Ever get confused by all the talk about foundries versus casting metal? You’re not alone—it seems like those terms get mixed up all the time. The truth is, one is a place and the other is a step in making metal parts, but there’s much more to it.

Casting and Foundry Definition

What Is a Foundry?

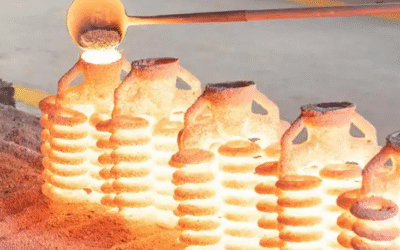

A foundry is a special place where Metal casting happens. This includes: – Melting raw materials like scrap metal and alloys in furnaces (such as induction or cupola furnaces) – Preparing molds (sand or metal) – Pouring molten metal into molds – Allowing the metal to cool and solidify – Performing finishing processes like machining and surface treatment

Foundries serve many industries. These include automotive, aerospace, construction, and machinery manufacturing. They work with metals such as iron, steel, aluminum, copper, and various alloys.

I’ve seen large Industrial foundries pour over 500 tons of molten metal per day. They produce engine blocks, gearboxes, crankshafts, and more.

Foundries manage quality control too. They use non-destructive testing methods, such as X-rays or ultrasonic inspection. They also house pattern and core shops as part of their operations.

What Is Casting?

Casting is a manufacturing process. It shapes metal by pouring molten metal into a mold. Then you wait for it to cool and solidify. This process includes:

– Creating the mold

– Pouring the molten metal

– Allowing the metal to solidify

Casting happens inside the foundry as one step of the workflow. The process produces items like valves (e.g., Investment casting), jewelry, and art pieces. Sometimes this happens on a smaller scale outside of an industrial foundry.

Key Differences Between Foundry and Casting

| Aspect | Foundry | Casting |

|---|---|---|

| Definition | Facility for all metal casting operations | Process of pouring molten metal into a mold |

| Scope | Covers design, melting, molding, finishing, and testing | Focuses on shaping metal by solidification |

| Example Usage | “The engine block was produced in a foundry.” | “The valve was made using investment casting.” |

| Processes | Melting, molding, pouring, solidification, and inspection | Molding, pouring, and solidification |

| Facility Type | Large industrial plants with special equipment | Not a facility, but a manufacturing technique |

| Typical Metals | Iron, steel, aluminum, copper, alloys | Works with any castable metal |

Summary:

Based on my experience, I recommend thinking of it this way: The foundry is the complete manufacturing place. It handles all operations. Casting refers to the specific process of forming metal parts by solidification inside that place.

Core Differences Between Foundry and Casting

I recommend understanding the key differences between a foundry and the Casting process if you work in metal manufacturing, engineering, or product procurement.

Distinct Objectives and Roles

Foundry: A foundry is a complete manufacturing facility. It manages the entire metal journey—from melting raw stock to final finishing. The foundry handles all steps: melting metal, preparing molds (sand, die, investment), pouring, solidification, cleaning, and post-processing.

Casting: Casting is the process of pouring molten metal into molds. The metal then solidifies. Casting is one key step within the larger foundry operation. It shapes the final product.

Scope of Processes

Foundry Process Scope: A foundry includes all needed procedures. It uses cupola, electric arc, induction, or gas furnaces for melting different metals. It has extensive mold-making equipment for pattern creation. It uses advanced pouring and cooling management systems. It has finishing tools such as grinders and machining centers.

Casting Process Scope: Casting focuses on filling the mold and producing the metal part. It uses different types of molds or gating systems based on design requirements.

Equipment and Technology

Foundries: Foundries have heavy industrial equipment. They use multiple furnace types (cupola for iron, electric arc for steel). They have auto sand mixers, pattern shops, and post-casting finishing stations.

Example: Large iron foundries may consume tons of coke fuel every day in cupola furnaces. Aluminum foundries use high-efficiency electric or gas-fired furnaces suited to lower melting points.

Casting: Casting uses the mold, gating system, and sometimes automated pouring mechanisms. Product complexity and required repeatability determine how sophisticated the casting process is.

Materials and Specializations

Foundries: Foundries handle many types of metals. These include ferrous (iron, steel) and non-ferrous (aluminum, copper, specialized alloys).

Casting Methods: Casting works with most castable metals. Process choice (investment, die, centrifugal) depends on alloy characteristics.

Production Scale and Industry Examples

Foundries: Foundries range from small custom shops to massive industrial plants. Some produce over 100,000 engine blocks per year via Sand casting for the automotive sector.

Casting Examples: Casting creates turbine blades (investment casting for aerospace), sewer pipes (centrifugal casting), art sculptures, and high-volume parts like gear housings.

Common Casting Processes in Foundries

- Sand Casting: Cost-effective. Suitable for large components or small-batch jobs.

- Investment Casting: Used for detailed, smaller parts (turbine blades, valves).

- Die Casting: Best for rapid, high-volume runs (hundreds of thousands of pieces per die set).

- Centrifugal Casting: Specialized for cylindrical items (pipes, tubes).

- Permanent Mold & Shell Molding: Suitable for non-ferrous alloys and precision components.

Applications and Industries

Foundry and casting metal processes sit at the heart of many key industries. I’ve seen how their flexibility makes them vital to modern manufacturing.

Major Industry Applications

Agricultural Equipment: Foundries form the core of farm machinery production. They make strong gear housings, axle parts, and counterweights for tractors and harvesters. These parts use cast iron and Ductile Iron. This ensures they last long and resist heavy wear.

Automotive Industry: Foundry work and metal casting drive the auto sector. Foundries produce large parts like engine blocks and cylinder heads. Metal casting works well for detailed shapes like turbochargers. It meets high-precision demands.

Aerospace: Precision matters most in aerospace manufacturing. Metal casting creates complex turbine blades and structural parts. These need tight tolerances and strong mechanical performance.

Construction: The construction sector relies on foundries for major products. They produce manhole covers, drainage parts, and large fittings. Durable Casting methods give these items strength and reliability in tough environments.

Art and Jewelry: I recommend casting for detailed artistic work. Foundries and small casting studios make fine jewelry pieces and custom sculptures. Metal casting offers excellent fine detail.

Industry Sectors Benefiting from Foundry and Casting

- Automotive: For both detailed and large parts.

- Aerospace: Focused on precision and performance.

- Construction: Needs sturdy, large-scale items.

- Machinery and Equipment: For complex mechanical parts.

- Medical: For high-precision medical tools and parts.

Notable Products

- Machine parts: gears, bearings, pumps.

- Automotive parts: engine blocks, cylinder heads, turbochargers.

- Pipes and valves: for industrial and plumbing systems.

- Tools and hardware: handles, hinges, brackets.

- Artistic and decorative works: statues, vases, custom metal designs.

Foundries worldwide produce more than 90 million tons of cast metals every year. The global casting market keeps growing. Automotive and aerospace industries drive this demand.

I’ve found that foundry and casting processes adapt well to different needs. Manufacturers can handle mass production and custom orders. This makes these processes essential across many sectors.

Comparison: Investment Casting vs. Forging

| Feature | Investment Casting | Forging |

|---|---|---|

| Design freedom | Most | Least |

| Tolerance | Best | Poor |

| Surface finish | Good | Average |

| Metal selection | Most | Average |

| Machining | Average | High |

Comparison: Investment Casting vs. Permanent Mold

| Feature | Investment Casting | Permanent Mold |

|---|---|---|

| Design freedom | Most | Average |

| Tolerance | Best | Average |

| Surface finish | Good | Average |

| Metal selection | Most | Average |

Types of Foundries

We categorize foundries by the type of metals they process. The two core types are:

Ferrous Foundries: These facilities handle iron-based metals. They work with Malleable Iron, grey iron, nodular iron, and steel. Ferrous metals represent about 90% of global metal production. So most foundry output focuses on iron and steel castings.

Non-Ferrous Foundries: These focus on non-iron metals. Common ones include aluminum, copper, brass, bronze, magnesium, and zinc. Non-ferrous foundries produce lightweight automotive components. They also make complex electrical parts and decorative castings.

Foundry Classification by Operational Structure

Jobbing Foundry: This type handles custom or low-volume orders. Common jobs include prototype castings. They also make specialized automotive parts for limited runs.

Production Foundry: This foundry targets high-volume, standardized production. They manufacture large batches of identical components. Sectors like automotive and heavy machinery rely on them.

Semi-Production Foundry: This strikes a balance between custom jobs and high-volume runs. I recommend this type for businesses needing both flexibility and moderate scale.

Captive Foundry: A manufacturing firm owns and operates this to supply its in-house metal part needs. For example, a large machinery company may use a captive foundry. They make exclusive engine blocks and housings there.

Important Foundry Processes

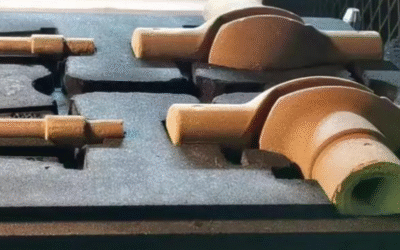

- Pattern making: Workers build the model of the final part.

- Molding: They create the mold cavity for casting.

- Melting and pouring: This involves heating and handling molten metal.

- Solidification and cooling: The shape takes form as the metal cools.

- Shakeout and cleaning: Workers remove sand or mold from cast metal.

- Inspection and finishing: Teams check quality and improve surfaces.

Many options exist for different needs. These include single-piece, split, match plate, cope and drag, gated, sweep, segmental, and shell patterns. Production complexity and casting quantity guide the choice.

Specialized Furnaces and Production Techniques

Furnace Types: Selection depends on metal and production scale.

- Electric Arc and Induction Furnaces, Cupolas: We use these for ferrous metals. Electric arc furnaces can run above 1,600°C (2,910°F).

- Reverberatory and Crucible Furnaces: These work for non-ferrous metals like aluminum, bronze, and brass.

- Low-Melting Alloy Furnaces: Power sources include electricity, propane, or gas. They run at around 500°C (932°F) for zinc or tin alloys.

The Role of Recycling and Sustainability

Foundries play a key part in metal recycling. Millions of tons of scrap metal get reprocessed every year. Sand used in mold making, for sand casting, is also recycled on a large scale. This cuts costs and reduces environmental impact. Based on my experience, this practice benefits both the industry and our planet.

The diversity in foundry types, operational models, and tech setups is impressive. It allows the industry to meet a wide variety of industrial needs. From heavy truck housings to lightweight engine parts and high-precision specialty castings, foundries serve them all.

Summary of Practical Implications for Foundry vs. Casting Metal

I believe understanding how foundry operations and casting processes affect your project can change your cost, efficiency, and final product performance.

Practical Cost Efficiency and Production Scalability

Metal casting cuts production costs and lead times by up to 50% compared to traditional machining or welding. You spend less on labor. You waste less material. Your overhead drops.

Foundries work well for both prototypes and mass production. You can switch between small test runs and large batches with ease. The process stays the same. You can cast multiple items at once in near-final shape. This means less finishing work.

Design Flexibility in Metal Casting

I recommend metal casting, particularly investment casting, for design freedom. You can create parts with complex shapes. You can make thin walls (down to 1/8 inch). You can add intricate internal channels. These designs are impossible or impractical with cutting and welding.

Foundries use this capability to produce parts that are lighter, stronger, and more efficient. There are no weak points from joins or welds.

Material Properties and Customization

Foundries mix metals like iron, aluminum, magnesium, zinc, steel, and copper to create custom alloys. Cast metal parts show uniform strength in all directions. Forging creates strength in specific directions.

You can tailor the chemical and mechanical properties of each part. Adjust for appearance. Adjust for corrosion resistance. Adjust for specific strength needs.

Quality Considerations and Control

Casting is efficient, but it can cause dimensional errors. Shrinkage or warping may occur. You may need extra machining to achieve tight tolerances.

Surface finish quality depends on the casting method. Sand casting often needs extra grinding or polishing to achieve smoothness.

Foundries ensure quality with non-destructive testing. They use X-ray and ultrasonic inspections. These catch defects like porosity or inclusions.

Secondary processes like machining and surface treatments are standard. Castings need these before they are ready for critical applications.

Choosing the Best Application

I suggest casting if you need hundreds or thousands of the same component. Choose it for specialized metals or alloys. It minimizes waste. It makes large parts cost-effective. If you need very high strength, precision, or flawless surface finishes, forging or CNC machining may be better.

In my experience, cast parts are often stronger and more economical than parts made from fabricated, forged, or machined bar stock.