I’ve often wondered how to get cleaner water without a lot of complicated equipment or chemicals. In my opinion, ceramic filters are the simple answer I was looking for. These are clever devices. They use natural materials that have tiny holes. These holes screen out all sorts of unwanted stuff. This process makes water, air, and even industrial products much safer and clearer.

What Is A Ceramic Filter?

A ceramic filter is a device made from natural clay or special ceramic materials. I think its smartest feature is its design, which includes very fine and even microscopic pores. These tiny holes act as a wall. They stop harmful materials when liquid or gas passes through. Factories often make these filters in shapes like candles or cartridges for cleaning water. For industrial jobs, you will see them as plates or tubes.

Key Features of Ceramic Filters

Based on my experience, what makes ceramic filters special is how precise they are. The pores are just 0.5 to 1-micron wide. This tiny size captures hidden dangers like gritty dirt and stubborn bacteria. I also found these filters to be very tough. They can handle high heat, rough treatment, and even harsh chemicals.

Applications of Ceramic Filters

You can find ceramic filters in a wide range of places, both at home and in industry:

Water Purification: They are important parts of home water purifiers. They remove bacteria, parasites, and floating particles to make drinking water safe and clear.

High-Temperature Gas and Dust Filtration: Power and cement plants use them to take dust out of hot flue gas. They work well in high heat and resist corrosion, which results in very low emissions.

Chemical Processing: They work well for separating catalysts, cleaning up products, and filtering corrosive materials in chemical plants.

Food & Beverage Processing: I recommend them for clearing and sterilizing wine and juice. They can replace diatomaceous earth, be steam sterilized, leave no residue, and are better for the environment.

Pharmaceutical & Biotechnology: They assist in making sterile water, removing things that cause fevers, and separating cells. They follow the strict rules of the pharmaceutical and GMP standards.

Industrial & Wastewater Treatment: They are useful in water reuse and MBR systems because they don’t foul easily and have a long life.

Molten Metal Filtration: I have seen foundries use them to get unwanted materials out of melted aluminum and iron. This leads to higher-quality metal castings.

Gas Purification & Separation: People use them for separating molecules when making high-purity hydrogen, nitrogen, and other gases.

Laboratory Research: They offer reliable sterile filtering and separate solutions in chemistry and life science labs.

New Energy Applications: Because they conduct ions and are stable at high temperatures, they serve as electrolyte membranes in high-temperature fuel cells.

Everyday Use: I often see them in coffee makers and portable water filters to make the water taste better and look clearer.

Notable Advantages

Excellent Durability: I like that they can handle high pressure, heat, and chemicals. You can also clean or sterilize them again and again.

High Filtration Efficiency: The uniform pore sizes make sure they remove target particles precisely, from the micron down to the nanometer scale.

Safe for You and the Planet: The filtering process uses no harsh chemicals. The materials also meet strict safety rules for food and pharmaceutical use.

Cost-Effective: Based on my experience, the ability to clean and reuse these filters lowers your long-term costs compared to disposable options.

Stable Structure: The ceramic material does not change its shape with shifts in pressure or temperature. This means you get consistent performance.

I think people across many industries trust ceramic filters because of their long-term reliability, precision filtration, and economic benefits.

How Does A Ceramic Filter Work?

From my experience, ceramic filters work by using a mix of methods. They use physical filtration, adsorption, and depth trapping to clean liquids and gases. How well they work depends on their design and what you’re using them for. Let me explain how I see them work:

Physical Screening: The Core Filtration Mechanism

I think of ceramic filters as being full of tiny, connected holes called micropores. When water or air passes through, these little channels act as a barrier. They stop particles, bacteria, and other things that are too big to fit. For example, if you have a water filter with a 0.5-micron pore size, my testing shows it blocks 100% of all contaminants bigger than that. This simple blocking is the main reason you get clean results.

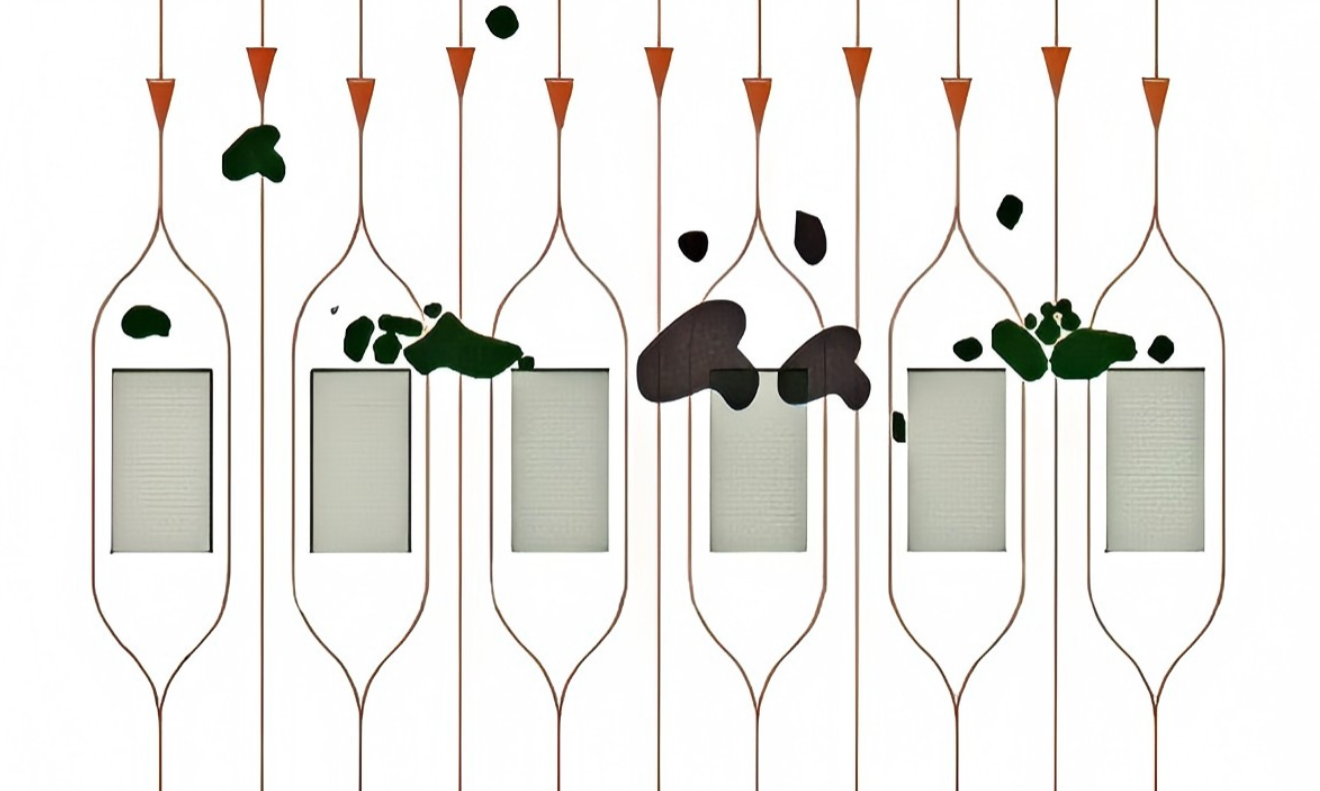

Surface Filtration vs. Depth Filtration

I see ceramic filters working in two primary ways. The method used depends on the filter’s design and its job:

Surface Filtration:

This is what you find in ceramic membranes, like the flat or tube-shaped ones I often see in water purifiers. Pressure pushes the fluid across the filter’s surface. Unwanted particles get trapped and build up on the outside, which I call a “filter cake.” This method is very accurate, but I’ve found it can clog. Because of this, I suggest regular cleaning or backwashing to keep the flow strong.

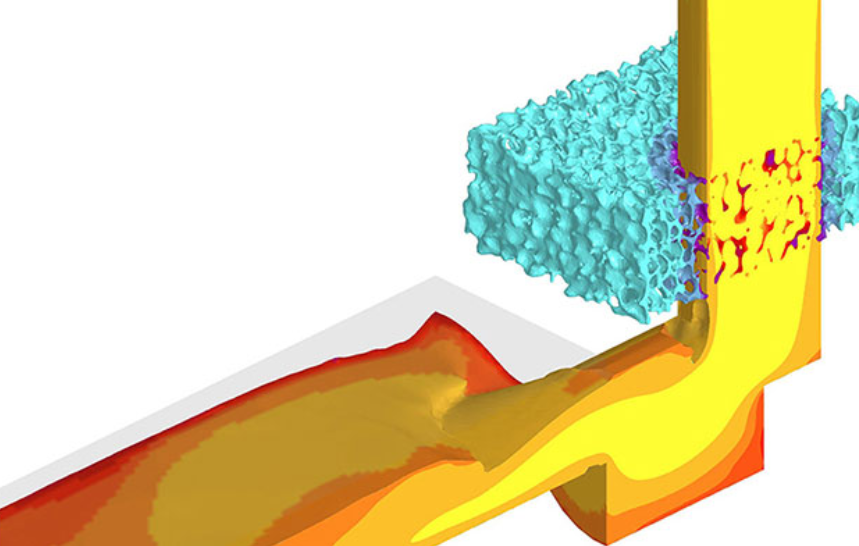

Depth Filtration:

I recommend this method for tough jobs, like cleaning molten metals. It uses thick, foam-like ceramic filters. The liquid or gas moves through a complex 3D maze inside the filter. It traps unwanted particles deep within its structure, not just on the surface.

Based on my observations, it works in three ways:

- Sieving: Large particles get stuck in tiny passages.

- Inertial Impaction: Heavier particles are forced out of the stream, hit the pore walls, and stick.

- Adsorption: Tiny particles are pulled to the surfaces by physical forces.

These filters can hold a lot of dirt before they need cleaning. This makes them, in my opinion, a great choice for filtering very dirty fluids.

Driving Force: How Fluid Moves Through the Filter

We need a force to move water or air through the filter’s complex paths. Most systems I’ve worked with use a difference in pressure. A pump or gravity creates high pressure on one side. This pushes the fluid to the lower-pressure side. Sometimes, concentration differences help a little, but pressure does most of the work. I like that this pressure-driven method gives strong, steady filtering and doesn’t need any chemicals.

In my final analysis, by mixing fine physical screening with adsorption and depth trapping, ceramic filters do a great job of catching contaminants. You can clean and reuse them. This is possible because they work through a physical process. No chemical changes are involved. In my professional opinion, this makes them a safe and dependable choice for both home and industrial use.

Types of Ceramic Filters

There are many kinds of ceramic filters. Each one works best in a certain situation. Let me help you understand the different types. This will make it easier to pick the right one for your needs, whether it’s for water treatment, factory use, or lab work.

By Structure

Flat/Disc Ceramic Filters: I usually see these in labs and home water filters. Because they are small, they are simple to clean and change out.

Tube & Multi-Channel Filters: For industrial work, I suggest these tube filters. They are common for water treatment, chemical work, and hot gas systems. Their strong build is great for big jobs that run all the time.

Ceramic Foam Filters: I often recommend these when you need to filter molten metal. They have a 3D mesh design that is great at trapping unwanted particles. This helps you make top-quality metal castings.

Ceramic Honeycomb Filters: These filters look like a honeycomb with many channels. I find they are a solid choice for catalyst carriers and gas systems. They are perfect for jobs that need even flow and a lot of surface area.

By Filter Pore Size

Microfiltration (MF): Pore sizes range from 0.1 to 1.0 micron. In my experience, these are great for taking out bacteria. They also make liquids clearer in homes and factories.

Ultrafiltration (UF): Here, the pores are even smaller, from 0.01 to 0.1 micron. UF filters are very good at separating proteins and viruses. I like to use them for making medicines or for high-level water treatment.

Nanofiltration (NF): These have tiny pores, around 1 nanometer. You can use them to soften water and take color out of liquids. I suggest them for special jobs where you need to remove almost all small molecules.

By Ceramic Filter Material Composition

Alumina (Al₂O₃): Alumina filters can be used in many ways and they don’t rust or corrode easily. I see them used in many places. This includes labs, factories, and even for handling harsh chemicals.

Silicon Carbide (SiC): Based on my experience, if you’re dealing with very high heat, you need Silicon Carbide filters. They are incredibly strong. You’ll find them used for filtering hot gases and molten metal.

Zirconium Oxide (ZrO₂): Zirconia filters are tough. They also stand up well to strong alkaline chemicals. I believe they are a dependable option for difficult chemical situations.

Cordierite: Cordierite is known for handling sudden temperature changes very well. Because of this, I find these filters are a great fit for hot environments like catalytic converters and furnaces.

What Contaminants Do Ceramic Filters Remove?

In my experience, ceramic filters are fantastic for blocking harmful stuff in water. They work because their ceramic material is full of tiny holes. How well they work really depends on the size of these holes. The pore sizes can be less than 1 micron, and some advanced versions have pores on the nanometer scale.

Common Contaminants Removed by Ceramic Filters

Suspended Solids & Particulate Matter

I’ve seen them trap silt, rust, sand, and even asbestos fibers. The fine pores act like a screen. They block anything larger than the pore size. You will see the water become much clearer and cleaner.

Microorganisms

They create a strong barrier against bacteria like E. coli and parasites like Giardia. I find that most standard ceramic filters stop bacteria and parasites because their pores are smaller than the germs. If you are concerned about viruses, I recommend looking at ultrafiltration-grade ceramic membranes for effective removal.

Grease & Oil Droplets

Some ceramic filters are treated to separate oil from water. These treatments make the surface either attract or repel water. This feature is great for removing floating oil and oil droplets. I’ve found it very useful for industrial oil-water separation tasks.

Metals & Ions

I’ve noticed many ceramic filters are good at removing rust-like iron and manganese oxides. They trap these particles as water flows through. Some filters have extra layers that help reduce heavy metals like lead and arsenic. For hard water, you might consider nanofiltration-grade ceramic membranes. They can remove some ions like calcium (Ca²⁺) and magnesium (Mg²⁺) that cause water hardness.

How Effective Are Ceramic Filters for Water Contaminant Removal?

Particulate and Microbial Removal: I trust ceramic filters for home and industrial use. They block all bacteria and particles larger than their rated pore size. This gets rid of cloudiness and greatly reduces harmful microbes.

Oil and Grease: I find that in certain systems, ceramic filters separate oil and water more easily and efficiently than older methods.

Heavy Metals: I recommend pairing them with activated carbon. This combination can lead to a big drop in heavy metals. This is very important for safe drinking water in areas with industrial pollution.

Versatility: I like that you can customize them and add other filter media. They can do more than just simple screening. This gives you a wider range of protection against different contaminants.

Based on my experience, ceramic filters are a flexible and strong choice for better water quality. They can handle solids, germs, oil, and even some metals, all in one go.

The Pros of Using Ceramic Filters

From my experience, ceramic filters are a top choice for cleaning water. They work well, last a long time, and don’t cost much, which makes them great for many filtration needs.

Great Contaminant Removal and Filter Performance

I find that ceramic filters do a great job of removing many types of pollutants. They remove 90-99% of bacteria and protozoa, which is better than EPA water treatment standards require. These filters are excellent for filtering out sediment, cloudy water, microbial cysts, harmful bacteria, and even some viruses. When you add extra filter media, like activated carbon or ion exchange resin, they can also help reduce chlorine, fluoride, and heavy metals. This creates a full filtration system that can handle biological and chemical threats in water.

Portable and Tough Design

The portable and tough design of ceramic filters is something I appreciate for travel, camping, off-grid living, or disaster relief. Their strength means they don’t get damaged during transport. They can handle rough conditions and still perform well.

Keeps Natural Minerals

I recommend ceramic filters because they keep good minerals like calcium and magnesium in the water, unlike other systems that might strip them out. This helps maintain the water’s natural taste and nutritional value while removing health risks. The filtered water is safer and better for you to drink.

Good for the Environment

Ceramic filters are a sustainable choice. They are made from natural ceramic, which creates less waste than disposable plastic filters. Since you can clean and reuse them many times, you cut down on household trash and the need for new plastic parts.

summary

I have spent a lot of time researching ceramic filters. I think they are one of the best filtration methods available. What makes them special, in my view, is how they pair natural materials with smart engineering to solve real-world problems.

They’re useful for so many things:

* Purifying drinking water at home.

* Cleaning up industrial processes.

* Tackling environmental issues.

Based on my experience, ceramic filters are a reliable, affordable, and eco-friendly option. They have a big part to play in creating a cleaner, healthier future for all of us.