You can group ceramic materials in many ways beyond the main five types. I suggest looking at composition, processing method, structure, and application.

Overview of the 5 Main Types of Ceramic Materials

Ceramic materials fall into five major groups. We classify them by composition, how they’re made, and what they’re used for: traditional ceramics, refractory ceramics, advanced ceramics, bioceramics, and electronic ceramics. Each type plays a unique role across industries. This comes from their specific material properties.

Traditional Ceramics: Construction and Household Use

These ceramics are made mostly from natural clay minerals and silicates. Common products include bricks, tiles, earthenware, stoneware, porcelain, and bathroom fixtures. Bricks and tiles are still essential in construction. Global brick production exceeds 1.5 trillion units per year.

Key benefits: affordable, moderate strength, and used in buildings and homes.

Refractory Ceramics: Built for Extreme Heat

Main ingredients: alumina, silica, magnesia, zirconia, silicon carbide.

These ceramics are made to withstand extreme heat. They keep their shape and strength above 1,500°C. I recommend these for industrial furnaces, kilns, and crucibles in steel and glass manufacturing. Magnesia-based refractories can endure temperatures up to 2,800°C.

Advanced (Technical/Engineering) Ceramics: High Performance for Industry

Producers make these from pure engineered powders. This includes oxides (alumina, zirconia) and non-oxides (silicon carbide, silicon nitride). These ceramics stand out for hardness, toughness, resistance to corrosion, and low electrical conductivity. You’ll find them in automotive brake discs, jet engine turbine blades, body armor, electronics, and aerospace. Based on my research, the advanced ceramics market will reach over $120 billion by 2027. alumina ceramics show compressive strength above 2,000 MPa.

Bioceramics: Work with Living Tissue

Designers create these for medical use. They integrate with biological systems. Typical materials include hydroxyapatite, alumina, and zirconia. Doctors use them in dental implants, bone grafts, and artificial joints. Over 2 million hip replacements per year feature ceramic components.

Main features: biocompatibility and bone-bonding capability.

Electronic Ceramics: Power Electronics and Communication

Engineers design these for specific electrical, magnetic, dielectric, or piezoelectric functions. This group includes capacitor ceramics, piezoelectric ceramics, magnetic ceramics, and superconducting ceramics. Manufacturers use them in capacitors, sensors, transducers, and MRI machines. Barium titanate is a key component in multilayer ceramic capacitors. Global demand exceeds 2 trillion units every year.

Summary Table: Key Functions and Typical Applications

| Ceramic Type | Example Materials | Main Properties | Key Applications |

|---|---|---|---|

| Traditional | Clay, porcelain, earthenware | Affordable, moderate strength | Construction, household |

| Oxide | Alumina, zirconia | High durability, insulating, heat stable | Medical, electronics, industrial |

| Non-oxide | SiC, Si₃N₄, WC | Extreme hardness, heat conduction | Tools, bearings, tech components |

| Refractory | Alumina, magnesia | High-temp, corrosion resistance | Furnaces, crucibles, kilns |

| Composite | CMC, bio-ceramic blends | Toughness, lightweight, custom traits | Aerospace, medical, automotive |

These five types show how ceramic materials meet the needs of everyday life and advanced technology. I suggest studying their varied properties and specialized uses. Each type offers unique benefits for different applications.

Core Properties of the 5 Types of Ceramic Materials

I believe understanding ceramic material properties is key to picking the right type for your needs. Below, I break down the performance and traits of five major ceramic groups: oxides, carbides, nitrides, borides, and silicates. I use real metrics and examples from industry.

Silicate Ceramics: Structure, Properties, and Industrial Uses

Silicate ceramics are nonmetallic and inorganic materials. They contain both glass and crystal phases. I find their structure fascinating because it creates great optical properties. They have high transparency and a beautiful natural look. Architects and product designers value these features.

Key Types of Silicate Ceramics and Their Functions

Technical Porcelain

Main ingredients: quartz, feldspar, and kaolin

Siliceous porcelain (Group C 100) works well in low voltage electrical applications. Aluminous porcelain (C 120 and C 130) uses alumina (Al₂O₃) instead of quartz. This makes it more than twice as strong as standard porcelain. I recommend aluminous porcelain for long-term stability. It handles permanent heat loads well. It’s perfect for overhead cable insulators and tough outdoor uses.

Steatite (Magnesium Silicate, C 200 Group)

Made from soapstone, with added clay and flux.

Types: steatite for low-frequency use (C 210), normal steatite (C 220), and low loss factor steatite (C 221) for high-frequency electronic parts.

Features: High mechanical strength and great insulating properties.

Porous steatite (C 230) can be machined with regular tools after sintering.

Cordierite (C 400 Group)

Made by sintering soapstone with clay, kaolin, corundium, and mullite. It has low heat expansion. It also resists thermal shock very well. Porous cordierite resists thermal shock better. Denser forms are stronger when bent.

Typical uses: Heat engineering and electrical engineering. These fields need stability when temperatures change.

Mullite-Ceramic

The ratio of alumina (Al₂O₃) to silica (SiO₂) in the raw mix controls the final crystal form. This includes mullite and corundium. It comes in both dense-sintered and open-porous types.

I like mullite-ceramic for its high strength and low heat expansion. It resists thermal shock and high-temperature leakage very well. Glass phase free mullite is best. Uses include thermocouple protection tubes and rollers for high temperature kilns. It works in high-temperature settings up to 1650°C.

Dental Applications of Silicate Ceramics

Feldspar Porcelain, Leucite-Enhanced Glass Ceramics, and Lithium Disilicate Ceramics are used often in dental work.

Lithium disilicate ceramics have lithium disilicate crystals in a glass matrix. They are tough and have great mechanical properties.

Production process: It starts as clear glass ingots (lithium orthosilicate, Li₄SiO₄). Lithium metasilicate crystals (Li₂SiO₃) give a bending strength of 130 ± 30 MPa. After heating at 850°C, lithium disilicate crystals (Li₂Si₂O₅) form. This raises bending strength to 360 ± 60 MPa.

Based on my experience, silicate ceramics are key in both industrial and medical fields. Their great properties make them versatile. They set the standard for insulation, strength, and heat performance.

Oxide Ceramics: Properties, Types, and Industrial Applications

Oxide ceramics are common ceramic materials. They form by combining metal and non-metal elements with oxygen. They offer great stability, strength, and resistance to heat and chemicals. I recommend them for many industries.

Main Types of Oxide Ceramics and Their Features

Alumina (Al₂O₃)

This is the most common oxide ceramic. It exists in two forms: alpha-alumina and beta-alumina.

Alpha-alumina has high hardness, strength, and thermal conductivity. Beta-alumina has high ionic conductivity. I suggest alpha-alumina for cutting tools, abrasives, and industrial wear-resistant parts. Beta-alumina works well in solid oxide fuel cells and high-temp electrolytes.

Zirconia (ZrO₂)

This material has excellent toughness and crack resistance. It performs much better than alumina in these areas. People use it in high-strength parts, dental crowns, and precision knives. It stays durable under stress and heavy structural loads.

Silica (SiO₂)

Silica has high strength, temperature stability, and corrosion resistance. It plays a key role in optical devices, glassmaking, and semiconductor production. It brings reliability to modern tech products.

Magnesia (MgO)

This magnesia material has mechanical strength and a very high melting point. It supports tough industrial uses like furnace linings. It works well in applications needing thermal and chemical stability.

Titania (TiO₂), Ceria (CeO₂), Yttria (Y₂O₃)

TiO₂ and CeO₂ show catalytic activity. They are vital for environmental protection, fuel cells, and chemical synthesis.

People often use Yttria to stabilize zirconia. This makes zirconia tougher and suitable for special electrical and structural tasks.

Key Properties of Oxide Ceramics

- Wear Resistance: High hardness makes them perfect for grinding, cutting, and abrasion-heavy jobs.

- High Temperature Resistance: High melting points let them stay stable in very hot conditions. I recommend them for refractories and furnaces.

- Corrosion Resistance: They resist acids, alkalis, and salts. This makes them good for chemical plants and harsh industrial settings.

- Base Resistance: People use them in alkaline environments. These include sewage, chemical storage, and wastewater facilities.

- Hydrophobic/Hydrophilic Surfaces: Surface treatments control water interaction. This helps create self-cleaning coatings or specialized filtration.

- Catalytic Activity: They speed up chemicals in pollution control and industrial reactions.

Industrial Uses of Oxide Ceramics

- Electronics: They serve as insulators, substrates, and specialized parts.

- Aerospace and Automotive: They provide structural supports and heat shields.

- Medical Devices: They make implantable components. Their toughness and bio-compatibility make this possible.

- Refractory Materials: People use them in kilns, furnaces, and high-temp equipment.

- Sensors, Filters, and Membranes: Their chemical inertness and customizable surfaces make them ideal for these applications.

Oxide ceramics have strong mechanical strength, good insulating properties, and stability. I find them essential in advanced manufacturing and technology-driven industries. Their flexibility and durability help drive innovation. This spans from electronics to medicine. In my opinion, these materials will continue to shape the future of many fields.

Carbide Ceramics: Properties, Types, and Industrial Applications

Carbide ceramics are special ceramic materials. They work well in extreme environments. Industries with tough demands use them. I find their unique properties make them stand out from other ceramics.

Key Properties of Carbide Ceramics

Outstanding Hardness and Wear Resistance: Carbide ceramics are among the hardest technical materials. They compete with diamond in hardness. I recommend them for cutting tools and abrasives because of this.

Excellent Thermal Stability: They keep their shape and strength at high temperatures. Furnace linings benefit from this. Aerospace applications need this too. Components face extreme heat in these uses.

Superior Chemical and Corrosion Resistance: Carbide ceramics don’t react with most chemicals. This means they last longer. I’ve seen them perform well in chemical processing plants. They also work great in marine environments.

High Mechanical Strength and Stability: They stay strong under mechanical stress. This makes them reliable. I suggest using them for bearings. They also work well in industrial machinery parts.

Electrical and Thermal Conductivity: Some carbide ceramics offer great electrical conductivity. Silicon carbide does this. They also provide good thermal management. Semiconductor applications use them for these features.

Common Types of Carbide Ceramics

Silicon Carbide (SiC)

It has high strength. It also has semiconducting properties. Heat conductivity is another benefit. I’ve seen it used in semiconductor manufacturing. Mechanical seals use it too. Pump components rely on it. SiC costs less than alternatives. This makes it popular for large-scale operations.

Boron Carbide

It has exceptional hardness. It’s almost as hard as diamond. The nuclear industry values it. Neutron shielding needs it. It absorbs neutrons well.

Major Industrial Applications

Cutting Tools and Abrasives: Carbide ceramics are extremely hard. This makes tools last longer. Precision improves too. Tools for machining metals use them. Composite machining relies on them. High-performance sandpaper contains them. Grinding wheels use them as well.

Aerospace Components: They stay stable at high temperatures. Carbides work in components that face intense heat. Flight generates this heat. Re-entry does too.

Industrial Furnace Linings: Furnace linings made from carbide ceramics handle continuous high heat. They protect the structure. Based on my experience, they improve energy efficiency.

Chemical Processing Equipment: Carbide ceramics resist corrosive chemicals. Equipment in processing plants lasts longer because of this.

Semiconductor Industry: Silicon carbide has great heat properties. Its electrical properties are excellent too. I recommend it for semiconductor wafers. Heat sinks need it. Other electronic parts that need reliable thermal management use it.

Carbide ceramics push innovation forward. Sectors that need the toughest materials use them. They need the most reliable materials too. Industry data shows demand keeps growing. Electronics drive this growth. Aerospace does too. Energy fields contribute as well. I believe mastering their benefits brings big performance gains. Cost advantages for advanced manufacturing are substantial.

Nitride Ceramics: Properties, Types, and Industrial Applications

I find nitride ceramics impressive because of their high melting points and strong mechanical properties. They resist wear well. They handle thermal shock. They survive harsh chemical conditions. These ceramics combine thermal and electrical properties in unique ways. This makes them useful in both industrial settings and electronics.

Main Types of Nitride Ceramics and Their Key Properties

Silicon Nitride (Si₃N₄)

- Breaks down above 1900°C in nitrogen. Its density sits around 3.2 g/cm³.

- Hot pressed forms show flexural strength of 600–1000 MPa. Reaction-bonded types range from 200–400 MPa.

- Vickers hardness measures 13–16 GPa.

- Thermal conductivity: 20–30 W/mK.

- Low thermal expansion (~3 x 10⁻⁶/°C) means less distortion when heated and cooled.

- Keeps its shape and precision up to 1400°C.

- I recommend Si₃N₄ for engine parts, pump seals, bearings, and ball valves. It also works well in cutting tools, spinal spacers, and dental implants.

- Reaction-bonded forms (RBSN) don’t shrink. This makes them perfect for precision work.

Aluminum Nitride (AlN)

- High thermal conductivity (>170 W/mK). It rivals metals like SiC and BeO.

- Strong electrical insulation (>10¹⁴ Ω·cm).

- Its flexural strength beats alumina and beryllium oxide.

- Thermal expansion (4.5 x 10⁻⁶/°C) matches silicon. This cuts stress in electronic parts.

- Chemical stability is excellent. It stays non-reactive with molten metals. It can endure 800–1000°C for over 3000 hours without corroding.

- I suggest AlN for electronic substrates, heat sinks, and thin films that protect sensors. It’s also great for LED tech, electronic packaging, crucibles, and thermocouple protection tubes.

- Its sapphire-like structure allows transparency.

Boron Nitride (BN)

- BN resists chemical reactions. It also lubricates well.

- People use it in high-temp crucibles, lubricants, and electrical insulators.

Performance Comparison Table

| Property | Silicon Nitride (Si₃N₄) | Aluminum Nitride (AlN) |

|---|---|---|

| Density (g/cm³) | ~3.2 | ~3.26 |

| Flexural Strength (MPa) | 600–1000 (dense); 200–400 (porous) | >300 |

| Thermal Conductivity (W/mK) | 20–30 | >170 |

| Thermal Expansion (10⁻⁶/°C) | ~3 | 4.5 |

| Electrical Resistivity (Ω·cm) | >10¹⁴ | >10¹⁴ |

| Hardness (Vickers, GPa) | 13–16 | 11–13 |

Key Advantages and Applications

High hardness and wear resistance: I like these for cutting tools and pump parts that face tough conditions.

Thermal shock resistance: These ceramics work in car engine parts and jet turbines. They handle fast temperature shifts well.

Chemical durability: They resist acids, bases, and oxidation at high temps.

Electrical insulation & conductivity: Power electronics and high-frequency modules stay safe with these materials.

Biomedical compatibility: Si₃N₄ is my top choice for spinal spacers and dental implants. It’s strong. It fights bacteria. The body accepts it well.

Synthesis and Manufacturing

Manufacturers use reactive sintering, hot pressing, and nitridation. These methods let them adjust toughness or porosity. They match materials to what you need for performance and cost. Reaction-bonded Si₃N₄ holds its dimensions well. It doesn’t shrink.

Sectors That Use Nitride Ceramics

- Electronics (substrates, sensor modules, heat control)

- Cars and planes (engine parts, turbo components, high-wear joints)

- Semiconductor making

- Medical device making (implants, spacers, dental parts)

- Defense (armor, high-performance friction and wear components)

Based on my experience, silicon nitride and aluminum nitride set the standard for reliability, strength, and thermal stability. Engineers pick these materials for tough jobs in manufacturing, electronics, and medicine. They perform where others fail.

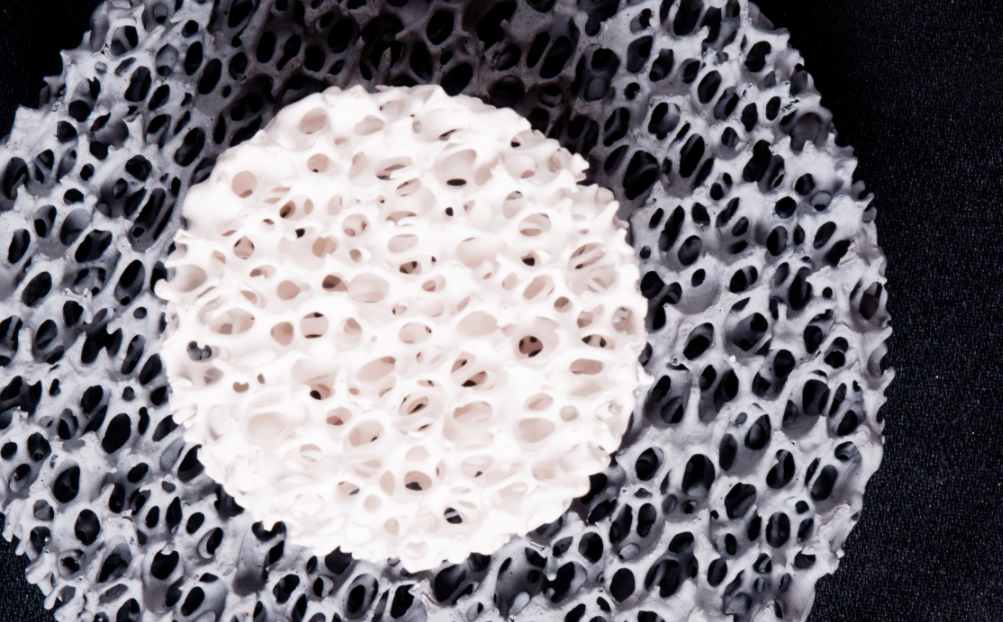

Composite Ceramics: Structure, Key Properties, and Industry Applications

Composite ceramics blend ceramic fibers into a ceramic matrix. Ceramic matrix composites (CMCs) stand out in this category. This design boosts toughness. It also improves thermal shock resistance. Plus, it cuts weight compared to traditional solid ceramics.

Core Structure and Reinforcement Materials

Main Reinforcement Fibers: Carbon (C), Silicon carbide (SiC), Alumina (Al₂O₃), Mullite (Al₂O₃-SiO₂)

Forms of Fibers:

- Continuous fibers: boost toughness and bridge cracks

- Short fibers, whiskers: strengthen crack resistance for wider uses

- Nanofibers: provide top mechanical strength and long life

Typical Matrix Materials: carbon, silicon carbide, alumina, or mullite

Notable Composite Ceramic Types and Performance Data

- C/C (carbon/carbon)

- C/SiC (carbon/silicon carbide)

- SiC/SiC (all-silicon carbide)

- Al₂O₃/Al₂O₃ (all-alumina)

Key measured properties:

| Property | CVI-C/SiC | LSI-C/SiC | SiSiC |

|---|---|---|---|

| Thermal conductivity [W/(m·K)] | 15 | 21 | >100 |

| Linear expansion [10⁻⁶·1/K] | 1.3 | 0 | 4 |

| Electrical resistivity [Ω·cm] | 0.4 | – | 50 |

| Elongation to rupture | up to 1% | up to 1% | up to 1% |

- Fracture toughness: 5–10× greater than standard ceramics

- Thermal shock resistance: much higher than traditional types

- Lightweight: about one-third the weight of typical nickel superalloy (standard for jet engines)

- Fiber diameter: continuous CMC fibers can be less than 10 microns—much finer than a human hair

Main Advantages of Composite Ceramics

- Toughness and crack resistance: Fibers bridge cracks. This stops total failure.

- Thermal stability: Linear thermal expansion stays low at 0–4×10⁻⁶·1/K. This cuts stress and bending.

- High-temperature function: CMCs stay stable above 1,800°F. Ultra-high-temperature CMCs (UHTCC) can go past 2,000°C.

- Corrosion and chemical resistance at extreme heat

- Good electrical insulation options exist. But conductive fibers change this.

Industry Use Cases and Performance Benefits

Based on my experience, I recommend CMCs for these key areas:

- Aerospace: turbine blades, nozzle inserts, and thermal barrier coatings. CMCs replace metals in jet engines. This can boost fuel efficiency by 1–2%.

- Automotive: brake discs and rotors. These parts are light and last long.

- Energy: components for high-heat or harsh plant conditions

- Medical (bioceramic composites): dental implants and bone repair materials. These resist infection and hold up well.

Cost savings and performance: CMCs work at higher heat. They also weigh less. This means better energy use and less upkeep.

Thermal barrier applications: Thin composite ceramic coatings shield metal engine parts. They push limits and extend part life.

Breakthroughs: I’ve seen next-generation CMCs use zirconium diboride and other ultra-high-heat matrices. These support hypersonic vehicles and modern turbines.

Composite ceramics combine several advances. They’re light. They’re tough. They handle heat well. These traits make them vital for extreme aerospace, energy, and medical uses. I suggest watching their market growth. It shows their clear value.

Summary

I recommend you look at these property differences when picking ceramics for electronics, manufacturing, biomedical devices, energy systems, and chemical processing. Performance and price connect to the strengths I’ve described. Based on my experience, matching the right ceramic to your need saves time and cost.