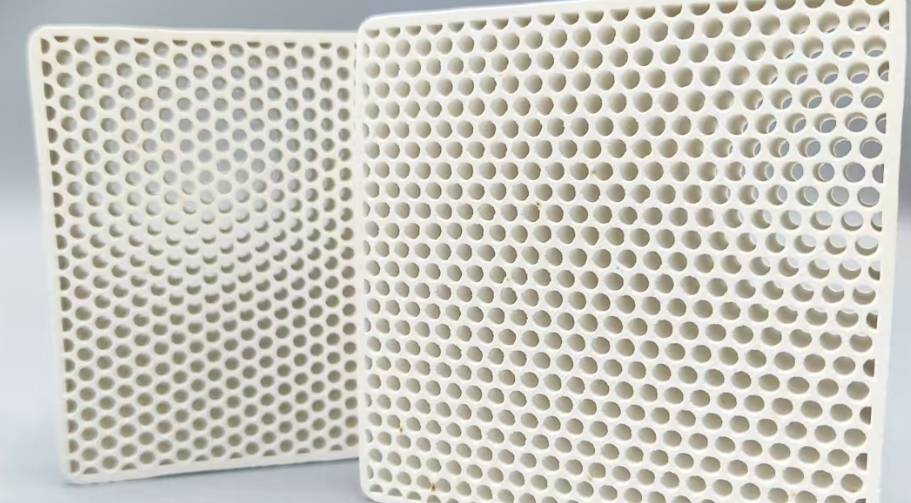

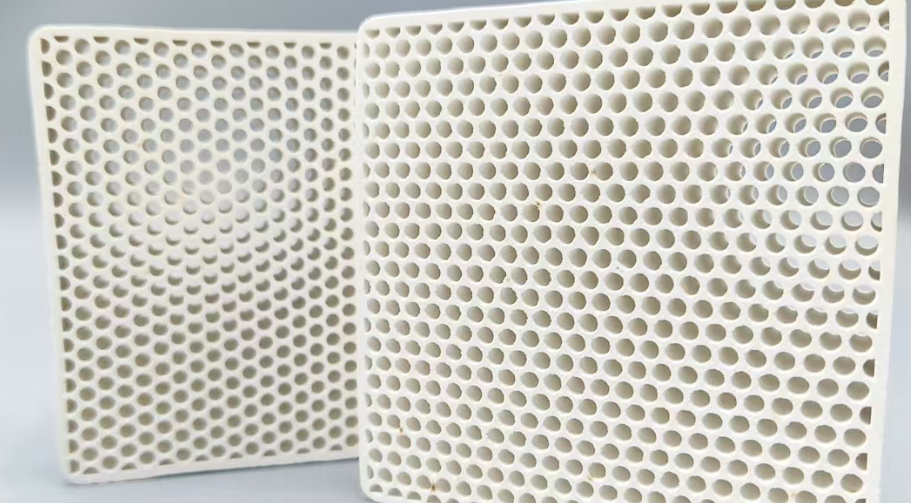

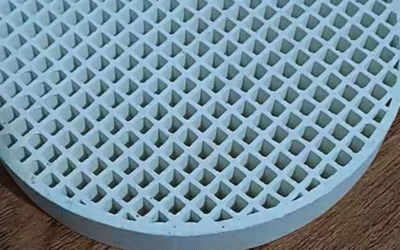

Finding a reliable honeycomb air filter supplier in China can feel tough. Countless manufacturers claim they offer the best quality and pricing.

You’re sourcing for HVAC systems, industrial ventilation, or cleanroom applications? The right manufacturer impacts your product quality. It affects delivery times and your bottom line too.

China has become a global leader in air filtration technology. The country has specialized manufacturers with decades of know-how in honeycomb filter production. This guide profiles the top 10 China honeycomb air filter manufacturers that have earned industry respect. They stand out for innovation, quality certifications, and export abilities.

Koinfilter (Suzhou, Jiangsu)

Koinfilter has been making air filters for over 16 years. Their factory sits in Suzhou Industrial Park. Since 2006, they’ve grown from a small local shop to a global supplier. Now they serve 100+ countries with 160 staff members.

Their honeycomb air filter range covers everything you need. You get HEPA and ULPA types for cleanroom particle capture. Activated Carbon filters take care of gas and odor problems. All products meet EN779 European standards. They pass strict PAO/MPPS scan tests. These tests check how well filters catch even the tiniest particles.

We run dust-free production workshops. These spaces stay free from contamination during manufacturing. This clean setup boosts the quality of our HEPA cartridge filters and pleated filter units. More than 400 clients across the globe use Koinfilter for industrial HVAC systems and cleanroom ventilation.

What makes our process stand out:

-

Fast response – Engineers get back to you within hours, not days

-

Clear pricing – You receive quotes within 2 business days with production timelines

-

Quality checks – Every filter gets air flow and pressure testing before it ships

-

Global shipping – Sea and air options available with installation guides

Need custom specs? Our 4-step process covers you from first inquiry to final delivery. We follow up at each production stage. Contact us at sales@koinfilter.com or call +86 512 62886688 to talk about your honeycomb filter needs.

Dongguan Air Guard Filter Manufacturing Co., Ltd.

Air Guard Purification Technology Group runs two production bases in China. You’ll find their headquarters at No.196 Keji Dong Road in Dongguan’s Shijie district. The second factory is in Suqian, Jiangsu province. These two sites cover 51,000 square meters of factory floor space. The space fits 29 automotive cabin air filter production lines and 6 lines for industrial and household purifier filters.

This size means big production power. Air Guard makes over 9,000 filter types. Annual output can reach 20 million units. Their honeycomb air filter range has activated carbon models, HEPA H12/H13 grades, and multi-pocket synthetic fiber pre-filters rated G3-G4.

Technical credentials:

-

IATF16949 certified – Auto industry quality standard

-

National CNAS Laboratory – Government-approved testing center

-

ISO/TC146/SC6 expert leadership – Chairman Dr. Zhang Wu works on international VOC standards groups

Pricing starts very low. HEPA H13 replacements begin at $1.59 USD. Minimum order is just 2 pieces. Industrial buyers pay $1.80-$2.90 per unit for MERV 8/11/13 pleated panels at 100-piece orders. Reusable automotive cabin filters cost $10-$15 for custom orders above 500 pieces.

Air Guard works with South China University of Technology and Guangdong University of Technology. These partnerships support R&D centers and doctoral workstations. The focus is on better filtration materials. Intertek checked their facilities in April 2025. The inspection confirmed production abilities across their China and Thailand factories.

Nanjing Tong Chang Environment Tech Co., Ltd.

Nanjing Tong Chang Environment Tech opened its doors in 2018 (some records show 2014). They’re based in Jiangbei New District, Nanjing, Jiangsu province. Over 100 employees work here. The focus? Air purifier parts and accessories. They got their high-tech enterprise certification in 2020.

Their product line centers on air purifier filters. You’ll find filters for home air purifiers, vacuum cleaners, and humidifiers. They make air conditioning filters too – both for homes and businesses. These come in small sizes and different shapes. Materials? synthetic fibers and washable types. Filter efficiency reaches H13 grade. That means they catch fine particles.

What makes them different:

40+ technical patents – They work with top universities: Chinese Academy of Sciences, Sichuan University, and Beijing Institute of Technology

International know-how – The core team has 25+ years in this field. They know USA and European filter testing rules inside out

Flexible business models – OEM, ODM, and OBM services for B2B clients

They sell to North America, South America, Europe, and Asia. SGS, BV, and UL have checked their production quality. The company runs two business lines. First: industrial air and water filters. Second: home portable gear and parts. This setup helps them take on big commercial jobs and consumer orders.

Zhejiang Zhengjia Technology Co., Ltd.

This Wuyi-based manufacturer does not produce honeycomb Air Filters. Their 15,866㎡ facility sits in Huanglong Industrial Functional Zone. They make sports equipment – baseball and softball gear.

What they make:

Aluminum baseball bats – Training bats, soft ball bats, and regulation models

Baseball accessories – Batting tees start at $0.85/piece (500-piece minimum), dimpled PU baseballs from $0.98

Protective sports gear – Motorcycle knee pads ($8.69-12/piece), cycling gloves ($1.49-1.59/piece)

Premium baseball products – Cowhide leather gloves at $46.90-52.90/piece, 85% wool core official league baseballs priced $3.05-3.29

Annual sales hit $4.87 million USD. The company holds BSCI certification for batting tee production. They showed up at ISPO 2025 with aluminum bat innovations. Export records list shipments under HS code 95 (sports requisites). US retailers like Tanners Team Sports buy from them.

Why this company appears in air filter searches:

Database mix-ups happen all the time. Supplier directories misclassify manufacturers sometimes. Zhejiang Zhengjia does sample-based customization for sports products. That’s it. They have no R&D capabilities for filtration technology. No HEPA materials. No cleanroom applications.

Need honeycomb air filters? Skip this supplier. They’ve been in business for five years. Their focus is competitive OEM factory services for baseball and softball equipment. Nothing else.

Shanghai Filterbag Factory Co., Ltd.

Steven Zhai started this factory in November 2006. We now bring in $12 million USD each year. Our production lines run across China. We also have an office in the United States. Over 50 employees work at both sites.

We run four needle punched felt production lines. Hundreds of filter bag sewing machines handle big orders. Our facility has 300 glass fiber processing units. These make specialized filtration materials.

Product range breakdown:

Dust collection bags – Made from PTFE, fiberglass, and Polyester. You’ll find these in cement plants, steel mills, power stations, and waste burning sites. They handle high heat and resist chemicals.

liquid filter bags – PP, PE, and nylon types. These come in 20 micron and 200 micron sizes. Used for chemical processing, food making, petrochemicals, and water treatment.

air filtration systems – HEPA and ULPA filters. We make these in cleanroom lines. They work in HVAC, pharmaceutical, electronics, and cleanroom settings.

Filter fabric – Raw filtration cloth. Prices run $1.03-$30 per square meter. Cost depends on what you need.

Shanghai Filterbag ranks in China’s top 3 for industrial liquid filtration equipment. We lead the home market for dust filtration and separation gear. Our quality control has ISO certification. This meets global safety and environmental rules. We have strong markets in the United States and Europe.

Pricing structure:

-

Dust filter bags: $1.90-$4.38/piece

-

Liquid filter bags: $1.80-$3.60/piece

-

Filter housing units: $110-$220/set

-

Standard air filters: $6.60/piece

Wuxi LENGE Purification Equipment Co., Ltd.

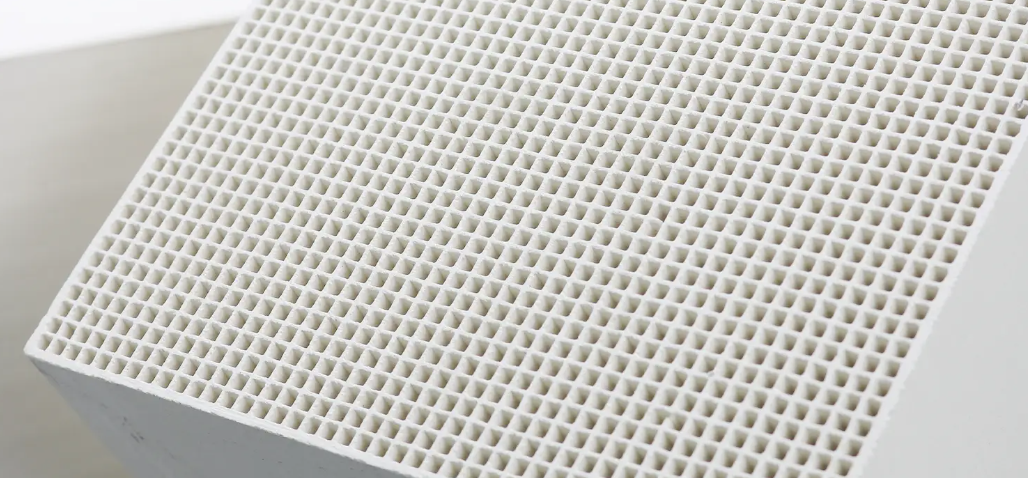

LENGE Purification Equipment runs operations in Wuxi, Jiangsu province. We focus on clean room solutions and industrial air filters. Our honeycomb air filter line covers medium to high-efficiency grades for pharma, electronics, and food plants.

What we make:

-

Honeycomb Activated carbon filters – Remove VOCs and control odors in factory exhaust systems

-

Panel air filters – G3 to F9 ratings with aluminum or steel frames

-

Clean room parts – FFU units, air showers, and pass-through boxes for controlled spaces

-

Custom filters – Built for semiconductor and biotech labs

We hold ISO 9001 quality certification. Our factory uses automated pleating lines and ultrasonic welding gear. This keeps filter shape and seals consistent. Tests check air flow resistance, dust capacity, and strength under pressure.

We serve cleanroom contractors in China and export to Southeast Asia. Our tech team visits sites for HVAC system help. Custom spec requests? You’ll hear back in 24-48 hours. We handle small batches and big project orders.

Our filters use Synthetic fibers, activated carbon bits, and non-woven material. We test filter performance by GB/T 14295 national rules. This lines up with ASHRAE and EN779 standards globally.

Guangzhou Fete Filter Technology Co., Ltd.

Guangzhou Fete Filter Technology started in 2013. The goal was simple: give air filtration clients complete customization freedom. Their factory sits in Guangdong province with 120 employees. The team works on automotive paint booths, pharmaceutical cleanrooms, and everything in between.

Core product lineup:

-

HEPA filters – High-efficiency units for cleanroom use

-

FFU systems – Fan filter units that pack blower and filtration into one compact box

-

Chemical filters – Activated carbon and special media that remove VOCs

-

HVAC filters – Climate control filtration for commercial and residential spaces

Fete holds over 40 technical patents. These patents power their custom work. Need non-standard dimensions? Unusual frame materials? Special pleat depths? Their engineering team builds it. The patents cover filter frame designs, media setups, and how everything fits together.

Manufacturing capabilities:

-

High-flow laser dust counters – These scan HEPA filters during production. Every filter gets checked for particle capture before shipping.

-

Injection molding lines – Plastic frames get made in-house. This speeds up delivery for custom frame shapes and sizes.

-

Fast production cycle – Frame making to filter paper folding moves fast. Output stays high. Quality holds steady for standard-size air filters.

Their R&D labs handle product research and tech development. They take filters from concept to finished product. You’ll find their filters in auto plants, paint shops, electronics facilities, and pharmaceutical labs. They also serve industrial sites, office buildings, and home appliance manufacturers.

The Guangzhou location opens up South China markets. Regional clients get faster delivery. Plus, they receive on-site technical support.

Guangzhou Clean-Link Filtration Technology Co., Ltd.

Clean-Link operates two factories in China. The Guangzhou and Changzhou sites total 247,000 square feet. We’ve focused on exports since 2007. 91-100% of what we make goes overseas. Our location near Huangpu, Sekou, and Wuchong ports makes shipping faster.

What we make:

-

HVAC air filters – Panel Filters, pocket filters, and prefilters for commercial climate systems

-

High-temp HEPA filters – Units that keep H13/H14 performance in extreme heat

-

Flame-retardant filters – Safety filters for paint booths and industrial exhaust

-

Filter Media rolls – Raw materials for companies building their own filter systems

-

AHU and FFU units – Complete air handling and fan filter systems

We hold ISO 9001 certification and belong to NAFA (National Air Filtration Association). Our team includes Certified Air Filter Specialists and Level I Certified Techs. This know-how supports our OEM/ODM work. Each client gets one dedicated expert. This expert manages everything from specs to delivery.

Our production lines have on-site testing equipment. Look for us at FILTECH 2026, the global filtration trade show. Our G4 and HEPA lines work with synthetic and glass fiber media. Custom designs? Our R&D team handles those. Support continues after we install your system.

Hi-Forest (Xiamen) Purification Technology Co., Ltd.

Hi-Forest started in 2014 in Xiamen, Fujian province. Their 120-person team has over 25 years of industry know-how. They earned high-tech enterprise status. Their focus? Special filtration solutions.

What they make:

-

HEPA and ULPA filters – Standard and high-temp models for critical spaces

-

Different efficiency levels – Primary, medium, and high-grade filters for all uses

-

Full cleanroom systems – Clean sheds, air showers, cargo shower rooms, pass-through windows, ultra-clean work tables

-

FFU units – Fan filter units with HEPA air outlets and air-supply ceilings

-

Industrial filters – Panel HEPA filters, air cleaning units, humidifier filters, water filter parts

Hi-Forest works with optoelectronics, semiconductors, car paint shops, and industrial painting sites. They supply pharmaceutical makers too. Plus, they handle high-end building projects. You’ll find their cleanroom gear includes self-cleaners, automatic hand washers and dryers, clean sampling carts, and laminar flow hoods.

The company owns patents for special designs. Their smell and smoke filter (patent CN213192960U) is registered with Bank of China Xiamen Tong’an branch. This proves they have money support and legal protection for their new ideas.

Need tech details on high-temp HEPA filters? Or full cleanroom ready-to-use solutions? Reach out to them.

Jiangxi SG Filter Company

Jiangxi Sange Filter Manufacturing Co. Ltd. works as both a maker and trading company. Their export records show $3.41 million USD in global shipments. The factory makes industrial filters. Motor protection is their main focus.

What they make:

-

Three-phase motor filters – Models 101D27P509 and 101D201514 work with 7.5kw and 15kw motors

-

Factory-direct pricing – Bulk orders start at US$10,000+

-

Motor protection filters – These stop dust and particles from damaging electrical systems

Their supplier rating sits at 5.0 out of 5 on verified platforms. They respond in 11.02 hours or less. Quick quotes for urgent projects? They’ve got you covered. The company passed audited supplier checks. This confirms they can produce and export at scale.

Jiangxi SG works with B2B clients. Manufacturing lines, processing plants, and industrial facilities all need motor filters. Their three-phase filters protect costly equipment in tough conditions. Dust gets blocked. Metal particles get stopped. Airborne dirt never reaches your sensitive motor parts.

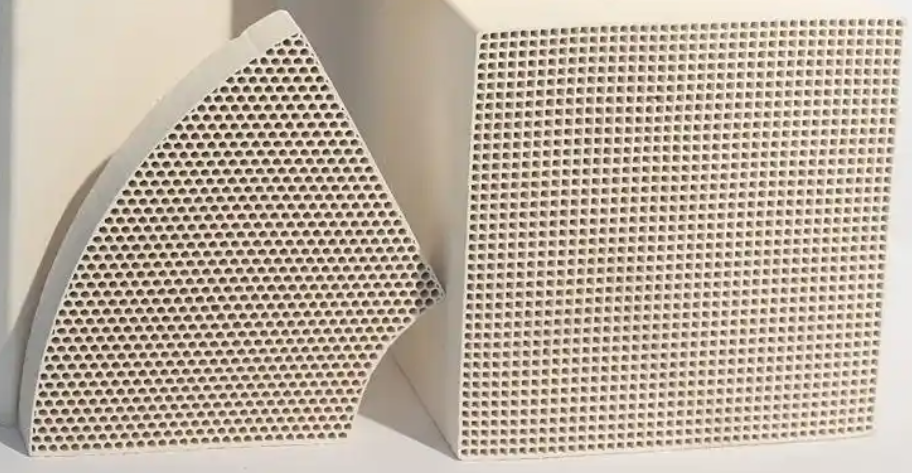

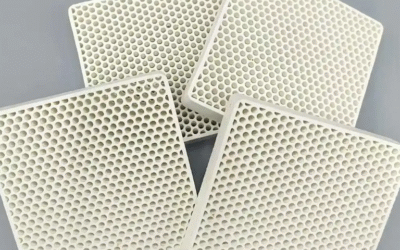

How to Choose the Right Honeycomb Filter Manufacturer

Your honeycomb filter choice sets system performance for 3-5 years. Wrong specs? You face constant replacements, production stops, and compliance problems. Here’s the selection framework procurement teams use.

Deriving Technical Requirements from Application Scenarios

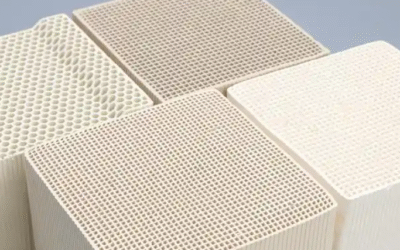

Industrial ULSI manufacturing needs SUS316L stainless steel honeycomb cartridges. Filtration precision hits 0.003μm. Flow rates run 10-200L/min. Heat resistance reaches 460℃. Why these numbers? Semiconductor production needs zero particle contamination. Standard materials fail at high temperatures.

Vehicle engine applications? PowerCore® Honeycomb Filters lead the market. They meet OEM specs. Twenty years of field data shows their strength in heavy-duty trucks and construction equipment.

Exhaust gas cleaning uses honeycomb activated carbon filters. High iodine value coconut shell carbon serves as the carrier. These meet national emission standards. China’s National VI standards push cell density to 300-750 cpsi for TWC/SCR/DOC substrates. Top manufacturers target 900 cpsi with wall thickness at 2-6mil.

Core Parameter Validation Checklist

Filtration precision – Industrial gas systems need 0.003μm particle capture. Check test reports under real operating conditions.

Flow capacity – Match your system’s 10-200L/min needs. Oversized filters waste money. Undersized units create pressure drops.

Cell density – 300-750 cpsi works for standard catalytic uses. National VI diesel emission systems need higher density near 900 cpsi.

Thermal expansion coefficient – ceramic substrates must stay ≤0.60×10^{-6}/℃. Thermal shock cracks filters during temperature changes.

Pressure drop – Low exhaust resistance impacts fuel efficiency. China’s National VI standard sets strict limits. Test data beats marketing claims.

Certification Document Checklist

|

Certification |

Application Scope |

Why It Matters |

|---|---|---|

|

EN 1822, IEST |

High-efficiency air filtration |

Cleanroom particle control check |

|

DVGW (EC 2014/68/EU, EU 2016/426 GAR) |

High-pressure gas filtration |

European safety compliance for gas systems |

|

FDA-grade polypropylene |

Chemical/oil compatibility |

Zero fiber migration in pharma processes |

|

GMP standards |

Replaceable high-efficiency filters |

Pharma manufacturing quality needs |

|

National VI standards |

Ceramic substrates |

Emission limit compliance for diesel vehicles |

Skip suppliers who can’t show original certificates. Copies don’t prove current compliance. Expired certifications mean old production methods.

Four Dimensions of Supplier Strength Assessment

Production capacity – Domestic leaders like Aofu Environmental, Shandong Guoci, and Nanjing Kerui hold mold precision processing patents. International giants Corning and NGK control premium markets. China’s domestic reach targets 70% for mid-range uses. Check if factories run dedicated production lines for your filter type.

Delivery timeline – Multi-length cartridge designs cut replacement time. OEM-spec manufacturers keep inventory. Ask about lead times during peak seasons. Production schedules matter more than claimed capacity.

After-sales support – Good suppliers handle quality issues fast. Zero fiber migration needs proper end-cap treatment. Technical teams should visit installation sites. Check service response times in contracts.

Pricing structure – Domestic kaolin clay fits mid-to-low-end needs. Imported US/Brazilian kaolin goes into National VI premium products. OEM manufacturers control costs by using domestic materials. Get itemized quotes. Compare material grades, not just total price.

Customization capability – Media compatibility with organic solvents and oils matters in chemical processing. Corning’s patented extrusion process sets industry standards. Cell density and wall thickness customization (2-6mil range) separates flexible manufacturers from rigid catalog sellers.

Five-step Selection Decision Process

Step 1: Match your application – Industrial high-temp work? Pick SUS316L. Vehicle engines? Go with OEM-certified PowerCore®.

Step 2: Lock down parameters – Precision 0.003μm, flow 10-200L/min, cell density 300-900 cpsi. Write these into RFQ documents.

Step 3: Verify certifications – Request EN1822, DVGW, FDA, or National VI certificates. Check expiration dates. Confirm scope covers your product category.

Step 4: Evaluate suppliers – Reputation comes first. Then check production capacity (domestic champions like Aofu, Kailong). Compare delivery guarantees, after-sales terms, pricing, and custom design abilities.

Step 5: Set performance benchmarks – Thermal expansion ≤0.60×10^{-6}/℃. Low pressure resistance. Request third-party test data before placing bulk orders.

Conclusion

China’s honeycomb air filter industry has grown into a strong ecosystem. Innovation meets manufacturing excellence here. The top 10 China honeycomb air filter manufacturers profiled here bring different strengths. Koinfilter leads in R&D capabilities. Dongguan Air Guard runs large-scale production. Hi-Forest focuses on environmental care. Jiangxi SG Filter offers budget-friendly solutions.

Your ideal honeycomb filter manufacturing partner depends on three key factors. First, your specific filtration needs. Second, production volume. Third, quality standards. You might prioritize customization flexibility. Or you need certification compliance. Maybe rapid prototyping matters most. This landscape offers options that match your operational goals.

Market trends now shift toward greener materials and smart filtration systems. Manufacturers who invest in sustainable innovation can protect your supply chain for years ahead. Don’t settle for generic solutions. Request product samples. Verify certifications. Conduct factory audits. This ensures your chosen honeycomb filter manufacturer delivers real performance improvements.

Ready to source? Contact 2-3 manufacturers from this list today. Compare their technical specifications. Request customized quotations. Your optimal air filtration solution is one conversation away.