From my experience, industrial oil filters are essential. They protect your machinery by cleaning harmful dirt from the oil. I find that good filtration is key to keeping systems running smoothly. It reduces wear on parts and helps you avoid expensive machine breakdowns.

Main Types of Industrial Oil Filters

I generally see three main types of industrial oil filters used in different industries:

Spin-on Oil Filters

These are self-contained, throwaway canister filters. I like them because they make maintenance easy with fast changes. You’ll see them a lot on construction sites and in dusty places. They offer a quick-change option in tough environments. Their strong steel casing and advanced filter material, like Champion’s resin-treated, full-pleat design, provide better protection. This can offer up to 30% more engine safety compared to other brands. They hold a lot of dirt and are built to handle tough jobs with lots of debris.

Cartridge Oil Filters

Cartridge filters use a filter element that you can replace inside a housing that you can reuse. This is a good way to create less waste. I suggest these for tight spaces or if you need special filtration for specific kinds of dirt. Advanced filter material, such as synthetic resin and layered glass fiber, allows for customization. This helps meet specific protection standards for unique machines or small industrial setups.

Magnetic Oil Filters

Magnetic filters have built-in magnets. These magnets grab and take out metal bits that come from machine wear. I’ve often seen them used together with other industrial filter types. This is helpful in places with a lot of metal-particle issues, like metalworking shops or with older equipment. By removing fine metal dust, they lower the risk of damage that standard filters might miss. This helps extend the life of your machinery.

Whether you choose a spin-on, cartridge, or magnetic filter, I believe they are crucial. They ensure your equipment is reliable, lasts as long as possible, and meets the standards needed in today’s tough industrial settings.

Spin-On Oil Filter: Types, Applications, and Performance

I recommend spin-on oil filters for industrial equipment. They install fast and are great for filtering different fluids like lubricating oil, hydraulic fluid, diesel, and fuel. They have a strong canister, often made of metal or tough plastic. This makes them last in rough conditions. Replacement is simple: you just “spin-on, spin-off.”

Types of Spin-On Oil Filters

Hydraulic Spin-On Filters: I suggest you install these on the return lines of pressurized hydraulic systems. You will find them in industrial and mobile machinery. They keep the hydraulic oil clean, which helps the systems run smoothly.

Lube Spin-On Filters: These are for engine oil, lubricating oil, and diesel. Inside, a special paper or glass fiber material catches harmful particles. I often see them in machinery, truck fleets, and large ships.

Fuel Spin-On Filters: They can capture water droplets and dirt as small as 10 microns. Because they hold a lot and are built tough, they last longer. This means you do not have to change them as often.

Transmission Spin-On Filters: These filters protect sensitive parts in your transmission. They keep the fluid clean from grit and debris. This leads to less wear and longer times between services.

Fuel-Water Separator Spin-Ons: My advice is to use these to remove water, dirt, and rust from fuel. They are built with materials that resist corrosion, so they hold up to constant use.

Bypass Spin-On Oil Filters: These can trap particles down to 9 microns at 50% efficiency and 22 microns at 99%. They are ISO:9001 certified. In my experience, they provide excellent protection for engines in very tough industrial jobs.

Filter Media Options and Micron Ratings

- Cellulose (Paper) Filter Media: From my experience, this is a cost-effective choice for petroleum fluids. It is a good option for general contaminant removal.

- Synthetic/Microglass Media: This material provides deep, effective filtering and holds more dirt. It helps your filter and system last longer.

- Stainless Steel Mesh: I like to use this for basic protection that you can reuse. It is often placed upstream to protect pumps and other sensitive components.

-

Aqua-Zorb Water-Absorbing Elements: These elements pull and hold water from petroleum liquids. This action stops dangerous water from building up.

-

Micron Ratings: You can get ratings of 1, 3, 5, 10, 25, and 100 microns. A lower rating means the filter catches finer particles. A 1-micron filter is for a single use. It offers the most precise filtering and can hold a lot of dirt. I find that 10-micron types are great for quick changes and work with many systems.

-

Hybrid Designs: Some filters mix a full-flow section (for particles >20 microns) and a microfilter section (<20 microns). This design grabs a wider range of junk in one go. It provides double the protection for your machines and engines.

You see these filters used in many fields. This includes agriculture, construction, forestry, manufacturing, mining, and on heavy equipment. I believe their long service life and ability to block both fine and coarse particles are a huge plus. They help extend the life of the engine and oil, which is vital for expensive industrial machines.

Cartridge Oil Filter: A Guide to Structure, Efficiency, and Use

From my experience, cartridge oil filters are a top choice for industrial filtering because of their design. You don’t replace the entire filter. You just swap out the inner cartridge. This helps you save money and create less waste.

Structure and Performance Features

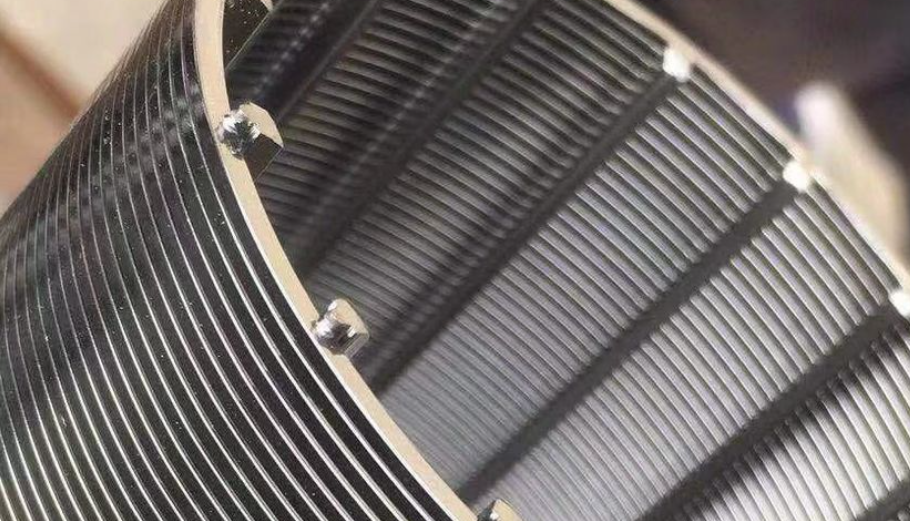

Advanced Filter Media: These industrial cartridge filters use high-quality materials like resin-infused paper or layered glass fiber. A corrugated steel center tube supports the pleated media. I have found this design prevents the filter from collapsing, which is very important during cold starts.

Strong Housing: The filter element fits inside a permanent housing you can reuse. It’s built from machined aluminum or coated steel. This construction provides excellent durability and resists corrosion. Their gaskets are made from Buna-N or FKM, so they can handle many types of oils and chemicals.

Precision Micron Ratings: These filters are very precise and can remove particles between 10 and 35 microns. For example, a residential model catches 10-micron particles at 15 PSI. It offers a filter area of up to 500 sq. in. with flow rates of 45 GPH. A commercial model can filter down to 35 microns, has a 700 sq. in. area, and supports flow rates up to 90 GPH.

Custom Flow and Size: You have many choices for inlet and outlet sizes. They come in 3/8”, 1/2”, 3/4”, and 1” NPT. This range serves everything from small home systems to large industrial machines. Heights vary from 5½” to over 10″, and widths go from 3¾” to 4-3/4″.

Filter Element Options and Maintenance

For filtering fuel oil or industrial oil, I recommend looking at stainless steel mesh cartridges. They are available in mesh sizes of 30, 60, 100, and 200. You can wash and reuse them, which I find lowers costs over time.

You only need to change the inner element. This makes cartridge filters more affordable and better for the environment than spin-on filter types.

Due to a large media area and deep pleats, these industrial cartridge filters hold a high amount of contamination. They are very reliable and prevent contaminants from bypassing the filter, so I recommend them for demanding industrial work.

Common Industry Uses and Examples

I often see these filters in engine lubrication systems, industrial oil processing, and hydraulic systems. They are used anywhere clean oil is needed for equipment to run well.

The Champion aerospace cartridge oil filter is a great example. It features a shorter, stronger steel case. Its collapse pressure rating is double that of competing filters, which gives the engine great protection.

Overall, I believe cartridge oil filters give you high efficiency and a strong design. They come with flexible options. This makes them a great tool for any professional who needs reliable oil cleanliness and long-term system protection.

Magnetic Oil Filters: What I Think You Should Know

From my experience, magnetic oil filters are essential tools for the industry. They use powerful magnets, like N45 grade neodymium alloys, to pull tiny iron and steel particles out of industrial fluids. You will find them in gearboxes, hydraulic units, and turbine drives. I’ve also seen them used often in steel mills and metalworking shops where fluid contamination is a major issue. I believe their biggest plus is capturing these tiny metal bits. This stops the particles from causing system wear or leading to unexpected breakdowns.

How These Filters Are Built

Magnetic Core: The core uses strong rare earth magnets, often N45 or N42 grade. I suggest you make sure their strength is checked with a hysteresis graph before they’re installed. You can get magnetic fields from 4,000 to 11,000 gauss. The higher gauss is for jobs that need to catch almost every particle.

Filter Housing: For the housing, you have two choices. Aluminum works for pressures up to 725 psi. For higher pressures up to 1160 psi, I recommend 316 stainless steel because it also resists corrosion well in tough industrial settings.

Magnetic Shielding: Many filters include special shielding systems like FluxCon™. I think this is a fantastic feature. It keeps the magnetic field contained inside the filter. This protects your nearby electronics and stops stray metal from sticking to the outside.

Flexible Installation: I like how adaptable their installation is. You can place them almost anywhere: before or after pumps, on delivery lines, or in fluid holding tanks. This flexibility makes them a good fit for many different system layouts.

Performance and Easy Cleaning

- High Flow Capacity: These filters can handle a flow rate of up to 200 gallons per minute. This capacity works for both large and small industrial setups.

- Wide Operating Temp Range: I have found their temperature range to be very practical. Standard models operate from 32°F to 284°F. If you work in extreme conditions, you can get special models that function from -40°F up to 300°F.

- Easy Maintenance: For me, easy maintenance is a huge selling point. There are no consumable parts to replace. To clean the filter, you just wipe the collected metal debris off the magnetic core. The process takes less than 30 seconds, and you avoid messy cartridges or hazardous waste.

In my opinion, magnetic oil filters are a smart investment for industrial oil systems. If you want long-term efficiency and reliability while cutting waste, I recommend you consider them. They are becoming a popular choice in manufacturing and heavy equipment maintenance for very good reasons.

My Guide to Specialized Industrial Oil Filters

From my experience, standard industrial oil filters don’t always cut it. You need special industrial filters for certain jobs. They use advanced methods to remove specific contaminants and improve your oil. I can help you match the right filter to your industry needs for the best results.

Centrifugal Oil Filters: Fast, Consumable-Free Separation

I often recommend centrifugal filters for their power. They spin very fast, from 3,000 to 15,000 RPM. This force separates dirt and particles based on their weight. You can get rid of 99.9% of particles bigger than 2 microns. I’ve seen them work great in systems with a lot of gunk. They are a go-to choice for smaller edible oil mills that handle cloudy oils like peanut or soybean.

Vacuum Oil Filters: Export-Grade Purity for Cold-Pressed Oils

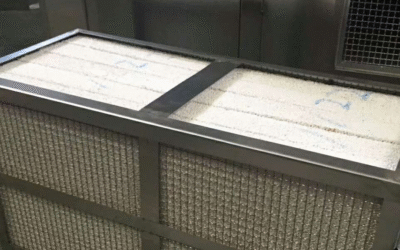

Vacuum oil filters use a different approach. They create a vacuum in a sealed tank. This pulls the oil through a very fine filter material. What I like is that this method removes tiny bits of water and particles. It works well even when the oil is cool. For high-end oils like coconut or olive meant for export, I suggest this type of filter.

Pneumatic Oil Filters: Durable and Automated for Medium-Scale Production

If you want automation, I would look at pneumatic oil filters. They use air pressure to consistently filter out solid waste. You will find them often in medium-sized plants that process rapeseed, cottonseed, and peanut oil.

Plate and Frame Filter Presses: The Gold Standard for Clarity

For top-quality craft oils, my recommendation is the plate and frame filter press. It gives the oil a final polish for amazing clarity. I see them used to finish cold-pressed oils like camellia or sesame. The result is an oil that looks clearer than what most other systems can produce.

Refining Oil Filters: Industrial Solutions for Purity and Shelf Life

During large-scale oil refining, you’ll need specific filters for different steps. After stages like degumming, these filters remove unwanted materials. In my opinion, their main job is to improve the final oil quality. This helps the oil last longer on the shelf and meet export standards.

Based on my experience, you should choose a filter based on what is most important for your operation. Think about the particle size you need to remove and how fast you need to work. Also, consider the final oil clarity you want, your maintenance budget, and your system type. Getting this right ensures you get the performance you need.

Key Features Comparison of Industrial Oil Filter Types

To pick the right industrial oil filter, you need to know your machine’s needs and your oil quality goals. I’ll break down the main filter types. I’ll compare their core features, performance, and practical uses. This includes what they filter, how well they work, when to replace them, their impact on the environment, and what they’re best for.

Centrifugal vs. Vacuum Oil Filters

Centrifugal Oil Filters

Filtration Target: Moisture, coarse solids (down to 10–30 microns).

It has no disposable parts. Instead, it spins at high speeds (up to 15,000 RPM) to push particles out. It processes oil quickly, so from my experience, it’s great for non-stop work in peanut or sunflower oil mills. The running cost is lower because you don’t buy replacement parts. You do need to clean it by hand from time to time.

Vacuum Oil Filters

Filtration Target: Fine impurities, water (down to 1–5 microns).

It uses vacuum suction for very pure filtration and works well at low temperatures. I recommend it for high-end oils like coconut, olive, or almond that are for export. You will need to replace the filter material often. The vacuum pump also requires regular maintenance.

Spin-On vs. Replaceable Cartridge Oil Filters

Spin-On Oil Filters

Filtration Target: General solids (10 microns and above).

Changes are fast and simple. The whole unit is self-contained, so you replace everything at once. I think they are great for jobs with a lot of dirt and metal bits, like in construction or mining.

Replaceable Cartridge Oil Filters

Filtration Target: General solids; customizable for various particle sizes.

You just replace the filter part inside, which cuts down on waste. You also get more choices for the filter material. I feel this gives it a better environmental footprint.

Magnetic Oil Filters and Plate & Frame Filter Presses

Magnetic Oil Filters

Filtration Target: Ferrous (metallic) particles (>10 microns).

It uses strong magnets to grab metal bits from the oil all the time. You can reuse it after a quick manual cleaning. I find it very useful where metal wear is a problem, such as in gearboxes, heavy machines, and trucks. It doesn’t work on impurities that aren’t metal. Custom options are limited, and I’ve noticed they can be more expensive.

Plate & Frame Filter Press

Filtration Target: Ultra-fine solids, providing a final polish for top oil clarity.

It works in batches using layers of filter material. In my experience, it gives the clearest oil. It’s a top choice for craft and high-end edible oils like sesame and walnut.

High-Efficiency Oil Filters

Filtration Target: Sub-5 micron impurities.

The cost is 2 to 3 times higher than a basic filter. You might also need a special adapter to make it fit.

It uses a modern synthetic material to catch very fine particles for the best protection. This can extend its service life by 2 to 3 times compared to standard filters. I recommend it for premium engines. It’s also great for any job where you must have the best filtration.

Every filter type has its own strengths. I recommend you pick an industrial filtration system based on the specific dirt you are dealing with. Also, consider how fast your system runs and what your green goals are.

summary

Based on my experience with many oil filters, I’ve learned an important lesson. Choosing the right filter is about more than just its technical details. You must understand your own specific needs. The main goal is to match the filter to your work environment.

Before you make a final decision, I suggest you check your machinery. Look at the contamination levels you deal with. Think about your ability to perform maintenance. In my opinion, making the right choice now will save you from future problems and costly repairs.