From my experience, industrial liquid filtration is a key step in many manufacturing fields. It’s a method we use to separate solids from liquids. We push a mixture of fluid and solid materials through a special filter. This action produces a clean liquid, which we call the filtrate. The solid material left behind is known as the filter cake.

How I’ve Seen Industrial Liquid Filtration Work

The basic idea is simple: you pass a liquid through a filter that is designed to catch solid particles. I’ve seen how effective this can be. The removal rate can be anywhere from 90% to over 99%. I believe this depends on the type of filter you use, the size of the particles, and the overall system design. These industrial filters are quite versatile. They can handle liquids with very few solids, as low as a few hundred parts per million. They can also process thick mixtures, like slurries with more than 30% solids by mass.

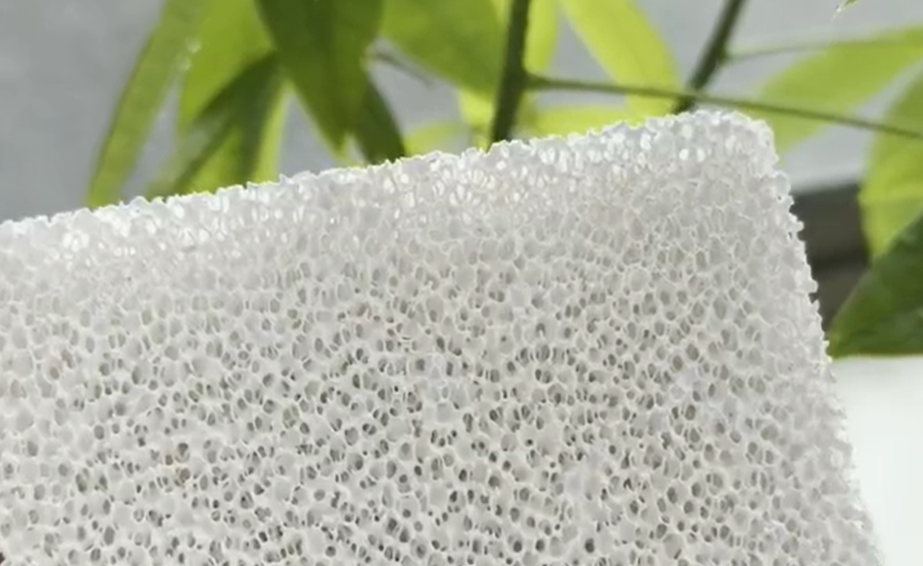

I think Filter Media play a huge part in this process: – The filter’s pore sizes can vary a lot. Some are large, like in simple gravel beds which have openings of several millimeters. Others are incredibly small for very fine filtering, with membrane filters having pores between 0.1 and 0.001 microns. – When we choose a filter material, we have to consider what the job needs. The choice between polymer, metal, or ceramic materials depends on factors like chemical and temperature resistance.

The Main Types of Industrial Filtration

- Pressure Filtration: I recommend this for tougher jobs. This method uses pressure that is higher than the normal atmosphere. You’ll find equipment like filter presses are common in mining and chemical work. They can reach pressures of 7-15 bar (100-225 psi) and typically form a solid cake that is 25–50 mm thick.

- Vacuum Filtration: This approach uses suction to create a pressure below the normal atmosphere (0.3–0.7 bar or 4–10 psi). I’ve often seen technologies like rotary drum or disk filters used, especially in paper-making and for processing minerals.

- Mechanical Filtration: This is a more direct method. Liquid flows through a medium such as sand, gravel, or a mesh screen. This simply captures the bigger particles.

Key Industrial Applications I’ve Encountered

I know that industrial liquid filtration is used in many different sectors. For instance: – water treatment: It is essential for producing safe drinking water. We use it to remove sand, silt, and organic materials. It is also used to help clean municipal wastewater. – Chemical Manufacturing: In this area, filtration purifies chemical products, recovers valuable catalysts, and dries out thick slurries. Based on my experience with pharmaceuticals, these filters must be kept sterile and are cleaned regularly. – Food & Beverage: This process helps clarify products like syrups, edible oils, beer, and wine. A technique I often see is pre-coat filtration, which uses materials like diatomaceous earth to aid the process.

The Steps in a Typical Filtration Process

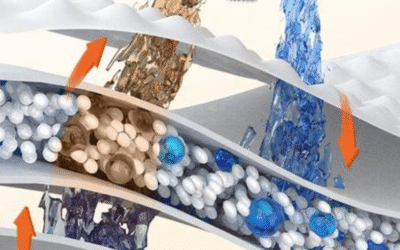

Let me walk you through the key steps I’ve seen in a standard filter press cycle:

1. First, you feed the slurry mix into the filter.

2. Next, you apply pressure. This separates the solid from the liquid and forms the filter cake.

3. You might then wash the cake to get more product from it or to improve its purity.

4. After that, you dry the cake using an air blow or by squeezing it.

5. Finally, you discharge the cake and clean the filter so it’s ready for the next cycle.

My Take on Industry Data and Important Trends

Here are a few industry facts that I find interesting: – The global market for industrial filtration is worth more than $30 billion USD each year. This figure covers both equipment and consumable parts. – In my experience, a durable filter cloth used in a demanding application can last for 500 to 1,000 cycles. – I suggest you look into automated cleaning systems. Features like spray rinses and backwashes help keep a filter efficient and make it last longer.

A Practical Example

Let me give you a real-world example. A mining site could use a filter press with 100 chambers. This setup can handle 10,000 liters of waste slurry in one cycle. I find it impressive that it can produce a 3-ton filter cake with less than 20% moisture in under an hour.

Based on my professional opinion, these filtration technologies are vital for modern businesses. They help companies meet regulations, get back valuable resources, and reduce waste.

Core Steps in the Industrial Liquid Filtration Process

Based on my experience, the liquid filter is a process with several clear steps. Each step helps improve how well the filter works, makes the product cleaner, and ensures the whole system lasts longer.

Material Loading and Initial Screening

We start by feeding the liquid into the system. This liquid contains solid particles. We use pumps or gravity to do this.

Next, we use coarse screens or strainers to remove large debris. I find that a mesh size between 1 to 100 microns works well here. This step is important; it keeps the other filters from getting clogged.

Example: For city water systems, I’ve seen this first screening remove things like sticks or leaves larger than 1 mm.

Coagulation and Flocculation (For Fine Particulate Removal)

If the liquid has very fine particles floating in it, we add chemicals called coagulants. These chemicals help the particles clump together into tiny “microflocs.”

Then, we gently mix the liquid. This process, which I call flocculation, helps the microflocs form larger, visible clumps. We might add polymers to help this along.

I’ve seen this process lower water cloudiness from 10 NTU to under 1 NTU. This is extremely important for making medicines or treating city water.

Example: We might add alum or polymers in a city water plant or a pharmaceutical factory.

Pre-Filtration / Clarification

The liquid then goes through a coarser filter. I suggest using filter bags or cartridges with a 1–100 micron rating. This step removes any larger particles we missed.

Example: From my work in the chemical industry, I know that 10-micron melt-blown filter cartridges are common for this stage.

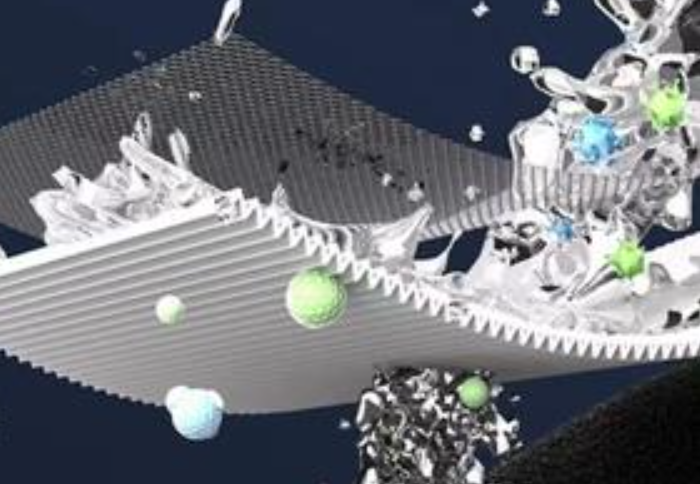

Main Filtration (Core Separation Step)

Now the clearer liquid is ready for the main filter. I recommend one of three main methods:

- Depth filtration: We use materials like sand or carbon. These trap particles inside the filter media.

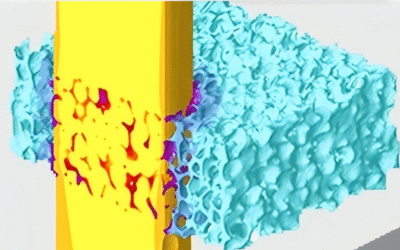

- Surface filtration: We use filters like membrane sheets. They catch particles on their surface. I find this works well for microfiltration.

- Membrane filtration: We use advanced membranes with very small pores, down to 0.2 microns. These are excellent for removing bacteria.

Performance: Sand filters can handle 6–12 gpm/ft²; I’ve seen pharma-grade membranes remove over 99.99% of bacteria.

Materials: We can choose from woven cloth, special polymers, black walnut shell, and other modern composites.

Post-Filtration / Polishing

Sometimes, a product needs to be extremely pure or sterile. For this, I recommend a final “polishing” step. We use submicron membrane filters, some as small as 0.1 micron.

Example: In my experience, pharmaceutical companies use 0.22 micron membranes. This makes sure injectable medicines are free of bacteria and pyrogens.

Disinfection / Microbial Stabilization (As Required)

After filtering, some industries need to disinfect the liquid. We can use chemicals like chlorine (at 1–4 mg/L), UV light, or ozone. This process kills or disables microbes and viruses.

Example: I know that water treatment plants add chlorine after filtration to make sure the water is safe to drink.

Cleaning and Sterilization of Filtration Equipment

We must clean and disinfect the filters and equipment on a set schedule. We can use chemical solutions, heat, or radiation. This prevents contamination and keeps the process reliable.

In my work with food and pharma companies, I’ve seen cleaning happen after every single batch. Sometimes it’s every few hours, depending on how much solid material is being filtered.

Key Parameters and Industry Data

We must closely watch the pressure drop across the filters. I recommend replacing filters when the pressure drop reaches 0.5 to 2.0 bar.

High-efficiency filters, such as HEPA, can remove 99.97% of particles that are 0.3 microns or larger.

Processing speeds will change based on the method. I find microfiltration processes 50–200 liters/hour/m², while ultrafiltration handles 10–50 liters/hour/m², depending on the type and load.

Industrial Liquid Filtration Step Sequence

Material loading → Screening → Coagulation/Flocculation (if needed) → Pre-filtration → Main filtration → Post-filtration → Disinfection (if needed) → Cleaning/Sterilization

Summary

Based on my experience in this field, I’ve learned something important. Industrial liquid filtration is not just a technical process. I feel it is the foundation that helps many industries succeed.

I see its impact all the time. For example, when clean water flows from a treatment plant or a drug company makes life-saving medicine. I am reminded that these simple separation techniques protect our health and our environment. I love its simple elegance. You push liquid through the correct water filter. This process changes dirty streams into pure, valuable products. These products are what our modern world runs on.