is critical.

Bonded Particle Filters for Aluminum Casting

Bonded particle filters are a top filtration solution in aluminum casting. They work well in furnaces, ladles, and at the casting point. You can use them in gravity casting, high-pressure die casting, and low-pressure die casting.

These filters are made from high-purity silicon carbide aggregate. A special ceramic binder holds the particles together. This gives them strong chemical resistance, excellent heat transfer, and the mechanical strength needed for molten aluminum.

Key Features, Materials, and Technical Performance

- Material composition: High-purity silicon carbide with a special ceramic binder. This creates durability and thermal stability.

- Temperature resistance: These filters handle temperatures up to 1560°C. They perform well in tough aluminum melt conditions.

- Structure: The design has lower porosity and a complex internal pathway. This removes inclusions efficiently and prevents refractory erosion.

- Filter forms: You can choose from box filters, vertical gate, pump, dosing tube, stalk tube, and crucible baffle designs. Foundries can pick or customize filters for every stage. This covers melting furnaces, ladle transfer, and the casting point.

- Pore sizes and grit grades: Options like 8 grit work well for high-cleanliness casting operations.

Filtration Efficiency and Operational Benefits

Inclusion removal: These filters match or beat standard 20 ppi ceramic foam filters. The 8 grit particle filters capture oxides, corundum, and other non-metallic inclusions. Industry Prefil and PodFA tests prove this.

Enhanced casting properties:

- Increases elongation and ductility of final products.

- Boosts machinability: Castings filtered through bonded particle technology show less tool wear. They also have fewer machining rejections. This supports high-volume, value-added operations.

- Scrap rates drop: Foundries see lower scrap levels and fewer surface defects after using these filters. This boosts marketability.

Metal fluidity: The unique structure helps molten metal flow smoothly. This reduces turbulence and casting defects.

Industry Applications and Real-World Results

- Automotive die casting: Many casting lines use these filters for LM24/A380 cylinder heads and transmission cases. Industries report better surface quality, fewer leakers, and lower machining rejects.

- High-end aluminum manufacturing: Companies need ultra-clean molten aluminum for critical components. They prefer bonded particle filters in performance-sensitive sectors.

- Global adoption: Major aluminum foundries choose bonded particle filters. They value their reliability, easy integration, and consistent high output quality.

Cost-Effectiveness and Implementation

Minimal additional cost and risk: Switching to bonded particle filters needs little extra investment. It causes minimal process disruption. I recommend this as a practical quality upgrade for most aluminum foundries.

Rigorous quality control: Strict oversight of materials and manufacturing creates exceptional filter uniformity. This ensures reliability.

Advantages at a Glance

- Cuts inclusion-driven scrap and boosts casting yields

- Raises surface finish and mechanical properties (strength, elongation)

- Supports steady, repeatable casting quality

- Reduces machining and tool wear costs. This extends die and tool life.

- Promotes metal fluidity and casting consistency

Industry and academic studies agree on this: Bonded particle filtration in aluminum casting creates clear improvements. You get better melt cleanliness, process efficiency, and product quality. These are measurable results.

Based on my experience, foundries seeking a modern, cost-effective upgrade in casting performance should consider bonded particle filters. I recommend this proven solution.

Summary

I’ve worked with aluminum foundries for years. Here’s what I’ve learned: there is no single “best” filter.

It’s not about picking one technology over another. You need to match your casting needs with the right filter. Are you doing aerospace work that needs high precision? Or are you running high-volume automotive production? Each requires a different solution.

I recommend understanding three things:

– What you’re filtering

– Why you’re filtering it

– How each filter type fits your needs

Based on my experience, this knowledge gives you a real edge. It turns filtration from a basic step into something that sets you apart from competitors.