Your metal casting method choice can make or break your manufacturing project. Lost foam casting and investment casting are two very different processes. Engineers, procurement teams, and product designers need to understand these differences.

Both techniques create complex metal parts. But they work in completely different ways. These differences affect dimensional accuracy. They also impact surface finish, production costs, and lead times.

Maybe you’re developing aerospace components. Or industrial machinery parts. Or high-volume automotive applications. You need to match the right process to your needs. Consider material compatibility. Think about mechanical properties. Factor in production volume and quality standards. Getting this right saves you serious time and money. It also prevents major problems later.

Lost Foam Casting Process and Core Characteristics

Lost foam casting uses an expanded polystyrene (EPS) foam pattern instead of traditional cores and molds. Molten metal contacts the pattern and makes it vaporize. The process begins by injecting polystyrene beads into precision aluminum tooling. This tooling sits on a horizontal molding press. Steam heat makes these beads expand and fuse together. The result? A pattern that’s 97.5% air and 2.5% polystyrene.

EPS Pattern Creation and Assembly

Steam expands the beads first. Then water flushing cools the pattern fast before ejection. The foam sections need time to age. This stabilizes dimensional shrinkage. Workers glue individual pattern sections, runners, and risers together. They do this by hand or with automated gluing machines. This forms complete clusters or trees. The target pattern density is 42 kg/m³. This gives you both strength and dimensional accuracy.

These lightweight patterns hit impressive specs. You get linear tolerances of ±0.005 mm/mm. Surface finishes range between 2.5-25 µm. Minimum wall thickness goes down to 2.5 mm. This precision means no draft angles needed. No parting lines. No flash removal.

Ceramic Coating Application

Multiple ceramic slurry layers coat each pattern. Methods include dipping, brushing, spraying, or robotic application. The slurry mixes colloidal silica with fine refractory powders. Each layer needs thorough oven drying. This ensures consistency. The coating must stay porous so gases can escape during pouring. It also needs enough strength to handle sand compaction.

Operators check slurry properties throughout application. Some foundries add optional burn-off or sintering steps in furnaces. This strengthens the refractory shell more.

Sand Packing and Metal Pouring

The coated cluster sits in a flask filled with dry, loose silica sand. No binders needed. Vibration compaction in layers removes voids. This creates dense support. Molten metal pours into the flask. The foam vaporizes on contact. Metal fills the void within the refractory shell. Gases escape through the porous coating and sand. This process works for aluminum, nickel alloys, steel, cast irons, stainless steels, and copper. Parts can weigh 0.5 kg to several tonnes.

Investment Casting Process and Core Characteristics

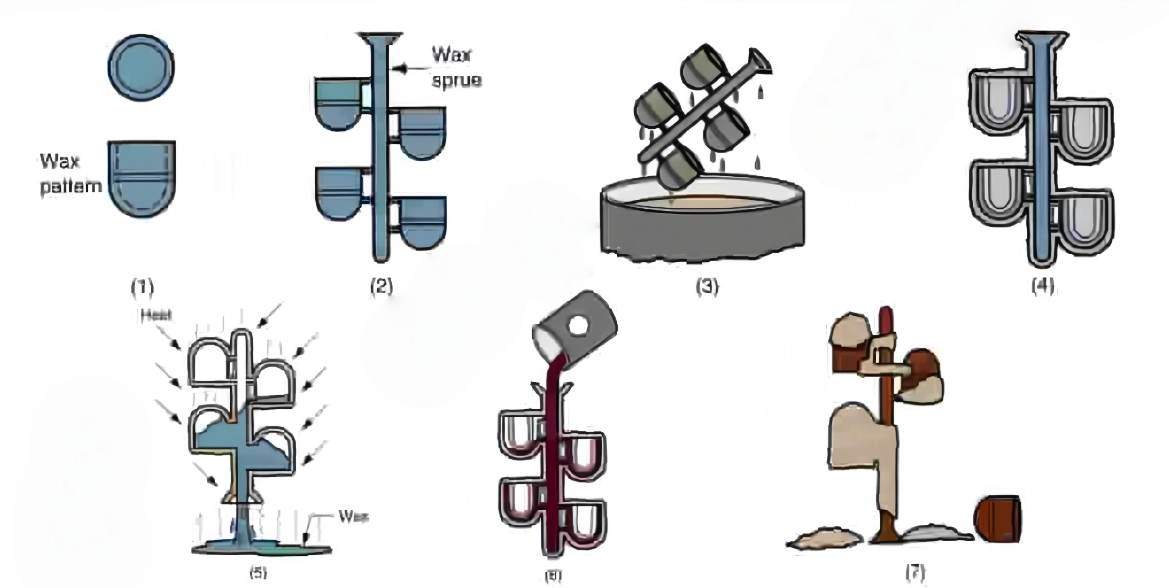

Investment casting builds metal parts through eight precise steps. Each step helps create parts with exact measurements. The process starts with making a master pattern and master die. These tools let you produce the same wax patterns over and over.

Wax Pattern Production and Tree Assembly

Wax patterns are the base of investment casting. Manufacturers inject hot wax into precision dies. The wax cools down. Then you get patterns that copy even tricky shapes. Turbine blades with internal cooling channels work well. Medical implants with organic shapes do too.

Workers attach single wax patterns to a central wax sprue system. This makes a “tree” structure for batch casting. One tree can cast multiple parts at once. You get better production speed and less wasted material.

Ceramic Shell Building and Dewaxing

The ceramic shell builds up through repeated dipping. Each tree dips into ceramic slurry. Then workers coat it with stucco particles. Six to eight layers create strength. Each layer needs 15-30 minutes to dry. Humidity and temperature stay controlled during drying. Total shell building needs 24-36 hours. Each dip cycle takes 1-2 hours.

Dewaxing takes out the wax pattern after the shell is done. Two methods work best:

|

Method |

Temperature/Pressure |

Time Required |

Key Benefit |

|---|---|---|---|

|

Autoclave |

150-200°C, 5-10 bar steam |

15-60 min |

Faster, cleaner removal |

|

Furnace |

200-500°C gradual ramp |

2-4 hrs |

Lower equipment cost |

Metal Pouring and Solidification

Workers preheat the shell to 900-1100°C before pouring metal. This heat keeps the molten metal flowing smooth. Ramp rates stay at 5-10°C/min. This stops thermal shock cracks from forming.

Three pouring methods give you different results:

-

Gravity pouring: 15-50% yield, inverted mold sits in sand bed

-

Pressure casting: Moderate efficiency, outside force helps metal fill the mold

-

Vacuum casting: Up to 95% yield, pulls metal in and drains extra metal back

The full cycle takes 48-72 hours total. This covers wax work (4-8 hrs), shell building (24-36 hrs), dewaxing (1-4 hrs), preheating (2-4 hrs), pouring (1-2 hrs), and post-processing (8-12 hrs).

Precision Specifications

Investment casting gives you tight specs. Dimensional tolerances hit ISO 8062-3 standards at ±0.1-0.5 mm for medium-sized parts. Surface finish reaches Ra 3.2-6.3 µm straight from casting. Part sizes range from few grams to 1000 kg. Minimum hole diameter drops to 1.6 mm with depth under 1.5x diameter. Shrinkage factors adjust 0.5-2% linear based on alloy type. This accounts for combined effects from wax, shell, and metal cooling.

Dimensional Accuracy and Surface Quality Comparison

Investment casting gives you tighter dimensional tolerances than lost foam casting in most production scenarios. Investment casting achieves ±0.1-0.5 mm tolerances under ISO 8062-3 standards for medium-sized parts. Lost foam casting maintains ±0.005 mm/mm linear tolerances. The difference? Each casting process uses different mechanics and material behaviors during solidification.

Surface Finish Performance

Surface quality differs between both methods. Investment casting produces Ra 3.2-6.3 µm surface finish straight from the casting process. This smooth finish comes from the fine ceramic shell contact with molten metal. Lost foam casting ranges between 2.5-25 µm Ra values. The wider variation depends on coating application quality and pattern density control.

The ceramic shell in investment casting creates more uniform surface contact. Lost foam’s refractory coating must stay porous for gas escape. This porosity affects final surface texture. Parts needing high cosmetic standards? Investment casting works better. Components requiring minimal post-processing benefit from investment’s superior finish.

Dimensional Stability Factors

Pattern material behavior impacts final accuracy in different ways. Wax patterns in investment casting shrink in predictable ways during dewaxing. Metal shrinkage calculations adjust 0.5-2% linear based on specific alloys. EPS foam in lost foam vaporizes the moment metal contacts it. This eliminates pattern removal steps but introduces gas-related variables.

Lost foam excels at zero-draft designs. No parting lines or flash means fewer machining operations. Investment casting requires draft angles where shell separation occurs. Complex internal geometries? Investment casting’s wax pattern capabilities handle these better. Turbine blades with internal cooling channels show this advantage.

Both processes meet tight specifications with proper control. Your choice depends on part geometry complexity, production volume requirements, and acceptable post-processing costs.

Mechanical Properties and Metallurgical Differences

Solidification rates reshape how metal crystals form inside your casting. The metallurgical difference between lost foam and investment casting impacts mechanical performance, defect rates, and long-term reliability.

Grain Structure and Solidification Dynamics

Investment casting produces finer equiaxed grains averaging 50-80 µm in diameter. Lost foam casting creates coarser columnar grains ranging 100-200 µm. The difference comes from foam decomposition heat in lost foam processes. This extra thermal energy slows cooling rates. It allows larger crystal structures to develop.

Faster solidification refines grain structure. Dendrite arm spacing drops from 50-100 µm under slow cooling to just 10-20 µm with rapid cooling. This refinement boosts material strength by 20-30%. Faster cooling also limits segregation patterns during solidification. Microsegregation decreases by 15-25% compared to slower processes.

Strength and Performance Metrics

Material performance varies across common casting alloys:

|

Metal/Alloy |

Yield Strength (MPa) |

Tensile Strength (MPa) |

Elongation (%) |

|---|---|---|---|

|

Steel A36 |

250 |

400-550 |

15-23 |

|

Al 6061 |

276 |

310-400 |

25 |

|

Ti-6Al-4V |

830-880 |

900-1200 |

10-15 |

|

SS 304 |

215 |

505-620 |

40-60 |

|

Inconel 625 |

414 |

760-1600 |

30+ |

|

Carbon Steel |

330-580 |

450-570 |

15 |

Strength-to-weight ratios matter for aerospace and automotive applications. Titanium Grade 5 delivers 950 MPa tensile strength at 4.43 g/cm³ density. Aluminum 7075 provides 540 MPa at 2.7 g/cm³. Standard steel offers 570 MPa at 7.85 g/cm³. Aluminum alloys maintain 25% elongation versus 15% for steel. This stretch resistance prevents brittle failure under dynamic loads.

Gas Porosity and Defect Formation

Lost foam casting faces higher gas porosity risks. Foam residue decomposition generates 0.5-2% porosity by volume. Carbon and ash inclusions increase defect rates 5-15% higher than investment casting. Carbon pickup reaches up to 0.1% in some alloys. Aluminum castings show 2-5% defect rates with gas holes measuring 50-200 µm.

Investment casting maintains cleaner metal pours. Porosity stays below 1% volume. Overall defect rates run 1-3% with gas content under 0.5 vol%. The ceramic shell dewaxing process eliminates organic material before metal contact. This prevents contamination at the source.

Lost foam requires 20-30% higher vacuum levels to compensate for gas generation. Investment casting shows 50% lower gas entrapment. Ferrous lost foam castings display 1-3% porosity compared to under 0.5% for non-ferrous investment castings. These metallurgical differences determine which process suits your strength requirements and quality standards.

Cost Structure Breakdown

Lost foam casting and investment casting have very different economics. The biggest upfront difference? Tooling costs.

Lost foam needs aluminum pattern molds for horizontal molding presses. These molds handle the high-temperature steam that expands polystyrene beads. Investment casting uses precision wax injection dies plus a full ceramic shell setup. Pattern mold prices go up with part complexity and surface detail needs. Multi-cavity wax dies for high-volume work need tight tolerances. They also need more frequent maintenance.

Direct Cost Categories

Labor splits the two processes apart. Lost foam offers more automation options during sand compaction and pattern coating. Robotic gluing systems put pattern clusters together with little operator help. Investment casting depends on manual shell building. Technicians hand-dip each tree through six to eight ceramic layers. Drying happens between each application. This needs constant watching. This labor-heavy method raises per-unit costs for small production runs.

Material costs work differently for each process. Lost foam uses dry silica sand (you can reuse it), EPS beads, and refractory coating slurries. Investment casting goes through specialized ceramic slurries, stucco materials, and premium wax blends that burn off during dewaxing. Ceramic shell materials cost 15-25% more than lost foam coatings per surface area. Wax reclamation systems cut waste. But they add equipment costs. Sand in lost foam gets recycled after shakeout. Processing is minimal.

Volume Economics and Break-Even Analysis

Unit costs change based on production volume. Lost foam shows lower per-piece costs at medium volumes (100-5,000 units). This comes from simpler tooling and less labor. Investment casting hits better economics above 10,000 units per year. Ceramic shell labor spreads across larger batches. Fixed costs for investment casting start 40-60% higher. But they drop faster as volume grows.

Quality costs affect total price in different ways. Lost foam has 5-15% higher defect rates. This increases scrap and rework costs. Investment casting’s 1-3% defect rates cut down on inspection and correction costs later. Parts that need heavy machining work better with investment’s tighter as-cast tolerances. This saves 20-35% on secondary operations. Complex shapes make investment casting worth the extra cost. Post-processing on lost foam parts can cost more than the initial price gap between the two methods.

Production Volume and Lead Time Analysis

Lead time differs between lost foam and investment casting. Lost foam casting finishes cycles in 5-10 days for medium-complexity parts. Investment casting needs 48-72 hours just for shell building. Add cooling and post-processing on top of that. Total lead time runs 2-4 weeks for standard orders.

Cycle Time Components

Lost foam moves through faster stages. Pattern creation takes 4-8 hours with steam molding. Coating application and drying need 12-24 hours. Sand packing and pouring take 2-4 hours. Cooling and shakeout add 8-16 hours. Most parts finish under 10 days.

Investment casting takes longer at each step. Wax injection runs 4-8 hours. Shell building takes 24-36 hours across six to eight dip cycles. Each layer needs 15-30 minutes to dry. Dewaxing takes 1-4 hours. This depends on whether you use autoclave or furnace. Preheating requires 2-4 hours at 900-1100°C. Post-processing adds 8-12 hours at minimum.

Volume-Based Production Efficiency

Lost foam works well for medium production runs between 100-5,000 units per year. Setup time drops to 2-3 days for repeat orders. Pattern molds last through multiple cycles. Investment casting performs better above 10,000 units per year. Multi-cavity wax dies cast 20-100 parts per tree. Batch processing spreads shell-building labor across larger batches.

Process standardization boosts on-time delivery. Lost foam hits 91-95% schedule attainment through simple tooling changes. Investment casting reaches 95%+ on-time performance in high-volume work. This happens once shell building rhythm becomes steady. Lead time varies ±2 days for lost foam versus ±3-5 days for investment casting. Ceramic shells react to humidity and temperature changes. This causes the difference.

Picking the Right Casting Method

The casting method you choose makes or breaks your project. Each process works best for different industries and part needs.

Auto Parts and Mass Production

Lost foam casting leads engine block production for aluminum and iron parts. It creates complex internal passages without cores. You skip core setting time and avoid core shift problems. Auto makers producing 5,000-50,000 engine blocks per year save money with lost foam’s simpler tooling. Pattern molds cost 30-40% less than permanent molds for complex shapes.

Investment casting works better for turbocharger wheels and exact drivetrain parts. These parts need Ra 3.2-6.3 µm surface finish and tight dimensions. The smooth surface cuts vibration in high-speed rotating parts. Turbine wheels spinning at 150,000-250,000 RPM can’t handle the rough surface from lost foam casting.

Aerospace and Medical Parts

Investment casting meets strict material standards in aerospace. You get full traceability through controlled ceramic shell chemistry and documented pouring data. Titanium turbine blades and structural fittings need material test reports, non-destructive testing records, and heat treatment certifications. Investment foundries keep these quality systems running.

Medical implants need biocompatible surface finishes and zero contamination risk. Investment casting’s clean dewaxing stops carbon pickup that harms tissue compatibility. Lost foam’s organic breakdown creates variables that don’t meet FDA 21 CFR Part 820 quality requirements for implantable devices.

Shape Complexity Factors

Undercuts and internal cavities divide these two processes. Investment casting creates complex internal cooling channels in turbine blades. Wax patterns come out of dies before ceramic shell building. Lost foam can’t form undercuts over 15-degree angles without damaging the pattern.

Thin ribs below 3 mm thickness work better with investment casting. The fine ceramic shell holds delicate features during metal fill. Lost foam’s porous coating has trouble with sections thinner than 2.5 mm. Gas can’t escape easily. Thin-wall regions get more fill defects.

Large parts over 500 kg cost less with lost foam. Pattern handling stays easy. Investment casting trees get too bulky above this weight. Shell cracking risks go up during handling and preheating.

Material Compatibility and Alloy Selection

Each metal reacts in its own way to chemicals and operating conditions. Investment casting works with more specialty alloys than lost foam casting. The ceramic shell process keeps the chemistry clean as metal solidifies. This is critical for nickel-based superalloys and corrosion-resistant materials.

PREN Values and Pitting Resistance

PREN (Pitting Resistance Equivalent Number) predicts how alloys perform in chloride environments. The formula is: PREN = %Cr + 3.3 × (%Mo + 0.5W) + 16 × %N. Higher numbers mean better resistance.

6-Moly alloys, Alloy 2507, Alloy 625, Alloy C-276, and Alloy 400 deliver top-tier chloride-induced stress corrosion cracking resistance. Investment casting keeps composition control tight. Lost foam shows ±0.3-0.5% variation in alloying elements because of gas interactions.

Superalloy Casting Capabilities

Investment casting excels at high-performance nickel superalloys:

|

Alloy |

Ni (%) |

Cr (%) |

Mo (%) |

Fe (%) |

Key Application |

|---|---|---|---|---|---|

|

625 |

61 |

21.5 |

9 |

— |

Chemical processing equipment |

|

C-276 |

58 |

15.5 |

16 |

— |

Hot sulfuric acid environments |

|

C-22/622 |

56 |

21.5 |

13.5 |

— |

Aggressive chemical exposure |

|

825 |

42 |

21.5 |

3 |

30 |

Dilute sulfuric acid systems |

|

G-30 |

42 |

29.5 |

5 |

15 |

Mixed acid conditions |

Lost foam struggles with these alloys. Carbon absorption throws off the exact chemistry required. Investment casting’s clean dewaxing stops contamination. This keeps the 61% nickel content in Alloy 625 or 58% nickel in C-276 stable throughout the pour.

Aluminum and Titanium Processing

Both processes cast aluminum alloys well. 6061-T6 aluminum shows 4-year compatibility in long-term tests. Pure aluminum and 6Al-4V titanium maintain near-zero pressure rise rates in vacuum applications. Investment casting delivers finer grain structure in titanium. This boosts fatigue strength by 15-20% over lost foam.

Lost foam works great for aluminum engine blocks and structural components. The 97.5% air, 2.5% polystyrene pattern vaporizes clean in aluminum pours. Titanium castings need investment’s controlled atmosphere. 18% Ni maraging steel and AM355 steel show too much pressure rise in some lost foam conditions. Investment casting’s vacuum systems stop this problem.

The Critical Role of Ceramic Filters in Both Processes

You can create a perfect mold. But impurities ruin the pour, and the part fails. Ceramic foam filters become key here. Both casting methods use them for quality. Yet, they handle different challenges to protect the metal’s integrity.

Managing Residue in Lost Foam Casting

Filters do heavy lifting in the lost foam process. Molten metal must replace a solid foam pattern. The foam turns to vapor and leaves residue behind. You get liquid polystyrene and carbon deposits. You must catch this “slag.” Otherwise, it flows into your final part. This leads to bad surface defects or weak spots inside.

Foundries place silicon carbide filters or alumina foam filters in the pouring cup or runner system. They have two jobs. First, they trap foam waste. Second, they calm the metal flow. Less turbulence helps the metal push out the foam. This prevents gas entrapment found in bad gating setups.

Ensuring Absolute Purity in Investment Casting

Investment casting works differently. The wax is already gone. We aren’t fighting pattern residue here. We focus on extreme purity. This counts for aerospace and medical parts. Tiny non-metallic specks can cause a turbine blade or hip implant to fail.

Engineers use high-purity zirconia or alumina filters for “laminar flow.” The filter smooths the molten stream entering the ceramic shell. It stops the metal from splashing or mixing with air.

Conclusion

Your choice between lost foam casting and investment casting depends on your project needs. Consider your production scale and quality standards.

Lost foam casting works great for complex, large parts. Tooling costs stay low. This makes it perfect for low to medium-volume production runs.

Investment casting gives you smooth surfaces and precise dimensions. Aerospace and medical parts need tight tolerances. This method delivers that precision.

Each process has its strengths. Lost foam offers design freedom and saves money on larger parts. Investment casting captures fine details and works with various materials for complex shapes. Match your choice to your production volume, tolerance needs, and budget.