I notice you’re looking for the world’s top industrial filter manufacturers. From my experience, you’re not the only one. Demand for high-tech, clean solutions is exploding in many fields. I’ve seen this in food, pharma, mining, and energy. The industry is changing because of stricter rules and new innovations. I believe knowing which brands lead the pack gives you an advantage.

Top 10 Industrial Filter Manufacturing Companies

From my perspective, becoming a leader in industrial filters requires innovation, quality, and proper certification. These companies also need to serve many different and tough industries. I’ve put together a list of what I consider the best filter makers globally. Each one offers great filtration products, meets international standards, and has deep knowledge in specific fields.

Freudenberg Filtration Technologies SE & Co. KG

I’m impressed by Freudenberg’s high-performance filtration systems for air, liquid, and cars. In my opinion, their strength is that they constantly invest in R&D and operate globally. They create special solutions for many different settings, which shows they focus on new ideas and quality.

Parker Hannifin Corporation

Parker Hannifin provides modern filtration technologies for industrial, hydraulic, and process uses. I find they are well-known for creating solutions designed for specific customer needs. They also strictly follow global standards. This makes Parker a good partner for anyone needing dependable and certified products.

MANN+HUMMEL Holding GmbH

MANN+HUMMEL is a major global player. They offer a complete range of filters for cars and industries. Based on my experience, their long history and good relationships with original equipment makers help them lead in new tech and custom designs.

Camfil

Sweden’s Camfil works in over 30 countries. People know them for their HEPA and ULPA filters, molecular filters, and cleanroom modules. I consider their products essential for hospitals, microelectronics, and life sciences. They make over $1 billion in sales each year and ship to more than 60 countries.

Donaldson Company, Inc.

I suggest looking at Donaldson for dust, fume, mist, and gas filtration. They focus on heavy industry, mining, and manufacturing. They built their reputation on making durable products and having lasting relationships with major industrial companies.

CleanLink Filtration Tech. Ltd.

CleanLink is a Chinese company I’ve noticed for its affordable filters. They are great for HVAC systems, paint booths, and cleanrooms. As they expand across the world, I see them becoming a go-to supplier for businesses that need good filters without a high price tag.

SIDCO Filter Corporation

SIDCO, an American company, is excellent at custom air filtration. I like that they offer fast service and many material choices for industrial and commercial HVAC. Their products meet ASHRAE, UL, and ISO 16890 standards. This makes them a good fit for controlled areas and important operations.

APC Filtration Inc.

From Canada, APC Filtration provides high-efficiency HEPA/ULPA, carbon, and commercial filters. These are made for cleanrooms and tough industrial settings. I think their strength is in special engineering and strict quality control. They are a solid choice for drug companies and process industries.

TripleAir Technology

TripleAir Technology is from the Netherlands. They supply advanced filtration for cleanrooms and hospitals. Their ULPA/HEPA filter systems hold certifications for the pharmaceutical and life-science fields. I recommend them for situations that need the highest level of air cleaning.

Koch Filter Corporation

Koch is a US-based leader I often recommend for HEPA, pleated, rigid, and carbon/gas-phase filters. They serve both industrial and healthcare clients. In my view, their reputation comes from their high standards and their skill in handling difficult, high-pressure situations.

What I Find These Top Companies Offer

- Filtration solutions made for specific client needs and quick prototype development.

- Modern filter materials: synthetic fibers, PTFE, carbon blends.

- Certifications: They meet ISO 9001, ASME, FDA, ASTM, ISO 16890, UL, and ASHRAE rules.

- Industry focus: chemicals, food & beverage, pharma, power plants, cleanrooms, and healthcare.

- The global market for industrial air filters should pass $10 billion in 2025. Most of these top companies sell their products all over the world.

In my opinion, these makers blend new technology with a commitment to following the rules. They can create special services, deliver quickly, and provide solutions for specific industries. I believe this is why they will remain leaders in the changing filter market.

Leading Applications: A Look at Industrial Filter Systems

From my experience, industrial filters are key for modern businesses. They help you maintain quality, meet regulations, and improve production. I’ve seen them used in many important industries, each with its own unique needs.

Oil and Gas Industry Filtration

I believe filters are very important in refineries and gas plants. They clean crude oil, gas, and other fluids by removing tiny particles and harmful substances. This protects your expensive machinery, keeps things running smoothly, and helps you meet strict industry rules.

Water and Wastewater Treatment

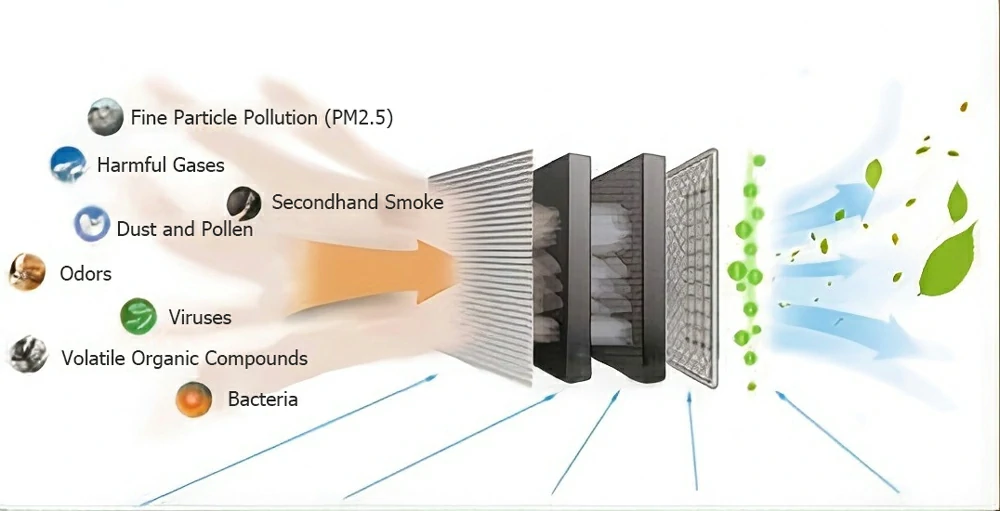

Based on what I’ve seen, water filtration is a huge market for industrial filters. These systems clean drinking water and treat wastewater. They remove floating particles, germs, viruses, and chemical pollutants. I suggest looking at the full range of options. You can find everything from simple filters to high-tech membrane systems for cities and factories that need cleaner water.

Pharmaceutical and Biotechnology Applications

I recommend high-quality depth and membrane filters to ensure drugs are safe and sterile. You need filtration to remove tiny particles and unwanted materials from medicines. This applies to both drug formulas and biotech manufacturing. This industry needs very exact filters because of strict rules and the need for a completely pure product.

Food and Beverage Processing

I’ve seen filtration used for clearing, cleaning, and sterilizing in food production. This includes things like juice, beer, wine, and honey. Filters take out sediment and tiny germs. This helps brands make safe, top-quality products that last longer on the shelf.

Chemical Processing

In my opinion, these filters are great for cleaning raw materials and finished chemicals. They help get rid of unwanted substances, save useful chemicals, and make sure the final product is consistent and safe. I notice that methods like adsorption and advanced depth filtering are often used to meet very high purity levels.

Manufacturing, Automotive, and Heavy Industry

I recommend using filter systems to keep fluids like hydraulics, lubricants, and coolants clean. This helps industrial machines last longer. It prevents expensive shutdowns and lowers maintenance costs. It works by stopping particles and dirt from getting into the mechanical parts.

Casting and Foundry Operations

I recommend using specialized filter systems, primarily ceramic foam filters, to clean molten metal directly in the gating system. You need this filtration to effectively trap slag, non-metallic inclusions, and other impurities before the metal fills the mold cavity. This applies to both ferrous and non-ferrous casting processes. This industry relies on robust, heat-resistant filters because of the extreme temperatures and the critical need for defect-free castings.

Mining and Mineral Processing

In mining, I’ve found filtration is very important for removing water from metal waste. It also helps clean up the liquids used in the process. You can use different levels of industrial filtration. Both help separate minerals well and manage waste better.

Energy Production and Biofuels

Filters are used to clean biodiesel and other biofuels. I think this is important to keep things running smoothly and ensure purity. I believe they are key to the growth of renewable energy. Cleaner fuels help meet worldwide emission rules.

Electronics, Semiconductor, and High-Purity Manufacturing

For making microchips, I suggest advanced filters like membrane and electrostatic types. They help achieve the super-high purity you need. To keep the system working right and have fewer defects, you really depend on these exact filtering methods.

Cosmetics and Fragrances

In cosmetics, we can use filtration to clean skincare products, polish oils, and separate fragrance ingredients. I believe this makes sure the final products are safe and work well.

Specialized Filter Solutions and Components

Here are some examples of new and creative products I’ve seen from top companies:

– Stainless steel filter cartridges, sintered bronze filter elements, wedge wire elements, and heavy-duty filter housings that can adapt to high-heat and high-pressure work.

– I’ve also worked with special filter systems. They are made for things like cleaning blood plasma, processing syrup and salad oil, or filtering marine gas.

Engineering, Customization, and System Integration

From my perspective, top filter makers offer strong engineering and custom designs. They also test everything themselves to meet your specific industry needs. Smart controls and smaller systems help things run without stopping. I find this is true even in tough, round-the-clock production settings.

Quick Summary Table

Let me give you a quick look at the industrial filter manufacturing market. I’ve gathered the latest data, key players, technologies, and industry drivers. I created this summary for professionals who need quick and useful information about market size, different segments, and company rankings.

Market Segmentation (2024)

By Type

- Liquid Filtration: 57.6% market share (largest segment)

- Air Filtration: Remaining share

By Application

- Chemicals & Petrochemicals: 24.7% of market (leading segment)

- Based on my experience, other key sectors include: Pharmaceuticals, Food & Beverages, and Power Generation

Top 10 Industrial Filter Manufacturers

- 3M Company

- Alfa Laval Inc.

- Donaldson Company, Inc.

- Filtration Group

- Freudenberg Filtration Technologies SE & Co. KG

- Mann + Hummel

- Pall Corporation

- Parker Hannifin Corp.

- Ahlstrom-Munksjö

- Hollingsworth & Vose Company

I suggest watching these other players:

Valmet Corporation, Sefar AG, Lydall AG, Clear Edge Filtration Inc., Fibertex Nonwovens, Nordic Air Filtration, Sandler AG

Major Filter Types Used in Industry

- Baghouse filters

- Dust collectors

- Cartridge collectors

- Mist collectors

- HEPA filters

Technological and Market Drivers

From my experience, more industrial growth across the globe is a major factor. Tougher government rules for clean air and water are pushing demand. I see a growing need for smart filters that use IoT and AI. Systems that track performance live and predict maintenance are becoming very important. I’ve also noticed growth in reusable filters that are better for the environment.

Key Industry Trends

I see more companies using smart filtration. This includes IoT, AI, and live data analysis. There is a new focus on using materials good for the environment and providing sustainable options. More filters are being used to meet emission and wastewater rules. For instance, I’ve seen power plants use baghouse filters. Water treatment facilities often use activated carbon.

I believe this summary gives you a solid overview of the industrial filter industry. It covers important benchmarks, top companies, and the major trends that I see shaping the market today.