What Porous Ceramic Filters Are

Porous ceramic particles for filtration are solid materials. They have networks of open pores that connect throughout. These pores let fluids pass through—water or air, for example. At the same time, they trap particles bigger than the pore opening. I find the basic principle simple: size exclusion. The porous structure acts as a barrier. Small molecules and particles pass through. Larger dirt and contaminants get blocked.

How the Filtration Process Works

Winding Pathway: Fluids move through twisting internal channels. Contaminants larger than the pore size get trapped. Smaller substances continue moving through.

Separation Methods:

- Surface Filtration: Bigger particles stay on the filter’s surface.

- Depth Filtration: Smaller particles get caught inside the filter material as they go deeper.

Physical Process: The process needs no chemicals. Filtration uses mechanical trapping. It uses direct interception and particle diffusion through the pore network.

Pressure Operation: Many advanced uses (like ceramic membrane filtration) force fluid through the ceramic filter under pressure. This gives precise control over which particles get removed based on pore size (from 0.1 microns to several microns).

Real Examples and Test Results

Drinking Water Filters: Ceramic “candles” (~0.5 microns) remove bacteria like E. coli and cholera. They also remove fine dirt.

Factory Systems: Cross-flow ceramic membranes separate thick liquids and emulsions clearly.

Adding controlled porosity can boost mechanical strength and elastic performance. Flow rate links to the pressure applied. It also relates to pore size—smaller pores mean slower flow.

Based on my experience, porous ceramic filtration works by combining connected pores, physical separation, and flexible design. I recommend this method because it removes dirt through size exclusion and mechanical trapping.

Materials and Manufacturing of Porous Ceramic Filters

I find porous ceramic filters use smart materials and methods. They achieve high filtration and last long.

Key Materials Used

High Porosity Ceramics: Filters can reach up to 60% porosity. This allows for better filtration and flow rates.

Chemical Resistance: The ceramic matrix resists strong acids, bases, and organic solvents. I recommend them for harsh industrial or lab settings.

Mechanical Durability: These ceramics handle high pressures well. They survive thermal shock. They keep stable performance even in extreme temperatures.

Main Manufacturing Processes

Self-Setting Hydrogel Reaction

A self-setting reaction occurs between metal particles and alkali compounds. Hydrogen gas forms. This creates connected pores throughout the material. Workers remove alkali metals after formation. This enhances the refractory properties. It also improves the ceramic’s thermal stability.

Additive Manufacturing (AM)

AM processes build porous ceramics. First, they create a polymer template in the desired shape. Ceramic material fills or replaces these templates. This results in precise, macro-porous structures. I suggest this for specialized applications.

Replication Technique

This uses polymer foam templates. Workers immerse them in ceramic slurry. After coating, they burn out templates. This leaves behind open-celled ceramic foams. Porosity levels reach up to 95%. This works well for filters needing very high surface area. It offers excellent thermal resistance.

Additional Pore Formation Techniques

Fugitive Constituent Method: Workers introduce temporary additives during shaping. These additives can burn or sublimate. During firing, they burn out or sublimate. This leaves pores of designed size and distribution.

Surface Coating with Ceramic Paste: A thin, controlled porous membrane coats the filter’s surface. This allows for fine filtration adjustments.

Firing and Post-Treatment: Workers fire ceramics at high temperatures. This solidifies the structure. It removes remaining unwanted materials. This finalizes the filter’s mechanical and chemical properties.

Industrial Applications Tied to Manufacturing

Metal Melt Filtration: Open-celled ceramic foam filter removes impurities well. They work during molten metal casting processes.

High-Temperature Gas Filtration: I suggest using these in industrial settings for filtering hot gases. Examples include engine exhaust or process gas purification. The material stays stable under thermal stress.

Key Properties and Advantages of Porous Ceramic Particles for Filtration

Porous ceramic particles excel at high-efficiency filtration. Their unique physical and chemical features make them stand out in industrial and environmental uses.

Essential Physical and Mechanical Properties

Controllable Porosity: You can adjust porosity from low to high. This lets you handle different filtration needs. Need microfiltration? Or coarse particle removal? Both work well.

High Surface Area: More contact with fluids means better filtration. It also helps trap contaminants more effectively.

Selective Permeability: Pore size and shape control what passes through. This creates a reliable barrier against different contaminants.

Thermal Insulation: Air-filled pores block heat transfer. This makes ceramics work well for high-temperature filtration and heat control.

Core Advantages in Filtration Applications

- High Temperature Resistance: Works in temperatures from 800–1500°C.

- Chemical Stability: Handles acids, bases, and organic solvents. Perfect for industrial and lab work.

- Consistent Mechanical Strength: Stays strong under pressure. This ensures reliable operation.

- Customizable Filtration Precision: Pore sizes range from 0.3 μm to 100 μm. You can adapt them for specialized tasks.

- Long Service Life: The materials last long. They’re non-toxic, easy to clean, and won’t release harmful substances.

Verified Filtration Performance

| Material | Bacteria Removal | Turbidity Reduction | Particulate Matter | Virus Removal |

|---|---|---|---|---|

| Alumina (fine pore) | 99.99% (4 log) | 95–99% | 99.9% down to 0.5 μm | Low |

| Silicon Carbide | 99.9% (3 log) | 90–95% | 99% down to 1.0 μm | Very Low |

| Silver-impregnated Ceramic | 99.9999% (6 log) | 95–99% | 99.9% down to 0.5 μm | Moderate |

| Ceramic + Carbon Core | 99.99% (4 log) | 95–99% | 99.9% down to 0.5 μm | Low–Moderate |

Filtration Flow Rate and Pressure Drop

| Filter Type | Typical Flow Rate | Initial Pressure Drop | Pressure Drop after 100h |

|---|---|---|---|

| Ceramic Disc (1 μm) | 1–5 L/hr/cm² | 0.1–0.2 bar | 0.3–0.5 bar |

| Ceramic Tube (5 μm) | 10–50 L/hr/cm² | 0.05–0.1 bar | 0.2–0.3 bar |

| Ceramic Foam (10 μm) | 50–200 L/hr/cm² | 0.01–0.05 bar | 0.1–0.2 bar |

| Honeycomb (1 μm) | 20–100 L/hr/cm² | 0.05–0.1 bar | 0.15–0.25 bar |

More Functional Benefits

Lightweight Construction: The low-density design works great for transportation, aerospace, and automotive sectors. I recommend it for weight-sensitive applications.

Sound Absorption: The porous structure dampens noise. You get acoustic control along with filtration.

Versatility and Biocompatibility: These materials fit many uses. Filtration, separation, medical, and biotech applications all benefit.

Based on my experience, porous ceramic particles offer a durable, customizable, and efficient filtration solution. They combine strong material properties with proven real-world performance. I suggest them for protecting water, air, and industrial fluids.

Filtration Mechanisms

Porous ceramic particles use several filtration methods to remove contaminants. These include surface filtration, depth filtration, mechanical entrapment, and adsorption. Each method plays a role in overall performance.

Surface Filtration

Particles larger than the ceramic pore size get trapped at the filter’s surface. As more particles collect, they form a filter cake layer. This layer acts as an extra barrier. It boosts filtration efficiency. But it also slows down flow over time. I recommend surface filtration for removing coarse impurities in high-flow industrial settings.

Depth Filtration

Particles travel through a network of internal pores. This maze-like path captures smaller particles. It works through direct interception, inertial effects, and diffusion. Depth filtration works well at trapping fine particles and nanoparticles. It has a large internal surface area. This creates many chances to trap contaminants. For example, SiC ceramic filters at around 62% porosity achieve capture rates up to 99.9% for nanoparticles.

Mechanical Entrapment

Interconnected pores capture and hold particles as fluid moves through the ceramic matrix. Pore size can range from micrometers to millimeters. This suits different filtration needs. Filters with porosity levels up to 68.4% maximize throughput. They keep high removal rates. For SiC ceramics bonded with mullite or cordierite, filtration efficiencies reach 96.9–99.9% depending on porosity.

Adsorption

Ceramic materials carry slight electrostatic charges. This allows them to adsorb charged or polar contaminants onto the filter surface. These include certain ions and dissolved organic species. Based on my experience, this adsorption mechanism works well with physical capture. It helps catch molecular species that might slip through by size alone.

Performance Data and Application Cases

- Typical Porosity: 50–68% for engineered ceramics

- Particle Capture Efficiency: Up to 99.9% (SiC filters at lower porosity work best)

- Water Flow Rate: Decreases with higher compaction pressure during fabrication

- Pore Size Example: Prototype filters ~0.5 mm, suitable for ≥0.5 μm particles

Application Examples:

– Metal Casting: Removes impurities from molten metal. This improves final casting quality and mechanical performance.

– Bioprocessing: Filters out particles ≥0.5 μm. It delivers chemical resistance and long-term durability for biomedical uses.

– Wastewater Treatment: Removes suspended contaminants. The result is cleaner water.

Filtration Design and Optimization

Pore Size and Distribution: Customization targets specific contaminants. Smaller pores boost fine particle removal. Larger pores maintain high flow and low pressure drop.

Porosity Adjustment: I suggest using sacrificial pore formers to increase permeability. This optimizes filters for both high throughput and contaminant capture.

Overall System Balance: Multi-scale pore structures create good trade-offs. They deliver high flow rates, low pressure drops, and effective contaminant filtration. This meets various industrial needs.

Applications of Porous Ceramic Particles by Industry

Porous ceramic filters offer efficient solutions across many sectors. They handle heat well. They resist chemicals. You can customize their pore structure. I recommend them for environmental protection and industrial use.

Water Treatment and Purification

- Ceramic pot filters make drinking water safe in developing regions.

- Household ceramic candle filters give families clean water.

- Municipal water facilities use large ceramic membrane systems. These systems serve the public.

Hot Gas Filtration in Industry

- End-use sectors: Power plants, industrial furnaces, waste incinerators.

- Temperature resistance: sustained operation at up to 1600°C.

- Particulate removal rate: Exceeds 99.9% for fine particulates (e.g. PM2.5).

- Pressure drop: 10–50 mbar under typical load.

- Chemical stability: Keeps filtering under corrosive acid gas. Works in harsh flue gas streams too.

Example: Flue gas cleaning systems in coal-fired power plants. They operate at exhaust temperatures from 350°C to 1000°C.

Molten Metal Filtration

- Use cases: Aluminum casting, steelmaking, precious metal refining.

- Filtration performance: Removes over 90% of non-metallic bits larger than 20 μm.

- Extreme temperature tolerance: Up to 1700°C. This includes direct contact with molten metal.

- Benefit: Improves finished product quality. Strengthens mechanical properties.

Food and Beverage Industry

- Sterile filtration and clarification of food liquids—wine, beer, edible oils, and dairy.

- Microbial safety: Removal rating up to 99.9999%.

- Industrial flow: 100–1000 L/hour to maintain production speed.

- Ease of maintenance: Works with CIP (Clean-In-Place) routines.

Application examples:

- Winery and brewery filtrations create crystal-clear drinks.

- Dairy filtering keeps safety and taste consistent.

Chemical Manufacturing

- Pre-coat and deep cleaning base in chemical production.

- Customizable filtration levels: You can layer it with adsorption materials. This boosts contaminant removal.

- Key example: Chemical plants use it as a carrier. It holds specialty filtration layers in advanced processing.

Environmental Protection and Waste Treatment

- Industrial exhaust and wastewater management: Takes out dangerous particles from waste streams. Removes harmful substances too.

- Domestic sewage treatment and gas plants: Handles tough chemical conditions. Survives high heat for long periods.

- Advantage: Meets strict environmental rules.

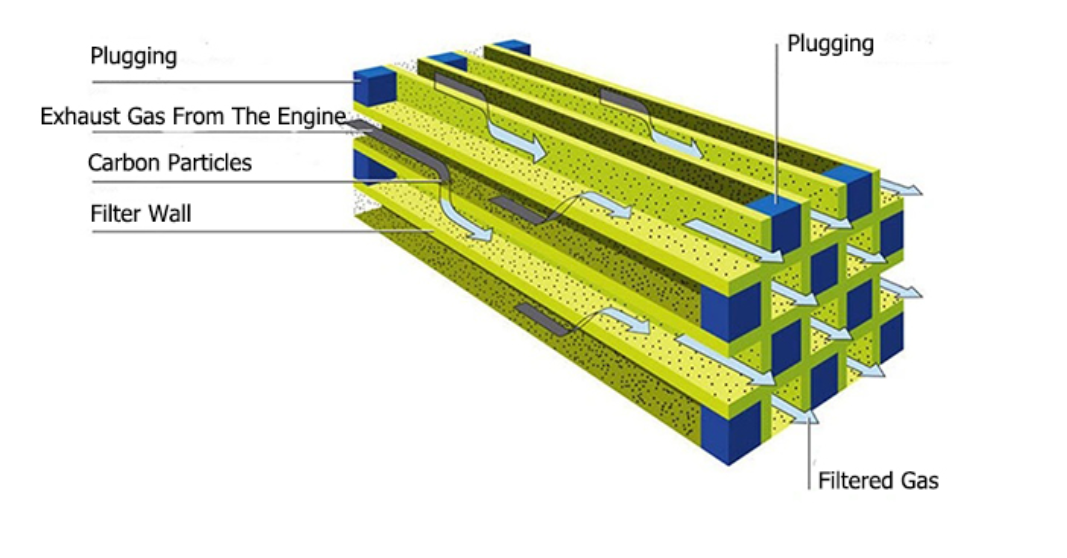

Automotive and Energy Sectors

- Diesel particulate filters: Porous ceramics cut down soot. They catch tiny exhaust particles.

- Energy and biomass gasification: Resists chemicals well. Handles high temperatures for emission control.

- Benefit: Makes systems last longer. Cuts environmental harm.

Porous ceramic particles work well in every industry I’ve seen. They combine efficiency, reliability, and long life. Few alternatives can match this. Their flexibility makes them popular worldwide. I recommend considering them for your filtration needs.

Conclusion: Why Porous Ceramic Particles Are the Future of Filtration

I believe porous ceramic filters stand out for three reasons. They offer high porosity. They give you precise control over pore size. And they resist chemical, thermal, and mechanical stress. These qualities make them essential in advanced filtration systems. Industries like water treatment, metallurgy, and chemical manufacturing rely on them.

Key Performance Highlights

High Porosity and Efficiency:

Ceramic filters can reach porosity levels of 60–70%. This increases the filtration area and raises flow rates. A 60% porosity filter delivered a 95% efficiency rate for 1-micron particle removal. An increase in porosity from 30% to 50% can raise flow rates by 30%. This streamlines processes without losing filtration precision.

Precise and Versatile Filtration:

Pore sizes range from 1 to 300 microns. This allows custom solutions for ultra-fine purification and industrial separation. Filtration accuracy reaches down to 0.1 microns. It removes bacteria, fine particles, and contaminants from water, air, and process fluids.

Exceptional Resistance and Strength:

These filters work well in harsh conditions. They stay stable against strong acids, bases, and organic solvents. They maintain operation at temperatures up to 800 °C. They withstand working pressures up to 6 MPa. Differential pressure resistance up to 1 MPa ensures use in demanding systems.

Application Examples

Industry Versatility:

Silicon carbide and alumina ceramics work best in demanding environments. I’ve seen them excel in oil/water separation, molten metal casting, chemical processing, and sterile air/gas filtration.

For water purification, ceramic membranes remove particles down to 0.1 microns. They maintain membrane permeability at the same time.

Longevity and Maintenance:

The sturdy structure resists chemicals. It supports long service life and repeated regeneration. You can integrate cleaning routines and maintenance processes easily. This reduces operational downtime and long-term costs.

Core Benefits at a Glance

- Large surface area for efficient contaminant capture.

- Uniform, customizable pore sizes for all filtration needs.

- Handles high heat, aggressive chemicals, and sustained pressure.

- Delivers reliable, long-term performance you can count on.

Future Outlook

Research now targets even higher filtration efficiency and flow rates. Advanced material engineering drives this progress. With precise control during manufacturing, these filters continue to set new standards for critical filtration applications.

In my experience, porous ceramic particles deliver unmatched reliability and customization for filtration. I recommend them for their strong material properties and flexible design. They ensure ongoing relevance and leadership in modern and future filtration solutions.