I find India’s industrial ceramics industry quite impressive. It’s one of the largest and most active in the world. The industry meets many different needs across sectors like construction, infrastructure, power generation, and manufacturing. The market is worth over $10 billion. Based on my experience, it’s a huge achievement that Indian makers export products to more than 100 countries.

Top 10 Industrial Ceramic Manufacturers in India

Leading Industrial Ceramic Companies and Their Strengths

Kajaria Ceramics

In my view, Kajaria Ceramics is India’s biggest ceramic tile maker. They produce an impressive 81 million square meters of tileseach year. The company brings in about $900 million in revenue and is valued at $2 billion. Founded in 1985, they have key factories in Uttar Pradesh, Gujarat, Rajasthan, and Andhra Pradesh. I like that their product line has over 3,000 tile designs. These are known for being tough, scratch-resistant, and meeting worldwide quality standards.

Ants Ceramics Pvt. Ltd. Ants Ceramics is a company I find interesting because it focuses on advanced technical ceramics. They partner with research groups like BARC and ISRO. Their products include items like carbon sulphur analysis crucibles and special Alumina ceramics. From what I see, Ants shows great strength in R&D. They provide custom solutions for tough industrial jobs.

Jyoti Ceramic Industries Pvt. Ltd. Based in Nashik, I know Jyoti Ceramic Industries for its technical ceramics, such as Zirconox and Duralox 92-99.7. Their modern facility uses advanced testing tools like X.R.D and laser particle analyzers. They also use high-pressure molding. I believe Jyoti is a leader in creating ceramics from steatite and alumina for engineering use.

Asian Granito India Ltd (AGL)

AGL has its main office in Gujarat and is a major name in the market. I suggest keeping an eye on them. They produce 35 million square meters of material and have yearly revenues of $450 million. The company has a value of $1 billion and exports to more than 57 countries. AGL makes large slabs, engineered marble, and quartz stone, focusing on new technology and creative designs.

Somany Ceramics Ltd

Somany Ceramics has been around since 1969, which gives them a lot of experience in my opinion. They make glazed, polished, and digital tiles. The company earns $320 million each year and can produce 75 million square meters. Somany Ceramics provides modern and lasting designs to customers in India and abroad.

H&R Johnson

I think H&R Johnson, active since 1958, is a great choice for premium tiles. Their processes are ISO-certified. The company runs its own feldspar mines, which helps them maintain high standards. They can make 54 million square meters of tiles and earn about $200 million in revenue per year.

Additional Industry Leaders and Product Categories

Here are a few other key manufacturers I recommend watching:

- Orient Bell – They make innovative glazed vitrified tiles.

- Future Stiles – I recognize them for their creative designer tiles.

- Nitco Limited – This company offers quality floor and wall tiles, along with marble.

- Simpolo Ceramics and Lavish Ceramics – I find that these two focus on high-end, advanced ceramic products.

Industrial ceramic product Range: Based on my research, here is a typical range of products:

– Alumina ceramics and Zirconia ceramics

– Steatite engineering ceramics

– Crucibles for analysis

– Ceramic jackets for metal melting

– Wall, floor, outdoor, and vitrified tiles

– Engineered marble and quartz slabs

Main End-Use Industries: In my work, I’ve seen these ceramics used in several key areas: – Power generation: for insulators, tubes, and crucibles – Metallurgy: using high-temperature kiln furniture and ceramic linings – Defense and aerospace: for specialized advanced ceramics – Industrial plant operations: for wear-resistant parts, valves, and seals

Range of Industrial Ceramic Products in India

From my experience, India’s industrial ceramic industry is quite impressive. It offers a wide range of products, from familiar tiles and sanitaryware to cutting-edge technical ceramics, which are expanding fast.

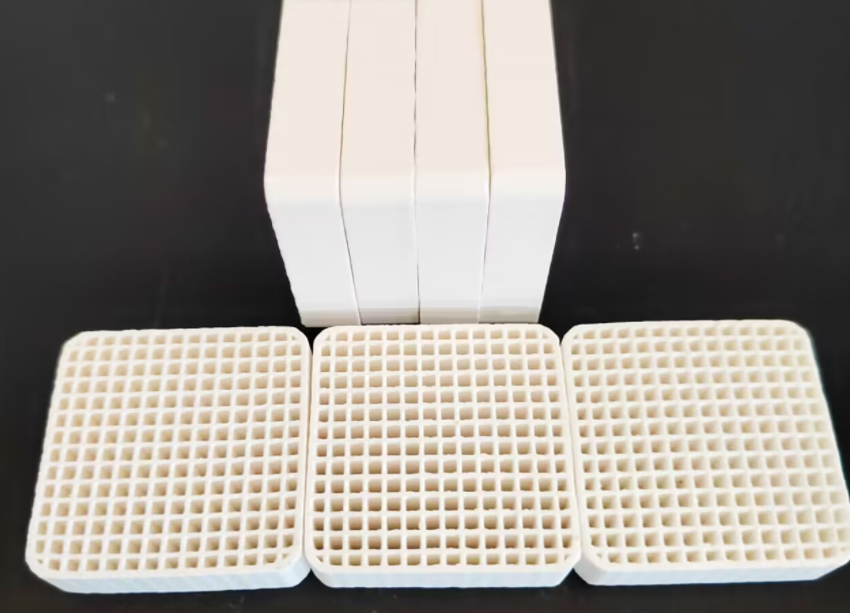

Technical and Advanced Ceramics

Technical ceramics are vital for many industries. I find this area particularly interesting. These materials include: Alumina, zirconia, steatite, silicon carbide, silicon nitride, ferrite, and advanced composites

Main uses are for electrical equipment, electronics, catalyst supports, engine parts, filtration, automotive, medical devices, and machinery. In 2022, the Indian market for advanced ceramics hit USD 7,443.1 million. I noticed that electronics applications made up 44.4% of that total. I suggest keeping an eye on this market, as it’s projected to grow to USD 12,280.1 million by 2030.

In my opinion, this is the most exciting part of the Indian ceramics industry because it’s the fastest-growing segment.

Examples of products:

– Mechanical wear parts (bushings, seals, nozzles)

– Electronic substrates (circuit boards, sensors)

– Filters and catalyst supports (for cars and general industry)

– I’ve seen a growing trend in using bioceramics for medical purposes, like dental and orthopedic implants.

Ceramic Tiles

In my view, the tile sector is the foundation of India’s ceramic industry. This includes ceramic wall and floor tiles, glazed vitrified tiles, porcelain tiles, unglazed tiles, mosaic tiles, and natural stone tiles. People use them for home, commercial, and industrial flooring. They also use them for wall cladding and roofing.

I remember the market was valued at about Rs 19,500 crore (USD 2.5 billion) back in 2013. It showed strong annual growth of 13–14%. Vitrified tiles lead with 50%. Wall tiles hold 20%, floor tiles 23%, and industrial tiles 7%. These tiles are made and sold all over India, including the North, South, West, and East.

Sanitaryware

When I look at the sanitaryware sector in India, I see it includes: Vitreous china bathroom products, sinks, water closets, faucets, and related fittings.

I would divide the market into two parts: organized and unorganized. Some organized brands are Hindware, Roca, Kohler, Cera, and Duravit. Production is centered in nine large factories located in different states. This sector makes up about 10–12% of the entire ceramics market.

Engineered Marble and Quartz

I’ve noticed that modern construction projects use more engineered stone products. These are composite marble slabs and quartz stone tiles. I recommend these for flooring, kitchen countertops, and upscale interiors in homes or businesses. While this market isn’t as big as tiles or technical ceramics, I’ve seen it expand quickly, especially in city projects.

Market Structure and Regional Hubs

From my knowledge, the main production hubs are in Morbi and Surendranagar (Gujarat) and Khurja (Uttar Pradesh). The whole Indian ceramic industry had a value of $10.5 billion in 2022. I expect it to grow to $18.7 billion by 2027. I find it interesting that tiles account for 80–85% of the industry’s income. Their share of exports is also growing.

Based on my analysis, technical ceramics and engineered stones are the categories with the fastest growth. This growth comes from demands in industry and infrastructure.

How India’s Ceramic Companies Lead with New Ideas and Awards

In my experience, India’s top industrial ceramic companies are great at both innovation and winning awards. These firms improve industry standards with new technology and research. They also win major awards for product quality, green practices, and branding.

Kajaria Ceramics: A Leader in Tech and Global Awards

I think Kajaria Ceramics stands out with its focus on new ideas. The company has eight modern manufacturing plants. They can produce 73 million square meters of tiles every year. I find it impressive that it is the one Indian tile brand to get the Superbrand award for 14 years in a row. Kajaria has also been called Asia’s Most Promising Brand in the premium market.

Innovation Highlights:

They use automated and robotic production lines, which reduces human error. I recommend their popular R&D series: The Ultima, Gres Tough, and Duratec XT.

Certifications: ISO-9001:2008, SA-8000, ISO-14001, ISO-22000:2005, ISO-50001:2011.

Global Impact: They export to more than 35 countries. Their catalog has over 2,800 tile varieties.

Asian Granito India Ltd: Great Exports and New Products

I suggest you look at Asian Granito for its global reach. It exports to over 100 countries. The company has won several national and international awards for its export success and sustainability efforts.

Innovation Focus:

They use modern digital printing technology for designs. Their manufacturing process is better for the environment and saves energy.

Accolades: They have won multiple awards for product design, exports, and business excellence.

Portfolio: You can find over 2,200 tile designs to meet market demands.

Somany Ceramics Ltd: Award-Winning Products for Hygiene and Safety

Somany Ceramics is another company I admire. It won Brand of the Year and is a repeat Superbrand winner. I believe they are a leader in marketing and new product creation.

High-Impact Innovations:

I like their award-winning products like Slip Shield, Germ Shield, and VC Shield Tiles. They focus on advanced surface protection, plus safety and hygiene features. They have received national awards for their marketing and new product releases.

Cera Sanitaryware Ltd: Creating Green and Smart Tech

Cera earned the title of Asia’s Most Promising Brand. It also won the Product of the Year award several times. This company, in my opinion, creates new and green bathroom solutions.

They develop water-saving, touchless, and smart bathroom technologies. The company gets regular praise for its green efforts and modern product designs.

What the Whole Industry Focuses On

- Upgrading manufacturing with automation

- Following international quality standards carefully

- Having a successful history in global exports and green practices

- Launching high-performance ceramic lines based on research

- Winning awards for excellent products, processes, and branding

Locations and Export Reach of Industrial Ceramics in India

I’ve noticed that India’s ceramic manufacturing is centered in a few main areas. These hubs have great production power and a wide export reach. They supply products within India and also help make the country a major global exporter.

Key Production Hubs and Their Export Strength

Gujarat (Morbi, Ahmedabad): In my opinion, Morbi is the center of India’s ceramics industry. It makes over 70% of the nation’s ceramic tiles and sanitaryware. The city has 800+ production units. It also exports to 140 global markets. Companies here use modern technology. They are close to sea ports, which makes exporting their goods easier and cheaper. I’ve seen that Ahmedabad handles both management and manufacturing for top ceramic companies.

Khurja and Sikandrabad, Uttar Pradesh: Khurja produces high-quality ceramics. I like that it mixes old craft skills with new methods. It is home to well-known makers like DNF Ceramics. Sikandrabad and Greater Noida are other important hubs. They have factories and distribution for brands like Orient Bell. I believe they serve both local and global markets well.

Maharashtra (Mumbai): I find that Mumbai serves as the headquarters for large ceramic companies, with H R Johnson Tiles being a prime example. This company runs ten manufacturing plants and has a large dealer network. It exports to countries in South Asia, such as Bangladesh, Nepal, and Sri Lanka.

Andhra Pradesh (Vijayawada, Srikalahasti): Factories in this area supply products to both India and export markets. I suggest looking at a company like Kajaria Ceramics, which leads a strong distribution network here.

Rajasthan (Jaipur, Malutana): Based on my experience, Jaipur and Malutana have factories that focus on exports. These plants greatly increase the country’s total export numbers.

International Export Reach and Competitive Advantages

- Top Indian ceramic companies export their products to over 85 countries. I’ve found that leading exporters like Kajaria Ceramics and Asian Granito India Ltd. sell in 58+ countries. Morbi alone serves 140 markets.

- Major buyers are in North America, Europe, the Middle East, Africa, and Southeast Asia.

- Some of these companies are among the world’s 50 most profitable ceramic makers. This shows they have excellent export setups and a good market name.

- Gujarat’s closeness to ports cuts export costs. This gives Indian producers an edge on global pricing and delivery speed.

- The business environment in Morbi helps factories scale up production quickly. It has smooth supply chains and lower labor costs, which I see as a major benefit.

Manufacturer and Market Penetration Examples

- Kajaria Ceramics: With 8 plants, its yearly output is over 70.4 million sq. m. It has large export and domestic sales channels.

- Asian Granito India Ltd.: This company exports to 58+ countries. It is known for growing fast and offering a wide variety of products.

- H R Johnson Tiles: It runs 49 branch offices and 28 showrooms. The company exports within its region using a large logistics network.

- DNF Ceramics (Khurja): This company supplies products across the nation. It also handles big international orders with its flexible production.

Overview Table: Major Hubs and Export Scope

| Major Hub | Key Example Manufacturers | Export Reach (Countries) | Notable Features |

|---|---|---|---|

| Morbi, Gujarat | Kajaria, Asian Granito | 85+, 58+, 140 | 800+ units, port proximity, large-scale |

| Khurja, Uttar Pradesh | DNF Ceramics | Wholesale international | Traditional + modern, bulk output |

| Sikandrabad, U.P. | Orient Bell | Broad distribution | Manufacturing, dealer network |

| Mumbai, Maharashtra | H R Johnson Tiles | South Asia neighbors | 10 production sites, showroom network |

| Vijayawada, Andhra Pradesh | Kajaria Ceramics | Major export base | Plant and distribution node |

| Jaipur, Rajasthan | Kajaria, others | Export-focused | Dedicated production for export |

From what I can see, India’s industrial ceramic hubs have strong export systems and regional strengths. These factors help the country maintain its top position in the global ceramic market.

Summary List: Top 10 Industrial Ceramic Manufacturers in India

From my experience, India has some world-class ceramic makers. They supply products both in India and around the world. I’ve put together a quick guide to the top 10 industrial ceramic companies in India. I will cover what they make, where they sell, and what makes them stand out.

1. Kajaria Ceramics Ltd

- Largest producer of ceramic and vitrified tiles in India. They rank 8th in the world.

- Annual capacity: 70.4 million square metres.

- Market share: Controls 10–11% of India’s total tile market. That is about 25% of the ceramic tile part.

- FY 2023–24 revenue: ₹46.7–47.6 billion.

- Production network: 8 modern plants in UP, Rajasthan, Gujarat, and Andhra Pradesh.

- Brands: Kajaria, GresBond, Eternity. They also have separate businesses for sanitaryware and plywood.

- Expansion: Added 12.4 million sq. m of new capacity.

2. Ants Ceramics Pvt. Ltd

- A leader in advanced technical ceramics. They focus on electro-ceramics, wear-resistant, and special ceramics.

- Their product range includes alumina, zirconia, and silicon carbide ceramics. They also make tubes, rods, beads, and insulators.

- I see they supply to the defense, electronics, power, and thermal industries.

- I like that they are known for creating custom solutions based on research.

3. Jyoti Ceramic Industries Pvt. Ltd

- They have over 50 years of experience in making technical ceramics.

- Specialty: I find their focus on zirconia/alumina ceramic beads, wear-resistant linings, and mill media interesting.

- Annual output: An estimated tens of thousands of tonnes.

- Export reach: More than 55 countries.

4. Asian Granito India Ltd (AGL)

- One of the top three ceramic companies in India based on volume.

- Annual production: 35 million sq. metres. This includes tiles, quartz, marble, and sanitaryware.

- Global reach: Exports to over 120 countries.

- Segment focus: I suggest looking at their large slab tiles and premium marble.

5. Orient Bell Ltd

- A leader across India for wall and floor tiles.

- Manufactures: Over 30 million sq. mtrs each year.

- Plants in: Uttar Pradesh, Karnataka, Gujarat.

- Product innovation: Their large-format and vitrified tiles with digital prints are noteworthy.

6. Somany Ceramics Ltd

- A top tile producer. They have a capacity of 75 million sq. mtrs from their own plants and joint ventures.

- Market presence: They have strong exports to Asia, Africa, and Europe.

- Product mix: They offer ceramic, vitrified, and glazed tiles, along with bath fittings.

7. H & R Johnson (India) Ltd

- An established brand under Prism Johnson, started in 1958.

- Production: 60 million sq. mtrs per year.

- Focus: They concentrate on wall/floor tiles, engineered stone, and sanitary products.

8. Varmora Granito Pvt. Ltd

- In my view, this company is known for its fast growth and international presence.

- Annual capacity: Around 35 million sq. mtrs.

- Export footprint: 70+ countries.

- Specialties: I recommend their glazed vitrified, porcelain, and ceramic tiles.

9. Rak Ceramics India Pvt. Ltd

- This is the Indian branch of the major international company RAK Ceramics from the UAE.

- Plant: Samalkot, Andhra Pradesh.

- Annual capacity: Over 10 million sq. mtrs. That’s about 30,000 sq. mtrs per day.

- Focus: Their main products are premium wall/floor tiles and sanitaryware.

10. Cera Sanitaryware Ltd

- A market leader for sanitaryware and faucets.

- Annual sanitaryware output: 38,000 tons. They also produce 2.7 million faucets.

- Tiles division: Their tile business targets the affordable market. They have a large retail network with over 400 showrooms and 4,000 dealers.

Based on my analysis, these top Indian ceramic manufacturers use their large capacity and modern technology. Their wide export network helps lead India’s ceramics market. I believe they also help establish India as a leader in the field worldwide.