FM-03 Zirconia Ceramic Foam Filters: High-Temperature Filtration Solution

FM-03 zirconia ceramic foam filter is designed for high-temperature metal casting filtration. Made from premium zirconia (ZrO₂), it removes harmful impurities from steel, nickel alloys, and other molten metals up to 1760°C, improving casting quality and reducing defects.

Key Benefits

Extreme heat resistance – Works up to 1760°C

Superior inclusion removal – Captures impurities in stainless steel, carbon steel, cast iron, aluminum, copper, and superalloys

Stabilizes metal flow – Reduces turbulence for cleaner, smoother castings

Universal compatibility – Fits all standard gating systems and refractory materials

Works with casting processes – Sand casting, gravity casting, precision casting, and more

Reduces waste – Lowers scrap and rework rates for higher profits

Why Choose FM-03 Zirconia Filter?

Best for extreme conditions – Unmatched performance in high-temperature metal casting

Proven to cut defects – Improves surface finish and mechanical properties

Easy to integrate – Directly installed into existing foundry equipment

Advanced Zirconia Ceramic Filter Technology for Superior Metal Purity

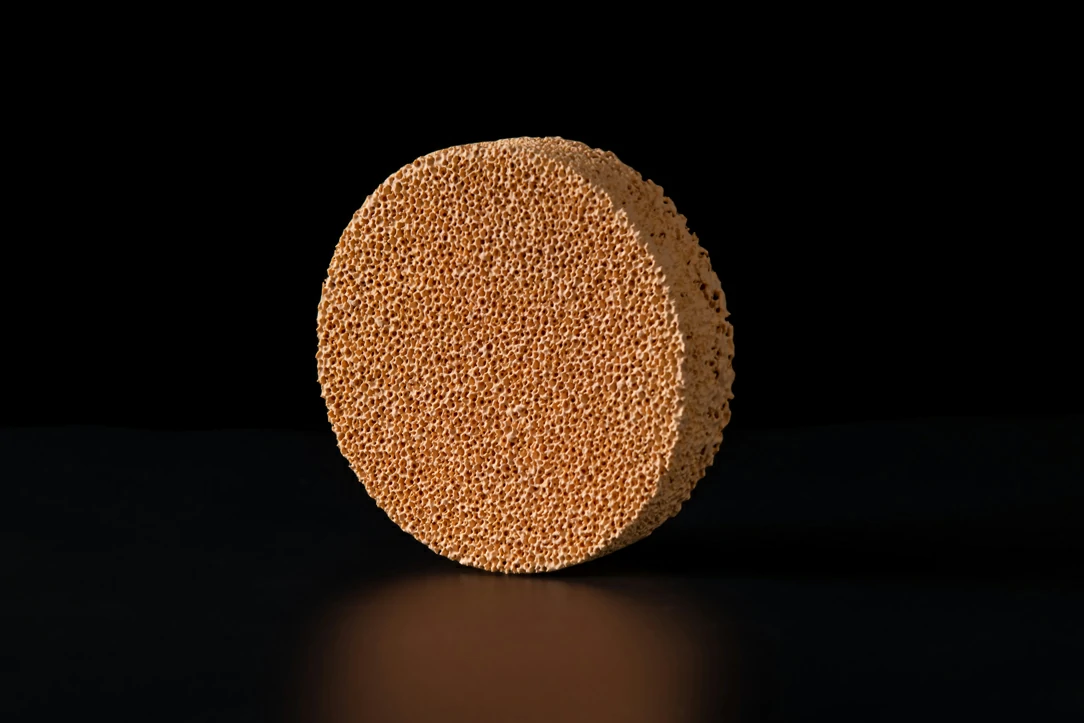

Made from high-quality zirconium oxide (ZrO2) material, our ceramic foam filters withstand temperatures up to 1760°C while effectively removing inclusions and transforming turbulent flow into laminar flow, significantly improving casting quality and yield.

Technical Specifications

| Material | Zirconia | |

| Operating Temperature (°C) | ≤1760 | |

| Pore Size (PPi) | / | |

| Compressive Strength (MPa) | ≥1.2 | |

| Density (g/cm³) | ≤1.5 | |

| Thermal Stability (1100°C/times) | 6 | |

| Composition | Al₂O₃ (%) | 10-35 |

| SiO₂ (%) | 0-5 | |

| SiC (%) | / | |

| ZrO₂ (%) | >70 | |

| Other (%) | 0-10 | |

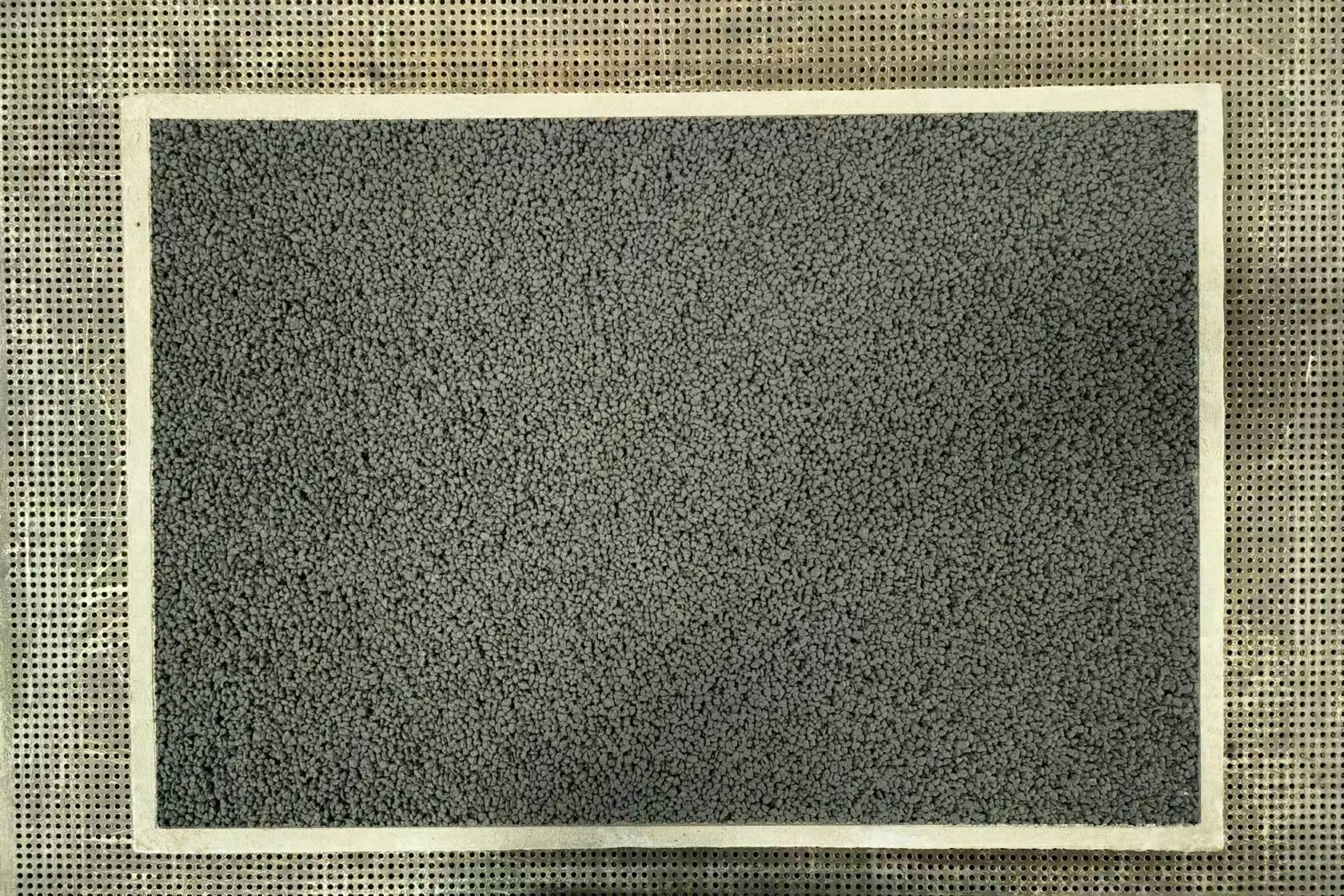

Custom Size

Custom specific filter sizes based on gating system requirements, from 50×50×15mm up to 300×300×50mm

Custom Shape

Available in a variety of shapes, including square, round, rectangular, and trapezoidal, etc.

Pore Size Range

Pore size ranges from 10 ppi to 40 ppi, selected according to the molten metal flow requirements

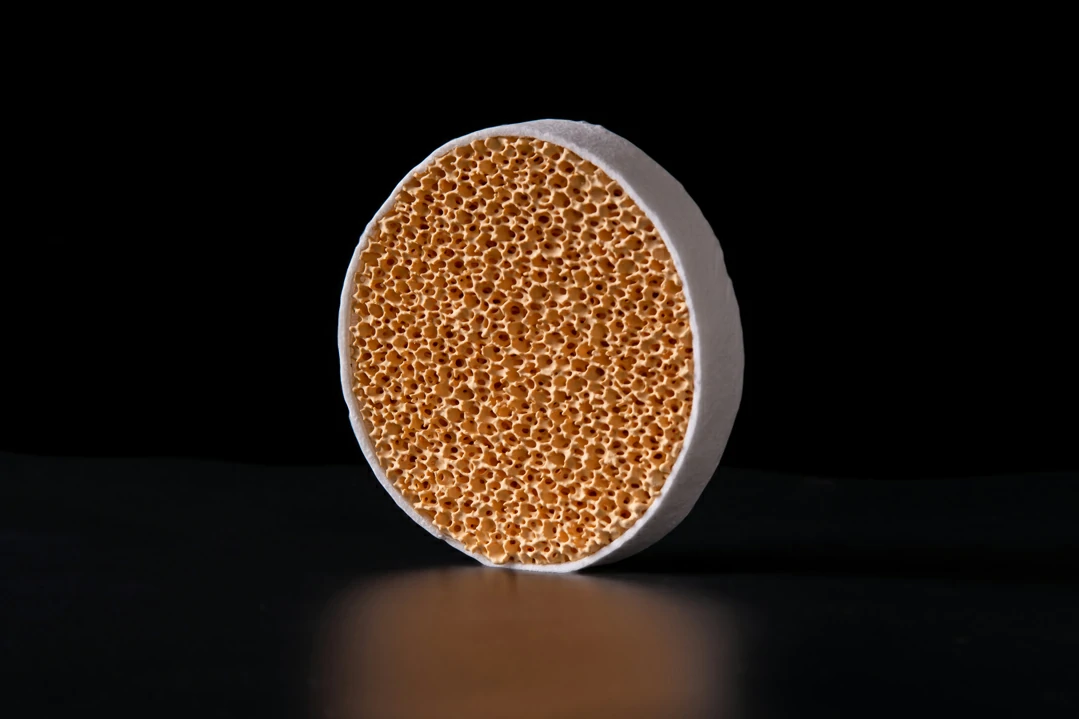

Edge Treatments

Edge-sealing technology prevents bypass and channeling during molten metal filtration

What Can We Offer?

Our FM-03 zirconia ceramic foam filters, with their exceptional high-temperature resistance, superior mechanical strength, and unique three-dimensional pore structure, are a molten metal filtration solution for a variety of high-end casting applications. They provide ultra-pure molten metal, significantly improving product quality, reducing production costs, and enhancing market competitiveness. We offer more than just products; we provide complete metal purification solutions and professional technical support.

Our zirconia filter product, featuring balanced porosity for steel and high-temperature alloy casting. These filters efficiently remove inclusions while maintaining optimal metal flow rates, making them suitable for a wide range of casting weights and geometries.

Three-dimensional porous structure captures both macro and micro inclusions

Converts turbulent metal flow to stable laminar flow, improving casting filling uniformity

High mechanical strength withstands the pressure of molten metal without damage or debris

Superior thermal shock resistance prevents cracking during preheating and pouring

Proprietary ZrO2 ceramic formulation ensures chemical stability with reactive metals

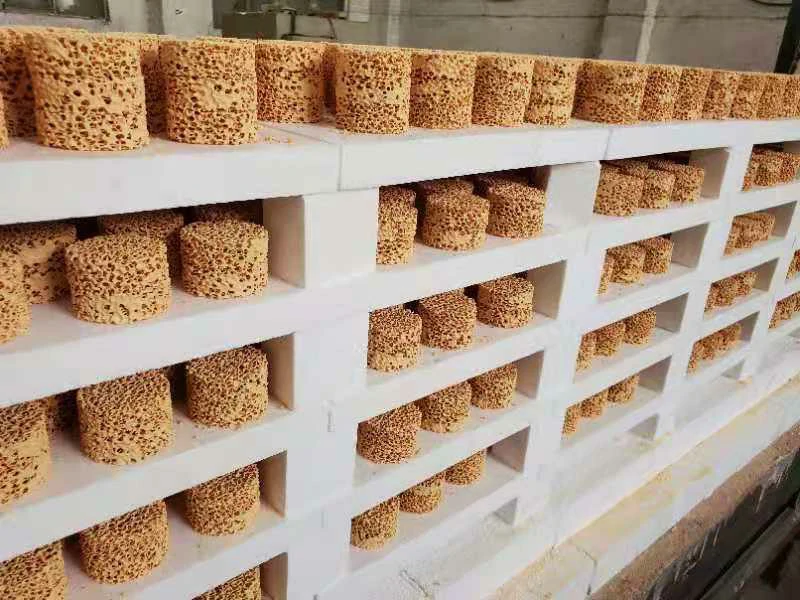

Available in a variety of filter sizes to suit most steel foundry gating systems

Available in custom dimensions and pore sizes to match specific casting requirements

ISO9001 certified quality management system, ensuring stable and reliable product quality

Ceramic Filters for High Temperature Steel Alloys

Our company offers a broad range of zirconia ceramic foam filters. We have developed additional filtration solutions tailored to specific applications and customer needs.

Developed specifically for high-temperature precision casting applications (≥1700°C) for materials such as specialty steels and high-temperature alloys. These ceramic filters provide enhanced filtration efficiency for precision castings where superior metal cleanliness is required. Ideal for producing high-end castings for aerospace, medical, and high-performance industrial applications.

Zirconia Filter Application

Apply Zirconia Ceramic Foam Filters to your existing casting process, following a systematic approach to ensure optimal results. Our Zirconia Ceramic Foam Filters are designed to integrate seamlessly with nearly all existing metal casting and investment casting processes.

In precision investment casting of critical steel components, ZrO2 ceramic foam filters are positioned within the gating system, typically in a dedicated filter print. During pouring, the molten steel passes through the filter, which removes non-metallic inclusions and oxides while converting turbulent flow to laminar flow.

Frequently Asked Questions

What is the difference between PPI ratings on your filters?

PPI (Pores Per Inch) indicates the filter’s pore density. Higher PPI values (30-60) provide finer filtration but restrict flow more than lower PPI values (10-20). The optimal PPI depends on your specific inclusion size distribution and flow rate requirements. Our graduated porosity designs often incorporate multiple PPI zones to optimize both filtration efficiency and flow characteristics.

How do ZrO2 filters compare to alumina filters for steel casting?

Zirconia filters offer significantly higher temperature resistance (1760°C vs. 1200°C for alumina), superior thermal shock resistance, and enhanced mechanical strength. This makes them the only viable option for steel casting applications where temperatures typically exceed the capabilities of alumina filters. Additionally, ZrO2 filters maintain their structural integrity throughout the pour, whereas alumina filters may degrade during extended contact with high-temperature steel.

Can the same filter materials be used for different metal types?

While technically possible in some cases, we strongly recommend using filters specifically selected for each metal type. Different alloys have varying inclusion characteristics, wetting behaviors, and temperature requirements that affect optimal filter performance. Our application engineers can help determine if a single filter specification can meet multiple needs in your operation.

Can filters be reused?

No, ZrO2 ceramic foam filters are designed for single use only. After exposure to molten metal, the filter structure contains solidified metal and captured inclusions that would compromise performance in subsequent uses. Additionally, the thermal cycling weakens the ceramic structure, making reuse unsafe.

How do I determine the correct filter size for my casting?

Filter sizing depends on several factors including metal volume, flow rate, and gating design. As a general rule, the filter area should be 2-4 times the choke area in your gating system. Our Technical Selection Guide provides detailed calculations, or our application engineers can assist with specific recommendations based on your casting parameters.

More Foundry Filters

Dedicated to excellence in foundry filtration, we provide high-quality molten metal filters to enhance your casting processes.

Request a technical consultation with our filtration specialists to identify the optimal Zirconia Ceramic Foam Filter specification for your specific application. Our team will analyze your current process and provide customized recommendations to maximize quality improvements.

Discover Your Optimal Filtration Solution

Request a free consultation with our filtration specialists to identify the ideal industrial filter technology.

CONTACT US

Let's Connect

Our Engineers Will Analyze Your Needs & Offer the Perfect Filter Design – Contact Us Today.

Address

Guanting Industrial Park, Cangzhou City,

Hebei Province, China