Overview of Sand Casting Sands

Sand casting uses different types of molding sands. Each type has unique properties. You select them based on what your project needs. The main types are green sand, resin-coated sand, sodium silicate sand, core sand, and facing sand. I recommend learning the differences. This knowledge helps you pick the right material. It affects casting efficiency, surface finish, and cost.

Green Sand: Composition, Advantages, and Industrial Applications

Green Sand Composition and Additives

Silica Sand (75–85%): This is the main sand component. We choose it for its high heat stability. For special alloy needs, chromite or zircon sand works better.

Bentonite Clay (5–11%): This acts as a binder. It holds the sand grains together.

Water (2–5%): Water activates the binder. It builds structural strength.

Additives:

- Inert sludge (3–5%): This improves texture and green strength.

- Sea coal (up to 5%): This cuts surface defects. It stops sand from sticking to molten metal.

- Gilsonite, cereals, dextrin, ground pitch, wood flour, silica flour, iron oxide, pearlite, molasses: Each additive adjusts specific properties. These include surface finish, gas venting, and release traits.

Physical Properties and Performance

- Permeability: This is vital for venting gases. It reduces porosity defects.

- Green Compressive Strength/Shear Strength: This keeps the mold in shape until metal hardens. It stops collapse and shifting.

- Dry and Hot Strength: Both are vital during pouring and cooling phases.

- Surface Finish: This ranges 250–1,000 micro inches. I find it moderate compared to resin and sodium silicate sands.

- Casting Wall Thickness: You can achieve walls down to 0.09 in. (2.3 mm) with precise sand control.

Production Scalability and Efficiency

Green sand suits lightweight parts (under 1 oz) and very heavy ones (up to 7,000 lbs). Modern foundries run at speeds over 300 molds per hour. This is perfect for mass production.

The process adapts to high-volume runs and small custom jobs. Foundries blend their own green sand. This ensures it matches specific metal alloys and job needs. You can get materials through construction and mechanic networks.

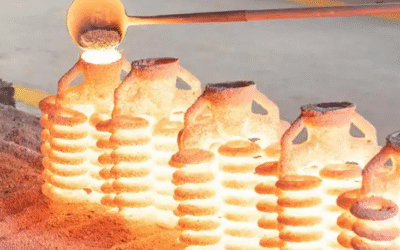

Sand Casting with Green Sand: Typical Process

- Load sand mixture into a flask.

- Compact the pattern (wood/plastic) into sand to shape the mold cavity.

- Remove the pattern, assemble the mold halves, and pour molten metal.

- After cooling, knock out casting, clean, and finish as needed.

Industrial Applications and Example Cases

Automotive: I recommend green sand for engine blocks, housings, and brackets. It works best with ferrous metals. But it also handles aluminum, magnesium, and copper alloys well.

Manufacturing: Gears, frames, and machinery bases are common uses.

General Foundry: This process flexes for both standard and complex shapes.

Key Benefits and Cost Analysis

Green sand offers great economics in high-volume or automated work. Material costs and reuse plans lower per-piece pricing. It molds easily. It handles many alloys and shapes. You can reclaim sand for dozens of cycles with minor fixes. This is a big sustainability win.

Additive Highlights: Roles and Value

- Sea Coal: This smooths surfaces. It prevents sand/metal adhesion.

- Gilsonite: This cuts nitrogen pinhole defects. It improves demolding.

- Silica Flour/Iron Oxide: These make molds more durable, especially in tough alloys.

Summary:

Green sand wins for its low cost, sustainability, and flexibility. It casts a wide range of component sizes and shapes. For simple to medium-complexity parts in high volumes, I suggest green sand. It offers the best balance of price and performance in modern foundry work.

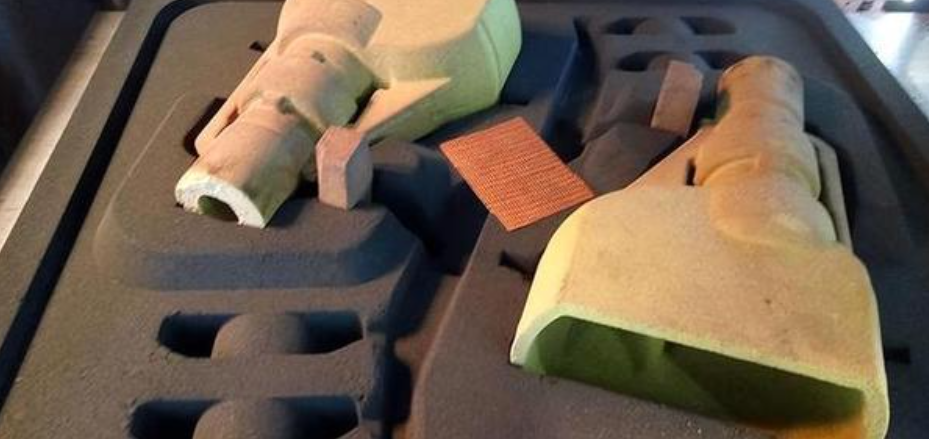

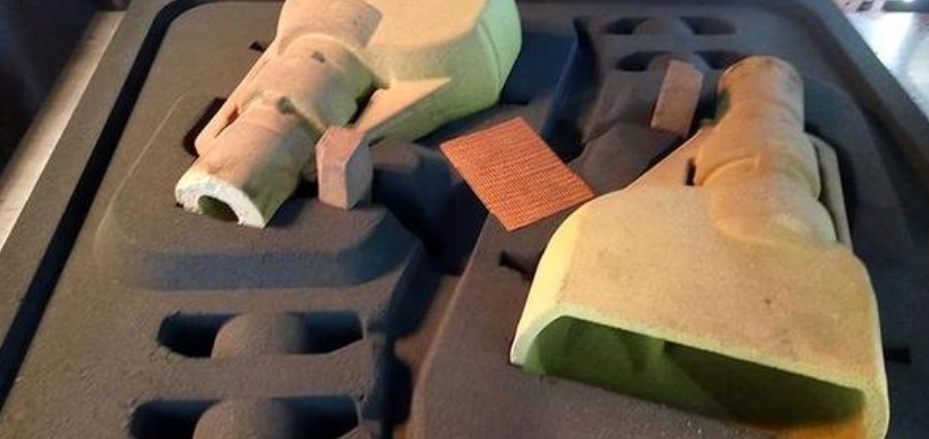

Resin-Coated Sand (Resin Sand): Composition, Process, and Casting Benefits

Resin-coated sand, often called resin sand, is made from high-purity quartz sand (like Sanei No. 6). We coat it with synthetic resins—thermosetting phenolic or furan resin. These sands are formulated for strong shells and accurate casting. Additives such as hexamethylenetetramine (HMT) act as curing agents. Calcium stearate and flow enhancers improve processing.

Typical Resin-Coated Sand Composition

- Quartz sand: 7000 parts (main component)

- Phenolic resin: 130–140 parts (binds and coats sand)

- Curing agent (HMT): 13–21 parts (mixed in solution)

- Calcium stearate: 7 parts (acts as a lubricant)

- All mixed at 130–140°C for uniform coating, with aeration to cool before screening.

You can also use novolac or resole phenolic bases depending on precise needs.

Processing Cycle and Mold Characteristics

- Shell process: Sand is preheated to ~150°C. Resin and catalyst are mixed in. After 20–40 seconds, the mixture is cooled, aerated, and screened. This cycle controls shell thickness and strength through temperature and dwell time.

- Typical shell core thickness: 5–25 mm, variable by application.

- Batch production rate: Industrial mixers can output several tons per hour. For example, 7000 kg of sand with 140 kg resin is a common batch for foundry use.

- Mold Production Speed: Shell molding lines can achieve 10–25 molds per hour.

Features and Advantages for Casting

- High green strength: 3–5 N/cm² (pre-cure); baked strength up to 6–12 N/cm² after heat curing.

- Tight dimensional accuracy: Achieves tolerances of ±0.2 mm for small and medium-sized castings.

- Excellent surface finish: Ra 1.6–3.2 µm—ideal for complex, smooth, or thin-walled castings.

- Mechanical strength: Cores/molds show compressive strengths up to 8 N/mm². This is double that of green sand.

- Consistent mold quality: Resin is 1.5–3.5% by sand weight to balance cost and performance.

- Gas emissions: Lower than traditional systems using low-emission resins (often <10% of older formulas).

Application Cases: Where Resin-Coated Sand Excels

Automotive: Thin-walled engine blocks, cylinder heads, and intake manifolds for high-precision surface finish.

Aerospace: Turbine blades, fuel system parts, and structural housings that require detailed contours.

Industrial: Hydraulic component housings, pump bodies, gear cases, and other parts that demand high strength and surface detail.

Japanese and German manufacturers use Sanei No. 6 sand blends to achieve top-tier quality on engine blocks and similar parts. Based on my experience, this combination offers the best results for precision work.

Production Efficiency and Economics

Resin-coated sand is about 1.5 to 2.5 times more expensive than green sand. This is due to the resin content and extra process controls. But it saves 10–15% on post-casting machining for parts with complex shapes. Foundries can adjust batch size and sand blend. Recycled phenolic and sand is common, with 20–50% recycled content in modern green factories.

- Cycle times: 1–3 minutes per core or mold. This is because curing requires time and care.

- Throughput: Lower than green sand. But the quality and accuracy gains often justify the slower pace for precision projects. I recommend this approach for high-quality work.

Step-by-Step Overview: Shell Molding Process

- Dump/blow sand onto the heated pattern.

- Invest (allow sand to gel/cure and build to desired thickness).

- Drain excess, uncoated sand.

- Rock the pattern to shake off sand that is not bound well.

- Dwell the shell for precise final cure.

- Strip/eject the cured core or mold from its pattern.

Summary:

For casting jobs that demand excellent dimensional accuracy, smooth finish, and high mold strength, resin-coated sand delivers. This is true for thin-walled or complex geometries. Though it costs more and is single-use, its advantages for quality-driven sectors like automotive and aerospace are clear. I recommend resin-coated sand for any project where precision and surface quality are priorities.

Sodium Silicate Sand (Water Glass Sand): Composition, Properties, and Industrial Applications

Composition and Chemical Reaction

Sodium silicate sand is also called water glass sand. We make it by mixing high-purity silica sand with sodium silicate (Na₂SiO₃). The typical mix ratio ranges from 1:1.5 to 1:4 (Na₂O to SiO₂ by weight). You can customize this ratio for specific mold properties.

To harden the mixture, we pass CO₂ gas through it. This triggers the following chemical reaction:

Na₂SiO₃ (aq) + CO₂ (g) → Na₂CO₃ (aq) + SiO₂ (s).

This sand uses industrial-grade binders with ≥99.0% purity. The modulus (SiO₂:Na₂O ratio) ranges from 2.0–3.5. This ensures consistency and stability. The density is about 2.4 g/cm³. The melting point is 1089°C.

Key Features and Casting Performance

Fast mold/core setting: Once we introduce CO₂, the mixture solidifies within minutes. This allows high-volume sand casting. It also speeds up production cycles.

Dimensional accuracy: These molds and cores maintain up to ±0.5 mm tolerance. They work well even for castings with complex shapes and internal channels.

Setting time control: You can adjust the sodium silicate modulus to fine-tune cure speed. This also affects final mold hardness. Different casting jobs need different settings.

Hygroscopic nature: Water glass sand absorbs moisture fast. You must store it in sealed containers below 60°C. If you keep it dry, its shelf life can reach two years.

Industrial Applications and Example Use Cases

I recommend sodium silicate sand for producing strong, removable sand cores. It works great in engine blocks, valve bodies, and pump housings. Use it anywhere you need complex internal passages.

For engine block sand casting, sodium silicate cores hold up against molten metal flow. After the metal solidifies, we remove cores by soaking or vibration. This cuts labor time. It also avoids metal part damage.

This process fits parts that need internal detailing. Think turbine blades, gear wheels, and water-cooled motor housings.

Physical and Mechanical Properties

Typical mix: About 98% silica sand and 2–4% sodium silicate by weight. We cure it with CO₂ gas injection.

Compressive strength: Molds reach strengths of 2.5–6 MPa. This depends on binder content and curing conditions. The result is both strong and collapsible molds.

Thermal resistance: Fast curing is a major advantage. But sodium silicate sand can degrade under constant high temperatures. It is less stable than green sand for repeated-use scenarios. In my experience, this limits its use in some high-heat applications.

Summary:

Sodium silicate sand (water glass sand) excels at rapid mold and core production. It delivers tight casting tolerances. It also forms complex cores reliably.

I find it works best in automotive and precision industrial castings. It shines for parts with challenging inner shapes. The process boosts productivity. But it needs careful handling and mixture control. This prevents stuck cores and casting defects.

For jobs that need internal detail and fast turnaround, I recommend this method. Just make sure your team controls sand composition and CO₂ curing quality. Based on my experience, quality control at these steps makes or breaks the final casting.

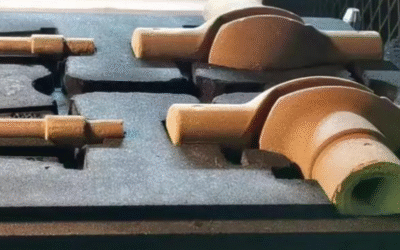

Core Sand: Properties, Types, and Key Applications

Core sand is a special sand for making cores. Cores are removable inserts. They form complex inner cavities and passages in sand castings. The sand’s formula and performance matter a lot. They help create detailed internal features that the main mold cannot shape.

Composition and Performance Requirements

- Base Material: Core sand often uses high-purity silica or specialty sand similar to mold sand.

- Binders: This is a key difference from standard molding sand. Core sand mixes with binders like oil, synthetic resin, or sodium silicate. These binders increase the sand’s strength and heat resistance.

- High Refractoriness: The sand must resist molten metal temperatures. It shouldn’t melt or react with the metal.

- Collapsibility: After cooling, the core should be easy to remove. It can collapse under force or dissolve with water or chemicals. This protects the finished casting from damage.

Types of Core Sand and Their Production Methods

Resin Core Sand:

- Uses thermosetting or thermoplastic resin binders.

- Creates strong, precise cores with low gas release. This cuts down on casting defects.

- I see this type used often in automotive engine heads and manifolds. These parts need complex inner passageways.

- Production Process: Hot Box Method. Heated metal core boxes cure the resin-coated sand fast. This creates rigid, accurate cores.

Sodium Silicate Core Sand:

- Uses sodium silicate binder that hardens with CO₂ gas.

- Cures fast. No oven drying needed. This improves cycle times.

I recommend this for castings that need strong, collapsible cores. Examples include pump bodies and water jackets.

Oil Core Sand:

- Contains sand, cereal, oil, and water.

- Provides good strength, smoothness, and consistent collapsibility.

- I prefer this for jobs where post-casting removal must be easy and clean.

Core Sand Manufacturing Methods

Hot Box Process:

- Sand mixes with a thermoset resin. It’s packed into a heated core box. The mix sets into a hard core fast.

- Best for high-strength, precise cores.

- Example: Mass production of engine blocks and cylinder heads uses this method.

Cold Box Process:

- Sand mixes with a gas-activated resin. The mix is blown into a cold core box.

- Creates intricate core shapes without heating. This improves flexibility and saves energy.

- Example: Custom, complex passages for hydraulic components and turbine housings.

Typical Applications and Practical Value

Internal Cavities: Core sand is the best solution for water jackets, oilways, and intricate passages inside automotive engine heads and valves. I haven’t found a better alternative for these applications.

Industrial Scale: Most core sand is single-use because of binders. But it’s critical for precision work. Dimensional accuracy is vital here.

Production Efficiency: Methods like cold box and hot box enable automated, repeatable production. They meet high-volume foundry demands.

I suggest choosing your core sand and binder method based on three things: part geometry, thermal load, and required casting accuracy. Based on my experience, fine-tuning the core sand formula and processing improves product quality. It also reduces scrap rates. I’ve seen this pay off many times in foundry operations.

Facing Sand: Composition, Performance, and Surface Finish Benefits in Sand Casting

Facing sand is the material you apply as the first layer against the pattern in sand casting molds. Its main job is to create a clean, smooth, and detailed surface on the final casting. I recommend using facing sand because it improves casting quality and cuts down on extra finishing work.

Facing Sand Composition and Mixing Ratios

Base Material: Fine-grained silica sand makes up most of the mix (70–262 GFN). Finer sand helps you get better detail and smoother surfaces.

Standard Additives and Proportions:

- Binder (cellulose): 0.8–2% for cohesion

- Foundry clay: 2–6% for mold strength

- Water: 3.5–7% to activate clays

- Core oil (vegetable-based or mineral): 1–2.2% for plasticity and surface finish

- Release agent (kerosene/lubricant): 0.3–0.5% for easier demolding

- Silica flour: Up to 20% for improved surface detail and defect resistance

- Corn flour, carbon, graphite: Used to reduce metal penetration and minimize burn-on

Preparation Case: For Gray Iron castings, I suggest this mix: silica sand (70 GFN), 1.4% corn flour, 4% southern bentonite, 10% silica flour, 5.8% water, 1.8% vegetable core oil, 0.4% kerosene. Mix the sand well. This gives you uniform properties.

Facing Sand Application and Process Flow

Layering: You can hand-pack or machine-apply facing sand in a thin, uniform layer onto the pattern. Make the layer just thick enough to cover the surface.

Bulk Packing: After facing sand is in place, add system or backing sand to fill the rest of the mold. This adds mechanical strength. Then compact the molds using jolt-squeeze or similar foundry machinery.

Usage Efficiency: Use facing sand sparingly—less than 10% of all mold sand. Focus it where it impacts casting surface quality.

Types of Facing Sand and Specialty Options

Green Facing Sand: This contains sand, clay, and water. It works well for ferrous metals. I like it for its ease and low cost.

Dry Facing Sand: This has sand plus clay, but no water. Use it for non-ferrous metals when you need maximum mold rigidity.

Self-Bonding Facing Sand: This uses synthetic binders with no water. It delivers the highest-quality finish on complex or intricate castings.

Key Advantages and Foundry Industry Practice

Maximized Surface Smoothness: Place facing sand right against the pattern. This ensures critical surfaces are defect-free. They need minimal finishing.

Detail Replication and Uniformity: Facing sand helps you reproduce sharp edges. It gives precise pattern fidelity.

Defect Reduction: It reduces harmful defects. These include sand burn-on, metal penetration, porosity, and scabbing.

Industrial Focus: Facing sand is essential for gears, valve bodies, pump housings, and other high-precision cast parts. Leading foundries keep refining facing sand recipes. This minimizes labor, time, and waste.

Facing Sand Application in Foundry Operations

- Step 1: Pack facing sand onto the pattern. Make sure you get even coverage.

- Step 2: Add backing sand until the mold box is full.

- Step 3: Compact the entire mold. This combines the facing layer’s superior surface with the backing sand’s strength.

Based on my experience, foundries use facing sand for more than just surface quality. It reduces rework. It enhances dimensional control. It improves overall production efficiency in competitive casting environments.

Summary Table: Common Types of Sand in Sand Casting

Below is a comparison of the most used molding sands in sand casting. This table covers composition, advantages, best uses, data, and real foundry examples for each sand type. Sand casting performance, cost, and application differ. These factors matter for foundry process optimization and casting quality.

Detailed Comparison of Sand Casting Sand Types

| Sand Type | Composition / Binder | Key Advantages | Typical Applications / Suitability | Notable Figures / Data | Industry Examples |

|---|---|---|---|---|---|

| Green Sand | Silica sand (85–95%) + bentonite clay + water (+ sea coal, add.) | • Very low-cost, recyclable • Works for many alloy types and part sizes • Good permeability, finish • Fast cycle times |

Mass production of iron, aluminum, brass parts; simple to medium complexity | Up to 95% silica; moisture 2–8%; 70–80% of foundry usage | Engine blocks, pipe fittings, gear frames |

| Resin-coated Sand | Silica sand + 2–5% synthetic resin + catalyst (phenolic/furan) | • High strength • Tight dimensional tolerance • Fine surface finish • Enables thin-walled, complex castings |

Precision and thin-walled iron/steel castings, aerospace prototypes | Resin 2–5% of sand; finish Ra 1.6–3.2 µm; up to 2.5× green sand cost | Cylinder heads, aerospace housings |

| Shell Molding Sand | Silica sand + 3–5% thermosetting resin (heated shell process) | • Consistent accuracy/repeatability • Rigid, thin molds • Minimal post-cast machining |

Intricate, high-precision components (medical, turbine, valve, gear parts) | Shell thickness 5–10 mm; cycle 1–3 min; batch up to tons/hr | Valve bodies, turbocharger housings |

| Ceramic/Specialty Sand | Zircon, chromite, olivine, ceramsite, perlite + chemical binder | • Great thermal resistance (>1800°C) • Non-reactive at high pours • Resists sand fusion |

High-alloy steels, superalloy castings, critical tolerance or temperature zones | Refractoriness >1800°C (zircon); cost >3× green sand | Turbine blades, power plant impellers |

| Dry Sand | Silica sand + clay, minimal water (pre-dried) | • Low steam/gas emission • Holds detail for thin-wall or precise parts |

Small/complex aluminum, non-ferrous castings needing solid mold integrity | Binder 5–10%, moisture <0.5% | Thin-section housings, lamp parts |

| Oil Sand | Silica sand + oil-based binder (Petbon, synthetics) | • Fine finish; detailed contours • Better than water-based sand for small, intricate aluminum parts |

Small gears, instrument cases, precision castings in non-ferrous alloys | Binder 2–3% or varies; low batch use | Precision gears, instrument casings |

Real-World Selection Examples

- Aluminum (700°C): I suggest green sand or oil sand for cost-effectiveness.

- Iron/copper (1000–1400°C): Green sand for reliability. Resin sand for precision.

- Steel, superalloy (>1500°C): Zircon/chromite sand is a must for mold survival and quality.

- Aerospace/precision: I recommend shell or ceramic sand to meet strict tolerance and metallurgical needs.

Your core choice for sand casting sand should consider metal type, pouring temperature, part complexity, and cost-performance balance. Leading foundries mix multiple sand types. They optimize for different sections of their casting workflows. I suggest you do the same.