Ever wondered how car engines, steel beams, or your phone’s metal parts get made? I’ve seen this process up close. Metal casting creates these parts. It uses molten metal and molds to form different shapes and sizes.

Here’s what most people know: pour the metal, let it cool, repeat. Simple, right?

But I’ve learned one thing sets casting methods apart. This detail gets overlooked. It changes everything about how we choose the right casting process.

Introduction to Metal Casting Processes

Metal casting is one of the oldest manufacturing methods. Molten metal is poured into a mold to create a specific shape. This process has been practiced for over 5,000 years. It remains crucial to modern industry. Based on my experience, about 90% of manufactured products involve cast metal components at some stage of their production.

Key Steps in Metal Casting

Patternmaking: This step begins with creating a precise replica—or “pattern”—of the part to be produced. Patterns can be made from wood, plastic, metal, or plaster. They must account for metal shrinkage during cooling. In industrial settings, patterns can be very large. For example, patterns used in heavy machinery manufacturing may weigh several hundred kilograms. This weight helps achieve the required precision.

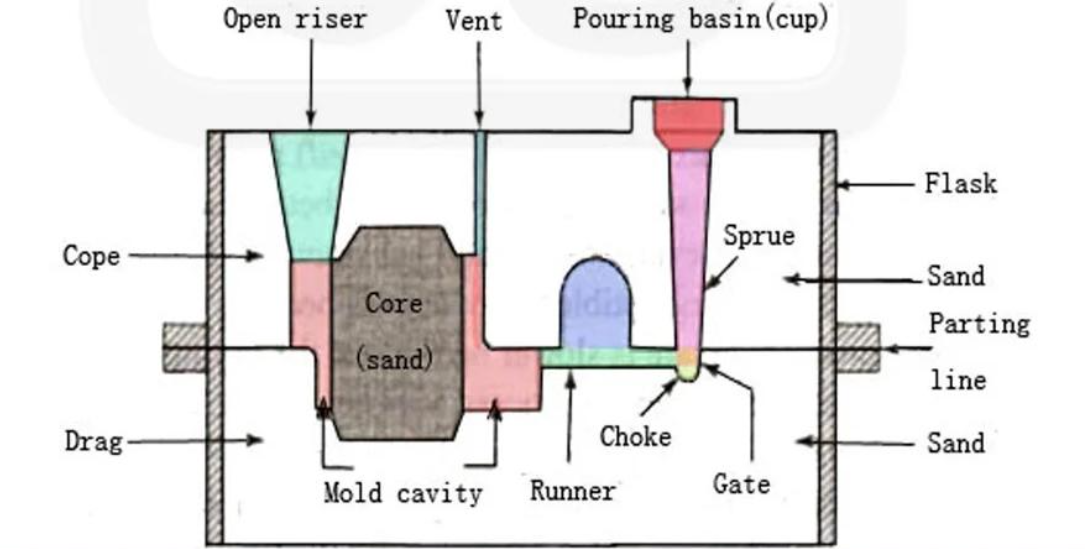

Coremaking: Cores are made to form internal cavities or complex geometries. Sand or metal is commonly used. These cores are essential in parts like car engine blocks. Such blocks often require up to 7 separate sand cores. These cores form coolant channels and internal passageways.

Mold Creation: Molds serve as the negative image of the final component. They can be made from sand (expendable), ceramic, or metal (permanent). There are two major categories:

- Single-use (Expendable) Molds: Sand casting is typical here. It alone makes up over 60% of all global metal castings.

- Permanent (Reusable) Molds: Die casting uses these molds. I recommend them for high production speed and mold longevity.

Melting and Pouring: The selected metal, often an alloy, is melted in a furnace or crucible. It is then poured into the mold. Parameters like temperature and pouring speed are controlled to ensure quality. Industrial foundries may handle small batches of a few kilograms. They can also handle massive pours exceeding 300 tonnes in a single operation.

Solidification and Cooling: As the molten metal cools, it solidifies within the mold. This step varies in duration. High-speed die casting takes just a few seconds. Large steel components may take several hours. Engineers manage cooling and use special riser designs. This helps reduce shrinkage effects and prevent defects.

Casting Removal: Once solid, the casting is taken out of the mold. In expendable mold processes, the mold is broken away. Permanent molds might use systems like ejector pins. High-volume automotive die casting equipment can produce 300 to 1,000 parts per hour. I suggest such systems for efficiency.

Finishing: After removal, castings undergo finishing treatments. These include cleaning, trimming, heat treatment, CNC machining, and inspection. Around 15% of total casting production time is spent on these finishing operations. This ensures they meet strict tolerance and surface requirements.

Metal Casting Applications and Data

Leading applications: Automotive engine blocks use sand casting with metal patterns and sand cores. Transmission cases use die casting. Construction steel beams use continuous casting. Aerospace relies on precise investment casting for components like turbine blades. I like how versatile this process is across different industries.

Industry statistics: Annual global metal casting output is over 112 million tonnes. Sand casting maintains dominance due to its versatility and cost-efficiency. Die casting is preferred for rapid, high-volume production. It achieves defect rates as low as 2% in optimized, automated setups.

Metal casting’s adaptability and cost-effectiveness make it an irreplaceable process across industries. It produces everyday automotive parts. It also meets the strict demands of aerospace engineering. From my perspective, this process will continue to be vital for manufacturing success.

Expendable Mold Casting Processes

Expendable mold casting uses molds that break apart after each use. This method is popular because it offers flexibility and saves money. It also handles complex shapes well. Here are the main expendable mold casting techniques and what makes each one unique:

Sand Casting

Sand casting is the most common and oldest expendable mold method. The process packs special casting sand around a pattern to form a cavity. To improve metal quality, filters such as ceramic foam filters or fiberglass mesh are often used in the gating system. After you remove the pattern, you pour molten metal to create the part.

– Advantages: Very versatile and cost-effective for small to very large parts.

– Surface Finish: Ra 12–25 µm. Parts may need extra finishing for smoother surfaces.

– Tolerance: ±1.5 mm. This makes it best for applications where you don’t need extreme precision.

– Common Uses: Engine blocks and pump housings.

I prefer sand casting for large items. It’s also my go-to choice when keeping tooling costs low is a priority.

Plaster Casting

Plaster casting replaces sand with gypsum molds. This improves detail and finish.

– Precision: Produces parts with surface finishes as fine as Ra 1–6 µm and tolerances of ±0.25–0.5 mm.

– Limitations: Molds are fragile. They can’t handle high-temperature metals. Part weights are under 20 kg.

– Best For: Small or medium-sized aluminum and brass components.

I recommend this for projects that need fine detail at a moderate price.

Shell Mold Casting

Shell mold casting uses resin-coated sand to form a hard shell. This delivers better precision and smoother finishes than traditional sand casting.

– Precision: Higher than sand casting.

– Industry Applications: Ideal for gears, bushings, camshafts, and valve bodies.

I consider this a strong option for mid-volume runs. It works well when you need precision and smooth casting surfaces.

Investment Casting (Lost Wax Casting)

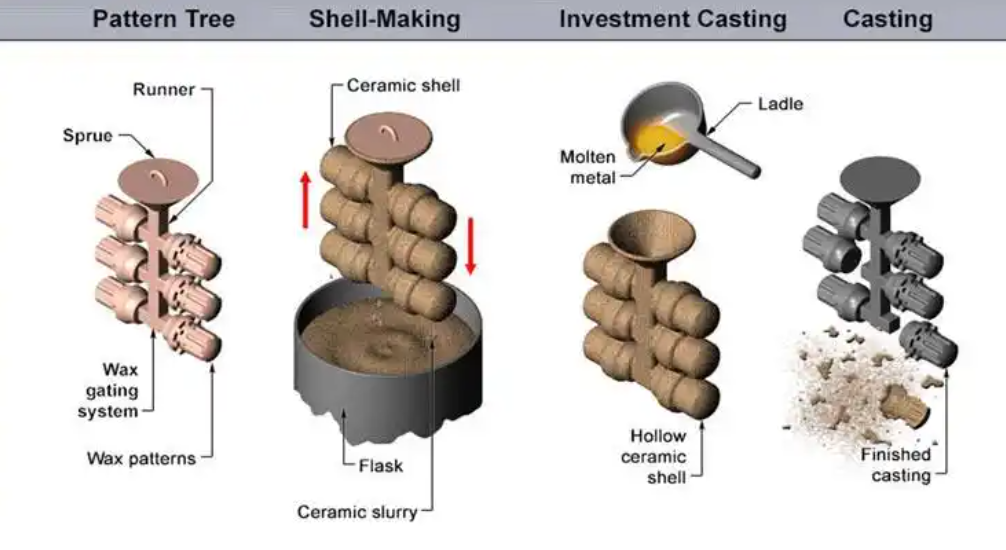

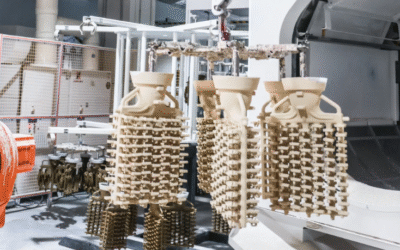

Investment casting starts by making a wax pattern. You coat it in ceramic, then melt out the wax. To ensure high metal purity, zirconia foam filters are commonly integrated into the gating system during mold assembly.

– Finish and Tolerance: Delivers high accuracy and excellent surface finish. It can produce complex, thin-walled parts.

– Ideal For: Aerospace and high-performance applications where you need complex shapes.

I often suggest investment casting for mission-critical parts. It’s perfect for components with fine details.

Lost Foam Casting

Lost foam casting uses a foam pattern that burns away when you pour molten metal.

– Key Traits: No need for parting lines. This results in clean, complex shapes.

– Finish: Ra 3–6 µm with tolerances of ±0.5–1.0 mm.

– Use Cases: Used for automotive components such as intake manifolds. Precision with complex geometry is important here.

I find this method stands out for designs that are too complicated for traditional molding methods.

Overview of Part Sizes and Applications

- Large parts: Sand casting (engine blocks, pump housings)

- Small, detailed parts: Plaster and investment casting (aluminum/brass components, aerospace parts)

- Complex geometry: Lost foam and investment casting (intake manifolds, fine hardware)

Each expendable mold process balances cost, speed, and performance. Based on my experience, these methods are essential for both everyday manufacturing and advanced industrial needs. I suggest choosing the right process based on your specific part requirements and budget constraints.

Non-Expendable Mold Casting Processes

Non-expendable mold casting uses strong, reusable molds. These molds are often made from iron, steel, or graphite. They produce metal parts many times. This increases productivity. It also gives you consistent results. Below are the major types and their key benefits.

Permanent Mold Casting

Works with metals like aluminum, magnesium, copper alloys, tin, zinc, and lead. Sometimes it works with iron or steel using graphite molds.

Most castings form by gravity filling. Gas pressure or vacuum can also fill the mold for specific needs. Uses strong metal molds. These molds can last for dozens or even thousands of cycles. The lifespan depends on the alloy and operating conditions. Slush casting is a variation. It works well for hollow castings.

- Advantages: Creates precise dimensions and smooth surfaces. You can reuse the mold. This saves money for long production runs.

- Applications: Automotive wheels, cylinder heads, marine hardware, cookware, and parts that need consistent quality.

Die Casting

Die casting injects molten metal under high pressure. The metal goes into precision-machined steel molds called “dies.”

Works best for nonferrous alloys. These include zinc, aluminum, and copper-based metals. You can also use it for some ferrous applications. Die casting accounts for over 50% of cast parts in some sectors, like automotive. In automotive, aluminum makes up about 80% of die-cast materials by volume.

- Performance: Creates thin walls and intricate details. It gives you excellent surface finish. It also delivers outstanding dimensional uniformity.

- Productivity: Produces 150–400+ castings per hour per die. This offers one of the highest throughputs in the industry.

- Applications: Automotive components, appliance housings, gearboxes, electronic parts, toys, and small mechanical components.

I recommend die casting for high-volume, complex, precision parts. Use it where quality and repetition matter most.

Centrifugal Casting

The process rotates the mold at high speed. Centrifugal force pushes molten metal outward against the mold wall. Works best for cylindrical or symmetrical parts. These parts need high density and few impurities. I’ve seen this used widely for pipes, bushings, rings, and cylinder liners. It also works for other tubular forms. Diameters and lengths can reach several meters.

- Variants: “True centrifugal casting” makes pure cylindrical components. “Centrifuged casting” handles other shapes in rotating molds.

- Typical Uses: Pipes for water and gas, flywheels, and cylinder liners.

Continuous Casting

Continuous casting pours a steady stream of molten metal into a cooled, open mold. The metal solidifies as it moves forward. This process continuously produces long, uniform products, including billets, blooms, bars, tubes, and slabs.

- Output: A single large continuous caster can produce hundreds of tons per hour. Steel slabs can be made up to 2,800 mm wide and 250 mm thick.

- Market Share: Over 95% of global steel uses continuous casting. It has almost totally replaced traditional ingot casting in major foundries.

- Applications: Structural steel beams, copper rods, aluminum bars, and other industrial stock.

Comparative Advantages and Typical Use Cases

- Cost-efficiency: Lowers overall mold costs for long production runs. You can reuse the molds.

- Repeatability: Delivers high dimensional consistency. Parts come out the same each time.

- Surface and Tolerance: Offers near net-shape castings with tight tolerances. It gives you better surface finish.

- Industry Coverage: Powers high-speed production in automotive, construction, aerospace, and manufacturing sectors.

Summary Table: Main Non-Expendable Mold Processes & Representative Parts

| Process | Typical Applications |

|---|---|

| Permanent Mold | Automotive engine blocks, gas burners, aircraft parts |

| Die Casting | Gearboxes, electrical housings, faucet valves, carburetors |

| Centrifugal Casting | Water/gas pipes, flywheels, cylinder liners |

| Continuous Casting | Steel billets, copper rods, aluminum bars, slabs |

Choosing the Right Process:

Pick your process based on production volume, part complexity, surface needs, and dimensional requirements. Consider mechanical property needs too. In my experience, non-expendable mold processes deliver speed, quality, and economy. They work for both everyday products and demanding industrial applications. I suggest you match the process to your specific production goals.

Specialized Casting Processes

I’ve worked with many specialized metal casting processes. They solve tough part requirements. You get better precision, stronger mechanical properties, and unique shapes. Traditional casting methods can’t always deliver these results.

Below, I share specific process features, real cases, and pros and cons. This information helps manufacturers, particularly in industries that demand quality and efficiency.

Vacuum Die Casting for High-Quality, Complex Parts

Vacuum die casting uses a vacuum inside the mold during metal injection. This cuts internal porosity. Surface quality and strength improve as well.

Vacuum pressure often stays at or below 100 bar. You get castings suitable for welding and heat treatment. This matters for automotive, aerospace, electronics, and telecom.

- Key Benefits: Low porosity, excellent surface finish. Perfect for thin-walled or intricate electronic cases and automotive body parts.

- Downsides: Tooling costs can be high. Mold sealing is complex. Short mold lifespans need consideration.

- Example Applications: Automotive chassis and electronic enclosures. Airtightness and strength matter here.

Low-Pressure Casting: Efficient, Dense Structures

Low-pressure casting fills molds from the bottom up. Pressure stays low (0.02–0.06 MPa). This ensures stable filling and dense, clean castings.

You don’t need feeding risers. Material use rates reach 90–98%. I recommend this for large, thin-walled castings.

- Advantages: Smooth surfaces, dense material. Ideal for cylinder heads, wheel hubs, and engine assemblies.

- Use Case: Automotive and industrial parts. These cannot risk defects from internal air pockets.

Squeeze Casting (Liquid Forging): Strength-Critical Castings

Squeeze casting combines casting and forging. Molten or semi-solid metal is pressed in a closed die under high pressure.

- Highlights: Eliminates porosity and shrinkage defects. Improves surface finish. Raises dimensional precision. Perfect for high-strength safety parts.

- Disadvantages: Shape flexibility is more limited. Precision control can slow production.

- Alloys: Works well with aluminum, zinc, copper, ductile iron.

- Examples: Automotive chassis, steering knuckles, and critical structural brackets.

Process Steps (Direct Extrusion Squeeze Casting)

- Spray paint die

- Inject alloy

- Close mold

- Apply high pressure

- Hold pressure

- Release pressure

- Open mold and remove part

- Reset for next cycle

Centrifugal Casting: Dense, Hollow Sections for Symmetry

Centrifugal casting spins molten metal at high speeds (hundreds of RPMs). Metal pushes outward. This forms void-free, dense layers.

- Benefits: No riser needed. Produces solid outer walls. Ideal for pipework, gun barrels, and large gear rings.

- Flexible Design: Works with both sand and metal molds. You can scale up or down for part size.

- Proven Use Cases: Cast iron pipes, water pipes, gear rings. Any long, cylindrical component that needs structural integrity.

Permanent Mold and Slush Casting: Versatile, Reusable Solutions

Permanent mold casting uses sturdy metal molds for many production cycles. Suitable metals include aluminum, magnesium, and iron alloys.

- Process: Molds are often loaded by hand. Sometimes rotated for efficiency. This ensures rapid heat transfer for fast shell formation.

-

Slush Casting Variant: Metal is poured and then drained before full solidification. This forms hollow items with thin shells.

-

Advantages: Fast production, consistent castings.

- Special Uses: Automotive pistons, decorative shells, lightweight hollow objects, and specialty items like seasonal ornaments or chocolate molds.

Comparative Table: Specialized Casting Process Selection

| Process | Key Features | Main Advantages | Typical Applications |

|---|---|---|---|

| Vacuum Die Casting | Mold vacuum, low gas content | Excellent surface/low porosity | Automotive, aero, electronics |

| Low-Pressure Casting | Bottom-up fill, 0.02-0.06 MPa pressure | Dense, high material yield | Wheels, engine heads, hubs |

| Squeeze Casting | High-pressure forged casting | Defect-free, high strength | Chassis, knuckles, brackets |

| Centrifugal Casting | High-speed spinning mold | Dense & void-free cylindrical | Pipes, gun barrels, gear rings |

| Permanent Mold | Steel/graphite/iron reusable molds | Rapid, uniform, shell solidifies | Pistons, decorative shells |

| Slush Casting | Part-emptied permanent mold | Thin-walled, hollow shells | Chocolates, ornaments, light covers |

Industry Insights and Data Points

- Vacuum die casting produces chassis and electronic cases with exceptional airtightness.

- Low-pressure casting achieves ~90–98% metal yield. This is critical for high-volume automotive production.

- Squeeze casting provides the finest surface finish and lowest defect rates. I recommend it for safety-related structural components.

- Centrifugal casting ensures strong, concentric pipes and rings. These perform well under mechanical stress.

- Permanent/slush casting offers affordable, rapid solutions for mass-produced pistons or decorative shells.

I believe these specialized casting methods make it possible to produce high-performance parts, complex geometries, and thin-walled, precision items. Based on my experience, you should match your project’s strength, cost, and geometry needs to the right casting process. This gives you the best value and performance.

Summary

I’ve worked in manufacturing for years. Metal casting is more than just melting and pouring metal. You need to match the right process to your needs. Are you making one prototype or millions of parts? There’s a casting method for each. The key is knowing what each process gives you. This knowledge changes how you think about production, quality, and cost. It has helped me a lot in my work. I think it will help you too.