Key Data on Porosity

Porcelain:

- Total porosity ranges from 3% to 6%.

- Open porosity can be less than 1.2%.

- Pore sizes are very small (often less than 1 μm). Most pores are closed.

- Result: Very low water absorption. Liquids and stains barely penetrate.

Traditional Ceramics:

- Total porosity can be up to 30% or higher. This depends on the product (e.g., terracotta, earthenware).

- Pores are larger. They are often open and connected.

- Result: High water absorption. I recommend these for uses like flower pots. Permeability is fine there.

Measurement Methods

Archimedes’ method and water absorption tests measure open porosity well. Mercury intrusion porosimetry and helium gas pycnometry give precise data on pore size and total porosity.

For example, helium gas pycnometry offers accurate results in just 2–4 hours.

Practical Examples

Porcelain Tiles: Low porosity and water absorption. I suggest using them in bathrooms and kitchens. They resist stains well.

Traditional Ceramics: High porosity and water absorption. They work great for decorative purposes and garden pots.

Comparative Table: Ceramic vs. Porcelain Porosity

| Material Type | Typical Total Porosity | Typical Open Porosity | Pore Size Range | Water Absorption | Common Applications |

|---|---|---|---|---|---|

| Porcelain | 3–6% | <1.2% | <1 μm | Very low | Floor tiles, sanitaryware |

| Glazed Porcelain Stoneware | 10–25% | Low | 0.08–0.9 μm | Very low | Wall/floor tiles |

| Traditional Ceramics | Up to 30% or more | High | Microns to mm | High | Flower pots, decorative objects |

Summary of Porosity Differences

Porcelain has a dense, closed-pore structure. It absorbs very little water. Based on my experience, this makes it ideal for high-moisture areas. I recommend it for stain-sensitive places. Traditional ceramics are more porous. They absorb water and stains more easily. But they are useful where breathability matters. The measurement method and product type can cause big differences in porosity numbers. I believe product-specific testing is key for quality control.

Key Data & Numeric Comparison of Ceramic vs. Porcelain Porosity

Porosity is the main difference between ceramic and porcelain. The numbers show how much less porous porcelain is. Here’s a data comparison:

Water Absorption Rates:

- Porcelain tiles: less than 0.5%

- Ceramic tiles: 1%–6%

Pore Size Ranges:

- Porcelain: about 0.08 to 0.9 µm—these tiny pores are closed. Almost no liquid can get in.

- Standard ceramics: have larger open pores, often above 1 µm

Total and Open Porosity:

- Standard ceramics: total porosity from 3% to 6%; open porosity less than 1.2%

- Glazed porcelain stoneware: combined open and closed porosity can reach 10–25%. But most pores are closed. So practical water absorption stays very low.

Measurement Methods:

- Archimedes’ Method: simple way to test open porosity via water displacement. Helpful for materials with big open pores.

- Helium Gas Pycnometry: much faster (2–4 hours) and more precise. It detects even closed pores. It confirms low pore volumes in porcelain.

Experimental & Imaging Data: Adding sand or coarse ingredients to ceramics raises their visible and measurable porosity. Porcelain uses finer particles and higher firing temperatures. It is almost nonporous. Multiple imaging studies (NLM-CNN, petrography) prove pore reduction of 20–40% compared to typical ceramics.

Practical Example: In real-world tests, glazed porcelain stoneware shows water absorption of less than 0.5%. This is true even with up to 25% total porosity. The reason? Its micro-scale pores are closed.

Key Takeaway:

Porcelain is at least two to ten times less porous than ceramic. This applies to both measurable water absorption and actual pore structure. That’s why porcelain excels in stain and water resistance. I recommend porcelain if you need superior protection against moisture and stains.

Manufacturing Process and Porosity: How Production Methods Affect Porosity in Ceramic vs. Porcelain

The manufacturing process causes the main difference in porosity between ceramic and porcelain tiles.

Raw Materials and Firing Techniques

Porcelain tiles start with a blend of fine kaolin clay, feldspar, quartz, and silica. The clay is pure and ground into fine particles. These tiles are pressed at high pressure. Then they are fired at temperatures between 2,200–2,500°F (1,200–1,400°C). The process uses single-firing (monocottura). This melts feldspar and silica. It creates a vitrified, glass-like structure. The tile becomes dense and almost non-porous. Porcelain’s water absorption rate is ≤0.5% (following strict industry standards). I recommend porcelain tiles for bathrooms, kitchens, and other wet areas.

Ceramic tiles are made from coarser, less refined clays. These clays often contain more mineral impurities. They use a double-firing process (bicottura):

- First, the tile is shaped and fired (called the “biscuit” stage).

- Next, a glaze is applied and the tile is fired again.

Firing occurs at 1,800–2,000°F (about 1,000–1,100°C). This is much lower than for porcelain. The lower temperature and coarser clay leave more open spaces in the structure. This makes the tile more porous.

Easy Reference Table

| Type | Firing Process | Firing Temp (°F) | Water Absorption | Porosity | Typical Application |

|---|---|---|---|---|---|

| Porcelain | Single-firing | 2,200–2,500 | ≤0.5% | Very low | Wet/high-traffic areas |

| Ceramic | Double-firing | 1,800–2,000 | 0.5–3% (up to 20%) | Moderate-high | Walls, low-traffic, pottery |

| Terracotta | Single-firing | 1,650–1,800 | Very high | High | Flower pots, high permeability |

Personal Evaluation and Real-World Examples

I suggest porcelain floor tiles as the best choice for wet environments. Their manufacturing process creates minimal liquid penetration.

In contrast, traditional red-clay ceramics (like terracotta flower pots) stay porous. This happens because of lower firing temperatures and rougher materials. This makes them perfect for plants. You want water to pass through.

Here’s what I’ve learned: Porcelain’s finer ingredients, higher compaction, and advanced firing methods create much lower porosity. Ceramics trade some waterproofing for decorative flexibility. They also sometimes cost less.

In short: The purity and fineness of raw materials matter. The force used to press the tile matters. The firing temperature matters most. All these factors shape the tile’s final porosity. They decide where to best use each type.

Porcelain’s vitrified, glass-like structure resists moisture, stains, and wear. If your priority is water resistance, I recommend you choose porcelain. If you need decorative, breathable pieces (like flower pots or wall décor), ceramics work best.

Real-World Uses of Porosity in Ceramics and Porcelain

Porosity affects how ceramics and porcelain perform in industrial, environmental, and medical settings. I’ll show you how porosity shapes their role in real-world use:

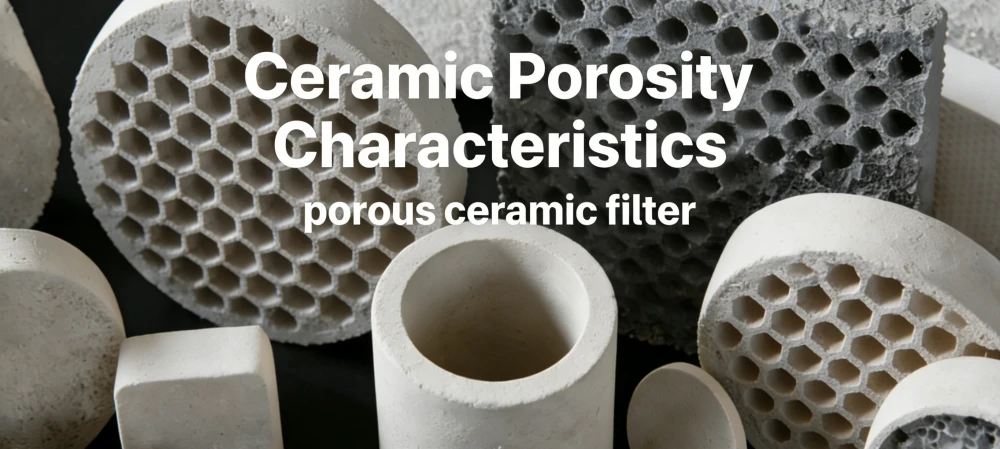

Filtration Efficiency and Flow

Porous ceramics with high open porosity—sometimes up to 40%—work well in liquid and gas filtration. The size and connectivity of the pores control how well contaminants are removed. They also control the speed at which fluids pass through.

ceramic filters work better than polymer and paper filters in high-pressure or high-temperature environments. Based on my experience, this is where ceramic filters truly shine.

Thermal Insulation and Heat Management

Thermal conductivity of ceramics drops as porosity increases. For instance, unidirectional porous YSZ ceramics can have in-channel conductivity from 0.2–0.54 W/(m·K). Perpendicular values can be as low as 0.06–0.1 W/(m·K). This makes Porous ceramics ideal for burners, barrier coatings, and furnace linings. I recommend low-porosity, dense ceramics for areas needing high wear or chemical resistance.

Biomedical Applications: Implants and Integration

Controlled, interconnected porosity is vital in biomedical ceramics for bone scaffolds. Pore sizes between 100–500 µm help bone ingrowth. Medical ceramics like dental crowns and hip replacements need the lowest possible porosity. This ensures the highest strength and fatigue resistance.

Gas and Liquid Management in Industry

Customization of pore size in technical ceramics supports their use as aerators, wicks, and drainage components. Pores range from below 1 µm to several hundred µm. They meet diverse demands in bioreactors, environmental sensors, or civil engineering.

Quality Control: Measurement Methods

I suggest using these tools to measure porosity:

– Archimedes’ Method for apparent open porosity and water absorption.

– Mercury Intrusion Porosimetry for detailed pore volume and distribution in filtration ceramics.

– Gas Pycnometry for telling apart open and closed pores. This is crucial for applications like insulation.

Industrial Examples & Case Data

- Hot gas filtration in metallurgy uses porous ceramic filters with 30–40% porosity.

- Refractory bricks with 15–25% porosity boost the energy efficiency of furnaces.

- Thermal protection in aerospace uses ceramics with up to 90% porosity. This puts low weight and insulation over mechanical strength.

Additional Related Insights

Advances in Measuring Porosity: Accuracy and Speed

Modern methods have improved how we measure ceramic and porcelain porosity. I recommend understanding both traditional and new approaches. Traditional testing like Archimedes’ water displacement and vacuum water absorption still set the baseline. They measure open porosity and water absorption rates well.

Helium gas pycnometry is a game-changer. It measures open and closed porosity in just 2–4 hours. That’s much faster than old methods. Based on my experience, the results from modified pycnometry and vacuum methods match well. This proves pycnometry works great for industry quality control.

Digital image analysis (DIA) takes measurement further. Thin-section images use neural network models (NLM-CNN). They measure total porosity and specific pore features. I’m talking about shape, size, and distribution. This technique cuts down estimate errors. It gives you precise batch-to-batch quality checks. I suggest this for complex or old ceramics.

Pore Types and Practical Impact

Open and closed pores work differently. Open porosity means pores connect to each other. This boosts filtration and liquid flow. But it can weaken the structure. It also lowers water resistance.

Closed pores sit alone, separated from others. They improve heat insulation. They don’t reduce strength as much. But too many closed pores can hurt reliability.

Manufacturing changes affect pore structure. Adding coarse materials like sand before firing increases pore amount. It also affects how pores connect. Firing temperature and process control which pores open or close. This impacts mechanical strength, staining resistance, and filtration ability.

Real-World Industrial and Price Context

Total porosity varies a lot in glazed porcelain stoneware (10–25%). But I think micro-pore size matters most for high performance. The sweet spot sits between 0.080 and 0.9 µm. Even with high overall pore volume, liquids can’t get through tiny pores.

Water absorption rates are key for cost and specs. Most porcelain tiles stay below 0.5%. This holds true even when total porosity is higher.

These differences affect pricing. Porcelain tiles with controlled porosity cost more. They offer better durability and water resistance. On the flip side, more porous tiles cost less. They have random pore patterns. Often they use less refined materials or additives like sand. I see these used for decorative or non-critical roles.

Chemical and Microstructural Influences

Porosity depends on more than firing method or clay particle size. The full chemical mix matters. The exact balance of minerals and additives shapes the final pore profile.

Grain boundaries, mineral bits, and additives all interact. Each batch of ceramic or porcelain develops its own microstructure. I recommend precise quality testing and careful material selection. This is critical for engineering, building, and industrial uses.

Summary List: Why Porcelain Is Less Porous Than Ceramic

Porcelain has much lower porosity than standard ceramic. This happens because of how it’s made, what it’s made from, and how its structure forms. Here’s a simple breakdown with data for easy comparison:

Key Reasons for Porcelain’s Low Porosity

Higher Firing Temperature: Porcelain is fired at 1200–1400 °C. Standard ceramics are fired at 900–1100 °C. The higher heat turns the clay into glass. This creates a tight, glass-like structure. Pores shrink and close up.

Superior Raw Materials and Clay Fineness: Porcelain uses clay and minerals that are ground finer. They are also purer. This creates a microstructure with smaller pores. The pores don’t connect to each other. Water, air, and chemicals can’t pass through.

Manufacturing and Grain Fusion: Advanced manufacturing melts minerals together. This causes strong grain fusion. It also creates a glass phase. The result? Fewer, smaller, and more isolated pores. Ceramics are often fired at lower temps. They end up less dense.

Water Absorption Rate Figures:

- Porcelain tiles: <0.5% absorption

- Ceramic tiles: 3–10% or higher (depends on how they’re made)

Microstructure Analysis: Digital imaging and microscopy show porcelain’s total optical porosity below 2%. Traditional ceramics show 5–20%+. This is more common when additives or coarse fillers are added.

Pore Distribution Differences: Porcelain contains closed and isolated pores. Ceramics have a network of open and interconnected pores. This makes ceramics more permeable. Water gets absorbed more.

Mechanical Strength and Durability: Less porosity means higher mechanical strength. Porcelain reaches 60–100 MPa or above. Typical ceramics fall in the 10–50 MPa range. I recommend porcelain for areas with heavy use. It’s far more durable and resists wear better.

Noteworthy Insights: Price and Real-World Application

Premium porcelain tiles have controlled porosity and water absorption. They cost more than most ceramics. But their better durability, stain resistance, and stability make them worth it. I suggest using them in wet areas, high-traffic zones, or where you need long-lasting materials.

More porous ceramic tiles use less refined materials or added sand. They cost less but absorb more water. This works well for decorative items, wall features, or flower pots. In these cases, breathability or low cost matters more than water resistance or strength.

Expert Takeaway

Porcelain fires at higher temps. It uses fine-grained raw materials. Advanced glass phase forms. The structure is dense with closed pores. All of this leads to much lower porosity and water absorption than regular ceramics. Based on my experience, porcelain performs better in moisture-heavy and high-traffic spaces. This makes the higher price worth it. I recommend porcelain for demanding applications.

Quick Reference: How to Identify Porosity in Ceramic and Porcelain

You need to identify porosity in ceramic and porcelain to choose the right tile or product. This is critical where water resistance or durability matters. Here’s a clear, practical guide covering common porosity testing methods. I’ve included industry data and real-world cues to help you.

Main Methods for Testing Ceramic and Porcelain Porosity

Archimedes’ Method (Water Displacement)

This method measures apparent open porosity. It tracks how much water the material absorbs. The industry uses this standard approach. Water absorption percentage shows how porous the material is.

Key data: Standard ceramic tiles absorb 3%–7% water. Porcelain tiles absorb 0.1%–0.5% or lower. This shows porcelain has much lower porosity.

Gas Pycnometry

This test uses helium or inert gases to calculate the sample’s true volume. It covers both open and closed pores. It’s rapid and precise. It measures total porosity in just 2–4 hours. I recommend this for porcelain with very fine closed pores. It gives accurate results.

Mercury Intrusion Porosimetry

This method measures total pore volume and size distribution. It forces mercury into the smallest pores under pressure. It reveals hidden microscopic porosity. Water tests cannot detect this. Based on my experience, this is a must for high-tech ceramics and scientific analysis.

Standard Water Absorption Tests (ISO 10545, ASTM C373)

These tests use boiling water or vacuum techniques. They saturate the sample and measure water absorption. The vacuum method gives more thorough results. It captures even very low-porosity tiles like glazed porcelain.

Direct Signs and Physical Checks

- Low-Porosity Porcelain: Place water on the surface. It beads up and stays visible. Almost no absorption happens. The tile feels dense and glassy.

- High-Porosity Ceramics: Water soaks in or leaves a damp patch. The tile feels less dense or a bit chalky.

Practical Steps: How to Identify Porosity for Buyers and Users

- Check the manufacturer’s stated water absorption rate. This percentage gives you a direct clue to porosity.

- Perform a drop test: Place water on the surface. Watch for rapid absorption or visible swelling.

- Examine product technical info. Look for the measurement type. Higher-end products will list methods like pycnometry or porosimetry. This gives you extra confidence.

- If laboratory analysis is possible, use pycnometry or mercury intrusion. These can reveal deeper pore structures. They verify manufacturer claims.

Important Considerations

Closed vs. Open Porosity: Simple water tests measure open pores alone. True low-porosity (like in porcelain) requires advanced methods. Gas or mercury-based tests give you full accuracy.

Test Method Influence: Standard boiling or immersion tests might underestimate open-porosity. This happens in dense porcelain tiles.

In summary:

Porosity identification combines lab techniques and simple real-world observations. For most users, check the absorption rate. Do a quick surface test. Check for technical test methods if accuracy matters. You can detect porcelain’s much lower porosity with both professional equipment and basic checks.

Sources of Porosity Differences in Ceramic vs. Porcelain Tiles

I want to explain what makes porcelain tiles less porous than regular ceramic tiles. It comes down to three key factors: raw materials, firing process, and pore types. I’ll break down these sources and show you how they affect water resistance, stain resistance, and price.

Raw Materials and Their Role in Tile Porosity

Porcelain tiles are made from a much denser base. The mixture uses fine, purified clays. It combines with a high percentage of feldspar (15–25%). Feldspar melts during firing. It fills gaps between clay particles. This reduces pore size.

Ceramic tiles use coarser clays and more varied mineral mixes. The raw materials are less refined. This creates a structure with more and larger pores.

The density and purity of clay minerals in porcelain lead to smaller and fewer pores. I’ve seen this difference firsthand in manufacturing settings.

Firing Temperatures and Vitrification

Porcelain tiles are fired at higher temperatures—between 1,300°C and 1,400°C. At these temperatures, more of the tile body becomes vitrified (glass-like). This closes off most pores. The result is a structure that absorbs almost no water. Ceramic tiles are fired at much lower temperatures—900–1,100°C. This temperature is not enough to seal pores through vitrification. The result: a more open, porous structure. It absorbs more water.

Types of Pores: Closed vs. Open

Porcelain has a tight, closed-pore microstructure. Most pores are microscopic. They are not connected. Water and stains struggle to penetrate. I recommend porcelain for this reason. Ceramic tiles tend to have larger, open, and interconnected pores. These are left behind by gas release during firing. This means higher water absorption. It also means less resistance to stains.

Sometimes porcelain may develop coarse closed pores due to feldspar decomposition. But these don’t impact its overall low porosity.

Water Absorption Rates and Practical Performance

Porcelain tile water absorption: almost always less than 0.5%. This is the industry gold standard for water resistance. Ceramic tile water absorption: ranges from 3% to 7%. This is much higher.

Based on my experience, porcelain tiles are ideal for high-moisture environments (like bathrooms and kitchens). Ceramics may need extra sealing and maintenance.

Other Critical Factors

The compaction pressure during tile formation matters. Porcelain tiles are formed under pressures that can exceed 2,800 kg/cm². This removes even more voids. It makes the material denser.

The feldspar content and high-heat firing create porcelain’s 60%–70% lower porosity than standard ceramics. Industry tests and data support this.

Summary:

Porcelain tiles owe their low porosity to denser clay and feldspar-rich raw materials. They also benefit from higher firing temperatures for maximum vitrification. Massive compaction pressures help. The microstructure is dominated by closed pores. Ceramic tiles retain higher porosity due to less refined materials. They use lower firing temperatures. They have a network of open pores. This makes them more water absorbent. They often need more frequent sealing or protective treatments. I suggest porcelain for areas exposed to moisture.