I’ve often wondered how busy factories operate efficiently and keep their products safe for all of us. From my experience, the answer is industrial filtration systems. These systems do the difficult work. They clean the air and liquids, protect expensive machines, and ensure companies follow safety rules. I believe they are essential for many businesses, from car makers to companies that produce medicine.

A Look at Industrial Filtration Systems in Manufacturing

From my experience, industrial filtration systems are essential tools in modern manufacturing. They work by cleaning liquids and gases, removing things like particles, germs, and harmful chemicals during production. You can find these systems in many industries, including automotive, food, pharmaceuticals, electronics, mining, foundry, and chemicals.

Industrial Filtration System Market Size and Growth

Based on recent reports, the numbers show strong growth, which I fully expect to continue.

– The global market for industrial filtration was worth between USD 36.03 billion and USD 44.53 billion in 2024.

– I predict the market will expand to between USD 53.81 billion and USD 65.08 billion by 2033. This reflects a compound annual growth rate (CAGR) of 4.2% to 5.2%.

– In North America alone, the market is expected to grow from USD 16.83 billion in 2023 to USD 21.50 billion by 2030.

– Just looking at U.S. HVAC industrial filtration, the market was USD 513.1 million in 2024. I project it will pass USD 652 million by 2030.

– Global car production increased by 10% in 2023, reaching 93.5 million vehicles. This growth directly creates more demand for filtration.

Key Jobs and Industry Uses

In my view, these filtration systems have a few main functions. They protect sensitive equipment, make sure products are high quality, and help manage emissions and waste. They are vital for meeting legal and environmental rules.

In the car industry, I see them used in paint spray booths and for cleaning coolants. This helps control pollution and maintain product quality. For making semiconductors, you need extremely clean rooms. Advanced filters are necessary for this.

Strict laws, like the U.S. Clean Air Act and the European Union Industrial Emissions Directive, require industries to use effective filtration.

Filtration Technology and Market Trends

I’ve noticed some important trends in filtration technology. Smart technologies like IoT and AI are being built into these systems. This allows for real-time monitoring and can predict when maintenance is needed. Special methods, like Electrocoagulation filtration, are being used to remove tough contaminants. A good example is “forever chemicals” like PFAS.

I’d recommend looking at advanced filters, such as HEPA and electrostatic models. They have a longer service life and use less energy. The industry is also moving toward sustainable, reusable filter materials. I believe this is a great step to cut down on industrial waste.

Types of Industrial Filtration Systems

I’ve worked with many different kinds of filtration systems. Here are some of the main types: – mechanical filters, which include membrane, cartridge, and bag filters – HEPA and ULPA filters, used for trapping very fine particles – Electrostatic precipitators – Activated Carbon filters, which are great for controlling gases and odors – Electrocoagulation systems for treating wastewater – Smart filters that use IoT and AI for diagnostics

Based on my observations, industrial filtration is no longer optional in manufacturing. With new technologies and a growing market, these systems are key. I recommend them for creating a safe, efficient, and legally compliant production line.

My Take on Why Industrial Filtration Matters

From my experience, industrial filtration systems are vital. They have a big impact on manufacturing efficiency, safety, and rule compliance.

Protecting Gear and Cutting Costs

Filtration systems clean liquids and gases by removing harmful particles. I’ve seen how this protection stops wear and tear on expensive machinery. It prevents damage and buildup. This means manufacturers have lower repair bills. They also avoid sudden shutdowns. I believe this makes the whole operation more dependable.

Making Sure Products are Pure and Safe

I think filtration is essential for high product purity. In my field, I see this in pharmaceuticals, food and beverage, and chemicals. Filtration systems stop different substances from mixing. This helps companies meet strict safety rules. We use technologies like nanofiltration to get rid of bacteria and other dissolved materials. The result is a better and safer product for everyone.

Meeting Enviro Rules and Controlling Pollution

Industrial companies face more and more regulations. I suggest using filtration systems to meet these tough standards. Good examples are the U.S. EPA Clean Air Act and the EU Industrial Emissions Directive. For example, U.S. rules now limit PM2.5 to 9.0 μg/m³. China has a goal to cut PM2.5 by 18% by 2025. This has pushed many companies in heavy industry to adopt better filtration.

Handling Waste and Lowering Emissions

Good filtration technology helps factories create less waste. It also cuts down on harmful emissions. I’m impressed by new methods like Electrocoagulation (EC). It removes stubborn pollutants like PFAS, the “forever chemicals,” from wastewater as it flows. I believe these new technologies help us produce things in a cleaner, more responsible way.

Pushing for Sustainability and Energy Savings

I’ve seen filtration systems make manufacturing more sustainable. They help save water and energy. They also encourage using filter materials that are biodegradable or recyclable. This lets companies shrink their environmental footprint. I like how companies such as Dupure use filtration solutions that are good for the environment. This helps them lower their total carbon output.

Based on my experience, industrial filtration is a key part of modern manufacturing. It supports cleaner production and keeps workers safe. It also ensures rules are met and promotes sustainability. I feel it is essential for efficiency gains in all major manufacturing industries.

The Main Benefits of Industrial Filtration in Manufacturing

From my experience, industrial filtration systems offer many benefits. They can make your manufacturing safer, more efficient, and more profitable. Here is a closer look at the core advantages I’ve seen:

Better Product Quality and Reliable Processes

It takes out unwanted particles and solids from liquids and air. This helps you make better products and keeps your processes running smoothly every time. For example, filtering water in the food and beverage industry removes chemicals and germs. I believe this makes products safe and taste great.

Longer Equipment Life

It stops buildup like sediment and rust on your pumps and valves. Based on my experience, this means you’ll have fewer expensive repairs and replacements. For example, using clean hydraulic fluids means your machines can run longer between service checks.

More Efficiency & Less Downtime

Clean air and fluids prevent your equipment from clogging and breaking down. I suggest using automated filters. You won’t need to change them by hand as often, which reduces stops in production. This results in a smoother and more productive manufacturing process.

Real Cost Savings

With less maintenance and downtime, you spend less money on operations. I have seen some systems recover useful materials from waste, which can create new ways to make money.

Helps the Environment and Reduces Waste

Filtration traps harmful fumes, VOCs, and dust. This lowers your factory’s impact on the environment. It also makes it simpler to follow environmental rules. For example, air filters can catch harmful airborne particles before they get into your workplace or outside.

Meeting Regulations

I find that filtration is necessary to meet tough laws for quality, safety, and the environment. It is vital for industries like food, healthcare, and pharma. They must follow WHO and national water standards.

Improved Energy Use

When fluids and air are clean, machines work better and use less energy. Less resistance means your pumps, compressors, and climate control systems use less power. For example, removing particles from the system reduces the total energy your process needs.

A Safer Workplace for Everyone

It protects your employees from breathing in harmful dust, chemicals, and germs. Good filtration is key for worker health. The U.S. EPA notes that indoor air can be up to five times more polluted than outdoor air.

The Dangers of Skipping Good Filtration in Your Factory

Based on my experience, running a factory without a good filtration system creates many serious risks. If you skip proper filtration, you’re asking for trouble. Let’s look at the main problems I’ve seen.

Operational and Efficiency Risks

Clogged Filters & Pressure Problems: Bad filtration slows down how you move materials. Sometimes, it stops production completely. I’ve seen clogged filters cause pressure to drop. This makes your blowers and motors work much harder. Your energy use goes up, and you face constant shutdowns.

More Downtime & Breakdowns: If you work with fine powders like sugar or cement dust, you need good filters. Without them, your systems will often shut down. I find that regular stops to clean or change filters mess up the whole production schedule.

Financial and Maintenance Impacts

Rising Operation Costs: With poor filtration, you’ll replace filters more often. I’ve noticed energy bills spike and equipment breaks down without warning. Every unplanned stop or fix adds to your costs and makes you late on deliveries.

Equipment Wears Out Faster: Letting dust and harmful particles build up in your machines causes faster wear. I’ve seen sensitive equipment fail much sooner than it should. This leads to expensive repairs. Your final products can also get ruined by these particles.

Example: Take cement manufacturing. It makes up 28.4% of the world’s air filtration market. In this industry, dust buildup damages machines and the final cement. This leads to higher costs for maintenance and replacements.

Safety and Regulatory Compliance

Dangerous Work Areas: Loose dust is more than just messy; I believe it’s a huge safety risk. It can harm your workers’ breathing. It can even cause dust explosions. I know of one case where a dry mix plant had to shut down because the dust levels became explosive.

Worker Health Problems: Breathing unfiltered air is dangerous. It can cause long-term breathing problems and skin or eye issues. From my perspective, this means more sick days, higher healthcare expenses, and the chance of being sued for an unsafe workplace.

Fines and Penalties: New rules in the US (NFPA 660) and UK (Air Quality Management) are very strict. If you don’t control airborne particles, you could get big fines. I suggest you take this seriously, as they can even force your plant to close for not following the rules.

Market and Sector Impact

A Growing Market: The need for filtration is clear from the market numbers. The global industrial filtration market was valued at USD 37.2 billion in 2025. It’s expected to hit USD 65.8 billion by 2035, growing at 5.7% each year. This shows me that companies are investing more in filtration to manage risks and meet new rules.

Industries at High Risk: From my point of view, some industries face bigger risks. These include metals, mining, chemicals, and energy. I would also add pharmaceuticals and bulk food production. They all deal with lots of harmful particles or liquids, so a filtration failure can be a disaster.

Summary of Main Risks Without Proper Filtration

- Lower efficiency and lost productivity from bad airflow

- Higher energy bills and running costs

- Unsafe work conditions due to dust and fumes

- Fines and forced shutdowns for breaking rules

- More maintenance and expensive, unexpected downtime

- Health risks for your team from bad air

- Damaged equipment and poor product quality

I believe that ignoring industrial filtration is a mistake. It puts your entire operation, your workers, and your profits in danger. With stricter rules and real examples of shutdowns, it’s clear that good filtration is essential. I recommend you make it a top priority.

How Different Industries Use Filtration Systems

From my experience, different factories need filtration systems for different reasons. It all depends on their rules for safety and getting the job done well.

Food & Beverage Manufacturing

I recommend reverse osmosis systems for making soft drinks. They take out dissolved solids. This keeps the taste the same and meets high safety rules.

To handle oils and fats, I suggest using activated sludge and advanced wastewater filters. This cleans the water so you can use it again or get rid of it safely. It’s better for the planet and saves money.

You need compressed air filtration to protect your packaging lines. It keeps dirt from the air out of the product. This is a key step to prevent having to recall a whole batch.

Automotive Industry

In car factories, compressed air filtration gets rid of moisture, oil, and tiny particles. This helps air tools like impact wrenches work well. I’ve found this cuts down on breakdowns and repair bills.

Car plants must treat their wastewater. Filtration systems remove heavy metals and paint before the water is released. I think this is a must-do to follow environmental laws and protect nature.

Pharmaceutical Sector

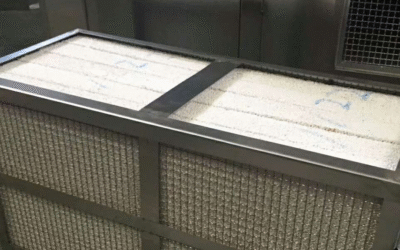

- Keeping the air pure is a top priority in this field. It stops products from mixing and meets industry rules. Based on my experience, companies use HEPA and cartridge filters in cleanrooms. This ensures products are sterile and everything is up to code.

- Filtration also keeps the machines on the production line safe. This means fewer surprise stops. A stable supply chain is a great benefit.

Power Generation

- Power plants install air and gas filtration systems. I believe this is smart because they remove dust and chemical vapors. This protects expensive machines from dirt inside and also cuts down on pollution.

- Using good filters helps power plants avoid big fines. It ensures their emissions stay within legal environmental limits.

Metalworking and Chemicals

- I see many plants use scrubbers and particle separators. They pull dangerous fumes and dust from the air. This makes the workplace safer and helps the company follow the rules.

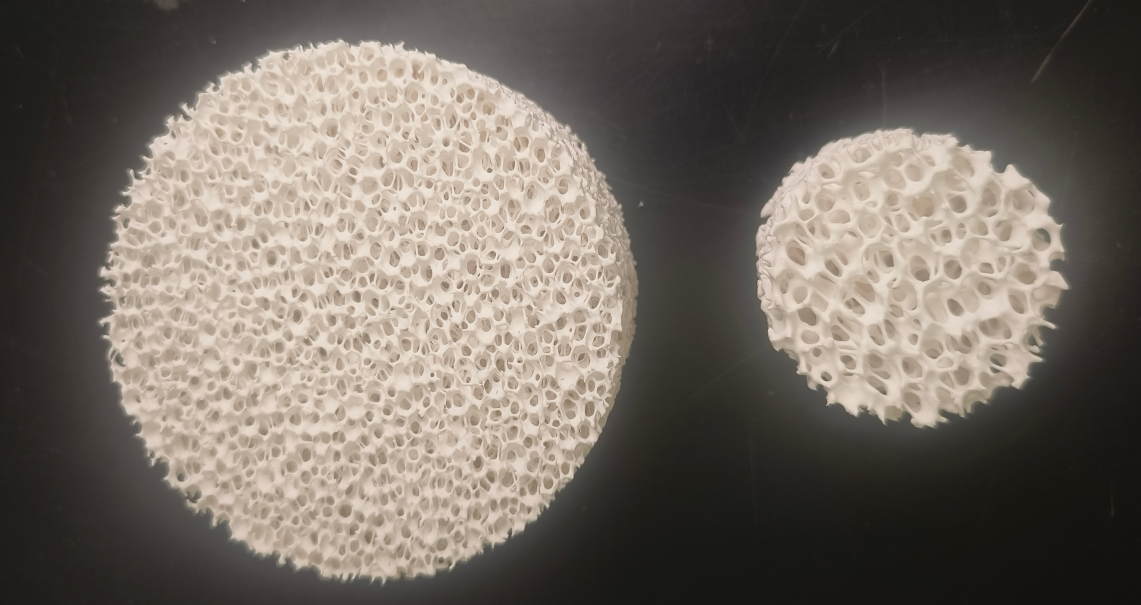

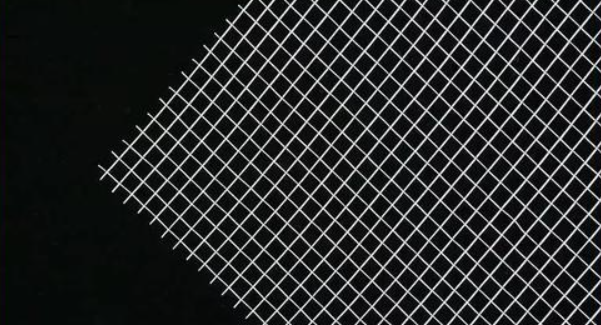

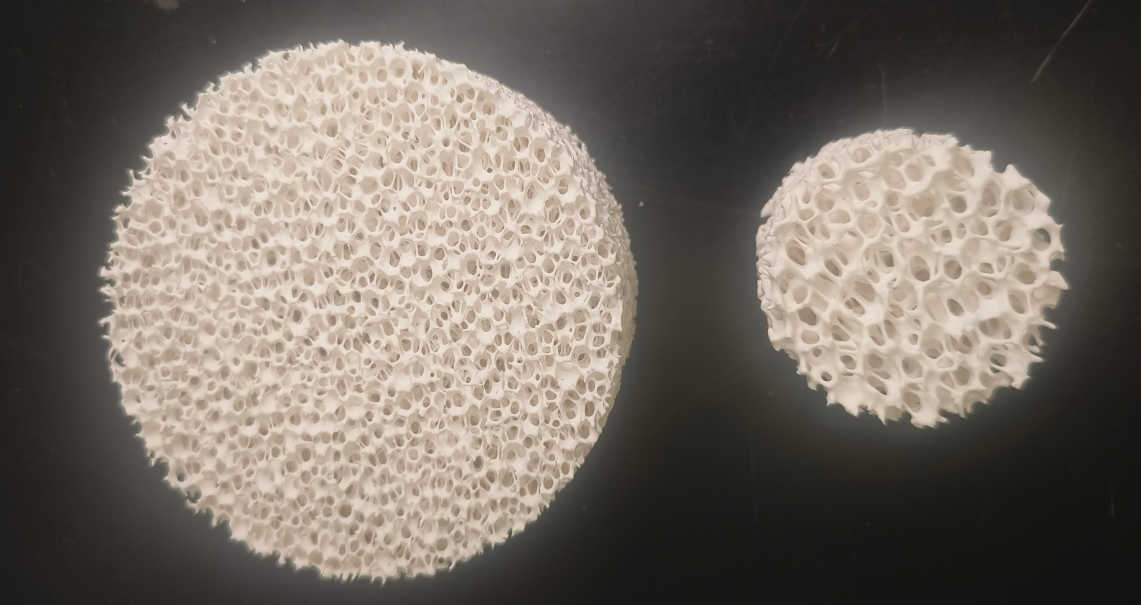

- Custom wire mesh or metal cloth filters are great for separating solids from liquids or air. In my opinion, they make the whole process work better. This leads to less time wasted on downtime.

Industrial Wastewater Treatment

- Filtration systems with multiple stages can clean industrial wastewater and sludge. They take out pollutants. After cleaning, the water can be safely released or used again.

- I often recommend porous metal filters that meet ISO 9001 standards. They are used for filtering sludge and wastewater. They deliver good results every time.

Cross-Industry Data and Typical Applications

- Did you know indoor factory air can be five times more polluted than outside air? From my perspective, this makes good filtration essential. It protects worker health and keeps the workplace safe.

- Good filtration improves energy use. It makes systems work less hard. This saves money on operating costs for any business.

- Filters keep dirt out of your machines. I’ve seen how this makes equipment last longer. You’ll have fewer breakdowns and lower repair costs.

Common Applications Include:

– Cleaning air and gas for better, more predictable results.

– Keeping expensive tools like pumps and compressors safe from harm.

– Improving product quality by filtering raw materials. This helps avoid product recalls.

– Cutting down on harmful emissions to meet environmental laws.

– Cleaning factory air, liquids, and waste to be more eco-friendly and follow regulations.

In my view, these examples from different industries show how useful and important filtration systems are. They are a key part of modern manufacturing.

summary

From my experience, filtration systems completely change how factories operate. I see them as more than just machines. I believe they are the very base for building a cleaner, safer, and more successful business. Industries are changing, and government rules are getting stricter. I am certain that making smart filtration choices today decides which companies will do well tomorrow. The real question is not if you need these systems, but how soon you can install them to get ahead.