Your lost foam casting project’s success depends on one key choice: the right foam material.

Most foundries stick to standard options. But knowing what type of foam is used for lost foam casting can change your final product’s quality, size accuracy, and production costs.

Aerospace parts need exact precision at the micron level. Automotive parts need cost efficiency at high volumes. Different foam materials give you different benefits and trade-offs.

You might work with complex shapes, high-heat alloys, or strict size requirements. This guide covers the three main foam types used in modern foundries—EPS, XPS, and PMMA. You’ll also learn the selection rules that separate good castings from expensive mistakes.

New foam technologies are changing the industry. You’ll find out which support materials can improve your Casting process from pattern creation to final metal hardening.

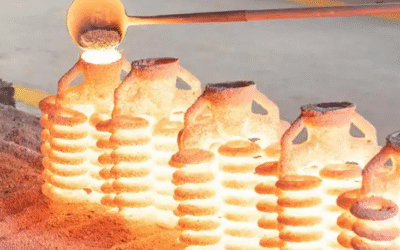

Expanded Polystyrene (EPS) – The Industry Standard for Lost Foam Casting

EPS runs the lost foam casting market. It wins on economics and technical performance. China’s foundry data shows the growth: EPS-based production jumped from 300 tons in 1991 to 300,000 tons per year by 2006. Over 200 foundries adopted this technology during 2005-2006 alone.

The numbers prove industrial preference. Four foundries in China’s top tier each produced over 10,000 tons per year in 2006. Twelve facilities exceeded 8,000 tons per year. Fewer than 15% of foundries operated below 1,000 tons per year. EPS works best at serious production volumes.

Why EPS Became the Go-To Material

The 2005 material breakdown shows what EPS handles well: 86.3% iron castings, 13.6% steel, and 0.1% aluminum. EPS excels with high-temperature ferrous metals.

Ideal EPS density sits at 1-1.5 lbs/ft³ for machining foam blocks into patterns. This density range keeps structural integrity during handling. It also vaporizes completely during metal pouring.

Pattern Production Speed and Methods

CNC machining and additive manufacturing deliver patterns in 1-4 hours per part. Traditional CNC milling runs at 5-10 m/min feed rates. Patterns complete in 2-4 hours. Modern 3D printing finishes complex EPS patterns in under 24 hours.

For volume production, injection molding takes over. A single mold produces 500 patterns per day. Density variation stays within ±1%. You can cluster up to 20 foam patterns per gating head. This maximizes metal yield per pour.

Real-World Casting Performance

The casting process moves fast. Sand filling and pouring complete in 30 minutes. Full production cycles run 5-15 minutes from start to finish. Your yield hits 90-95%. That’s competitive with most Casting methods.

Temperature needs vary by metal. Aluminum pours at 660°C. Iron demands 1,400°C. Solidification takes 30-60 seconds as molten metal replaces vaporized foam.

Precision and Quality Metrics

Dimensional tolerance reaches ±0.5-1.0 mm (CT8-CT10 grade). Pattern accuracy sits at ±0.25 mm. Surface roughness measures 3.2-6.3 µm Ra. You’ll need machining allowances of 1.5-3 mm for finished parts.

Minimum wall thickness drops to 2.5 mm. Maximum part size stretches to 2 meters and 500 kg. That’s larger than many other processes handle. Scrap rates from foam defects stay between 5-10%.

Economic Reality Check

EPS material costs run $0.50-1.00 per kg as a consumable. Individual foam patterns cost $100-300 each for tooling.

The break-even point sits at 5,000-10,000 units per year. This compares to sand casting with cores costing $1,000+. Take a 50 kg aluminum part at 5,000 units per year. Expect about $22 per unit. That’s 20-30% lower than traditional sand casting. It’s 40-60% cheaper than Investment casting.

Common uses include automotive manifolds, engine blocks, high-alloy steel molds, heat furnace cages, and anti-abrasion components. EPS delivers maximum value through its combination of speed, cost, and precision.

Extruded Polystyrene (XPS) – Better Performance Option

XPS offers structural benefits EPS can’t provide. The extrusion process creates a closed-cell structure. This delivers 40-60 PSI compressive strength (275-415 kPa). Your foam patterns survive handling, assembly, and coating operations without bending or breaking.

Better Heat Stability for High-Temperature Casting

The closed-cell design gives XPS a heat flow rate of 0.0334-0.0344 W/mK (average 0.0341 W/mK at 24°C). Tests on five European manufacturer samples show strong consistency. Precision stays within 1%. Accuracy stays within 5%.

You get an R-value per inch of 5.0 °F·ft²·h/Btu (0.88 m²K/W) for standard 40/60 PSI grades at 75°F mean temperature. This rises to 5.4 at 40°F and 5.6 at 25°F. advanced types like Styrofoam Ultra SL with patented carbon-black technology reach 5.6 R-value with 0.97 RSI per 25mm thickness.

Long-term heat resistance (LTTR) stays at a minimum 5.0 hr·ft²·°F/Btu/inch (0.88 m²K/W). DOW’s 12-year study showed 21% aging loss, dropping to R-3.95 per inch. This still beats aged EPS by a large margin.

Water Resistance That Keeps Patterns Intact

XPS absorbs just 0.3% moisture because of its closed-cell structure. This stops mold and rot during storage. Below-grade and cold-climate field studies (ASCE 32, Connor’s 5-21 year Alaska data) prove XPS needs 1.5-2x less thickness than EPS for the same long-term performance.

XPS Makes Economic Sense Here

The smoother surface from extrusion cuts coating needs. Higher stiffness means fewer pattern rejections from handling damage. You’ll install XPS on braced framing. It’s non-structural but holds its shape better than EPS during coating and drying phases.

Precision castings need tighter tolerances. Patterns sit in inventory before use. XPS’s water resistance and structural strength make the 15-25% material cost increase over standard EPS worth it.

Polymethyl Methacrylate (PMMA) – Precision Casting Solution

Aerospace engineers face a tough problem. They need to cast parts with tricky shapes. Traditional methods can’t do this at a good price. PMMA acrylic plastic fixes this. It burns out cleanly and machines with precision rated at 7-8 out of 10.

Where PMMA Beats Standard Foam Materials

PMMA creates fine details and tricky shapes with no limits. You don’t need support structures. These supports slow things down and take time to remove. CNC machines cut smooth surfaces. Tools don’t wear out fast. The material burns out well. This cuts the risk of shell breaks during casting.

investment casting with PMMA uses material better than cutting from solid bars. You recycle more. Reject rates fall over time. Pattern quality stays the same batch after batch.

Real Aerospace Production at Scale

TITAL GmbH makes critical Airbus A400M parts. They use 3D-printed PMMA patterns from voxeljet systems. Their Channel Fitting measures 1200 x 350 x 300 millimeters. This big part goes in the landing gear shaft. The main landing gear needs it. Over 90% of TITAL’s customers are aerospace makers. Airbus and Boeing are on that list.

The tech works with many metals. Aluminum, magnesium, steel, titanium, bronze, and TiAl6V4 titanium alloy. Each metal needs different heat control. PMMA burns out the same way across all these metals.

Medical-Grade Surface Quality You Can Achieve

A medical device maker needed Ra < 0.1 µm surface finish for an eye lens implant. Standard PMMA machining couldn’t hit this target at first. The fix used diamond-finished tools. Plus multi-stage machining. And controlled vapor polishing.

Final Ra values hit 0.08 µm across all parts. This fixed past biocompatibility problems. Gone. The downside? Production costs went up 30% to get this surface quality. For medical implants, this cost stops product recalls. It prevents rule failures too.

Production Economics and Speed

Small batches become cost-smart with PMMA patterns. You skip tooling costs. All of them. Prototypes and small-to-medium runs finish fast. A single CAD file prints perfect patterns in one step.

voxeljet’s VX1000 system offers 1000 x 600 x 500mm build volume. This size handles medium molds and casting patterns. The smaller VX200 works for material tests and prototypes. Both systems process plastics, sands, and ceramics. Not just PMMA.

Environmental and Weight Benefits

Topology optimization cuts weight. Traditional casting patterns can’t match this. Your finished parts need less raw material. Energy use drops compared to cutting from solid bars. CO2 output falls across the whole production cycle.

PMMA shines for projects needing top accuracy for tricky shapes. Auto precision parts, electronic cases, dental implants, and optical parts all gain from PMMA’s strengths. The material fits into current production lines. It meets German quality rules and medical-grade biocompatibility needs.

Foam Selection Criteria Based on Casting Requirements

Match foam density to your part’s complexity. This determines casting success or failure. Skip this step and you’ll face carbon inclusions, size drift, and scrapped parts.

Density Requirements Drive Your First Decision

Pattern complexity sets your density baseline. Simple shapes work fine at 1.4-2.0 pcf (pounds per cubic foot). Complex parts with thin walls, deep cavities, or intricate features need 2-5 pcf. This keeps structure strong during handling and coating.

Higher density foams resist warping during sand packing and coating. Your patterns stay stable through the entire process. But there’s a trade-off during metal pouring. Dense foam vaporizes slower. This creates more gas volume in less time. Poor venting leads to carbon inclusions in your final casting.

Lower density foam vaporizes fast and clean. But fragile patterns break during coating or cluster setup. You’ll reject more patterns before pouring starts.

Metal Type Dictates Vaporization Chemistry

Ferrous metals require sulfur-free polystyrene grades. Grey iron and steel react with sulfur compounds during foam vaporization. This creates porosity. It also reduces strength. Your supplier’s material data sheet must show sulfur content below detection limits.

Aluminum and brass castings work with standard EPS grades. The lower pouring temperatures (660°C for aluminum vs 1,400°C for iron) reduce gas pressure buildup. Carbon residue risks drop with these non-ferrous metals.

Precision Targets Set Your Foam Choice

Tolerance requirements filter your options fast. Standard EPS delivers ±0.5-1.0 mm tolerances with Ra 3.2-6.3 μm surface roughness. This works for most automotive and general industrial uses.

Aerospace components need tighter control. These parts demand XPS or PMMA. XPS’s closed-cell structure maintains ±0.005 mm/mm precision through coating and handling cycles. PMMA achieves medical-grade surface finishes below Ra 0.1 μm with special machining methods.

Production Volume Economics

Your production volume determines the break-even point between foam types:

-

Below 500 units: Use machined XPS or 3D-printed PMMA patterns. Skip tooling costs.

-

500-5,000 units: Medium-density EPS with simple injection molds balances cost and quality.

-

Above 5,000 units: High-volume EPS tooling pays back through $0.50-1.00 per kg material costs.

Test foam performance with a prototype run. This prevents expensive failures at scale. Cast 10-20 test pieces with your target metal. Measure size accuracy, surface finish, and internal defect rates. Check for complete vaporization with no carbon residue on breakout inspection.

Five-Step Selection Protocol

Step 1: Calculate part complexity score. Count undercuts, wall thickness changes, and core needs.

Step 2: Match metal pouring temperature to foam burn traits. Use supplier vaporization data.

Step 3: Run ProCAST simulation. This verifies gas evacuation patterns and spots potential defect zones.

Step 4: Request certified material grades from suppliers. Get metal-specific compatibility testing.

Step 5: Prototype with 2-3 foam options. Measure results against specs, then scale production.

One automotive foundry switched from 1.8 pcf to 3.2 pcf EPS for complex aluminum intake manifolds. Carbon inclusion defects dropped from 12% to under 2%. The denser foam cost 18% more per pattern. But it removed an entire rework station. Net savings hit $47,000 per year on a 15,000-unit production run.

Supporting Materials in Lost Foam Casting Process

Unbonded sand is the main support material in lost foam casting. Chinese foundries used 105,000 tons of unbonded sand in 2005 alone. That’s about 50% of all lost foam work in the country. Why unbonded sand? You can shake it out easily. Just dump the flasks after the metal solidifies.

Sand Selection Changes Everything

Silica sand works well for most basic jobs. But high-magnesium steels need something better. Specialty alloys do too. Olivine sand lasts 6-8 times longer than regular silica sand. It has zero free silica content. This makes it safer for workers and equipment. Some Chinese foundries use olivine as filling sand. They also use it as a refractory material in coatings for tough alloy jobs.

Steel casting brings special heat stress problems. Synthetic mullite works as the filling material in some Chinese foundries. These shops focus on steel lost foam casting. Synthetic mullite handles extreme steel temperatures. It doesn’t break down.

Coating Production Economics and Quality Control

Most Chinese foundries make their own coatings. They don’t buy pre-mixed products. Why? Lower costs and faster changes to meet specific casting needs. But this creates a quality issue. In-house mixing isn’t always consistent. This causes coating properties to vary. Scrap rates go up.

Foundries check coating quality with two key tests: air flow rates and liquid absorption values. These tests spot problems before production starts. There’s not much good data on foam breakdown and coating behavior. So foundries rely on trial runs. Gas-to-liquid ratios during foam burning follow Arrhenius relation models. These models come from real casting tests.

Material Efficiency Gains

Lost foam casting gives you 80-90% material yields. That’s casting weight divided by total metal weight. Green Sand casting only delivers 50-60% yields. The difference? No core making needed. Plus simpler gating.

Energy and productivity numbers show the same benefits. Lost foam cuts core making completely. That’s 0% energy use compared to 8-20% in traditional sand casting. Mold making drops to 10% of energy use and 30% of productivity costs. Compare that to regular sand processes.

Tests on A356 alloy motor housings found the best settings: 700°C pouring temperature, 50 W/m²K interfacial heat transfer coefficient, and 0.5 W/mK sand thermal conductivity. These settings give you stable filling patterns. Metal flows from thin to thick sections. Critical parts come out defect-free.

New Foam Technologies and Options

The foam industry is moving toward green solutions. Performance stays strong. The global foam market will grow from $118.9B in 2026 to $186.16B by 2033 at CAGR 5.9%. This growth comes from new materials. They solve old problems: recyclability, carbon footprint, and performance in tough conditions.

Bio-Based and Recyclable Foam Development

Europe and North America push hard for recyclable mono-material foams and bio-based options. R&D teams work on high-R-value boards with low-GWP (Global Warming Potential) formulas. Rigid foam shows the fastest innovation. The segment hits $34.13B in 2026 and climbs to $55.63B by 2034 at CAGR 6.3%.

Vacuum-insulated and aerogel-infused foams hit production lines now. These materials cut heat transfer by 40-60% compared to standard EPS. Lost foam casting gets better shape stability during metal pouring.

Engineered EPE and EPP Performance Foams

Expanded polyethylene (EPE) and expanded polypropylene (EPP) are the fastest-growing options. The flexible foam packaging segment reaches $8.7B in 2026 and $12.4B by 2033. Asia Pacific dominates with 34.3% market share. China leads EPE and polyurethane production. Japan targets precision medical and electronics uses.

EPP absorbs crash energy better for car parts. Plus, you can recycle it completely. Return-stream EPP programs recover patterns after metal cools. Clean and reuse the material for new patterns. This cuts material costs by 25-35% in high-volume casting.

Car Weight Reduction Drives Polyurethane Innovation

The car foam market grows from $52.3B in 2026 to $72.1B by 2036. Polyurethane foam holds 42% share. China’s EV production in Shanghai and Guangzhou pushes CAGR 4.2%. USA EV plants in Michigan and Texas deliver CAGR 3.5%.

Low-GWP polyurethane formulas work with aluminum and magnesium casting. These foams turn to gas at lower temperatures. Gas removal gets easier. Carbon defects drop below 1% in controlled tests.

On-Demand Foam Systems Cut Storage Costs

Foam-in-place and bead molding systems remove the need for pattern storage. You make patterns hours before metal pouring. Density control lets you change foam properties within one pattern. Dense foam goes in high-stress spots. Low-density parts speed up gas release in thick walls.

Cold-chain EPS trays show the packaging crossover potential. These same density-control methods work for lost foam casting patterns. You get better gas removal with targeted density zones.

Conclusion

The right foam makes or breaks your lost foam casting success. EPS works well for most jobs. It’s cost-effective and performs reliably across different casting projects. Got complex shapes that need tight tolerances? XPS and PMMA give you better precision. But they cost more, so check your ROI first.

What type of foam is used for lost foam casting in your shop? Three things matter: how complex your parts are, how many you make, and your budget. Look at foam density, how well the beads fuse, and how it breaks down. Match these to your needs. This boosts both part quality and shop efficiency.

Want better casting results? Check your current foam against the standards we’ve covered. Try different materials on less critical parts first. Measure how much more accurate they are. Add up the real costs—both material price and fewer defects. The right foam does more than fill your pattern. It changes your whole production cost picture.

Your next move: Talk to your foam supplier. Give them your density specs and ask for samples to test.