In my years of designing and operating water treatment systems, I’ve learned that effective Industrial water filtration isn’t just a single process; it’s a carefully choreographed sequence. Each stage is designed to tackle specific contaminants, building upon the last to transform raw, often problematic water into a pure, reliable industrial resource. Understanding these seven key steps is vital for anyone involved in manufacturing, municipal water treatment, pharmaceuticals, or electronics. The right industrial filter or combination of filters, applied in the correct order, is what separates a system that merely functions from one that excels in reliability, cost-effectiveness, and compliance.

Coagulation and Flocculation: The First Chemical Handshake

The journey of industrial water filtration begins with a chemical handshake. Raw water is full of tiny, suspended particles like silt, clay, and organic matter. These colloids are so small and carry such a stable negative charge that they repel each other, remaining in perpetual suspension. A standard mechanical industrial filter simply cannot capture these fine particles on its own.

This is where coagulation comes in. In this first step, we add positively charged chemicals, known as coagulants—aluminum sulfate (alum) and ferric chloride are common workhorses. When dosed into the water at precise rates (typically 10–100 mg/L, based on water quality testing), these coagulants neutralize the negative charges on the colloids. This destabilization allows the particles to come together upon collision, forming tiny, microscopic clumps called “microflocs.”

Flocculation is the gentle yet crucial follow-up. The water is moved to a separate basin where it is agitated slowly for 15 to 45 minutes. This gentle mixing encourages the microflocs to collide, bond, and grow into larger, visible, snowflake-like aggregates called “flocs.” We sometimes add polymer flocculant aids to strengthen these bonds and create larger, denser flocs. From my experience, this step is deceptively simple. Getting the chemical dosage, pH, and mixing energy just right is critical. Too little coagulant, and the particles won’t clump; too vigorous mixing, and you’ll shear the delicate flocs apart. When executed correctly, this process prepares the water for efficient solid-liquid separation, setting the stage for the next critical phase of filtration.

Sedimentation: Letting Gravity Do the Work

Once the flocs have formed, the water is directed into large, quiet basins known as sedimentation tanks or clarifiers. The objective here is straightforward: let gravity do the heavy lifting. The flow rate is drastically reduced, creating a calm environment where the dense, heavy flocs can gradually sink to the bottom.

This is a passive but remarkably effective separation process. As the water slowly advances toward the overflow weirs, the suspended solids settle out, leaving a clear layer of water above. Mechanical scrapers continuously move along the tank bottom, pushing the accumulated sludge toward a hopper for removal. A well-designed sedimentation tank, sized to provide a retention time of 2 to 6 hours, can remove between 70% and 90% of the suspended solids.

I cannot overstate the importance of proper sedimentation design. An undersized tank won’t provide enough residence time, allowing solids to carry over and overload the delicate—and expensive—filtration systems downstream. This leads to frequent backwashing, higher operating costs, and potential damage to sensitive Filter Media. Sedimentation is the workhorse that protects your investment in the finer industrial filters to come.

Filtration: The Multi-Layered Barrier

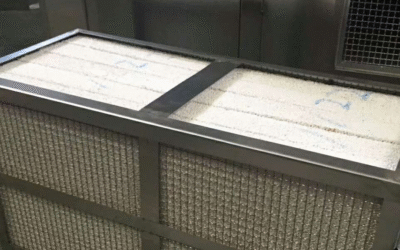

After sedimentation, the water is significantly clearer but still contains fine particles, some microorganisms, and dissolved contaminants. This is where the core industrial filtration process begins. The water is passed through one or more layers of porous media, each with a specific job. The most common configuration is a multi-media filter, often consisting of layers of coarse anthracite coal, fine sand, and supporting gravel. This graded approach allows for depth filtration, where larger particles are trapped in the upper layers and finer particles are captured deeper within the bed, preventing premature clogging.

A critical component often integrated here is the Granular Activated Carbon (GAC) filter. GAC is not just a mechanical filter; it’s an adsorptive powerhouse. The carbon particles are incredibly porous, creating a massive surface area (often 800–1200 m² per gram) that attracts and holds onto dissolved organic chemicals, chlorine, pesticides, and compounds that cause taste and odor. In my projects, integrating GAC filtration has consistently led to dramatic improvements in water quality, particularly when dealing with source water affected by agricultural runoff or municipal chlorination. The water exiting a well-operated filtration train is often crystal clear and free of many chemical contaminants, though it is not yet microbiologically safe.

Disinfection: The Microbial Safety Net

Filtration can remove many pathogens, but disinfection is the non-negotiable step that ensures the water is safe from harmful bacteria, viruses, and protozoa. We have several powerful tools for this job:

-

Chlorination: The most widespread method. Adding chlorine gas or sodium hypochlorite at a dose of 1-5 mg/L is highly effective. Its key advantage is the creation of a protective “residual” disinfectant that remains in the water, safeguarding it from recontamination within the distribution system. The drawback is the potential formation of disinfection by-products (DBPs) if the water contains high levels of organics.

-

Ultraviolet (UV) Light: A clean, chemical-free technology. We pass the water through chambers containing powerful UV lamps. The UV radiation at a specific wavelength damages the DNA of microorganisms, rendering them harmless. A typical dose is 40-120 mJ/cm². UV’s great advantage is that it produces no DBPs, but it provides no residual protection.

-

Ozonation: Ozone (O³) is a potent oxidant generated on-site. It is excellent at killing a broad spectrum of microbes and breaking down persistent compounds. However, it is complex to operate and leaves no residual.

From my experience, the choice depends heavily on the application. A municipality might prioritize chlorination for its residual effect, while a pharmaceutical plant would opt for UV or ozone to avoid introducing any chemicals into its ultra-pure water. I often recommend combined approaches, such as using UV as the primary disinfectant with a minimal chlorine residual, to leverage the strengths of each method within the overall water filtration strategy.

Advanced Purification: Pushing the Purity Envelope

For industries like electronics, pharmaceuticals, and high-pressure boiler feed, standard filtration and disinfection are insufficient. These applications demand the removal of dissolved ions and the achievement of ultra-pure water standards.

-

Reverse Osmosis (RO): This is a cornerstone of high-purity water production. RO systems use high pressure (8-14 bar) to force water through a semi-permeable membrane. The membrane’s pores are so tiny that they block dissolved salts, ions, organic molecules, and even most viruses. RO can remove up to 99% of total dissolved solids (TDS). In my view, RO is vital but demanding. The membranes are susceptible to fouling and scaling, which is why the meticulous pretreatment in Steps 1-4 is absolutely essential to protect this significant capital investment.

-

Ion Exchange: This process specifically targets dissolved ionic contaminants, like the calcium and magnesium ions that cause scale. Water passes through columns filled with resin beads that exchange undesirable ions for harmless ones (e.g., sodium or hydrogen). This is exceptionally effective for water softening and demineralization. The resins require periodic regeneration with chemicals, which is an important operational cost to factor in.

Polishing: The Final Touch

Polishing is the ultimate refinement step, designed to remove the last traces of contaminants that may have escaped the RO membrane or been introduced by the system itself. This stage is critical for the most sensitive applications.

-

Polishing Mixed-Bed Ion Exchange: This refined version of ion exchange uses a mixture of cation and anion resins in a single vessel to remove the final traces of ions, achieving resistivity levels of 18 megohm-cm, the gold standard for ultra-pure water.

-

Final Membrane Filtration: Installing a final 0.22 or 0.45-micron absolute-rated filter at the point-of-use acts as a final barrier against any particles or microbes.

I consistently recommend this stage for critical applications. In a semiconductor fabrication plant, for instance, a single particle can ruin a microchip. This final polish is the insurance policy that guarantees ultimate product quality and process integrity.

Storage and Distribution: Protecting the Product

The final, and often underestimated, step is ensuring the purified water does not degrade after treatment. The design of the storage and distribution system is paramount. I always recommend using tanks made from non-reactive materials like 316L stainless steel or high-density polyethylene. Tanks should be sealed, equipped with hydrophobic vent filters (0.22 µm) to prevent airborne contamination, and designed to avoid stagnation. This is typically achieved with a loop system featuring continuous circulation pumps.

For ultra-pure water systems, we often implement continuous UV sterilization within the loop and schedule regular hot-water or chemical sanitization to prevent biofilm formation. Every dead leg in the piping, every imperfect seal, is a potential site for microbial regrowth. Based on my experience, a brilliantly designed treatment train can be completely undermined by a poorly designed storage and distribution system. Vigilance in this final phase is what separates a good industrial water filtration system from a great one.

Conclusion

These seven steps—coagulation/flocculation, sedimentation, filtration, disinfection, advanced purification, polishing, and secure storage/distribution—form a comprehensive and interdependent chain. Each link is vital. The process demonstrates that industrial water filtration is not about a single magic filter, but about selecting and sequencing the right technologies for the specific water quality goals. From my perspective, mastering this sequence is what allows industries to operate safely, efficiently, and in compliance with ever-stricter regulations. It transforms a basic natural resource into a precise industrial tool, enabling everything from the manufacturing of life-saving drugs to the creation of the technology that powers our modern world.