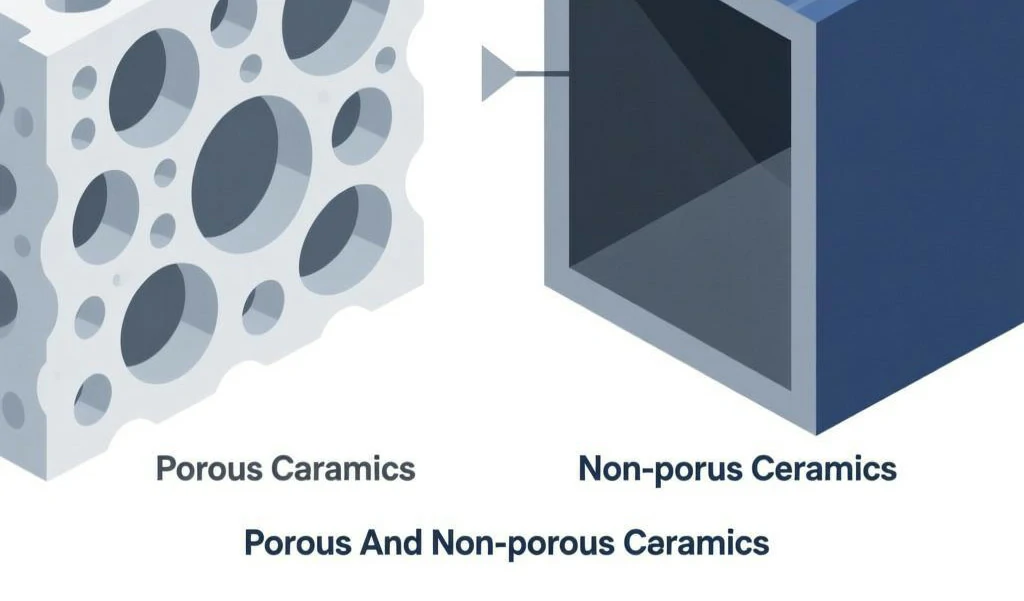

You can tell porous ceramics and non-porous ceramics apart by their pore structure. Pores are tiny holes or spaces in the material.

What Are Porous Ceramics?

Porous ceramics have many tiny holes called pores. These pores are empty spaces filled with air. Some pores connect to each other (open pores). Others stay separate inside the material (closed pores). Many ceramics have both types.

You can control how many pores there are, how big they are, and where they sit. This depends on what you need the ceramic to do. Pore sizes start very small at a few angstroms (Å). They can grow up to several hundred micrometers (μm). This wide range gives porous ceramics many different uses.

- Porosity Levels: These ceramics can have 20%–90% porosity. This makes them much lighter than solid ceramics.

- Water and Gas Absorption: The connected pores let water and gases pass through. The ceramic can soak up and move these fluids.

- Density: Most porous ceramics weigh less than 1.5 g/cm³.

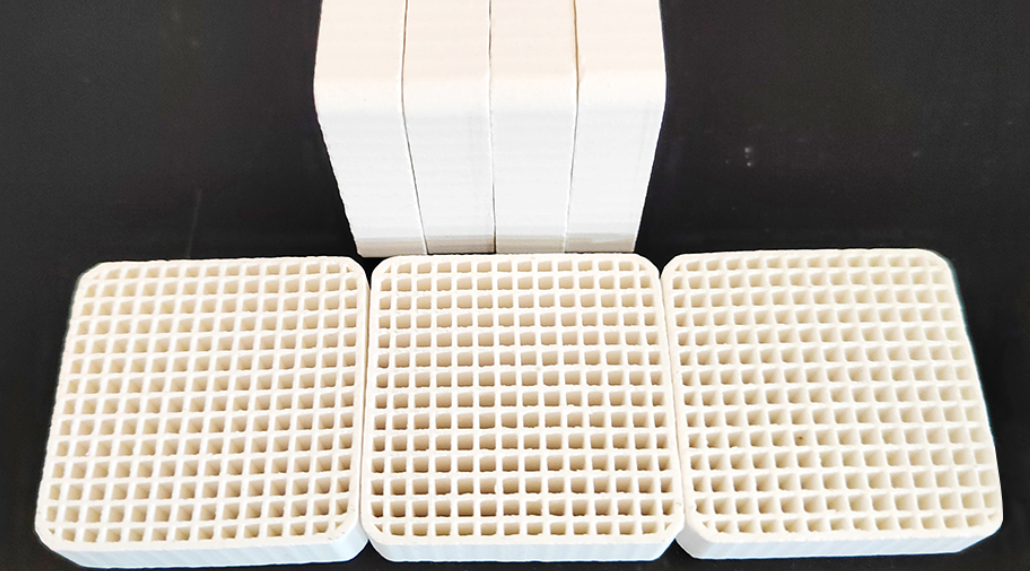

Examples: Alumina filters, catalyst carriers, honeycomb structures, zeolites, diatomaceous earth.

Representative Materials: Alumina, silica, zirconia, zeolite, diatomaceous earth.

What Are Non-Porous Ceramics?

Non-porous ceramics are thick and solid. They have very few pores or none at all. The solid ceramic fills almost all the space. This tight structure stops fluids and gases from getting through.

- Porosity Levels: These ceramics have less than 5% porosity. The structure is very tight and compact.

- Water and Gas Resistance: Water and gases cannot pass through these ceramics.

- Density: Non-porous ceramics like porcelain weigh between 2.3–2.5 g/cm³.

Examples: Porcelain dinnerware, tiles, sanitaryware, stoneware.

Representative Materials: Bone china, glazed pottery, glass ceramics, stoneware, porcelain.

Key Terms in Ceramic Porosity

- Porosity: This measures how many empty spaces exist in a material. It affects how much the material can absorb and how strong it is.

- Open Porosity vs. Closed Porosity: Open pores link together. Closed pores stay separate and isolated.

- Glazed Ceramics: You can coat ceramics with glaze. This coating fills the pores and turns porous ceramics into sealed, non-porous ones. I recommend this for any items that touch food or liquids. The glaze creates a safe, waterproof barrier.

Structural Characteristics of Porous and Non-Porous Ceramics

Porous ceramics and non-porous ceramics have different internal structures. This affects how they perform and where you can use them.

Porous Ceramics: Pore Types and Architecture

Pore Network Structure:

Porous ceramics contain a network of pores. These pores can be:

- Open and connected (fluids and gases can pass through easily)

- Closed and isolated (air gets trapped inside)

- Pores can connect in 3D patterns, form 2D slits, or align in one direction

Porosity Levels and Pore Sizes:

These ceramics often have more than 40% porosity.

I suggest grouping pore sizes this way:

- Micropores: Less than 2 nanometers (examples: zeolites, gels)

- Mesopores: 2–50 nanometers (examples: mesoporous silicas)

- Macropores: Over 50 nanometers. Some reach hundreds of micrometers. Examples include honeycomb ceramics and foams.

Pore Orientation and Mechanical Properties: Pores aligned in one direction create different strengths in different directions. Take unidirectional porous alumina as an example. It reaches 153±30 MPa compressive strength along the axis. But it only achieves 54±14 MPa across the radius. Pores arranged at random offer more uniform strength. But this strength is often lower overall.

Example Structures and Uses: Honeycomb ceramics, inverse opals with colorful 3D pores, ceramic filters, Catalyst supports, medical implant scaffolds

Non-Porous Ceramics: Dense Microstructure

Dense, Compact Structure: Non-porous ceramics have a tight and uniform structure. Porosity stays below 5%. Often it drops below 1%.

- Gaps or voids are almost missing. The material forms a solid, unbroken network.

Material Consistency: This tight structure gives these ceramics high strength and toughness. They resist fluids and gases well.

Common Types: Porcelain, Dense alumina, Stoneware, Zirconia, Tiles

Comparison: Key Structural Features

| Feature | Porous Ceramics | Non-Porous Ceramics |

|---|---|---|

| Pore Content | Abundant; open/closed pores | Minimal; almost none |

| Pore Size | <2 nm to 100+ μm | Negligible (<1% porosity) |

| Microstructure | Often networked or aligned | Dense, uniform, sealed |

| Density | Lower (trapped air) | Much higher (solid) |

| Example Materials | Zeolite, honeycomb, opal | Porcelain, alumina, tiles |

| Mechanical Props | Tunable, often anisotropic | Isotropic, high, brittle |

Physical Properties Driven by Structure

- Weight & Density: Porous ceramics weigh much less. Trapped air inside makes them lighter.

- Thermal & Electrical Properties: Air-filled pores reduce thermal conductivity. They also lower heat capacity compared to dense ceramics.

- Surface Area: High surface area matters most in very porous structures. It boosts performance in filtration, catalysts, and adsorption. Based on my experience, this makes porous ceramics ideal for chemical processes.

Notable Examples

Porous Synthetic Structures:

- Inverse opal ceramics (well-ordered 3D porosity, optical effects)

- Industrial honeycomb ceramics (used in filters, emissions controls)

Natural Porous Materials: Zeolite, Diatomaceous earth

I think the key difference is simple. Does the ceramic’s internal structure hold, connect, or seal off pores? Or does it remove them for maximum tightness? This structural choice determines every property. It affects density, strength, and where you can apply the material.

Physical Properties of Porous vs. Non-Porous Ceramics

Porous and non-porous ceramics have very different physical properties. The main reason? The amount and spread of pores differ greatly. These differences matter in real use—from factory filters to building structures.

Apparent Porosity, Water Absorption, and Density

Porous ceramics have high apparent porosity. This often reaches 40–65% or more. More pores mean more water absorption (25–40%, sometimes up to 40%). The bulk density of these materials is low. It drops even more as porosity goes up.

- Example: Porous mullite ceramics can show porosity over 63 ± 1%. Their water absorption hits 40 ± 1%. Lower-porosity versions have about 40% porosity and 25% water absorption.

Non-porous ceramics have very low apparent porosity. This is below 5% in most cases. Water absorption stays under 1%. Their bulk density is close to the maximum possible for the material. This makes them much heavier and stronger for carrying heavy loads.

Thermal Conductivity and Insulation

More porosity in ceramics means air gets trapped inside the material. This cuts down thermal conductivity and boosts insulation.

- Example: Porous ceramics with high silicon content can have thermal conductivity as low as 0.2–0.6 W/mK.

Non-porous ceramics trap less air. They have much higher thermal conductivity (from 2–40 W/mK, based on what they’re made of). So they don’t insulate well.

Mechanical Strength and Fracture Toughness

Porous ceramics see a sharp drop in mechanical strength and fracture toughness as porosity goes up.

- Example: Porous hydroxyapatite (used in medicine) has high porosity and pore sizes (100–600 μm). This helps bone grow into it. But the mechanical strength drops fast. This makes them poor choices for bearing weight.

- Fact: Mechanical strength falls fast as porosity rises. Fracture toughness also drops a lot.

Dense, non-porous ceramics keep better strength and toughness.

- Example: Dense hydroxyapatite ceramics show Young’s modulus of 35–120 MPa. That’s many times stronger than porous versions.

- They also handle brittle breaks and wear much better.

Permeability, Chemical Resistance, and Electrical Properties

Porous ceramics: High open porosity gives them great permeability. Gases and liquids can pass through. I suggest these for filters, scaffolds, or insulation panels.

Non-porous ceramics: Almost no permeability. This maximizes resistance to chemical attack. They also keep stable electrical conduction or insulation (based on material structure and makeup).

Typical Applications

Porous ceramics: I recommend these for filters, catalyst supports, bone scaffolds, insulation panels, and ceramic foams (for sound and heat absorption).

Non-porous ceramics: These work well for tiles, sanitaryware, kitchenware, engineering structural parts, and electric insulators.

How Porous and Non-Porous Ceramics Work Differently

Porous and non-porous ceramics work in different ways. Their inner structures make them unique. I suggest learning these differences to pick the right ceramic for your needs.

Key Features

Permeability and Adsorption

Porous ceramics work great for high permeability and adsorption tasks. They have open pores that let fluids and gases pass through. This makes them useful as filters, catalyst supports, adsorbents, and water treatment membranes.

Non-porous ceramics have dense surfaces. They block water and air. I recommend them for electronics, medical implants, and exterior tiles where you need a sealed surface.

Surface Area and Sound Absorption

Porous ceramics have large surface areas. Their pore structures create this. They absorb sound well. They also perform better in chemical adsorption.

Non-porous ceramics have smaller surface areas. They don’t absorb much sound. They focus on dense packing. This gives them durability and strength.

Weight and Thermal Insulation

Porous ceramics are lighter. Air gets trapped in their pores. This lowers density and weight. They also conduct less heat. This makes them good insulators. You can use porous ceramics as radiation shields or thermal insulation panels.

Non-porous ceramics are denser. They conduct more heat. They offer less insulation but more mechanical strength.

Where Each Type Works Best

Use Cases for Porous Ceramics:

- Fluid and Gas Filtration – great for chemical filters, water treatment membranes, and catalyst carriers.

- Thermal Shields – used as insulation where you need low heat transfer.

- Adsorbents – zeolite and diatomaceous earth work well for adsorption in chemical processing.

- Sound Absorption – perfect for spaces that need noise reduction.

Use Cases for Non-Porous Ceramics:

- Chemical and Water-Resistant Surfaces – good for porcelain dinnerware, sanitaryware, and medical devices that need a sealed barrier.

- Electrical Insulation – used in insulators and substrates for electronic devices.

- Durable Structural Components – ideal for tiles, bearings, and parts that face moisture or chemicals.

Based on my experience, these differences help you choose between porous and non-porous ceramics. Think about what matters most for your project. Do you need permeability, adsorption, and insulation? Or do you need a sealed surface and strength? Your answer will guide your choice.

Applications of Porous and Non-Porous Ceramics

Porous ceramics and non-porous ceramics serve different purposes. Their internal structure, pore size, and air flow ability shape these uses.

Key Applications of Porous Ceramics

1. Filtration and Environmental Technologies

– I recommend porous ceramics for exhaust gas filtration, air purification, dust collection, and drinking water purification.

– Their high surface area and connected pores filter and absorb materials well.

– Examples include zeolite filters, diatomaceous earth, and honeycomb ceramic filters.

2. Industrial and Manufacturing Uses

– Porous ceramics are vital in vacuum packing for electronics and semiconductors. They hold wafers securely because air passes through them and they stay rigid.

– I suggest them for thermal insulation. They work well in thermal barrier coatings, burner linings, and insulating layers.

– Here’s real data: Unidirectional porous YSZ ceramics reach thermal conductivities as low as 0.06–0.1 W/(mK) across pore channels and 0.2–0.54 W/(mK) along them.

– They work as catalyst supports and direct catalysts. Their 3D pore networks boost catalytic reach and activity.

– They act as adsorbents and control humidity. You’ll find them in humidity-control tiles and chemical adsorbents.

– Buildings use them for sound absorption. Their air flow and pore structure make this possible.

3. Medical and Biological Fields

– Doctors use these ceramics in artificial bone and dental implants.

– Porous hydroxyapatite and apatite ceramics help bone grow inward. Their pore sizes can be adjusted to improve bone integration.

– Common uses include scaffolds, bone substitutes, and artificial teeth.

4. Structural and Specialty Uses

– Lightweight structures: High-porosity ceramics weigh less than resin sponges. Yet they hold weights up to 10,000 times their own weight.

– Photonic crystals: Ordered porous ceramics (like inverse opal structures) have special optical properties. I recommend them for photonics applications.

5. Technical Highlights and Data

– Pore sizes span from a few angstroms to several hundred micrometers.

– Engineers design porosity and pore structure for specific jobs. This drives performance in filtration, insulation, catalysis, or bio-integration.

– You can polish porous ceramics for precision handling of delicate parts. Think microelectronics and semiconductor wafers.

Typical Uses of Non-Porous Ceramics

People choose non-porous ceramics when they need no air or water passage and smooth, dense finishes:

- Pottery, tiles, and insulators (they resist moisture and air)

- Sanitaryware, kitchenware, porcelain dinnerware

They don’t work for filtration, absorption, or medical scaffolding. Their lack of open internal pores limits air flow and functional surface area.

Based on my experience, controlling pore sizes, structure, and overall porosity lets porous ceramics excel in filtration, catalysis, medical implants, and insulation. Non-porous ceramics remain essential where you need a dense, sealed surface.

Common Examples of Porous and Non-Porous Ceramics

Porous and non-porous ceramics have clear representatives. These show their unique features and real-world uses. I recommend learning these common types. They help you identify where each one works best.

Typical Porous Ceramic Examples

- Zeolites: These are aluminosilicate minerals. They can be natural or synthetic. People prize them for their network of connected tiny pores. Their pore sizes range from 0.3 to 1.0 nm. You’ll see them in filters and as catalysts. They work great for precise molecular screening.

- Activated Carbon: Makers produce this from carbon-based materials. They use physical or chemical activation. Activated carbons have a specific surface area of up to 4000 m²/g. This makes them excellent for adsorption and water purification.

- Pillared Clays: These are modified clays. They have tiny metal oxide columns between layers. They offer strong adsorption power. People use them for pollution control and catalytic processes.

- Inverse Opal Structures: These are patterned SiO₂ ceramics. Their 3D ordered porous networks serve advanced uses. Think photonic crystals and special filters.

- Porous SiC, Si₃N₄, ZrC: Ceramics like silicon carbide and nitride can be made with custom pores. Engineers choose them for tough filtration jobs. They also work as catalyst supports and high-temperature insulation.

- Macroporous Ceramics: These have pores over 50 nanometers wide. Makers use foaming, sintering, or templating methods. Some even use wood as a mold. This creates lightweight or absorbent ceramics. In some cases, porosity can exceed 80% by volume.

- Representative Applications: I’ve seen these materials serve many purposes. They work as catalysts and catalyst bases. They support tissue engineering scaffolds. You’ll find them as adsorption membranes, water filters, and air filters. They also make good soundproof or heat insulating panels.

Common Non-Porous Ceramic Examples

- Porcelain: This is a classic dense ceramic. It has all pores sealed or isolated. Open porosity is often less than 1%. Porcelain stands out for its strength, water resistance, and smooth surfaces. People use it in tiles, toilet ware, and table settings. It also works as electrical insulators.

- Technical Ceramics (Alumina, Zirconia, Silicon Nitride): Engineers make these as dense and tough as they can. They have no open pores. I suggest these for cutting tools, bearings, and high-demand mechanical components. They also fit engine parts and medical implants.

- Glazed Tiles and Bricks: Standard ceramic bricks and tiles become non-porous after treatment. Makers apply a glassy glaze and fire them at high temperatures. The result is a water-proof, easy-to-clean surface. I like these for bathrooms, kitchens, and exteriors.

These examples show how pore size and structure control matters. Ceramics can filter molecules or resist heavy loads and frequent cleaning. Your choice depends on your needs. Do you need permeability and high surface area? Or do you need impermeability and strength? Based on my experience, understanding these differences helps you pick the right ceramic for your project.

Summary of Core Differences: Porous Ceramics vs Non-Porous Ceramics

Porous ceramics and non-porous ceramics show very different properties. The main reason? Their internal pore structures. These differences impact their strength, weight, price, function, and best uses.

Core Structural Differences and SEO Keyword Overview

Porous Ceramics:

These have interconnected or closed pores. We classify the pores as macroporous (>50 nm), mesoporous (2–50 nm), or microporous (<2 nm). This structure creates high permeability. I recommend porous ceramics for filters, membranes, and catalyst supports.

- Open porosity ranges from 0.9% (with some forming agents) up to 22.96%. The amount depends on how much pore-forming agent you use. Common agents include starch, PMMA, polypropylene, or sawdust.

- Closed porosity falls between 7.59–9.77%.

- Bulk density is low: 1.06–2.17 g/cm³. Lower density means a lower price per unit.

- Water absorption increases as open porosity increases. It can reach up to 14.11%.

- Thermal conductivity is low: 0.2–1.0 W/mK. This makes them ideal for thermal insulation.

- Production methods: Organic pore formers give you control. Using more pore formers lowers the cost and density. But it raises water permeability and surface area.

- SEM imaging shows that more pores appear with organic pore formers. This increases performance and permeability.

- Example uses: gas separation, ceramic membrane filtration, adsorbents, insulation, and specialist catalyst supports. For example, porous yttria-stabilized zirconia works well in tough chemical environments.

Non-Porous Ceramics:

These have minimal to no open pores. Hot-pressed types have almost zero open pores. Closed porosity stays under 2%. Some less dense types reach up to 5%.

- Bulk density is much higher. Alumina reaches up to 3.94 g/cm³.

- Water absorption is near zero (<0.1%). This is critical for sanitaryware or electronics.

- Thermal conductivity is high. I suggest non-porous ceramics for efficient heat transfer or high mechanical strength.

- Strength: These ceramics have much higher mechanical robustness. They have no voids or defects.

- Prices may be higher. But the performance is essential for demanding environments.

- Densification techniques (hot-pressing, high-temperature sintering) create dense, strong ceramics. They absorb little to no water.

- Example uses: electrical insulators, wear-resistant components, precision structural parts, and medical devices. For example, dense alumina in bearings and cutting tools. Machinable dense ceramics in electronics.

Quick Property Comparison Table

| Property | Porous Ceramics (Keywords: high porosity, low density, filters) | Non-Porous Ceramics (Keywords: dense, high strength, sanitaryware) |

|---|---|---|

| Pore Size/Porosity | 0.9–22.96%+ (tunable; macroporous/mesoporous/microporous) | 0–2% (closed), negligible open pores |

| Bulk Density (g/cm³) | 1.06–2.17 | 3.94 (Alumina); 2.52 (Machinable) |

| Water Absorption | 0.41–14.11% | <0.1% |

| Thermal Conductivity (W/mK) | 0.2–1.0 (insulating) | High (efficient heat transfer) |

| Mechanical Strength | Moderate to low | High |

| Uses | Filters, membranes, insulation, catalyst supports | Insulators, wear parts, medical/structural ceramics |