Introduction to Shrinkage Defects in Casting

Shrinkage defects are common problems in Metal casting. They can hurt the quality of your finished castings. These defects happen when there isn’t enough molten metal to fill the spaces left by natural contraction. Metal shrinks as it solidifies and cools.

Key Factors Leading to Shrinkage Defects

-

Casting Design: Heavy or thick sections solidify last. These areas need more liquid metal to fill spaces as they contract. This increases their shrinkage risk. If your design doesn’t account for this, voids can form.

-

Pattern and Core Making: Patterns with larger volume sections in the cope (top half of the mold) cause problems. Insufficient core prints do too. The molten metal can’t feed these areas well. This results in localized shrinkage in those regions.

-

Gating and Risering System: An inefficient gating and risering system causes many shrinkage defects. I’ve seen this issue frequently in foundries. Smaller diameter risers don’t provide enough backup molten metal. Risers placed in the wrong spots create the same problem. These areas become vulnerable to voids as the metal cools and pulls away from the mold.

-

Melting and Pouring: Pouring metal at too low a temperature creates issues. Using insufficient volume does too. The metal won’t fill all parts of the mold. Some areas solidify before the mold fills. This causes empty spaces or shrinkage porosity inside the casting.

-

Moulding Process: Poor mold design leads to uneven cooling. Designs with sharp corners are problematic. So are designs with poor heat dissipation. This causes variations in solidification rates. It contributes to shrinkage.

Types of Shrinkage Defects

Open Shrinkage: This includes visible surface defects. Pipes and caved surfaces are examples. They are open to the atmosphere.

Closed Shrinkage: This includes internal defects such as shrinkage porosity and sponge shrinkage. They form within the casting. You cannot see them right away.

Minimizing Shrinkage Defects

I recommend using directional solidification to reduce shrinkage defects. This technique controls the cooling direction. It ensures continuous feeding of molten metal. Foundries also use casting simulation software. This software optimizes gating, risering, and overall process design. Based on my experience, these methods improve molten metal feeding throughout the casting. They help you avoid costly defects.

Causes of Shrinkage Defects in the Casting Process

Shrinkage defects happen when thermal, material, and design issues disrupt proper solidification and metal feeding. I recommend understanding these root causes to improve casting quality.

Unequal Temperature Gradients and Hot Spot Formation

Some areas in the mold cool faster than others. This creates uneven solidification. Heavier or thicker sections retain heat longer. We call these hot spots. They are more prone to forming shrinkage voids.

Poor heat dissipation in the mold makes this worse. These sections cannot get enough molten metal fed to them in time.

Feeder System & Gating Design Problems

Poor feeder or riser placement limits molten metal flow during solidification. The same goes for bad gating system designs. They restrict the metal supply.

For example, moving the riser from point “B” to “A” can reduce shrinkage. The feeding path becomes longer and works better.

Plant data proves this point. After one gating system redesign, shrinkage defects jumped to 18%. Total casting faults rose from 60% to 68.66%. Based on my experience, gating and feeder design have a huge impact on defect rates.

Pouring Temperature, Speed, and Process Variables

High and low pouring temperatures both cause shrinkage problems. High temperatures superheat the metal. This increases shrinkage. Low temperatures prevent full mold filling. This leads to incomplete solidification.

Pouring speed matters too. Too fast or too slow disrupts smooth flow and cooling. This raises the chance of defects.

Alloy Composition & Metallurgical Factors

Different alloys shrink at different rates. Stainless steel contracts by about 2.8%. Copper alloys can reach up to 6%.

Some compositions make shrinkage worse. Sulfur in Gray Iron stops helpful graphite from forming. This increases shrinkage. Magnesium and silicon also affect how bad defects get.

High levels of magnesium or cerium raise shrinkage risk. I’ve noticed this is a bigger problem in thick, isolated sections.

Core and Mold Design Considerations

Core shapes that isolate metal sections stop feeders from delivering fresh melt. This causes internal shrinkage cavities during solidification.

Mold material choice also plays a role. High thermal conductivity speeds up solidification. It can block feeding paths too early. This leaves some areas unfilled.

Common Types and Indicators of Shrinkage Defects

Open Shrinkage Defects: You can see these on the surface. They look like pipes or caved surfaces. They often extend inward from the casting exterior.

Closed Shrinkage Defects: These are internal voids. Examples include porosity, sponge shrinkage, dendritic shrinkage, and filamentary tern shrinkage. You can detect them with X-ray. You might also notice them through dimension errors and cracks.

Shrinkage Rate Data

- Stainless steel: ~2.8%

- Copper alloys: up to 6%

Key Preventive Strategies

I suggest focusing on these areas to reduce defects:

- Optimize riser and feeder design

- Control cooling and solidification rates

- Select proper alloy and process variables during pouring

Revising your riser and gating systems can cut shrinkage defects by over 10%. Plant trials confirm this. Strategic changes in feeding duration and riser position lead to real reductions in defect rates. I recommend making these adjustments a priority in your process.

Types of Shrinkage Defects in Casting

Shrinkage defects during the Casting process fall into two main categories: open shrinkage defects and closed shrinkage defects. I believe understanding these types helps improve casting quality. It also cuts down production losses.

Open Shrinkage Defects

Surface Appearance: Open shrinkage defects form on the casting surface. You can see them with your eyes. They are the first defects inspectors find.

Common Forms:

- Pipes: Tube-shaped cavities on the surface. They can extend inward from the outer layer.

- Cave/Sink Defects: Surface dips formed in thicker sections. They look like shallow depressions.

- Microporosity: Fine, scattered holes across the surface. These are small. They can build up and hurt both appearance and strength.

- Macroporosity: Larger, visible holes. Trapped gas or poor feeding causes them.

- Hot Tearing/Cracking: Surface cracks appear at thin webs. They also show up where section thickness changes fast. Stress during final cooling creates these cracks.

Main Consequences: These defects lower structural strength. They cause surface flaws. You can spot them earlier than other defects.

Affected Alloys: Materials with high shrinkage rates show these defects most. Aluminum and copper alloys are common examples.

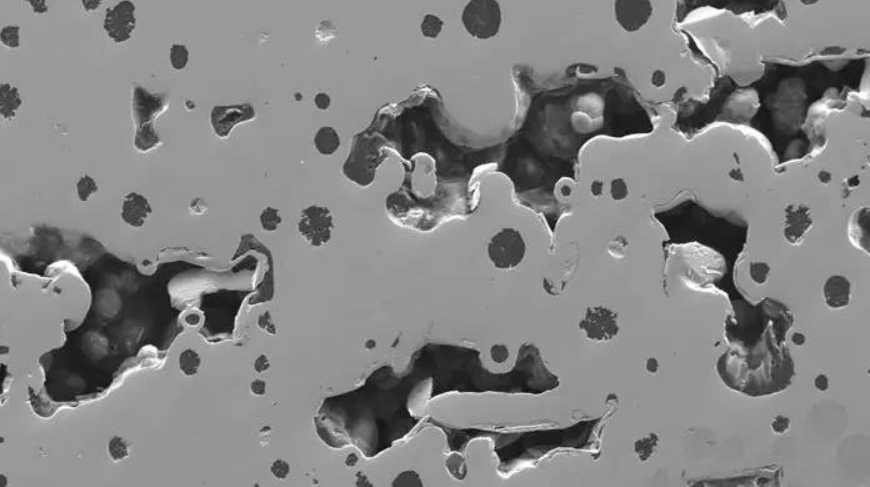

Closed Shrinkage Defects

Internal Position: Closed shrinkage defects develop inside the casting. You cannot see them from the outside.

Typical Forms:

- Shrinkage Porosity: Internal cavities and pores. They can be angular or rounded. Macro porosity is visible once you cut the part open. Micro porosity needs magnification to see.

- Sinks: Dips in thick section surfaces. Hidden cavities underneath cause them.

Causes: Poor feeding links to these defects. Small or misplaced risers are a problem. Fast cooling around isolated zones also causes them. Large differences in cooling rates throughout the part make things worse.

Mechanical Impact: These defects weaken the metal’s strength. They reduce tensile strength and ductility. They may cause bending, internal cracks, or size changes you did not expect.

Detection Methods: You need advanced testing to find closed defects. X-ray or ultrasonic inspection work well. You cannot see these defects from outside.

Incidence, Data, and Prevention

Incidence Rates: In factories, shrinkage porosity affects 15–20% of cast regions with aluminum alloys. This happens in areas not fed well during cooling.

Key Causes:

- Not enough molten metal flows in as the casting cools.

- Uneven wall thickness causes different cooling speeds. This leads to shrinkage.

Prevention Tactics:

- I suggest upgrading feeder and riser design. This ensures steady molten metal flow during cooling.

- Redesign castings for more uniform wall thickness.

- Use internal chills to control cooling rates.

- Adjust pouring temperatures to reduce shrinkage size.

Shrinkage Defect Comparison Table

| Defect Type | Location | Appearance/Forms | Main Consequence | Detection |

|---|---|---|---|---|

| Open Shrinkage | Surface | Pipes, sinks, caves | Reduced strength, visible flaws | Visual inspection |

| Closed Shrinkage | Interior | Porosity, internal sinks | Weakened strength, internal cracks | X-ray, ultrasonic |

Both open and closed shrinkage defects add to total casting waste. I recommend strong feeding system design. Process fine-tuning is key for controlling how often and how bad these defects get.

Prevention and Remedies for Shrinkage Defects in Casting

I recommend preventing shrinkage defects by combining smart design, better materials, useful tools, and good process controls. Here are remedies and prevention strategies that work:

Optimized Gating and Riser Design

- Design gating systems to ensure smooth metal flow. This reduces turbulence and keeps cooling rates even.

- Use well-placed risers as molten metal reservoirs. They feed metal into areas that tend to contract. This stops shrinkage voids from forming.

- Plant data show that careful riser and gating adjustments can lower shrinkage defect rates by over 10%.

Alloy Selection and Metallurgical Adjustments

- I suggest choosing alloys that resist shrinkage. For example, alloys that form graphite during solidification help offset contraction effects.

- Add elements like manganese to neutralize sulfur in iron alloys. This reduces the risk of shrinkage by blocking bad reactions.

- Adjust alloy composition based on section thickness. Thicker, isolated regions benefit most from metallurgical control.

Simulation-Driven Process Optimization

Use casting simulation software to predict potential shrinkage zones before production begins. This helps you pinpoint problem areas. Optimize mold and riser design based on simulation data. Also optimize metal flow paths. This reduces wasted trials and saves costs.

Controlled Cooling Rates and Local Heat Dissipation

- Achieve uniform cooling throughout the mold. Adjust its design, insulation, or use temperature-controlled environments.

- Insert chills or metals with a similar melting point in heavier sections. This removes heat from hot spots fast. It promotes balanced solidification.

- Avoid sudden temperature shifts. They lead to contraction cracks or residual porosity.

Mold Design Enhancements and Machine Maintenance

- Ensure molds are designed with care. Make sure they are well-ventilated to prevent gas entrapment and improve heat dissipation.

- Inspect and maintain both molds and die casting machines on a routine basis. This helps detect wear, which can contribute to defect formation.

- Tweak die casting parameters, such as increasing working pressure within safe limits. Fine-tune cooling fluids to help eliminate shrinkage porosity.

Monitoring and Detection

I recommend routine visual and radiographic inspections. Identify and address shrinkage defects as soon as possible. Use dimensional checks and non-destructive testing. This is crucial for detecting closed or internal shrinkage not visible on the surface.

Data and Practical Notes

- Metals contract during solidification due to density changes. Compensating for this requires strong feeder systems and material quality controls.

- Regular upkeep of equipment and careful process management are essential. They help minimize defects on a consistent basis.

- Case studies prove this: Upgrading to high-quality molds and optimizing pour temperatures delivers real reductions in shrinkage-related casting losses.

By combining these process enhancements, casting teams can reduce shrinkage defects in a meaningful way. This improves yield, reliability, and part quality.

Summary

I’ve worked with casting processes for years. I’ve learned that preventing shrinkage defects isn’t just about following rules. It’s about understanding how metal behaves. It’s about respecting the physics of solidification.

Every casting tells a story through its defects. Once you listen, you’ll know where to improve. I suggest starting with one change at a time. Measure your results. Keep refining. Your castings will improve because of it.