ceramic filters are now key parts in modern foundry work. They act as barriers between molten metal and final cast products. These porous structures use alumina-silicate compositions, aluminum oxide (Al₂O₃), and diatomite-based ceramics. Each type traps unwanted materials while letting clean molten metal flow through.

The global foam ceramic filter market hit USD 450 million in 2024. It’s expected to reach USD 790.69 million by 2032. That’s a 7.2% CAGR growth rate. Casting industries want better quality, so demand keeps rising. These filters work with cast irons, aluminum, and copper-based alloys. You can use them across many foundry applications worldwide.

Core Structural Characteristics

Top Ceramic filters have controlled pore designs:

-

Average pore diameter: 10.023 μm

-

Specific surface area: 230 m²/g

-

Total porosity: 71.74%

-

Macroporosity: 53.40% in aluminum oxide variants

Flow-Rite® filters come in cell sizes from 10ppi/100csi to 30ppi/300csi (pores per inch/cells per square inch). You pick the right filtration density based on your metal type and casting needs. Random foam structures vary in quality. But engineered ceramic filters give you the same cellular structure from filter to filter. This means consistent performance across all your production runs.

How Ceramic Filters Remove Impurities

Ceramic filters work in two ways: mechanical entrapment and surface adsorption. Molten metal flows into the filter. The pore network creates a winding path. Non-metallic bits hit the ceramic walls. Particles get stuck in the connected spaces. Clean metal keeps flowing through.

Pore Size Controls What Gets Trapped

Pore diameter decides which particles get caught. Filters sintered at 850°C make 0.73 μm pores. Heat to 950°C and pores grow to 1.07 μm. Diatomite-based filters have 10.023 μm average pore diameter. They also pack 230 m²/g surface area. Position these at 40° elevation angle. You get 74.05% impurity removal rate.

More surface area means more spots where particles stick. Diatomite ceramics hit 71.74% total porosity. This creates huge void volume. It captures oxide formations, mold debris, and slag particles. Aluminum oxide versions reach 67.6% porosity. They hold 14.35 MPa compressive strength too. So they handle casting pressures without cracking.

Chemical Bonding Grabs Specific Impurities

Filters don’t just trap particles. Ceramic surfaces bond with certain impurities. Test tetragonal cristobalite with methyl orange dye for 90 minutes. It shows 40.43% decoloration rate. Aluminum oxide filters have 53.40% macroporosity. They pull methylene blue molecules from test solutions. This proves the chemistry works in real casting.

Different metals need different filtration ratios:- 3:1 ratio for Gray Iron casting- 4:1 ratio for aluminum and copper-based alloys- 5:1 ratio for ductile iron applications

These specs give enough surface area to catch impurities. They don’t create pressure drop that slows your production line.

Uniform Flow Stops Impurity Escape

Engineered cell structures spread molten metal across the whole filter face. Metal flows uniformly. No bypass channels form. Impurities can’t sneak through. Random foam structures perform inconsistently. Weak spots create unpredictable flow paths.

Flow-Rite® engineered filters deliver identical performance filter-to-filter. Precise manufacturing ensures this. The runner system controls metal stream speed. This cuts down turbulence. Less turbulence means less oxidation during pouring. Fewer fresh oxide bits form after the filter stage.

Sintering Temperature Shapes Performance

Sintering temperature controls how well filters work. Diatomite ceramics perform across 600-1000°C range. Aluminum oxide filters need 1400°C for best results. Raise temperature from 850°C to 950°C. Porosity jumps from 35.38% to 43.90%. Compressive strength climbs from 6.55 to 7.02 MPa. You get enough void space plus structural strength. The filter won’t collapse under metallostatic pressure.

Ceramic filters use both methods—blocking particles and chemical bonding. This removes non-metallic inclusions, oxide particles, and mold erosion debris. Works across cast iron, aluminum, and copper alloy casting.

Types and Structures of Ceramic Filters

How you make ceramic filters shapes their performance in real casting. Three main production methods create different structures. Each structure affects how well the filter works.

Extrusion Method for High-Strength Applications

Extrusion builds strong filters with excellent mechanical properties. These aluminum oxide filters are sintered at 1400°C. They deliver 14.35 MPa flexural strength. High-pressure casting environments need this strength.

The method achieves 67.6% total porosity. It also creates 53.40% macroporosity. Large connected voids trap dirt and particles. Molten metal still flows through without blockage.

Makers control key factors during extrusion. These include filling rate, nozzle diameter, and filling angles. This control produces uniform pore shapes throughout each filter. Linear shrinkage stays at just 2.51%. Size stays the same from batch to batch. Your filters fit into gating systems every time. No adjustment needed.

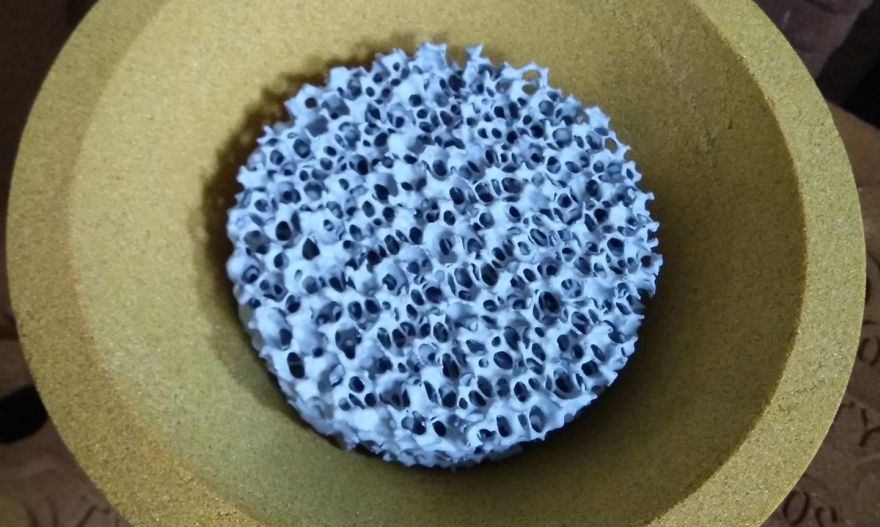

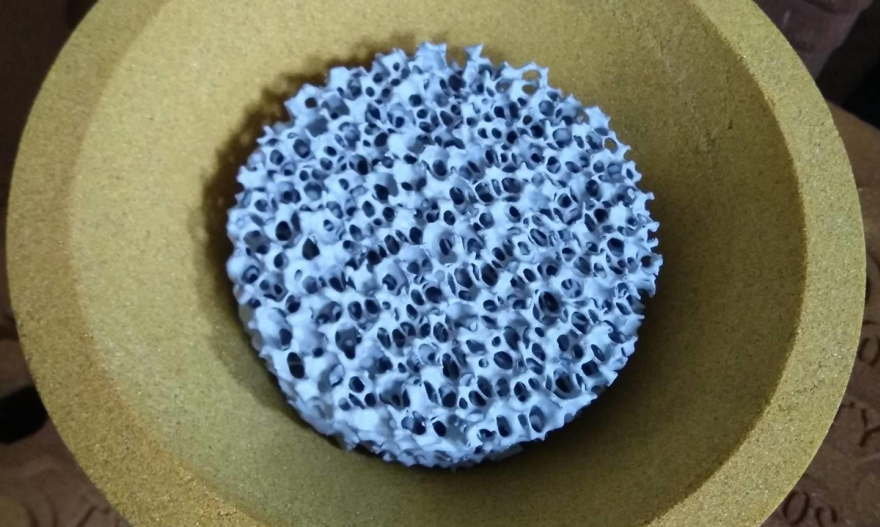

Hand Compression for Maximum Surface Area

Diatomite-based filters use hand compression molding. This creates completely different traits. Total porosity reaches 71.74%—the highest of all filter types. Average pore size measures 10.023 μm. The specific surface area hits 230 m²/g.

More surface gives more contact points. Dirt sticks to these points through chemical bonds.

These filters work at 600-1000°C sintering temperatures. Lower heat cuts production costs. Compressive strength reaches 4.535 MPa. Most aluminum and copper alloy work needs this level. Lab tests show clear results. These filters achieve a 40.43% decoloration rate. They remove methyl orange dye in 90 minutes. This proves real chemical adsorption power. It goes beyond just mechanical trapping.

Cast TOMO Process for Advanced Geometries

The Cast TOMO process is cutting-edge. This method builds engineered complex internal structures. Traditional methods can’t make these. Filters show lower variation in flow rate and pressure drop. Random foam designs can’t match this.

Uniform cell design delivers identical performance filter-to-filter. Production stays the same. Results stay predictable across thousands of castings. The process creates stronger designs. Thermal shock resistance improves. Filters survive fast temperature changes during metal pouring. No cracking happens.

Industry standards set cell density from 10 ppi/100 csi to 30 ppi/300 csi. Coarser 10 ppi filters handle dirty melts with lots of contamination. Finer 30 ppi versions catch tiny particles in clean metal. Match cell density to your dirt problems and metal thickness.

Impurities Targeted by Ceramic Filters

casting defects start with what ceramic filters catch. These filters target non-metallic inclusions. That’s the main problem in cast irons, aluminum, and copper alloys. The porous structure works two ways. It blocks solid particles. It also cuts down turbulence in the metal stream. Less turbulence means less oxide forms and less mold wears away during hot pours.

What Gets Trapped and How Well

Field data shows ceramic filters achieve 74.05% impurity removal rate at 40° elevation angle. The stable flow keeps particles from escaping. But the chemistry plays a role too. Diatomite-based filters remove organic dirt through absorption. Lab tests back this up—40.43% methyl orange color removal happens in just 90 minutes.

The secret sits in pore design. Different dirt sizes need different catching methods:

-

Particle-level filtration: 10.023 μm average pore diameter catches oxide bits and slag pieces

-

Chemical absorption sites: 230 m²/g specific surface area bonds with dissolved dirt

-

Size-based trapping: Pore space ranges from 35.38% to 43.90% based on heat treatment temperature

Real-World Quality Gains

Better dirt removal shows up where it matters:

-

Lower scrap rates and fewer customer returns

-

Smoother cast surfaces straight from the mold

-

Easier machining with less tool wear

-

Higher yield through better runner system design

Pore size tuning makes this work. Bump heat treatment from 850°C to 950°C. Average pore diameter grows from 0.73 to 1.07 μm. Pore space jumps from 35.38% to 43.90%. You control which particle sizes get caught.

Cell density choice matters for targeting specific dirt. 10 ppi filters handle heavy dirt in contaminated melts. 30 ppi versions catch tiny bits in pre-cleaned metal. Match the cell count to your dirt type. You get steady results from pour to pour.

Benefits of Using Ceramic Filters in Casting

Cleaner castings mean real cost savings across your production line. Ceramic filters cut scrap and reduce machining time. Foundries using these filters see fewer customer returns, lower rejection rates, and smoother post-casting operations.

Direct Quality Improvements

Metal flowing through ceramic filters comes out with better surface finish. The twisted flow paths trap unwanted particles before they reach your mold cavity. Your castings need less grinding and finishing work. Machining gets easier too. Tools last longer because cutting edges hit fewer hard oxide particles in the metal.

Surface quality improves right after shakeout. Castings come out with better as-cast finish. Less surface prep means parts move through your shop faster. Your customers get components that meet tighter specs without extra processing steps.

Production Efficiency Gains

Optimized runner systems pair well with ceramic filters to boost yield. Metal flows into cavities without turbulent mixing. This avoids creating fresh oxides. Less turbulence means less mold erosion during the pour. Your gating systems last longer. Core wash stays put where you need it.

Standard filtration capacity ratios guide proper sizing:- Gray iron: 3:1 minimum ratio- Aluminum and copper alloys: 4:1 minimum ratio- Ductile Iron: 5:1 minimum ratio

Match these ratios to your metallostatic head and metal temperature. This maintains consistent flow without excessive pressure drop that slows fill rates.

Broad Material Compatibility

One filter technology handles multiple metal families. Ceramic filters work well with all cast iron grades, aluminum alloys, and copper-based metals. Stock filters in 10ppi to 30ppi cell densities. This covers coarse filtration for contaminated melts and fine filtration for precision casting.

The versatility cuts inventory complexity while keeping performance strong across your product mix.

Quantitative Effectiveness

Lab tests show ceramic filters remove measurable impurities across multiple metrics. E. coli removal rates hit 97.7–99.9% under controlled conditions. Log removal values (LRVs) range from 4.46 to 4.89. Field studies in Longhai City, China show different results. Removal efficiency spans 75–100%. The average reaches 94.7% in actual foundry environments. Lab and field performance differ. Variables like metallostatic head, metal temperature, and contamination levels cause this gap.

Metal Contaminant Removal Performance

Ceramic filters remove dissolved metallic impurities well. Lead removal reaches 99.9% efficiency. Chromium removal matches this at 99.9%. Tests with methyl orange dye show 41% removal through chemical adsorption alone. The filters work two ways. They use mechanical trapping. They also use chemical bonding.

Turbidity drops sharply through ceramic filtration. Test results show reduction from 13 NTU to 0.45 NTU. Total dissolved solids (TDS) fall from 1245 mg/L to 360–530 mg/L. Fluoride levels decrease from 3.4 mg/L to 0.053 mg/L. This meets WHO drinking water standards. You get cleaner metal streams in casting operations.

Flow Rate Performance and Operational Limits

Optimal flow rates range from 1.9 to 2.5 L/h under controlled conditions. Maximum discharge reaches 39 mL/h with optimized filter preparation. Flow rates decline during extended use. They drop from initial 1.2–2.0 L/h as pore clogging progresses. Performance degrades over time. You need periodic filter replacement. This maintains consistent impurity removal throughout production runs.

Why Ceramic Filters Remove Impurities

Six proven ways explain how ceramic filters remove impurities in casting:

1. Pore Structure Design

The filter has controlled pore networks. These create winding flow paths. The best designs reach 67.6% total porosity with 53.40% macroporosity. This setup traps non-metallic particles. At the same time, metal flows through smoothly. Higher sintering temperatures expand pores from 0.73 μm to 1.07 μm. This adjusts what particle sizes the filter can catch.

2. Chemical Bonding Sites

High surface area allows chemical bonding with dissolved dirt. Filters show 41% organic dye removal through surface chemistry alone. This goes beyond simple trapping. Heavy metals like lead and chromium? 99.9% removal efficiency. The filter uses both physical and chemical ways to catch them.

3. Steady Flow Pattern

Install the filter at a 40° elevation angle. This creates even metal distribution. You get a 74.05% impurity removal rate. Lower turbulence stops fresh oxide from forming during pouring. Plus, it cuts down on mold erosion throughout the casting cycle.

4. The Filter Cake Effect

This isn’t a designed feature, but rather a natural benefit of casting. Large impurities clog the intake surface, not disappearing but instead piling up into a “filter cake” layer. This filter cake itself acts as a finer sieve. As pouring continues, this natural barrier traps particles smaller than the pore size, making the molten metal cleaner.

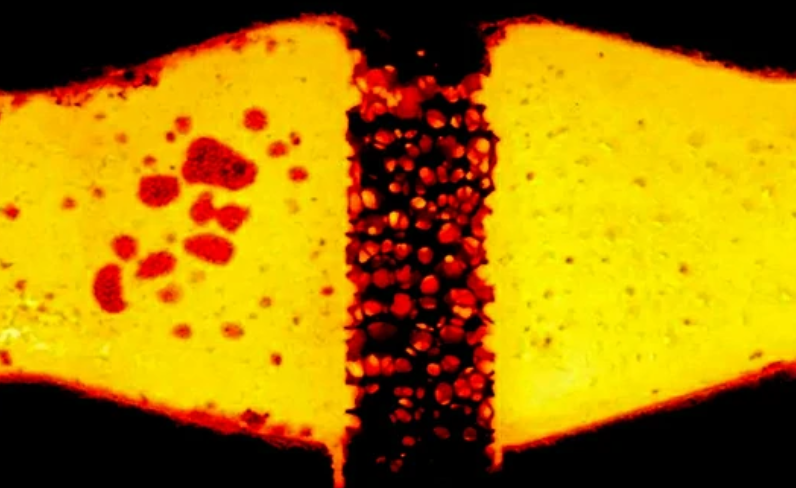

5. Deep Bed Filtration

Cut open a ceramic filter, and you’ll find it’s like a maze. This 3D structure doesn’t just trap impurities on the surface. As the molten metal flows through the winding channels, small inclusions get stuck in “dead corners” or deep pores. This is why particles smaller than the pore size can also be removed.

6. Physical Adsorption

Microscopic physics also plays a role here. The large surface area inside the filter generates van der Waals forces. Tiny impurities approach the tube wall, and the attraction holds them in place. This is especially effective for micron-sized particles that are too small for mechanical interception.

Conclusion: Choosing the Right Filtration Strategy

Ceramic filters are more than just sieves. They combine interception, rectification, and adsorption. A good filter can remove 99.9% of impurities. Therefore, choosing the right specifications is crucial.

Balancing “cleanliness” and “flow rate” is important. Pursuing high pore density (above 30ppi) to catch fine impurities? The flow rate will be slow, easily leading to cold shuts. Large pore size for precision parts? The surface finish won’t be achieved.

We need to adjust the material and density according to the alloy type, temperature, and quality requirements (strength or surface finish). The best filters not only remove impurities but also perfectly integrate into your current production process.