Honeycomb filters show up in many industries today. You’ll find them in molten metal foundries and air purification systems. Their unique cellular structure raises common questions. Why are they designed this way? What makes them work so well?

Seen these distinctive filters and wondered about their purpose? Many people have the same questions.

The honeycomb shape isn’t just for looks. It’s an engineering solution that gives better filtration performance across tough applications.

You might be specifying filters for industrial processes. Or maybe you’re troubleshooting contamination issues. Perhaps you’re just curious about filtration technology. Either way, knowing what honeycomb filters do helps you make better choices. Understanding their design matters too.

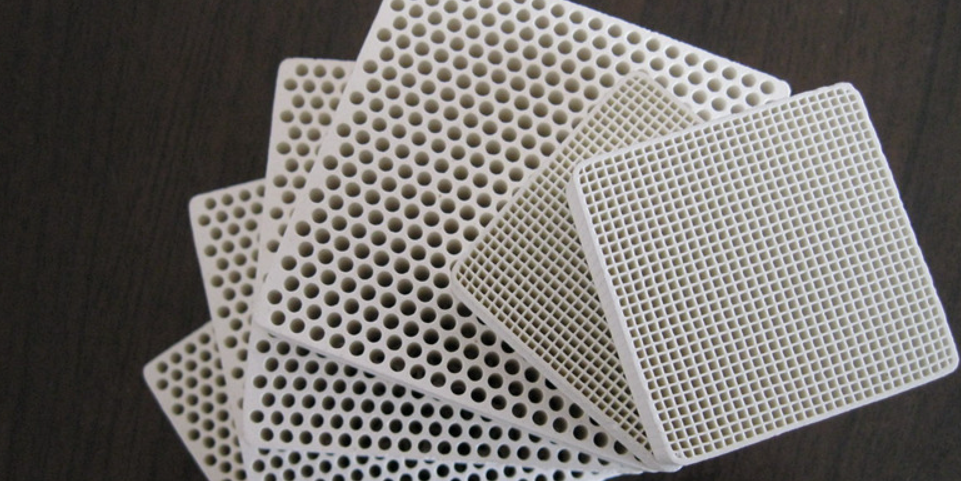

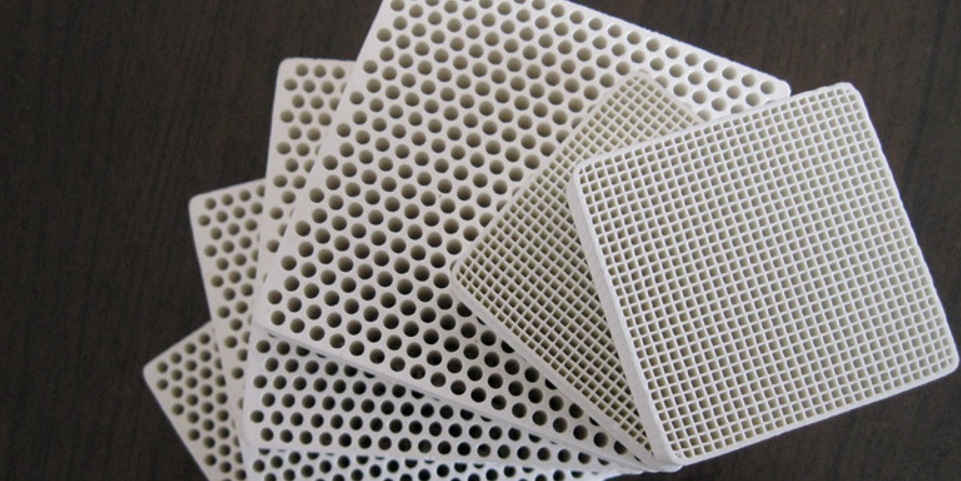

What Is a Honeycomb Filter (Definition and Structure)

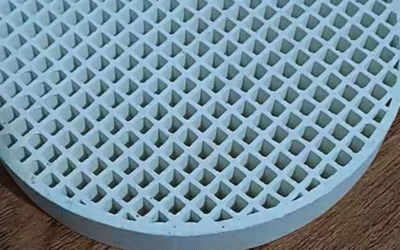

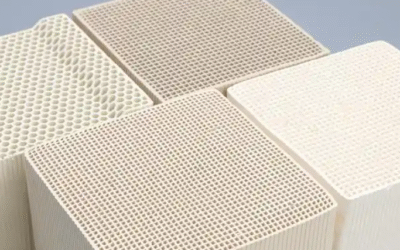

A honeycomb filter is a special filtration device. It’s built from thin, porous walls that connect to form many parallel cells. These cells run from the inlet face to the outlet face. The key feature? Alternate cells are sealed in a checkerboard pattern at opposite ends. Fluid must pass through the porous walls themselves. It can’t just flow straight through open channels.

The Unique Cellular Architecture

The structure uses hexagonal cells arranged in a matrix of connected channels. Each cell is hollow and open-ended. But here’s the key difference: every cell closes at either the inlet or outlet end.

How the checkered pattern works:

– Inlet cells: Open at the front face, sealed at the back

– Outlet cells: Sealed at the front face, open at the back

– Result: Fluid enters through open inlet cells. It hits the sealed end. Then it crosses through porous walls into nearby outlet cells to exit.

The walls are thin and porous. They have connected open porosity. They stay the same thickness across the entire structure. This narrow wall size matters for cross-flow filtration. Walls are shared between nearby inlet and outlet cells. Every square millimeter gets used for filtration.

The end faces can be circular or custom-shaped. The checkered plugging pattern ensures 100% wall use. Traditional filters can’t do this.

Material Types and Their Designs

Different jobs need different materials. But the honeycomb structure stays the same:

|

Material |

Structure Design |

Key Specifications |

|---|---|---|

|

Extruded Ceramic (cordierite, SiC) |

Hexagonal channels in solid matrix; resists heat and chemicals |

Handles molten metal heat; gives large surface area for even flow |

|

Activated Carbon Fiber (ACF) |

Honeycomb-arranged fibers in paper filter form |

Gives maximum surface area for gas treatment |

|

Glass/Silica Fiberglass |

Woven mesh with coating; honeycomb-like channels |

Resists heat up to 1620°C (silica thick type), 900°C (carbonized version) |

Geometry settings define performance: cell density, cell area, aspect ratio, wall thickness, pore size, and porosity volume. Makers adjust these specs. It depends if you’re filtering molten aluminum or cleaning exhaust gases.

Structure Comparison: Honeycomb vs. Traditional Filters

The design differences between honeycomb and traditional filters affect performance:

|

Feature |

Honeycomb Filter |

Foam Filter |

Fiber/Granular Filter |

|---|---|---|---|

|

Channel Organization |

Parallel, straight hexagonal grid (ordered layout) |

Random, winding pores (disordered structure) |

Loose fibers or granules; no fixed channels |

|

Flow Path |

Even, wall-crossing via controlled porosity |

Uneven paths through foam matrix |

Surface capture or depth packing with changing resistance |

|

Wall Utilization |

100% (all thin walls shared between inlet/outlet cells) |

Partial surface contact |

Layered structure, less efficient per volume |

Foam filters create random flow paths. Contaminants get trapped in a maze-like structure. Fiber and granular filters use surface capture or depth packing. Neither design gets as much surface contact as the honeycomb’s shared-wall system.

Primary Purpose 1: Molten Metal Filtration in Foundries

Foundries process millions of tons of molten metal every year. Each pour carries hidden threats: solid bits, oxides, slag particles, and non-metal debris. These pollutants range from 1 to 100 micrometers in size. They’re small enough to hide in the melt. But they’re large enough to ruin final castings. Honeycomb ceramic filters stop these pollutants before they reach the mold.

How Filtration Works Across Different Metals

The filtration method changes based on what you’re casting. Ceramic foam filters use deep bed filtration for most jobs. Solid bits get trapped inside the porous structure as molten metal flows through. Alumina particles in steel melts stick to square-celled alumina ceramic filters. The filters hold them through surface grip. Fiberglass Filters catch oxides, slag, and non-metal bits during aluminum filtering.

Each metal needs specific filter materials and temperature limits:

|

Metal |

Typical Filter Material |

Maximum Temperature |

|---|---|---|

|

Aluminum |

Ceramic foam, fiberglass meshes |

750-800°C |

|

Steel |

Alumina ceramic (monolithic extruded) |

Up to 1700°C |

|

Iron |

Ceramic foam |

Up to 1500°C |

|

Copper alloy |

Ceramic foam |

Up to 1200°C |

Impact on Casting Quality and Production

Clean metal means better parts. Filtration cuts scrap rates and rework costs. Foundries get cleaner melts with better strength. Tensile strength goes up. Ductility goes up. For steel casting, removing alumina bits before refining protects later processes.

The scale matters more than you might think. Based on 1999 U.S. casting production estimates, iron (gray and ductile) dominated at 60-72% of total tonnage. Steel accounted for 11%. Aluminum made up 8% but showed the fastest growth at 4-8% each year. Copper alloys held 4% market share.

Sand casting remains the primary method—60% of U.S. castings by weight use green sand molds. Filters sit in the sprue and riser paths. They catch debris and slag during bottom-up filling. This setup stops polluted material from reaching the mold cavity.

The Energy and Environmental Context

Gray and ductile iron foundries alone consumed 154 trillion BTUs per year. Melting operations lost 39% of energy to waste. These plants recycled 13.3 million tons of scrap metal each year—85% of their feedstock came from recycled sources. Good filtration protects this massive energy investment. It stops pollution from turning recycled metal into unusable waste.

Primary Purpose 2: Gas and Air Purification

Activated carbon honeycomb filters lead industrial gas treatment systems around the world. The global air purification market hit $31.4 billion USD in 2026. Experts expect it to reach $48.2 billion by 2033—that’s 6.3% growth each year. This growth comes from rising needs to remove VOCs, dangerous gases, and tiny airborne particles. These systems clean air in factories, office buildings, and homes.

Industrial and Commercial Gas Treatment Systems

Factories use honeycomb filters to catch toxic fumes, chemical vapors, and combustion waste. Food processing plants use them to clear out odors and organic compounds. Metal shops depend on cartridge and carbon filters to trap dust, welding fumes, and toxic particles. The industrial air purifier segment grew from $5.70 billion in 2024. It’s expected to hit $16.47 billion by 2035—a 10.12% growth rate each year. Stricter workplace air quality rules push this growth.

Hospitals, office buildings, shopping malls, hotels, schools, and theaters all need clean air. These places keep indoor air quality (IAQ) high with hybrid filter stacks. The systems catch particles and absorb gases at the same time. Countries with bad particulate matter pollution adopt these systems fast. Bangladesh recorded PM2.5 levels of 79.9 µg/m³ in 2024. Pakistan hit 73.7 µg/m³. India reached 54.4 µg/m³. These numbers far exceed WHO safety limits. So businesses in these areas invest heavily in IAQ systems.

Technology Integration and Market Leadership

Modern purification systems stack HEPA filters with activated carbon honeycomb structures. HEPA units catch particles as small as 0.3 micrometers. Carbon honeycomb channels soak up gas molecules and VOCs through tiny porous surfaces. Advanced setups now use AI-based IAQ analytics. These systems predict pollution spikes. They adjust filter strength in real time.

Big manufacturers—Camfil, Trane, Daikin, IQAir, Honeywell—build special HEPA-carbon combos for VOC removal. China holds 38.7% of global market share. New GB 36893-2024 standards require strict energy efficiency and performance benchmarks for all air purifiers sold after October 2025. The U.S. market alone reached $4.55 billion in 2024. It’s growing at 7.2% per year through 2030.

Primary Purpose 3: Industrial Liquid and Gas Stream Cleaning

Honeycomb filters remove harmful particles from industrial liquid and gas pipelines. Chemical plants, refineries, and natural gas facilities use these systems to strip out particles, droplets, and debris from their process streams. Suspended solids cause big problems. They corrode equipment, block valves, and can shut down entire production lines.

Gas Stream Purification Performance

Wet scrubber systems use honeycomb structures with different collection rates. Venturi scrubbers deliver over 99% particle removal—the top performance level. Simple spray towers capture 40-60% of contaminants. Bigger particles work better. Spray towers remove 90% of particles larger than 5 micrometers. They catch 60-80% of 3-5 micrometer particles. Below 3 micrometers, efficiency drops under 50%.

Packed tower setups reach 95% efficiency for particles above 5 micrometers. Submicron particles are tougher. These systems capture 60-75%. Tray towers handle high gas flow rates from 1,000 to 75,000 scfm. They achieve 97% removal for particles exceeding 5 micrometers. Mist eliminators target liquid droplets. They remove 90-99% from gas streams.

Venturi scrubbers work best with liquid-to-gas ratios between 7-10 gallons per 1,000 cubic feet. Ratios above 10 gallons raise operating costs. You won’t see better performance. Industries using these systems include boilers, incinerators, metals processing, chemical production, fertilizer plants, lime kilns, foundries, and pigment manufacturing.

Liquid Pipeline and Process Stream Cleaning

Natural gas pipelines carrying wet gas or condensate need cleaning every few months. Honeycomb filters and coalescer systems remove built-up liquids and solids. This protects downstream equipment from damage. Nitrogen purging works with filtration. It drives out oxygen, corrosion particles, and moisture. The inert nitrogen stream stops combustion risks. It also pushes contaminants through collection points.

Special flushing operations mix chemicals—water, isopropyl alcohol, diesel, methanol—with mechanical pigging. Engineers pick solutions based on how deep they penetrate, pH balance, and safe handling needs.

Hydrocyclones separate solids in process water systems. Target performance keeps suspended solids below 100 ppm in overflow streams. Systems hitting under 25 ppm reduce equipment wear. These units run without moving parts. Influent density and solids changes can affect how well they separate.

Coalescer pads capture aerosols across many size ranges. Single-pad systems remove 4-6 micron droplets. Multi-pad designs with blotting stages capture particles as small as 1-3 microns. This precision is critical in chemical synthesis and drug production. Trace contamination can ruin entire product batches.

The gas scavenger market shows growing demand for stream cleaning tech. Market value reached $650 million USD in 2024. Projections show growth to $1.2 billion by 2030—an 8% compound annual growth rate. Stricter process purity standards drive this growth.

Types of Honeycomb Filters by Material

The material you pick decides where honeycomb filters work best. Engineers select ceramic composites, activated carbon, or specialized alloys. This choice depends on temperature limits, chemical exposure, and contamination types. Each material fits different industrial needs.

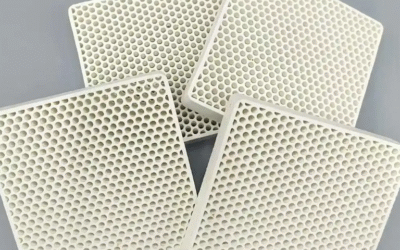

Extruded Ceramic Honeycomb Filters

Ceramic materials lead the high-temperature filtration market. The honeycomb ceramic filter industry hit $1.2 billion USD in 2024. Analysts expect it to reach $2.3 billion by 2033—a 7.5% annual increase. Stricter emissions rules and hybrid vehicle adoption fuel this growth. The broader honeycomb ceramics market grew from $2.547 billion in 2024 to a projected $4.442 billion by 2032, keeping 7.2% growth each year.

Mullite-Based Filters

Mullite offers top-tier thermal shock resistance for foundry work. Manufacturing temperatures go beyond 1500°C during sintering. This builds a stable structure that won’t crack. It also prevents slag particles from dropping into molten metal streams. The structure keeps flow rates steady even as inclusion loads pile up on filter surfaces. Room temperature strength guards filters during handling, shipping, and installation. This cuts down breakage losses in the chain from factory to site.

Cordierite Structures

Automotive exhaust systems use cordierite honeycomb substrates. This material supports catalytic converters and diesel particulate filters (DPF) in passenger vehicles. Flow-through cordierite substrates make up a major segment, growing at 5.0% each year from 2024 to 2030. You’ll find these in automotive, industrial machinery, and maritime diesel systems. Cordierite controls thermal expansion while providing enough mechanical strength for high-vibration settings.

Silicon Carbide (SiC) Applications

Silicon carbide tackles extreme conditions that other ceramics can’t handle. Diesel particulate filter substrates need SiC for operating temperatures above 1200°C. The material fights off chemical attack from acidic exhaust compounds. SiC holds its structure under rapid temperature cycling. This matters for regeneration cycles that burn off trapped soot.

Alumina for General Metallurgy

Alumina filters handle broad metallurgical and general filtration jobs. The material stands up to metal flow impact during pouring. Chemical stability stops composition changes from acidic or alkaline melts. Performance tests prove alumina honeycomb filters beat foam and fiber options. They make less turbulence in metal streams. Plus, they remove contaminants better.

Leading manufacturers include NGK Insulators, Applied Ceramics, Saint-Gobain, Porvair, Sefu Ceramic, and DAIDO STEEL. These companies provide ceramic honeycomb systems to foundries, automotive plants, and aerospace facilities across the globe.

Key Advantages Over Other Filter Types

Honeycomb filters beat foam, fiber, and granular designs in four key performance areas. The structured channels deliver real benefits that traditional filters can’t match. This is especially true in high-heat and high-contamination settings.

Superior Heat Resistance Under Extreme Conditions

Ceramic honeycomb filters stay intact at temperatures above 1700°C. Foam filters start to break down above 1200°C. Fiber types fail even faster. The parallel-wall design spreads heat stress across the whole structure. This stops hot spots from forming. Hot spots crack traditional filters during molten metal pours. Foundries see 40-60% longer service life compared to foam options for filtering aluminum and steel alloys.

Controlled Flow with Low Pressure Drop

The straight-channel design creates predictable flow paths. Fluid passes through thin porous walls. It doesn’t navigate random foam mazes. This cuts pressure drop by 25-35% compared to foam filters at the same filtration level. Lower resistance means faster processing speeds. You also use less pump energy. Chemical plants using honeycomb gas scrubbers reduce operating energy costs by up to 20% versus packed bed systems.

Maximum Surface Use

Every internal wall works as active filtration surface. The shared-wall setup between inlet and outlet cells achieves close to 100% material use. Foam filters waste internal space in dead zones. Flow bypasses pores in these areas. Fiber media clump in uneven patterns. This creates channeling paths. Honeycomb structures get rid of these problems. Tests show 50-70% more effective surface area per unit volume compared to foam designs of the same external size.

Strong Build and Easy Handling

Extruded ceramic walls resist mechanical impact during installation and operation. The rigid grid won’t collapse under pressure spikes or vibration. Foam filters compress and deform. Fiber beds settle and compact over time. Honeycomb filters ship intact. They install without special support frames. Foundries report breakage rates below 2% versus 8-12% for foam ceramic filters during transport and setup.

Limits and Selection Factors

No filter technology solves every problem. Honeycomb filters work well in specific cases. But material limits, costs, and use boundaries decide where they fit best. Know these limits to avoid expensive mistakes. This helps you pick the right filter for your real working conditions.

Material Temperature and Chemical Limits

Each honeycomb material has strict limits. Cordierite substrates handle car exhaust up to 1200°C. They fail in molten steel work needing 1700°C resistance. Silicon carbide handles more heat. But it costs 3-5 times more than mullite options. Chemical contact creates similar trade-offs. Alumina filters break down in strong acidic slag. Zirconia-based composites keep their structure in these conditions.

Activated carbon honeycomb structures lose their power above 60°C. They break down past 150°C. Hot industrial gas needs ceramic options. This removes carbon’s strong VOC removal benefits. Moisture matters too. Wet gas fills carbon filters fast. Service life drops from months to weeks in humid chemical plants.

Flow Rate and Pressure Drop Limits

Honeycomb filters work best at low-to-medium flow rates. Their structured channels keep smooth flow patterns. High-speed uses create rough flow. This cuts filter performance and raises pressure drop sharply. Foundries pouring molten aluminum over 200 kg/minute often see filter failure. Too many particles fill the pores faster than the filter can handle.

Pressure issues limit use in closed systems with tight pressure needs. Adding a honeycomb unit may need pump upgrades or slower processes. These changes can cancel out filter benefits. Engineers must check system curves carefully. Retrofit setups in current pipelines sometimes find too little pressure room after startup problems.

Cost Analysis for Your Use

Ceramic honeycomb filters cost $50-$300 per unit. Size and material affect the price. Large foundries justify this cost through less waste and better quality. Small custom casting shops face cost problems. Filter costs hit 15-20% of per-run material costs. Foam options at $8-$25 each work better despite shorter life and lower performance.

How often you replace filters affects costs. Heavy dirt loads need filter changes each day. Disposable options cost less than cleanable honeycomb types. Chemical plants with harsh streams figure total costs. This includes disposal fees for dangerous used filters. Ceramic units handle tough cleaning and reuse. But special handling needs add labor costs that simple filter swaps avoid.

How to Choose

Pick honeycomb filters for these needs:

-

High heat stability over 1000°C where plastic and fiber options melt

-

Exact dirt control for strict quality needs in aerospace or medical casting

-

Long service times in remote spots where replacing filters is hard

-

Chemical resistance to acids, bases, or solvents that eat standard filters

-

Steady pressure drop across changing dirt loads for stable process control

Skip honeycomb designs for these cases:

-

Fast flow changes create pressure spikes that break ceramic

-

Very fine particle catch below 1 micron needs deep loading that blocks structured channels fast

-

Often filter changes make throwaway options cheaper

-

Tight spaces stop installation of rigid solid structures

-

Low working temperatures let cheaper plastic options work just as well

Mix honeycomb filters with other tech for best results. Pre-filters using coarse mesh screens take out large debris. This stops early blocking of honeycomb pores. Post-filter polish with activated carbon cartridges catches leftover VOCs. Honeycomb units handle bulk particle loads first. Hybrid systems balance upfront costs and working efficiency. They cover the full range of dirt your process makes.

Conclusion

Honeycomb filters earned their place as industrial workhorses for good reason. Their cellular structure delivers better filtration across molten metal casting, emissions control, and chemical processing. Plus, they maintain excellent flow rates and strength that traditional filters can’t match.

What is the purpose of a honeycomb filter? It solves your toughest filtration challenges. You need contamination control, high-temperature resistance, and long service life—this filter handles all three. Eliminating slag in aluminum foundries? Scrubbing VOCs from industrial exhaust? Purifying catalyst streams in chemical plants? Honeycomb technology gives you proven results with real ROI.

The right honeycomb filter depends on your specific needs. Consider material compatibility, pore size, thermal conditions, and flow characteristics. Precision matters, so skip generic filtration. Work with your filtration engineering team to find the best ceramic, metallic, or composite honeycomb setup for your process and sustainability goals. Your product quality depends on it. So does your operational efficiency.