Your coffee mug and a spacecraft heat shield—both ceramics. Strange, right? They come from different worlds.

Traditional ceramics use what nature gives us. Clay, feldspar, and quartz come straight from the ground. Advanced ceramics? Engineers build them at the molecular level. They use man-made powders with precision measured in nanometers. Same category, but they play different games.

The real kicker? Push these materials to their limits and see what happens.

Raw Materials

Raw materials form the base of any ceramic product. Traditional and advanced ceramics differ most here.

Traditional Ceramics: Nature’s Building Blocks

Traditional ceramics use three primary natural minerals pulled straight from earth deposits:

-

Clay – Gives the plasticity needed for wet molding and shaping

-

Feldspar – Works as a flux to lower sintering temperatures and boost material density

-

Quartz – Adjusts thermal expansion and adds mechanical strength

These natural materials need little prep work. Manufacturers pull clay, feldspar, and quartz straight from mining sites. They use them for wet molding like grouting, slurry molding, or plastic mud molding. After shaping, the products go through high-temperature sintering. No complex chemical treatments needed.

Simplicity has its costs. Natural minerals contain impurities and varying compositions. Clay from different areas produces ceramics with different textures and properties. This variation makes quality control tough. Performance consistency suffers.

Advanced Ceramics: Engineered Precision

Advanced ceramics work differently. They use man-made powders with controlled purity levels:

-

Aluminium oxide (Al₂O₃) – The most common advanced ceramic, prized for low cost, hard surface, high-temperature resistance, and electrical insulation

-

Silicon carbide (SiC) – Known for extreme hardness and thermal conductivity

-

Silicon nitride (Si₃N₄) – Offers top fracture toughness and thermal shock resistance

-

Zirconium oxide (ZrO₂) – Gives unmatched strength and wear resistance

-

Beryllium oxide (BeO) – Delivers excellent thermal management

Manual control over ingredient ratios changes everything. Scientists calculate exact compositions. They create refined powders with minimal impurities. This allows exact engineering of chemical structures. You get uniform microstructures with controlled porosity and grain size down to the nanometer scale.

Traditional ceramics accept what nature gives. Advanced ceramics build materials from the molecular level up.

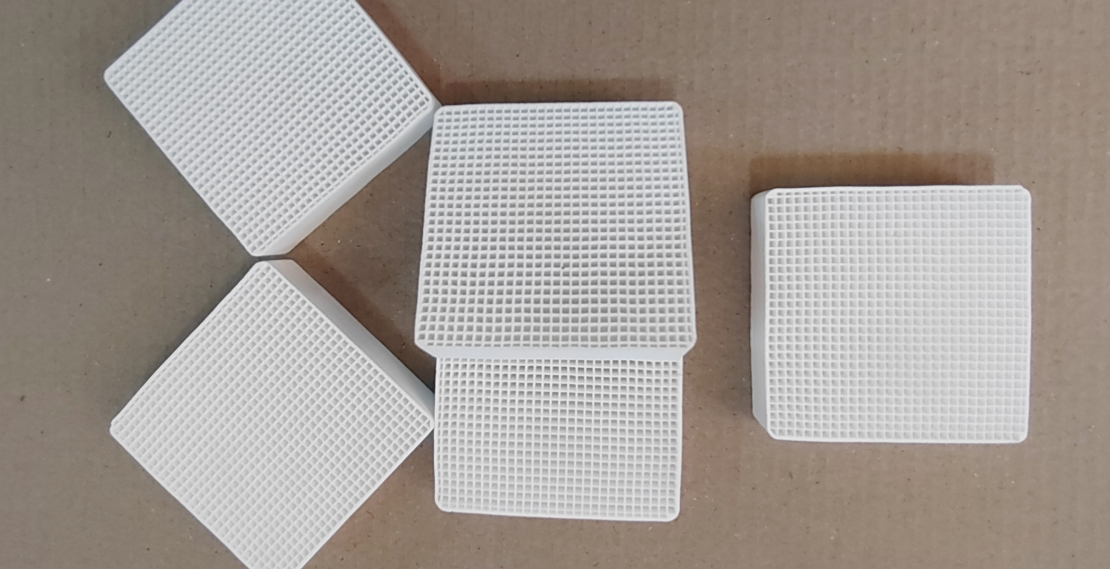

Microstructure

The internal structure of ceramic materials decides how they perform in real use. Look at traditional and advanced ceramics under a microscope. You’ll see very different structures.

Traditional Ceramics: Nature’s Irregular Blueprint

Traditional ceramics have single crystalline phase structures. The lattice arrangements are simple. But simple doesn’t mean good.

Natural clay and minerals create granular, porous structures through the material. These pores are weak points. Cracks begin at these empty spaces. They spread through weak spots between grains.

The problems add up:

-

Many defects and impurities spread through the structure at random

-

Uneven grain distribution changes based on clay source and mix

-

Changing porosity levels make quality control almost impossible

-

Weak bonds between particles mean the material breaks under stress

This uneven structure explains why traditional ceramic tiles crack when hit. It’s also why pottery breaks so fast.

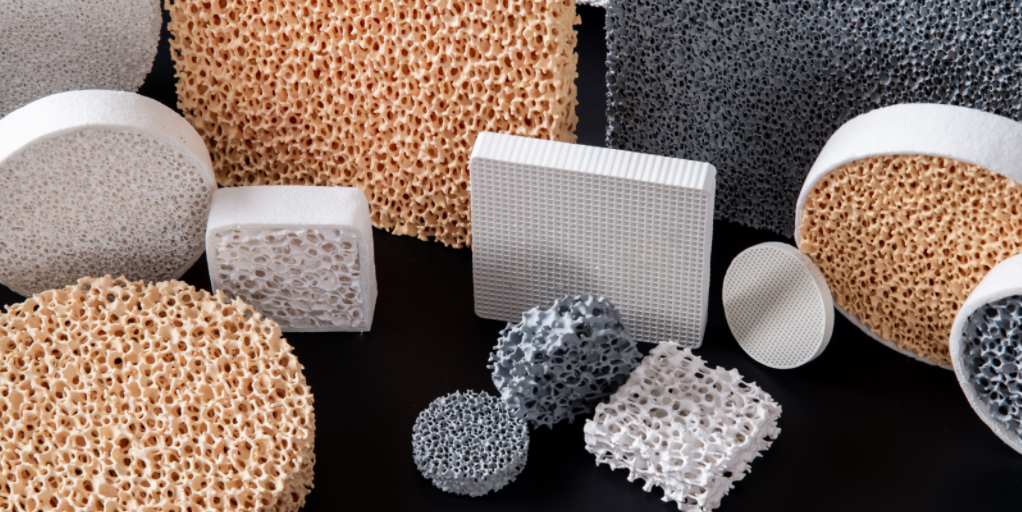

Advanced Ceramics: Engineered Precision Structures

Advanced ceramics show multi-phase structures or nano-sized grains made for specific jobs. Pure ingredients and controlled production create dense, uniform designs with very few flaws.

Key structural benefits:

-

Strong bonds between grains stop cracks from spreading

-

Controlled pores down to nanometer size remove random gaps

-

Pure chemical structures (over 99% pure) behave in predictable ways

-

Fine, uniform grain size spreads stress across the material

Ceramic-metal mixes go beyond this. Add small metal phases to alumina. This changes how particles bond and boosts toughness a lot. The metal bits absorb impact energy. Without them, pure ceramic would shatter.

This microscopic quality shows in performance. You get top mechanical strength, resistance to heat shock, and long life in extreme conditions. Traditional ceramics can’t match this.

Bonding Mechanisms

Atomic connections decide if a ceramic shatters on impact or absorbs the shock and survives.

Traditional Ceramics: Strong but Stiff Bonds

Traditional ceramics use ionic and covalent bonds between atoms. These connections create stiff, locked structures throughout the material.

Ionic bonds form when atoms swap electrons. Clay minerals develop these electric pulls during firing. Covalent bonds share electrons between atoms. Both bond types resist breaking under normal conditions.

The strength has a big weakness: zero flex. Stress hits the material. These stiff atomic connections can’t bend or adjust. The bonds stay fixed until they break. Traditional ceramics fail fast. They don’t bend like metals. Hit a ceramic tile hard enough and it breaks into pieces. The bond structure has no middle ground between whole and broken.

Advanced Ceramics: Smart Bond Design

Advanced ceramics change the bonding game through planned chemical changes:

-

Metal bonds added to the mix – Metal elements added during production create more flexible atomic connections next to the stiff ionic and covalent bonds

-

Controlled bond ratios – Scientists adjust the balance between ionic and covalent bonding to cut down on brittleness

-

Specific element additions – Small amounts of nickel, titanium, or other metals change how particles connect in alumina and other ceramic bases

These bonding upgrades create materials that mix top-level strength with real toughness. The metal bonds absorb impact energy that would crack pure ceramic. Fracture resistance jumps up. Advanced ceramics bend a bit before breaking. This gives them survival benefits in aerospace parts, medical implants, and factory cutting tools.

Manufacturing Process

Production methods create the biggest gap between traditional and advanced ceramics. Traditional methods use old techniques. Advanced methods need precision equipment and multiple processing stages.

Traditional Ceramics: Time-Tested Simplicity

Traditional ceramic making follows a simple three-step process that has changed little in hundreds of years:

Step 1: Raw Material Preparation

Makers pull natural minerals straight from mines. Clay, feldspar, and quartz need little processing. Workers mix these materials in basic ratios based on what they want to make.

Step 2: Wet Molding

The mixed materials go through one of three shaping methods:

– Grouting – Pour liquid slurry into molds for complex shapes

– Slurry molding – Use semi-liquid clay for uniform products

– Plastic mud molding – Shape soft clay by hand or simple machines

Step 3: High-Temperature Sintering

Shaped products go into kilns for firing. Temperatures reach 1,000-1,400°C. Heat fuses particles together. Natural chemical reactions create the final ceramic structure.

That’s it. No extra operations. No precision machining. Products come out of the kiln ready for use or basic glazing. The whole production cycle takes days, not weeks.

This simplicity keeps costs low. But precision suffers. Natural mineral variations mean each batch differs a bit. Quality control depends on experience, not measurement.

Advanced Ceramics: Engineered Complexity

Advanced ceramic production needs four specialized stages with strict technical controls:

Stage 1: Powder Synthesis

Raw materials go through chemical processing to create ultra-fine powders. Scientists control particle size down to micrometers or nanometers. Purity levels exceed 99%. This stage alone takes weeks of processing and testing.

Stage 2: Precision Molding

Forget wet clay shaping. Advanced ceramics use high-tech forming methods:

– Isostatic pressing – Apply equal pressure from all directions to create uniform density

– Hot isostatic pressing – Combine heat and pressure for maximum compaction

– Injection molding – Force ceramic slurry into precision molds for complex shapes

Each method needs specialized equipment that costs hundreds of thousands of dollars.

Stage 3: Controlled Sintering

Sintering temperatures climb to 1,400-2,000°C. The exact temperature depends on the material. But temperature is just one factor. Makers control:

– Heating rates – Slow temperature increases prevent thermal shock

– Atmosphere makeup – Oxygen, nitrogen, or vacuum environments affect bonding

– Pressure use – Some materials need heat and compression at the same time

– Cooling curves – Controlled cooling prevents cracks

Stage 4: Post-Processing

Advanced materials always need finishing work. You don’t get this with traditional ceramics:

– Precision grinding – Diamond tools machine surfaces to exact sizes

– Lapping and polishing – Get mirror finishes for optical or medical uses

– Laser cutting – Create complex patterns without mechanical stress

– Surface coating – Add protective or functional layers

This final stage takes up 30-40% of total production time. A single aerospace part might need weeks of post-processing to meet specs.

The production cycle runs from weeks to months. Costs are 10-100 times higher than traditional ceramics. But the performance gains make the investment worth it for critical uses.

Performance Comparison

Put traditional and advanced ceramics side by side in real tests. The performance gap shows up fast across every measurement.

Mechanical Strength: From Brittle to Resilient

Traditional ceramics deliver high strength numbers on paper. The catch? They fail without warning. Hit them hard and they shatter into pieces. Zero toughness means zero forgiveness under impact.

Advanced ceramics flip this weakness. Multi-phase structures and ceramic-metal composites absorb shock that would destroy traditional materials. Fracture resistance jumps 300-500% in typical uses. Alumina ceramics with added metal elements bend a bit before breaking. This toughness keeps aerospace parts intact during extreme vibration and heat cycles.

Thermal Performance: Good Versus Exceptional

Both ceramic types handle heat. But performance under heat stress separates them.

Traditional ceramics resist high heat well enough for kilns and furnaces. Heat expansion creates problems. Temperature swings cause uneven expansion. Cracks form. Products fail.

Advanced ceramics solve this through lower heat expansion rates and better heat transfer. Silicon carbide parts in combustion engines survive temperature changes that would crack traditional ceramics in seconds. Zirconium oxide maintains strength above 2,000°C while moving heat away from critical areas.

Functional Versatility: Single Use Versus Multi-Purpose

Traditional ceramics do one job: insulation. Their electrical properties stop there. No conductivity options. No magnetic capabilities. No optical functions.

Advanced ceramics deliver multiple functional properties in single materials. Need electrical conductivity? Adjust the chemical makeup. Want optical clarity? Control the grain structure. Need magnetic response? Add specific metallic phases. This flexibility makes advanced ceramics irreplaceable in electronics, medical devices, and defense systems.

Wear Resistance: Durable to Near-Indestructible

Traditional ceramics wear down over time in normal conditions. Factory cutting tools made from traditional ceramics need replacement every few weeks.

Advanced ceramics extend tool life 10-20 times longer. Silicon nitride cutting edges stay sharp through thousands of operations. Silicon carbide seals in chemical pumps last years without measurable wear. The dense, uniform structure prevents surface breakdown that destroys traditional ceramics.

Bottom line: Advanced ceramics cost more upfront. Performance gains justify every dollar in demanding uses where traditional ceramics can’t survive.

Key Material Properties

Material properties decide if a ceramic survives or fails in its job. Traditional and advanced ceramics share some basics but differ greatly in critical performance areas.

Strength and Toughness: The Brittleness Problem

Traditional ceramics deliver high compressive strength under steady loads. Press down on a ceramic tile and it holds firm. But sudden impact changes everything. These materials are brittle with low fracture toughness. They can’t absorb shock energy. Stress builds up at tiny flaws. Cracks spread through the material fast. You won’t see the damage coming.

Advanced ceramics fix this problem through microstructural engineering. Toughness increases by 3-5 times compared to traditional versions. Zirconia ceramics resist crack spread that would destroy clay-based products right away. Multi-phase structures and ceramic-metal composites create energy-absorbing paths. Stress hits the material. The force spreads across multiple phases instead of going through weak points.

Thermal Behavior: Managing Heat and Expansion

Both ceramic families handle high temperatures. Traditional ceramics work fine in kilns and furnaces at normal heat levels. Problems show up during thermal cycling. Natural materials expand at different rates as they heat up. Cool them down and contraction rates vary across the structure. Temperature changes happen again and again. Internal stress builds up. This leads to cracking.

Advanced ceramics solve this with controlled thermal expansion and better heat conductivity. Silicon carbide parts in combustion engines survive thousands of heat cycles without breaking down. Beryllium oxide moves heat faster than most metals. It stays structurally sound above 2,000°C. This thermal stability makes advanced ceramics irreplaceable in extreme environments. Traditional ceramics fail in these same conditions within hours.

Functional Versatility: Beyond Insulation

Traditional ceramics work as electrical insulators. That’s it. No conductivity. No magnetic response. No optical properties. One job, one capability.

Advanced ceramics deliver multiple functional properties through chemical composition control. Adjust the formula. You get electrical conductivity for electronic substrates. Add specific elements. You create piezoelectric responses for sensors. Engineer the grain structure. You achieve optical transparency for laser components. Single materials now provide conductivity, semiconductor behavior, magnetic functions, catalytic activity, and biological compatibility.

This functional flexibility explains why advanced ceramics dominate electronics, medical devices, and precision instruments. Traditional ceramics can’t compete. Applications need more than simple insulation.

Applications

Traditional and advanced ceramics serve different markets. Each type matches specific needs.

Traditional Ceramics: Everyday Reliability

Traditional ceramics dominate construction and household markets. You don’t need extreme performance here:

Building Materials

– Bricks and tiles – Foundation materials for homes and businesses

– Ceramic pipes – Water systems in buildings

– Roofing materials – Weather-resistant coverage for structures

These products work because they cost less to make. They last years under normal use. A ceramic tile floor handles foot traffic just fine. It won’t survive rocket engine heat, but it doesn’t need to.

Consumer Products

– Dishes and kitchenware – Plates, bowls, mugs for meals

– Decorative pottery – Vases, sculptures, ornamental pieces

– Bathroom fixtures – Sinks, toilets, bathtubs

Industrial Insulation

Traditional ceramics still meet basic insulation needs. They resist electricity naturally. They tolerate heat well. This works for furnace linings, kiln structures, and standard thermal barriers. The performance bar stays modest.

Advanced Ceramics: High-Tech Dominance

Advanced ceramics dominate critical applications. Metal alloys and polymers fail here. These materials deliver properties you can’t replace across tough industries:

Aerospace and Defense

Silicon nitride turbine blades survive heat above 1,400°C. They spin at extreme speeds without breaking down. Zirconia coating shields rocket nozzles from exhaust gases. Those gases would melt steel in seconds. Military armor plates use boron carbide ceramics. They stop armor-piercing rounds. Plus, they weigh 60% less than steel options.

Automotive Engineering

Silicon carbide parts in diesel engines take combustion heat. They cut friction losses too. Ceramic brake discs on performance cars resist fade. They work through hard stops from 200+ km/h over and over. Oxygen sensors use zirconia ceramics. They function at 600°C for 150,000+ kilometers without fail.

Electronics and Semiconductors

Alumina substrates form the base for 70% of electronic circuits. These boards block electricity. They also pull heat away from chips. Piezoelectric ceramics in smartphones turn pressure into electrical signals. This creates touch sensitivity and vibration feedback.

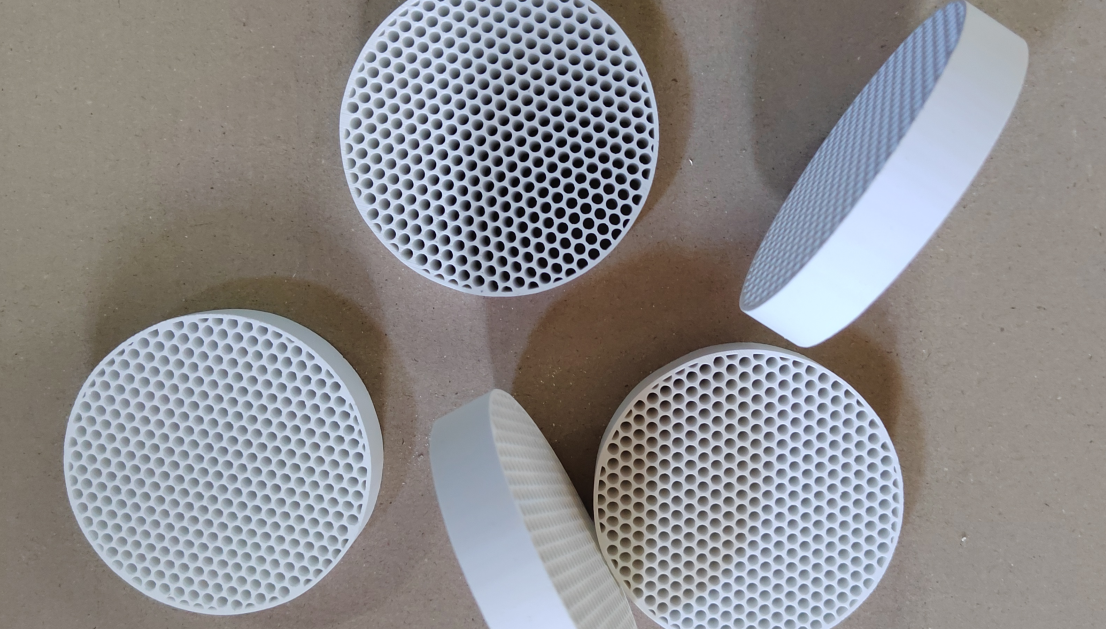

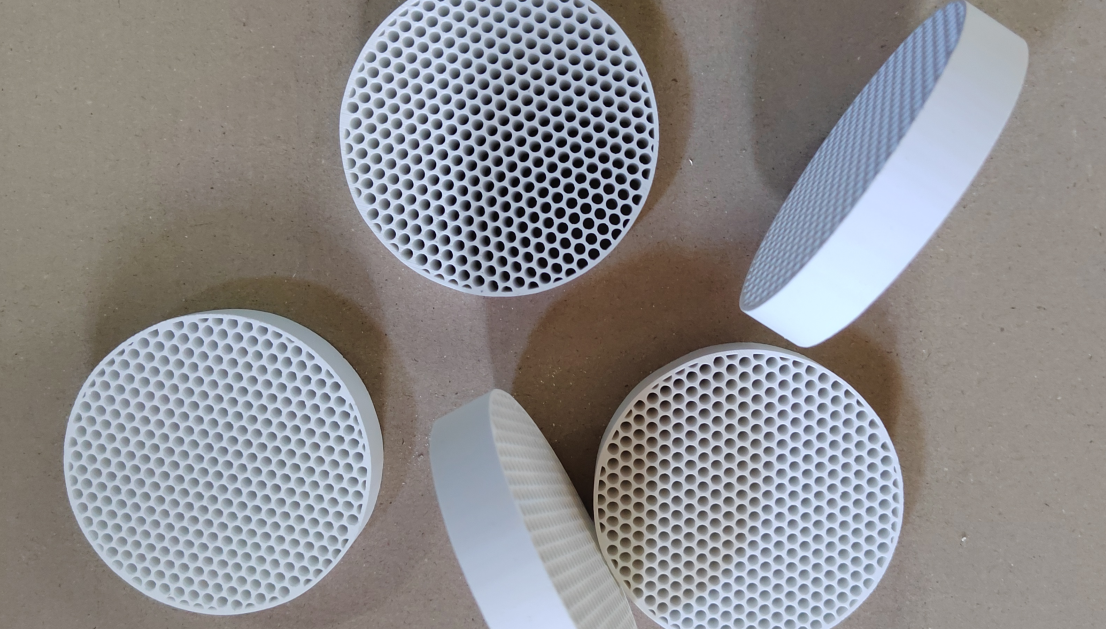

Chemical and Petroleum Processing

Silicon carbide seals in chemical pumps resist acids. Those acids eat through metal parts in weeks. Ceramic catalyst supports in oil refineries hold their structure at 900°C. They handle corrosive sulfur compounds without breaking down. Alumina tubes contain chemical reactions. They keep products pure.

Medical Devices

Zirconia dental implants match bone strength. They avoid metal allergies. Alumina hip joints outlast metal versions by 5-10 years. Body fluids cause zero corrosion. Biocompatible ceramics bond with human tissue. They don’t trigger immune responses.

Nuclear and Energy

Uranium oxide fuel pellets hold up under radiation. That same radiation destroys most materials. Silicon carbide cladding contains nuclear fuel. It resists both heat and radiation damage.

The gap between these types is clear. Traditional ceramics cover everyday needs. Advanced ceramics solve problems nothing else can fix. Performance needs decide which one gets the job.