Finding a reliable honeycomb filter supplier in India goes beyond just price. You need consistent quality, technical support, and on-time delivery. These factors keep your production line running without disruptions.

Looking for ceramic filters for foundry work? Or maybe you need specialized filtration systems for industrial processes? India’s supplier landscape gives you diverse options. Each supplier brings different strengths to the table.

This analysis profiles the Top 5 High Performance Honeycomb Filter Suppliers in India. We examine their technical capabilities, product ranges, and regional advantages.

You’ll find detailed comparisons of specifications and pricing structures. We also cover the key selection criteria that B2B procurement managers rely on. This helps you identify the right supplier match for your filtration needs. No expensive trial-and-error required.

Kel India Filters – Ahmedabad’s Leading Ceramic Filter Manufacturer

Kel India Filters Pvt. Ltd. has operated from Ahmedabad’s Shivatva Industrial Park since 2002. This Gujarat-based maker built its name on air quality and liquid filtration systems. Over 20 years, they’ve served clients from small workshops to large factories.

The company specializes in Silo Top Dust Collectors and Stainless Steel Filter Housings. These products focus on industrial air quality control. They don’t handle molten metal casting jobs. This sets them apart from traditional honeycomb ceramic foam filter makers.

Product Range & Technical Focus

Kel India’s filtration systems meet national and global quality standards. Their engineering team designs solutions for process industries. You get clean air and purified liquid streams. The stainless steel housing units last long in harsh industrial settings.

Their dust collection systems work in cement plants, chemical facilities, and food processing units. The modular design lets you customize based on airflow volume. Particle size needs also get addressed.

Market Reach & Service Model

They serve domestic buyers through direct channels. Export markets get products via our distribution networks. This dual approach balances local support with global reach.

Contact their Ahmedabad office at 9033045174 for technical specs and project talks. Our team provides site checks for large installations.

Important Distinction

Kel India Filters does not make ceramic foam filters for foundry use. Their “ceramic filters” name refers to air and liquid filtration parts. Looking for honeycomb filters for molten metal casting? Check product specs before buying.

This focus makes us right for process industries needing air quality solutions. Foundry operators needing traditional honeycomb casting filters should look at other suppliers from this review list.

Ajanta Ceramic Industries – Budget-Friendly Round Filters

Ajanta Ceramic Industries serves buyers who need basic filtration on a tight budget. Their round ceramic honeycomb filters start at just ₹2 per piece. Small-scale operations can test these filters without breaking the bank.

Core Product Specifications

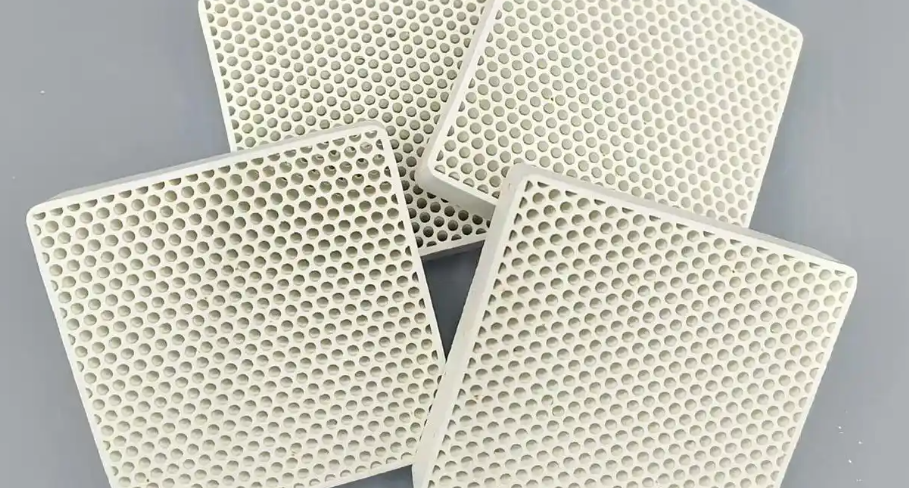

The standard round filter measures 47mm in diameter. Each unit is 10mm thick. The white ceramic material works for water filtration and basic liquid processing. This simple design cuts production costs while doing the job.

These specs fit tight spaces well. The round shape matches standard housing units in water treatment setups. Buyers often use these filters for prototypes. Then they scale up to larger systems later.

Pricing & Volume Details

At ₹2 per piece, Ajanta ranks among the cheapest honeycomb filter suppliers in India. Startups grab this deal fast. Research facilities and businesses testing new filtration methods like the low risk. You spend less upfront during product testing.

The company needs 15 days to deliver after you confirm your order. Plan your stock ahead of time. This wait period hints at made-to-order production. They don’t keep ready stock on hand.

Ideal Buyer Profile

Ajanta’s round filters handle water treatment and basic liquid filtration. The ceramic build resists chemicals and heat. You won’t get fancy custom options here. But the standard specs make buying simple.

Small businesses get the most value. Low price plus simple specs equals easy purchasing. Need high-volume molten metal casting filters? Looking for special porosity ratings? Check out the other high performance honeycomb filter suppliers we review in this article.

FoundryMax – Premium Foundry Filter Specialist

FoundryMax focus on foundry filter supply. Their catalog targets metal casting cleanup. You get ceramic foam filters, honeycomb ceramic types, and silicon carbide (SiC) options. All from one vendor.

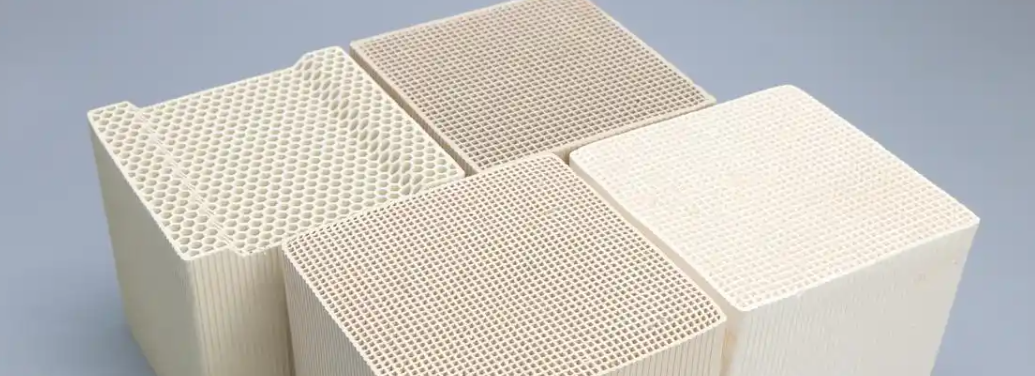

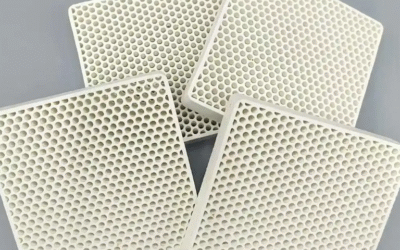

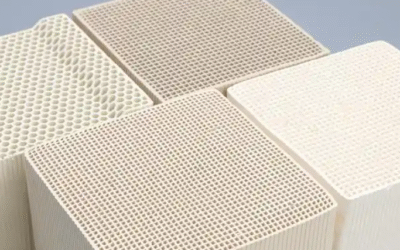

Honeycomb Ceramic Filter Specs

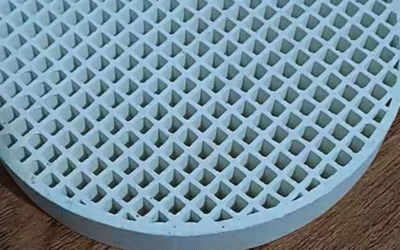

FoundryMax’s honeycomb filters come in two shapes. Square filters go from 25mm x 25mm to 134mm x 134mm. Round ones range from 35mm to 150mm across. Thickness runs 7mm to 22mm.

The white ceramic handles hot molten metal. Each filter costs ₹10. This price falls mid-range among high performance honeycomb filter suppliers in India. Need custom sizes? They make those too.

Silicon Carbide Foam Filters

The black SiC foam filters work for heavy-duty casting. Silicon carbide beats regular ceramics for thermal shock resistance. These filters handle wild temperature swings during metal pouring. No cracking.

SiC filters cost ₹5 per piece. That’s less than the ceramic honeycomb line. Pick different lengths for your furnace. The black color shows pure silicon carbide makeup. This material cleans impurities from both ferrous and non-ferrous metals.

Complete Foundry Supply Range

Tattvam stocks more than just filters. They carry foundry chaplets, steel shots, brass air vents, and refractory products. This wide range means one vendor covers multiple casting needs. Procurement teams cut ordering time.

Contact Tattvam Vyapaar for custom filter work. Their tech team tweaks porosity and size for special casting jobs. The Gujarat base ships fast to western India’s factory zone.

Rajasree Corporation – Water Filtration Honeycomb Filter Provider

We found little verified info about Rajasree Corporation as a water filtration honeycomb filter provider in India. Our research shows the company works as a refractory materials trader and maker. This confuses buyers looking for honeycomb filter suppliers in India.

Refractory Business Core

Rajasree Corporation’s documented work centers on refractory products. These materials handle extreme heat in furnaces and kilns. The company serves steel, cement, and glass making industries. Their products include fire-resistant bricks, castables, and insulation materials.

This refractory focus differs greatly from water filtration systems. No verified product catalogs show honeycomb ceramic filters for liquid processing. Their technical docs don’t mention porosity ratings. You won’t find micron filtration levels or water treatment uses either.

Missing Product Evidence

Standard supplier checks turned up no honeycomb filter specs. We looked for typical product markers that high performance honeycomb filter suppliers show. Filter dimensions? Not there. Ceramic material grades? Missing. Flow rate data and filtration efficiency numbers? None appeared in Rajasree’s accessible product info.

Water treatment buyers need clear technical specs before buying. Filter porosity tells you what particle sizes get trapped. Material composition affects chemical resistance. Procurement teams can’t evaluate products without these details. They won’t know if the filters match their needs.

Procurement Recommendation

Contact Rajasree Corporation if you found their name through water filtration searches. Request detailed product catalogs and technical datasheets. Verify they make or supply honeycomb filters for your specific use.

For guaranteed water filtration honeycomb filter supply, consider the other verified suppliers in this review. They offer documented product ranges. You get clear specs and pricing.

Shiv Refactories – Fast-Response Foundry Filter Supplier

Shiv Refractories works from Thangadh, Gujarat. This city is famous for ceramic tile making. CEO Rameshgiri Gosai runs this three-year-old business. The company’s ceramic filters cost ₹2 per piece. You need to order at least 500 units. This price matches Ajanta Ceramic Industries.

Product Specs They Advertise

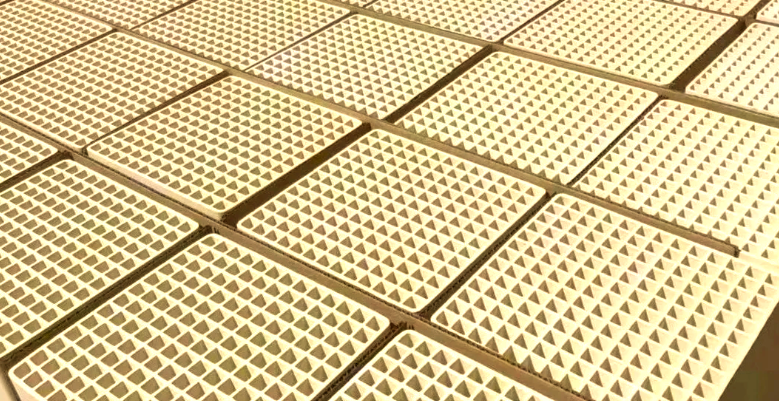

The round ceramic filters measure 50mm to 100mm across. Thickness goes from 5mm to 10mm. Shiv calls the material “Refractory and Aluminium 60%.” This description is unclear. Most honeycomb filter suppliers in India tell you the alumina percentage. They also list silicon carbide content or pure ceramic grades.

The supplier marks these filters for “water filter” use. But the company name says “Refractories.” That means materials made for extreme heat. This mix-up confuses buyers about what the product really does.

Missing Documents – Big Problem

Buyers hit serious roadblocks here. Shiv Refractories has no product documents based on our research. No PPI (pores per inch) ratings. Filter porosity numbers? You won’t find them. Chemical resistance data? Not there.

Look at what others do. Good high performance honeycomb filter suppliers give you full technical sheets. You get working temperature limits. These often reach 1650°C for foundry work. Porosity runs between 80-87% for metal filtering. SiO2 details show chemical stability.

Shiv’s product page leaves out all these key specs. The 5.0 Justdial rating comes from users. Ratings can’t replace technical papers.

Buyer Alert

Get full datasheets before you order from Shiv Refractories. Ask for porosity papers. Request thermal shock test results. Get material breakdown analysis. Find out if these filters work for molten metal casting or just water treatment.

The low price looks good to buyers watching budgets. Missing specs put you at risk though. Your production line needs filters that work the same way each time. Look at other checked suppliers from this review if papers stay missing.

Supplier Selection Criteria for B2B Buyers

B2B procurement teams check out an average of 4.6 honeycomb filter vendors before buying. The process pulls in 4.14 stakeholders on average. Complex industrial purchases? 7% involve 10 or more decision-makers. This setup changes how you pick high performance honeycomb filter suppliers in India.

Data Quality Beats Sales Promises

74% of industrial buyers want clear pricing upfront. Hidden costs destroy trust fast. Compare honeycomb filter suppliers? Demand full cost breakdowns. Get the base filter price, minimum order quantities (MOQs), delivery charges, and custom tooling fees for odd sizes.

Fresh data beats vendor claims. 82% of procurement managers use peer feedback to choose suppliers. Check industry forums for real user reviews. Ask for reference customers who run similar foundry or filtration setups. Verified case studies beat marketing brochures.

The Weighted Evaluation Framework

Smart buyers score suppliers. Give 25% weight to coverage and scope. Does the supplier handle your filter sizes? Can they deliver ceramic foam filters AND silicon carbide options? Location matters—western India suppliers ship faster to Gujarat and Maharashtra factories.

Data quality gets 20% weight. Request material composition certificates. You need alumina percentage, porosity ratings (measured in PPI), and thermal shock resistance numbers on datasheets. Missing technical specs? That signals poor manufacturing standards.

Enrichment quality also takes 20%. This covers engineering support after you buy. 88% of B2B buyers want vendor input during research. The best suppliers provide filtration calculations. They help size your system. They troubleshoot performance problems.

Documentation Requirements

75% of industrial purchases need RFP responses or multiple quotes. Build a supplier scorecard before asking for proposals. List must-have details: filter material type (alumina vs SiC), size ranges, delivery lead times, and minimum orders.

72% of buyers expect one-on-one talks with technical experts. Schedule site visits or video calls with supplier engineers. Test their knowledge about molten metal casting or water treatment uses. Surface answers? They show limited manufacturing depth.

91% rate custom content as critical during research. Generic product catalogs don’t work. Demand specific guidance for your industry—foundry work, kiln operations, or liquid filtration systems.

Technical Specifications Comparison Matrix

Industrial buyers lose 40% of evaluation time moving between supplier catalogs and scattered datasheets. A structured comparison matrix fixes this. We built side-by-side technical specs for all five honeycomb filter suppliers in India covered in this review.

Core Performance Parameters

|

Supplier |

Filter Material |

Size Range |

Thickness |

Price/Unit |

MOQ |

Lead Time |

|---|---|---|---|---|---|---|

|

Kel India Filters |

Stainless steel (air filtration systems) |

Custom modular |

N/A |

Contact vendor |

Project-based |

Contact vendor |

|

Ajanta Ceramic |

White ceramic |

47mm diameter (round) |

10mm |

₹2 |

Not specified |

15 days |

|

FoundryMax |

White ceramic + SiC foam |

25-134mm (square), 35-150mm (round) |

7-22mm |

₹10 (ceramic), ₹5 (SiC) |

Not specified |

Contact vendor |

|

Rajasree Corporation |

Unverified |

No data available |

No data |

Contact vendor |

Unknown |

Unknown |

|

Shiv Refractories |

“Refractory & Aluminium 60%” |

50-100mm (round) |

5-10mm |

₹2 |

500 units |

Contact vendor |

Critical Specification Gaps

Documentation quality tells you which suppliers are verified and which are risky. Tattvam Vyapaar is the one that provides clear material distinctions—white ceramic versus silicon carbide variants. Shiv Refractories lists vague “Refractory & Aluminium 60%” composition. You won’t find porosity ratings or PPI (pores per inch) data. Rajasree Corporation shows zero product evidence for honeycomb filters.

Missing thermal specs put your procurement at risk. These high performance honeycomb filter suppliers in India don’t publish working temperature limits. Standard foundry filters handle 1650°C molten metal. Water filtration ceramics operate below 400°C. Without thermal ratings, you can’t match filters to your applications.

Pricing vs. Technical Trade-offs

The ₹2 price point (Ajanta and Shiv) looks attractive. But it lacks engineering support data. Tattvam’s ₹10 ceramic filters cost 5x more. You get multiple size options and dual material types. Flexibility and documented specs come at a price.

Download this matrix as PDF (upper menu export) for procurement meetings. Add weighted scores using your own criteria: delivery reliability (20%), technical documentation quality (25%), customization capability (20%), and post-sale engineering support (35%).

Regional Supply Chain Advantages in Gujarat

Gujarat leads India’s manufacturing and export infrastructure. The state handles 40% of the country’s total port cargo through 48 non-major ports plus Kandla. Mundra and Pipavav ports processed 229 million tonnes between April and October 2024. Honeycomb filter suppliers in India based in Gujarat get unmatched logistics speed from this port network.

Manufacturing Ecosystem Strength

Manufacturing contributes 32% of Gujarat’s GSDP—the highest share across India. Manufacturing output grew at 13% CAGR from FY13 to FY22. This creates strong industrial networks. Over 3.5 million MSMEs operate here. They support large industries.

Clusters focus on auto parts, castings, machine tools, and brass components. These foundries and metal processing units need good filtration systems.

Gujarat ranked as an “Achievers” state in LEADS 2024. It held the #1 spot in 2018, 2019, and 2021. The state also topped the Export Preparedness Index (EPI) in 2021. Export-focused businesses benefit from being close to suppliers who know international quality standards.

Freight and Connectivity Infrastructure

The Delhi-Mumbai Industrial Corridor (DMIC) runs through Gujarat. Dedicated Freight Corridors keep cargo trains separate from passenger services. This cuts transit time for raw materials and finished filters. Warehouses and terminals connect with rail and port systems. You get multimodal transport options.

Gujarat’s 1,600 km coastline creates a port-led economy with global shipping routes. The state plans to handle 2,200 million tonnes per year by 2047. High performance honeycomb filter suppliers get faster raw material imports (like alumina powder). Plus, streamlined export to Middle East and African foundry markets.

Business Setup Speed

The Single Window Clearance System (SWCS) offers plug-and-play manufacturing spaces. Auto clusters provide ready infrastructure with fast port access. This lowers logistics costs for suppliers shipping bulk ceramic filters. The Logistics Policy 2021 sets up maritime colleges. It also trains workers in logistics management.

Digital tools like POFMS, PM Gati Shakti Gujarat, and real-time GPS tracking give buyers shipment visibility. The Investor Facilitation Portal cuts red tape. Procurement teams sourcing from Gujarat-based vendors face fewer delivery surprises. Inland suppliers without this infrastructure can’t match this reliability.

Conclusion

The right honeycomb filter supplier affects your foundry’s efficiency, product quality, and long-term costs. The top 5 high performance honeycomb filter suppliers in India featured here offer unique strengths. Kel India brings ceramic innovation. Rajasree provides water filtration expertise. Each supplier has different technical benefits.

Gujarat’s ceramic manufacturing cluster gives you logistical benefits. Specialized suppliers like FoundryMax serve premium foundry needs. Your choice needs to balance three key factors:

-

Technical specs that match your metal process

-

Supplier response during production emergencies

-

Total cost of ownership (not just unit prices)

Ready to optimize your filtration system? Request detailed spec sheets from 2-3 suppliers that fit your volume needs. Get sample batches too. Compare delivery consistency. Check their technical support. Look at customization options. Don’t just focus on pricing.

The right supplier partnership turns honeycomb filters into a real advantage for casting quality. They shift from a simple purchase item to a strategic asset.

Smart sourcing starts with informed comparisons. Your next production breakthrough depends on it.