Metal casting quality depends on one key choice most foundries miss: picking the right porous ceramic filter. Molten metal flows through your casting system. Tiny impurities, oxide films, and slag particles can ruin your final product. Pick the wrong filter and you face more than rejected parts. You’ll deal with harder machining, tools that wear out fast, and unhappy customers.

alumina ceramic filters handle about 70% of metal casting work worldwide. That doesn’t mean they’re right for your needs. Temperature needs, metal alloy type, flow rates, and budget all change which porous ceramic filter works best. This guide skips the marketing talk. You’ll see which filter type fits your casting process. Real performance data and cost-benefit details help you invest smart—not just copy what others do.

Alumina (Al₂O₃) Ceramic Filters – The Industry Standard

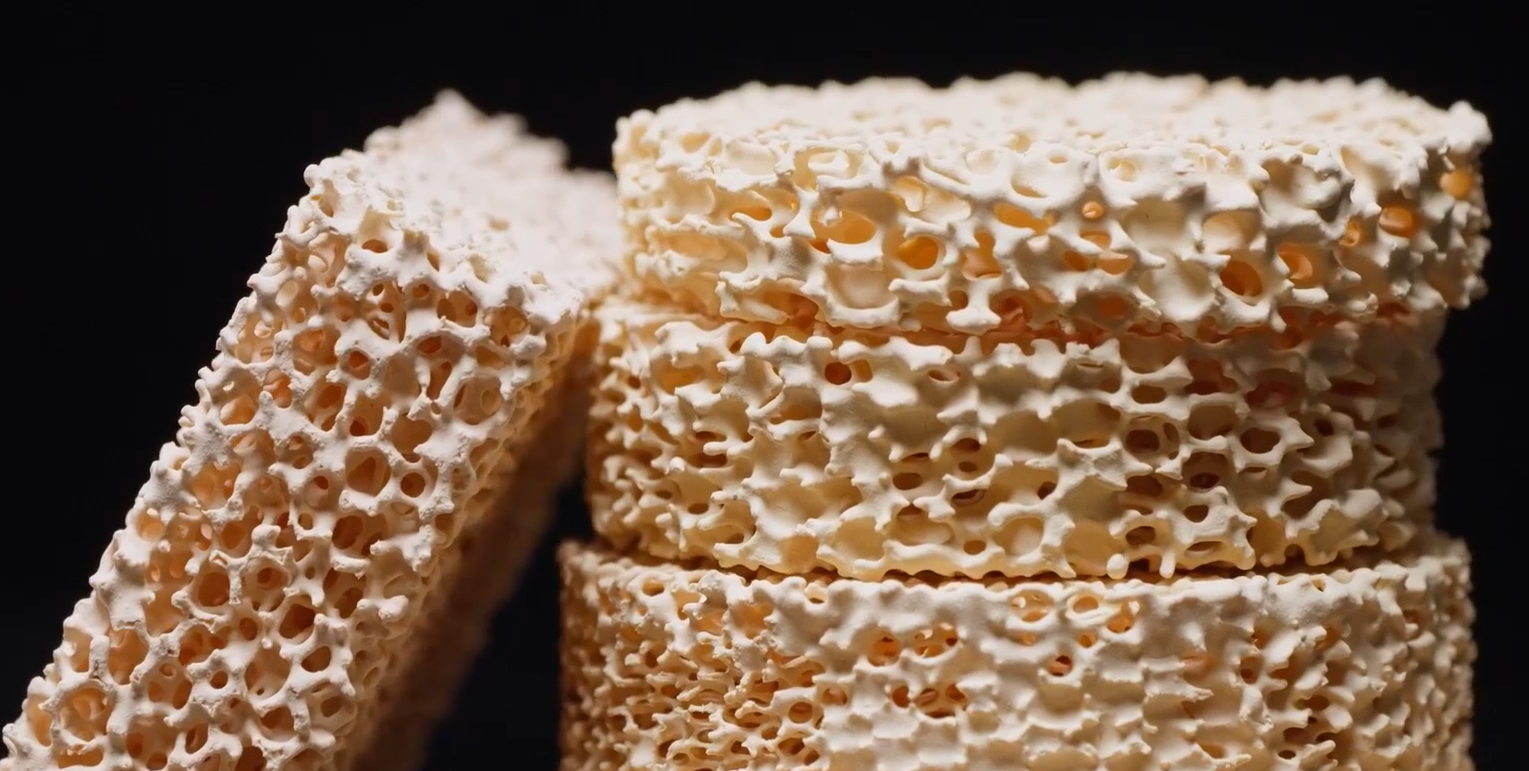

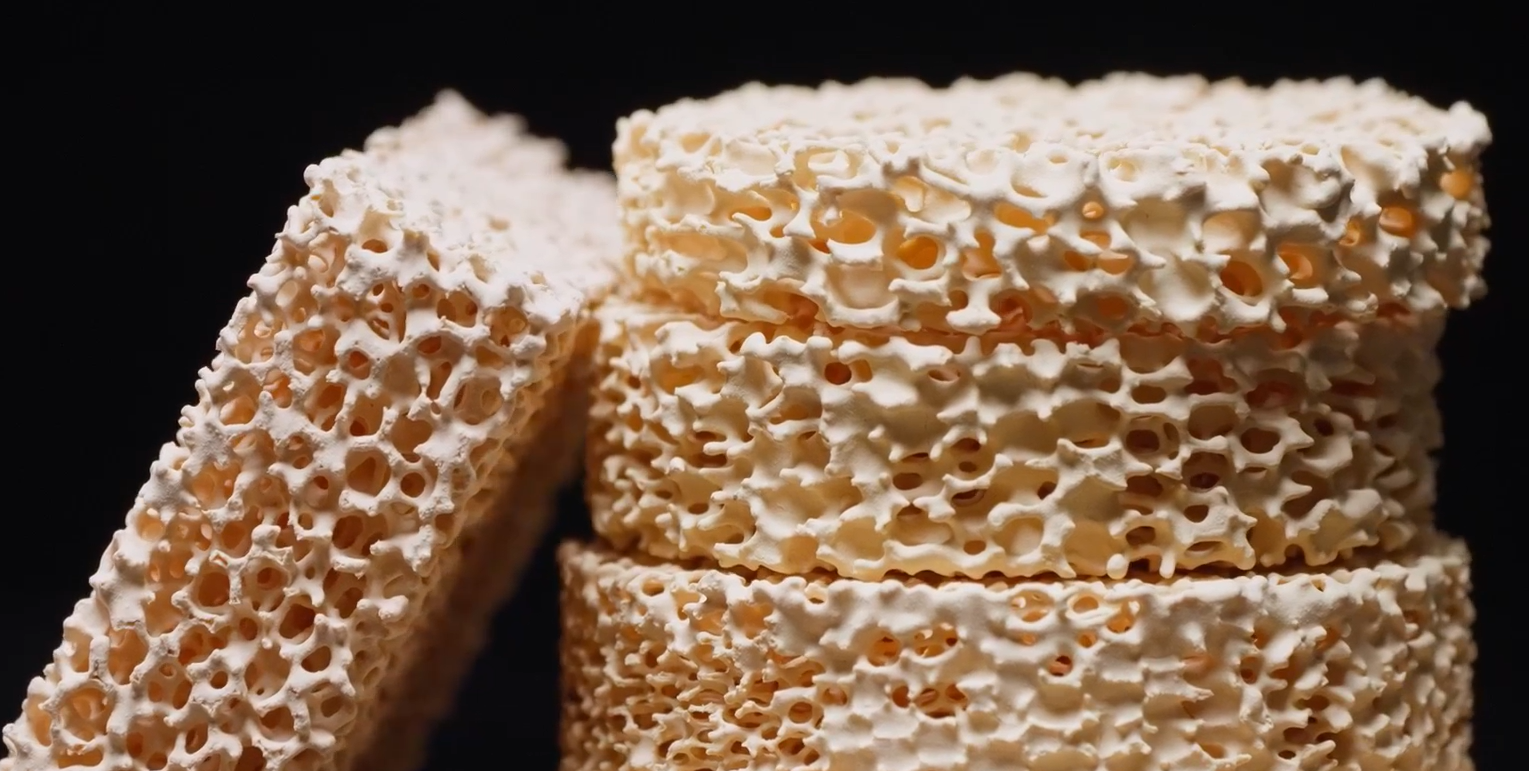

Foundries worldwide keep coming back to alumina ceramic filters for one simple reason: they work. These filters trap oxide films, slag particles, and inclusions that would wreck your castings. The secret? Their cellular structure. 80-90% porosity creates a maze. Molten metal passes through countless filtering pathways. Flow rates stay where your production schedule needs them.

Technical Specifications That Matter

alumina filters operate at temperatures up to 1200°C (2192°F). Specialized versions handle extreme ranges from 1350-1800°C. Bulk density runs between 0.35-0.50 g/cm³. Light enough to handle with ease. Dense enough to withstand compression forces exceeding 1.0 MPa (145 psi) at room temperature.

Thermal shock resistance separates quality filters from cheap alternatives. A proper alumina filter survives repeated cycles from 800°C down to room temperature. No cracking. No degrading. This durability gives you consistent filtration performance throughout your production run.

PPI Selection Changes Everything

Pores per inch (PPI) determines what your filter catches. It also controls how fast metal flows through. Here’s what each range delivers:

10-20 PPI: Use these for large castings where flow speed matters more than catching every tiny particle. Your metal moves fast. The filter captures bulk inclusions. No backpressure created.

30-40 PPI: The industry standard for gravity aluminum casting. This range balances filtration efficiency against flow rate. Most foundries producing engine blocks, wheels, and detailed components use this specification. It catches defect-causing particles. Production speed stays high.

50+ PPI: Thin-wall castings and high-performance applications need this finer mesh. You’ll trap smaller particles. Filtration efficiency goes up. Flow rates slow down, though.

Real-World Performance in Aluminum Casting

Alumina filters transform aluminum casting operations by attacking multiple defect sources at once. They trap inclusions larger than their pore size. Simple physics at work. But the filtration doesn’t stop there. Captured particles form a filter cake. Efficiency improves as casting continues. The cellular structure promotes smooth flow. Remaining inclusions float upward. Away from your casting cavity.

The results show up in your finished parts. Gas porosity drops. Slag defects disappear. Cold shuts and cracks become rare exceptions instead of recurring problems. Your scrap rate falls. Machining operations run smoother. Cutting tools hit fewer hard inclusions.

Aluminum profiles for architectural frames arrive with structural integrity intact. Smooth surface finishes too. Aluminum foil production achieves uniform thickness. Essential for packaging applications. Engine blocks pass quality inspections with minimal flaws.

Installation Requirements You Can’t Ignore

Size your filter at 2-4 times your gating system’s cross-sectional area. Undersized filters create chokepoints. This defeats their entire purpose. Match the filter capacity to your metal flow rate. Otherwise, you’ll restrict production speed. Or unfiltered metal will bypass the system.

Look for filters with beveled edges and compressible gaskets. These design features create tight seals. Molten metal can’t sneak around the filter. A common failure point in bad setups. The filter must sit flat with accurate dimensions. Gaps mean unfiltered metal contaminating your casting.

Sintering strength matters more than most buyers realize. Low-quality filters drop slag into your mold during use. High surface hardness and special coatings extend filter life. Performance stays consistent from the first pour to the last.

Why Alumina Dominates Metal Casting

Numbers tell the story first. Alumina ceramic filters hold 70% of the global aluminum casting market. Not through marketing pushes. Through real performance that cuts costs and lifts quality.

Filtration That Cuts Your Waste

Alumina filters catch 90-98% of particles larger than 20 micrometers. Foundries drop reject rates from 5-8% down to under 2% after the switch. Surface quality jumps from Ra 6.3 μm to 1.6 μm. Smoother surfaces need less finishing.

Quality gains show up in your profits fast. Porosity drops 40%. Tensile strength rises 15%. That’s 250 MPa climbing to 288 MPa in car parts. Scrap rates fall 60%. Each percentage point saved means thousands back in your pocket each month.

Market Growth Shows Real Value

The aluminum casting market with alumina-lined tools grows 5.3% per year. It reaches $126.22 billion by 2032. die casting with alumina filters grows faster at 6.24% CAGR. That adds 5,944,800 metric tons between 2020 and 2025. Performance drives growth. Foundries choose with their wallets.

Silicon Carbide (SiC) – For Extreme Heat Applications

Most ceramic filters fail under high heat. silicon carbide handles temperatures that melt standard equipment.

SiC filters work at 1650°C with no load. Standard use sits at 1470°C. Alumina tops out at 1500°C. This gap matters for copper alloys, steel, and specialty metals that need extreme heat. SiC melts at 2700°C. No foundry gets close to that.

Heat Performance That Matters

Heat flows through SiC three times faster than silicon. Heat transfer rates hit 12-20.7 W/m·K based on crystal form. Alumina can’t match this. Quick heat transfer keeps your filter at steady temperature throughout. No hot spots form. No weak areas build up from heat stress.

Heat expansion stays low at 7.9-11 × 10⁻⁶/°C. This pairs with high heat transfer to give strong thermal shock defense. Pour 1600°C molten metal into a cold mold. The sic filter takes the temperature jump without breaking. Cast after cast. Hour after hour.

The material builds a silicon oxide shield at 1200°C. This layer protects up to 1600°C in air. Strength holds steady with pure grain boundaries. Your filter stays solid near 1600°C. Running at 470°C? It lasts thousands of hours without breaking down.

Zirconia and Silicon Nitride – Specialized Applications

Some applications need materials that handle extremes. Zirconia and silicon nitride work where silicon carbide can’t. These aren’t standard casting filters. They run oxygen sensors, turbocharger rotors, and semiconductor fabrication. One degree too hot or one micron of wear causes complete failure in these spots.

Zirconia – The Transformation Toughening Champion

Zirconia does something unique among ceramics. A crack hits it. The material changes its crystal structure right there. This phase change soaks up the fracture energy. The crack stops spreading. Engineers call it transformation toughening. Foundries call it insurance.

Thermal conductivity sits at just 2-3 W/m·K. Silicon carbide reaches 12-20.7 W/m·K. This big difference creates a heat barrier. Your engine parts get protection. Heat stays where it belongs. Zirconia handles the hottest zones.

Where zirconia works best:

-

Oxygen sensors track exhaust gas content at temps that melt standard electronics. Zirconia resists oxidation and stays stable at high heat. You get precise readings through harsh gases and pressure spikes.

-

Turbocharger rotors spin at extreme speeds. Low density reduces inertia. High strength handles the spinning forces. Engine efficiency goes up. Performance improves.

-

Fuel injectors need materials that resist wear and hold exact dimensions. Zirconia does the job. Fuel injection angles stay precise. Spray patterns stay the same. Fuel economy gets better.

-

Sensor components measure pressure and temperature in harsh environments. High strength, corrosion resistance, and electrical insulation keep readings on target.

The market sees the value. Zirconia ceramics reached $2.76 billion in 2024. Growth rate: 5.4% CAGR. Pretty good for a “specialized” material.

Silicon Nitride – Top Performance Under Stress

Silicon nitride beats zirconia during fast temperature changes. The stress from rapid heating and cooling cracks other ceramics. Silicon nitride stays stable. Toughness goes beyond what transformation toughening offers. Wear resistance ranks higher across all uses.

Applications that need silicon nitride:

Automotive powertrains run hot and fast. Silicon nitride bearings last 3-5x longer than steel. Turbochargers and exhaust valves work beyond normal limits. Low density means less weight. Acceleration improves. Fuel economy gets better.

Aerospace components can’t fail. Turbine blades face extreme temperatures and huge forces. Silicon nitride’s strength-to-weight ratio meets the standard. The material survives conditions that destroy metal alloys.

Medical implants need biocompatibility first. Performance comes second. Silicon nitride gives you both. SINTX Technologies proved it with spinal implants. Bone fusion improves. Infection risk drops. Patients heal faster.

Semiconductor fabrication at TSMC and Intel uses silicon nitride thin films. Gate dielectrics. Passivation layers. Protective coatings. Transistor performance improves. Reliability lasts longer.

5G infrastructure pushes radio frequencies higher. Silicon nitride protects RF components from heat damage. Base stations run stable under loads that destroy standard materials.

Electric vehicle IGBTs make serious heat. Silicon nitride substrates shed thermal energy faster than other options. Components last longer. Powertrain efficiency stays high through tough cycles.

Renewable energy applications use silicon nitride’s heat management. Photovoltaic inverters run cooler. Electrical insulation holds under load. Solar panel efficiency gains percentage points. Wind turbine bearings last years longer.

Market projections show the trend. Silicon nitride grows from $136.01 million in 2024 to $235.45 million by 2032. That’s 7.10% CAGR. Faster than zirconia. Performance drives adoption.

Filter Design Types for Different Casting Setups

Honeycomb and foam filters look similar until molten metal hits them. Flow capacity separates the winners from the problems. Honeycomb designs push metal through at 1000 mL/sec right from the start. Foam filters manage 600 mL/sec under the same conditions. That 40% difference changes your production timeline.

Debris tells another story. Honeycomb channels guide metal through straight passages. Nothing breaks loose. No particles float downstream. Foam structures trap inclusions in their cellular maze. Good for filtration. Bad news: captured debris breaks free during turbulent pours. Maintenance needs follow the physics. Honeycomb Filters run clean session after session. Foam versions need inspection and cleaning between campaigns.

Design Configurations That Control Your Results

Filter placement decides everything else. Design 2 delivers the best performance: slag trap sits upstream from the filter, metal spreads across the full filter face, turbulence drops before and after the ceramic barrier. Flow stays smooth. You use the full filter capacity. Your metal arrives at the mold cavity ready to solidify clean.

Design 1 works as the backup choice. Standard filter print without a slag trap. You get maximum filter capacity with uniform flow distribution. Both setups reduce flow angularity. Both maximize front-face filter usage. Design 2 handles inclusion separation better before filtration starts.

Flow rate data proves the point. Standard filter print design moves 0.75 kg/s through optimal locations. Reduced entrance and exit areas push that to 0.94 kg/s. Sounds better at first. But here’s the catch: 25% more metal concentrates through limited filter sections. Uneven loading means early filter saturation. Fill time runs around 24 seconds at 4.5 kg/s overall flow rate across proper setups.

Selection Guide: Matching Filter to Your Casting Process

Your casting process tells you which filter to use. Temperature, metal type, flow needs, and budget narrow the options fast. Skip the guesswork. Match filter material to your real operating conditions.

Temperature Requirements Drive Material Choice

Magnesium-stabilized zirconia beats everything for extreme thermal shock resistance. Cycling between 1600°C pours and room temperature mold prep? This material survives what kills other filters. The magnesium stops cracks during fast temperature changes.

Zirconia-mullite composites handle medium to high temperatures. They cost less than pure zirconia. Steel foundries running 1450-1550°C find the sweet spot here. You get thermal stability without paying for extras you don’t need.

Pure alumina filters work up to 1500°C. Aluminum, brass, and bronze casting operations stay in this zone. The 70% market share shows alumina gives steady results at good prices.

Mullite ceramic filters work for high-temperature jobs. They offer medium thermal shock resistance. Copper alloy foundries get mullite’s mix of heat handling and crack resistance. It costs less than zirconia. Plus, it beats standard alumina in thermal cycling.

Flow Rate Versus Filtration Efficiency

More open filter ratings mean lower flow resistance. Flow rates climb. But particle capture drops. A 10 PPI filter moves metal 40% faster than 40 PPI. You trade fine particle removal for speed.

Finer micron filters create higher pressure drops at first. That 50 PPI Ceramic foam catches particles down to 20 micrometers. Pressure drop runs 15-25% higher than 30 PPI versions. Your fill time goes up. But filtration efficiency jumps.

Filters with the same pore size differ in open area and loading capacity between makers. Test real performance. One company’s 30 PPI filter might flow like another’s 40 PPI. Loading capacity sets how long the filter works before it clogs and kills flow rate.

Figure out enough Filter Media area to handle your desired flow rate. Too-small filters choke flow or let metal bypass. Too-large filters waste money. Match cross-section area to metal speed and total pour weight.

What Filters Remove

Non-metallic junk comes from many sources. Furnace and ladle refractory materials break loose during metal transfer. Slag forms from oxidation and flux reactions. Molding sand gets into the metal stream from rough filling. De-oxidation products form when you add aluminum or silicon to kill oxygen. Re-oxidation happens when metal hits air during pouring.

Each type makes different defects. Refractory particles cause hard spots that wreck cutting tools. Slag makes porosity and weak zones. Sand bits lower tensile strength and crack under service loads. Oxide films stop proper fusion and create leak paths.

Testing Beats Assumptions Every Time

Test different filters and setups in your real production space. Lab data doesn’t cover your exact gating design, pouring method, or metal chemistry. Run test heats with different PPI ratings. Measure flow rates, filtration work, and finished part quality. Track total cost per good casting, not just filter price.

Work with seasoned engineers to design filter layouts that support flexibility and future growth. Your production volume might double next year. Can your filtration system grow without total redesign? Modular setups allow step-by-step capacity adds.

Talk to experts who know Investment casting needs. General filtration knowledge misses key details. Someone who knows your exact alloy chemistry, section thickness needs, and quality standards saves you costly trial-and-error learning.

Buy tough equipment and materials to cut long-term costs. Cheap filters look good until you add up replacement labor, production delays, and reject rates. premium ceramic casting filters cost 40% more. They last 300% longer and cut defects 60%. Your total cost per ton drops 25%.

Cost-Benefit Analysis and Performance Metrics

Filter selection without financial analysis wastes money. Net Present Value (NPV) helps you spot smart investments. It also shows you budget drains. NPV measures the gap between present value of benefits and present value of costs. Positive NPV means your filter choice makes money. Negative NPV means you’re losing cash.

A foundry installs alumina filters with $104,925.04 NPV over five years. This proves the money works. The investment pays back with room to spare. Compare that against cheaper filters showing negative NPV. Initial savings disappear fast. Reject rates climb. Replacement cycles speed up.

Financial Metrics That Guide Filter Investments

Benefit-Cost Ratio (BCR) divides total benefits by total costs in present value terms. BCR above 1.0 means benefits beat investment. A ratio of 1.18 means every dollar spent creates $1.18 in returns. Silicon carbide filters often hit 1.3-1.5 BCR in high-temperature steel casting. Yes, upfront costs run higher. But extended service life and better filtration drive the returns.

Profitability Index (PI) uses the same calculation as BCR. Higher values mean better profits. Premium zirconia filters show PI of 1.4. They beat standard alumina at 1.2 for thermal cycling processes. The math shows which material performs better in your application.

Internal Rate of Return (IRR) finds the discount rate where NPV equals zero. This metric compares filter investments against other capital uses. IRR of 18% on Ceramic foam filters beats most equipment upgrades. Your money works harder on filtration than other projects.

Payback Period counts years until savings match total investment. Break-even year marks the point your filter system generates positive cash flow. Alumina filters pay back in 14-18 months through reduced scrap rates and lower machining costs. Silicon carbide systems need 24-30 months. But they deliver value over 4-5 year service lives.

Real-World Investment Analysis

A mid-size aluminum foundry spends $50,000 on automated ceramic filter systems. Labor costs drop $30,000 each year. Five-year time horizon with 5% discount rate gives NPV of $45,000 and BCR above 1.2. These positive numbers confirm better resource use. Reject rates fall 60%. This adds another $22,000 in savings each year. Initial labor calculations missed this benefit.

Manufacturing capital budgeting combines break-even analysis with cost savings estimates. Equipment investments need solid numbers. A $120,000 Silicon Carbide filter installation cuts defects by 75%. This creates real savings. Tool wear drops 40%. Machining time falls 25%. Quality claims from customers stop. Present value of these benefits over equipment life determines go/no-go decisions.

Savings Investment Ratio (SIR) divides present value of cost savings by net investment after residual value. Ratios above 1.0 mean profitable projects. Higher numbers mean stronger returns. honeycomb filter systems reach SIR of 1.6. They beat foam alternatives at 1.3 through better debris management. Plus, they run longer between cleanings.

Standard discount rates run 3-7% for foundry equipment analysis. This converts future benefits into today’s value terms. Long-term filter investments need proper discounting. This helps you compare options on equal terms.

Conclusion

Alumina ceramic filters dominate metal casting operations for good reasons. They balance filtration efficiency, heat resistance, and cost better than alternatives. That’s why 70-80% of foundries worldwide choose them. Running Aluminum Alloy or bronze casting? Knowing which porous ceramic filter works best in metal casting affects your profits and product quality.

Your next step depends on your casting needs. Check your metal temperatures first. Then look at your budget and quality standards. Compare these against the filter selection matrix we outlined. Standard aluminum and bronze work? Alumina is your best bet. It’s proven, reliable, and affordable. Working with specialty alloys above 1,600°C? Silicon carbide costs more, but it’s worth considering.

Picking the right filter does more than remove dirt. It protects your reputation, one perfect casting at a time. Poor filtration hurts scrap rates, upsets customers, and cuts profits.

Ready to improve your filtration system? Contact your ceramic filter supplier. Share your casting parameters and get a technical consultation.