Filter foam is a porous material made for filtration. It has two main structures: open-cell or closed-cell networks. These structures decide how well the foam filters air or liquid.

Types of Filter Foam

Filter foam comes in many types. Each one serves different filtration needs. I recommend choosing the right type based on its structure, materials, and where you plan to use it.

Primary Structures and Materials

Open-Cell Filter Foam

- Features: Connected pores for maximum airflow and water flow.

- Best for: Air and water filtration, HVAC, cars, aquariums, and industrial machines.

- Common materials: Polyurethane (including reticulated types), reticulated polyester, and polyether. These are the main options I see used most often.

Example: Black reticulated polyester foam for air filters. Blue reticulated polyurethane for water filters.

You can buy these as sheets, rolls, or custom pads. They work as filter wadding, canister inserts, pond blocks, and more.

Closed-Cell Filter Foam

- Features: Sealed, rigid cells for minimal permeability.

- Best for: Water resistance, insulation, structural support, packaging, sound dampening, and gaskets. I find these useful for so many tasks.

- Common materials: Polyethylene, neoprene, crosslinked polyethylene.

Common Functional Types

Mechanical Filter Foam

- This foam traps dust, debris, and particles.

- Used in: HVAC systems, automotive air filters, ponds, and aquariums.

- Pore Size: Ranges from coarse (10 PPI) for pre-filtration to fine (up to 60 PPI) for detailed cleaning.

- Economic note: Coarser foams are cheaper. They offer higher flow. Finer foams catch more particles.

Biological Filter Foam

- High surface area encourages growth of beneficial bacteria.

- Key for: Aquariums and pond filters. These systems need biological waste breakdown.

- Material: Open-cell polyurethane or reticulated polyether. These stay stable underwater. They are easy to maintain long-term. Based on my experience, they last much longer than other types.

Chemical Filter Foam

- Contains additives like activated carbon.

- Benefit: Absorbs chemicals. Neutralizes odors. Ideal for water and air purification.

- Example: Activated carbon foam pads.

Specialty Foams and Advanced Filters

Reticulated Polyurethane Foam

- Very porous. Resists mildew and chemicals.

- Used in: Demanding filtration tasks. Engine and compressor filters. Electronics.

- Variants: Polyester and polyether based.

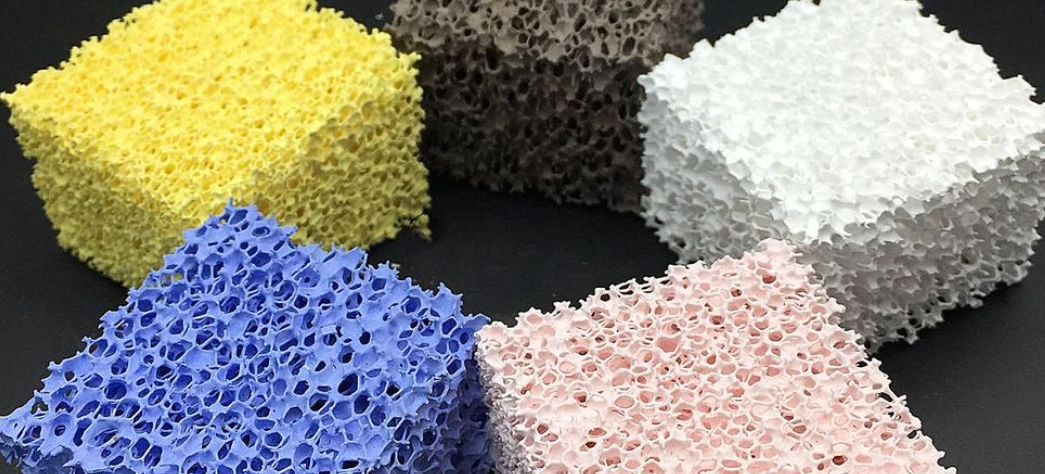

Ceramic Filter Foam

- Built for high-temperature filtration (up to 1620 °C).

- Used in: Metal casting, foundry work, and as catalyst support.

- Examples: Silicon carbide (SiC) and silica fiberglass mesh filters.

Metal Filter Foam

- Combines strength, chemical resistance, and reusability.

- I suggest these for special industrial applications.

Electrostatic Foam

- Enhanced design for targeting fine airborne particles. Uses static charge to trap them.

Practical Filter Foam Forms

- Filter wadding and customizable pads for pre-filters and main filters

- Hang-on and canister filter inserts (easy replacement)

- Large pond filter blocks for garden or commercial use

- Sump and submersible filter foams for water features

- Wet/dry trickle filters and cyclone stages. I recommend these for advanced filtration setups.

Key Data and Selection Guide

- PPI (Pores Per Inch): Ranges from 10 to 60. Lower means larger pores. Higher means finer filtration.

- Durability: Most open-cell reticulated foams last through multiple wash cycles. They resist chemicals and oils well.

- Temperature resistance: Ceramic foams reach up to 1620 °C. Ideal for molten metal filtration.

- Color identification: Black for air. Blue for water. This is the industry convention.

Pro Tip:

I suggest you choose foam based on your target contaminant, environment, and cleaning needs. For aquariums, reticulated polyether supports long-lasting biological action. I like it for this purpose. For odor removal, activated carbon is my go-to choice. For heavy industry, ceramic or metal foams offer durability under extreme conditions. Based on my experience, they handle tough jobs better than standard foams.

Key Properties and Structure

Filter foam has three main features: high porosity, customizable structure, and strong durability. I recommend it for filtration tasks that need specific performance.

Structural Types

Open-cell foam has connected pores. These pores allow air and fluids to flow through easily. Reticulated polyurethane works best here. It gives you the most contact surface for deep filtration. Porosity ranges from 10 to 100 pores-per-inch (ppi). Higher ppi means finer filtration. But it also creates more flow resistance.

Closed-cell foam gives you a rigid structure that nothing can pass through. It offers excellent water resistance, durability, and structural strength. I suggest this type for packaging, flotation devices, and specialty water filters. Use it where you need moisture protection and strength.

Material Selection

Polyurethane foam is the most common choice for filtration. It’s soft, bounces back well, and has high porosity. I prefer the open-cell forms for most jobs.

Polyethylene foam works well because it’s rigid, floats, and resists chemicals. I recommend it for closed-cell uses.

Reticulated foam lets fluids pass through better than other types. It has low flow resistance. This makes it perfect for tough filtration systems.

Ceramic foam handles heat well and stays strong under pressure. I like it for jobs like molten metal filtration.

Physical and Mechanical Metrics

Net density (kg/m³): High density gives you more stability and strength. Low density makes it lighter. I suggest low density for air or fluid filtration.

Compression strength: Soft foams compress easily. Rigid foams resist compression strongly.

Firmness and thickness: Compression ratios go up to 20. Thicknesses start at 0.025″. You can design precise custom filters with these options.

Application Examples

Reticulated filter foam appears in many air filters. You’ll find it in industrial systems, automotive parts, and HVAC units. It also works in aquarium filters, cleaning sponges, and sound barriers.

PVC-coated foam is open-pore polyurethane with a PVC coating. It resists chemicals and tears better. I recommend it for harsh environments.

Electrostatic foam attracts and traps fine particles. This makes it key for air cleaning in HVAC systems and electronics cooling.

Typical Performance Data

- Porosity (ppi): Standard values are 10, 20, 30, 45, 60, 80, up to 100.

- Temperature resistance: It handles temperatures from -70°C to +120°C for short periods.

- Firmness: Ratings go up to 20. Thicknesses go down to 0.025″.

Performance Features

Dust holding capacity: Foam filters catch particles in their three-dimensional structure. This gives them a longer life than paper or gauze filters.

Water resistance: Polyurethane foam keeps working even when wet. Paper filters don’t do this.

Customization: You can cut or shape filter foam for complex housings. I like using it for convoluted airboxes.

Product and Additive Options

- SIF® reticulated flexible polyester polyurethane foam works for standard and specialty filters

- PVC-coated open-pore foam fits environments that need chemical and tear resistance

- Ceramic foam handles high-temperature molten metal filtration

Functional additives: You can add anti-static, anti-microbial, flame retardant, and electrostatic dissipative features. These let you customize for your specific use.

Summary of key characteristics:

– Porosity: 10–100 ppi

– Density: High for strength, low for lightweight filtration

– Compression strength: Controls how rigid it is

– Temperature resistance: -70°C to +120°C

– Applications: Air and water filtration, industrial, packaging, flotation, thermal barriers, dust collection, medical devices

How Filter Foam Works: Mechanisms Behind Effective Filtration

Filter foam works because of its porous structure. It interacts with moving air or water. Fluid is forced through the foam’s connected pores. The foam acts as a physical barrier. It traps particles and debris down to 10–50 microns. This process achieves over 95% removal efficiency for suspended solids. I recommend this for both aquaculture and industrial filtration systems.

Multi-Stage Filtration Processes

Mechanical Blocking: Large particles get stopped at the surface. They also get caught within the open-cell matrix. The pores are smaller than the contaminants. This initial filter action reduces visible solids in water or air.

Filter Cake Formation: Particles pile up. They layer on the foam’s surface. This creates a “filter cake.” This extra barrier improves filtration. It targets smaller particles.

Physical Adsorption: Tiny contaminants stick to the internal surfaces of the foam. Even molecular ones do this. The foam has a huge internal surface area. I find this makes it very effective.

Capillary Action: Fine particles get drawn into the foam structure. This happens in water due to capillary forces. It improves retention of small debris.

Biological Filtration within Foam

In aquatic systems, filter foam’s large surface area supports colonies of helpful bacteria. These bacteria do biological filtration. They convert toxic ammonia and nitrite to less harmful substances. Ammonia and nitrite are byproducts of waste breakdown. Based on my experience, this is vital for stable and healthy aquariums, ponds, and recirculating aquaculture systems.

Advanced Industrial Uses

In metal casting, ceramic filter foam adds another level of precision:

– The zigzag channels “trap” and block metallic bits right at the inlet.

– As the “filter cake” forms, the cleanup of molten metal improves. This results in higher yield and fewer defects.

– Physical adsorption and capillary action polish the quality. They remove fine slag and impurities.

Selection Criteria: How to Make the Right Choice

I recommend focusing on these core criteria when you select the best filter foam. This ensures good filtration, durability, and cost-effectiveness.

Numeric & List-Based Core Content

Key Performance Metrics for Filter Foam Selection

Arrestance & Dust Holding:

- SIF® Filter Foam delivers an average arrestance between 63% and 75% at 500 fpm (2000 cfm) airflow.

- Dust holding capacity spans 210 to 330 grams for a standard test piece (1/2″ x 24″ x 24″).

- Pressure drop stays low—as little as 0.1 in H₂O at 800 fpm.

- It adjusts based on velocity and pore structure.

Pore Size and Density Overview (PPI Table)

| Porosity (PPI) | Density (pcf) | Tensile Strength (psi) | Ultimate Elongation (%) | Dust Holding (gm) |

|---|---|---|---|---|

| 10 | 1.9 | 20 | 45 | – |

| 20 | 1.9 | 25 | 30 | 245 |

| 30 | 1.9 | 25 | 25 | – |

| 45 | 1.9 | 28 | 20 | – |

| 60 | 1.9 | 33 | 10 | – |

| 80 | 1.9 | 35 | – | – |

| 100 | 1.9 | 35 | – | – |

- Custom orders range from 3–110 PPI.

- The factory controls minimum and maximum pore size.

Polyether vs. Polyester: Material Selection Guide

| Property | Polyether-Based Foam | Polyester-Based Foam |

|---|---|---|

| Moisture Resistance | Excellent, hydrolysis-resistant | Moderate, degrades with moisture |

| Durability in Humidity | Resistant | Prone to humidity-related breakdown |

| Recommended Use | Water filtration, aquatics | Air-based and dry filtration systems |

Filtration Standards and HEPA Requirements

- High PPI reticulated foam: I recommend this for HEPA level filtration.

- It offers greater airflow and efficiency.

- Low PPI neoprene foam: This works for gaskets and water blocking.

- It does not work for fine particle filtration.

- EN1822 standard tests performance down to 0.08–0.15 µm.

- This serves as a reference for EPA/HEPA/ULPA compliance.

- EN779 rates dust capacity, removal %, and classes (G1–F9).

Dimensional and Mechanical Design Variables

- Thickness: Available in 1/16″ increments from 1/8″ to full bun height.

- This helps you optimize cost and size.

- Firmness/Compression: You can control up to 20 compression ratio (SIF® Felt).

- Minimum thickness goes down to 0.025″ (compressed reticulated foam).

- Temperature Range: Built for high and low extremes.

- I suggest this for wide-ranging environments.

Application-Specific Selection Criteria

- Match PPI/pore size to your target filtration.

- Use high PPI for fine particles.

- Use low PPI for pre-filtration.

- Think about moisture, humidity, and temperature.

- Choose polyether for water settings.

- Choose polyester for dry or air settings.

- Durability & Maintenance: I recommend investing more up front for reusable foams.

- They lower lifecycle costs.

- Certification: Confirm your foam meets industry or regional standards for your use case.

Performance Snapshot by Use Case

- Industrial: Fine, high-density foam handles heavy contamination.

- It works for frequent use.

- Aquariums/Household: Medium-density foam balances high flow and biological action.

- Automotive/HVAC: Polyurethane or reticulated foam works well.

- It improves dirt arrestance, airflow, and cleanability.

Numeric Summary Table: Quick Reference

| Property | Range/Example | Typical Value |

|---|---|---|

| Pores Per Inch (PPI) | 3–110 | Common: 10, 20, 30 |

| Density (pcf) | 1.4–1.9 | 1.4 (20 ppi foam) |

| Tensile Strength (psi) | 20–35 | 25 (20 ppi foam) |

| Dust Holding Capacity | 210–330 gm (500 fpm) | 245 gm (20 ppi foam) |

| Thickness | 0.025″–full bun height | Custom increments |

| Pressure Drop (in H₂O) | 0.01–0.5 (velocity dependent) | 0.1 (800 fpm) |

| Ultimate Elongation (%) | 10–45 | 30 (20 ppi foam) |

Practical Takeaway

- I recommend choosing by numbers.

- Match PPI, thickness, density, and performance data to your filtration goal.

- Think about your environment and cost expectations.

- Use high PPI and polyether for aquatics or HEPA.

- Use medium PPI for household.

- Use low PPI for pre-filtering and industrial pre-applications.

- Based on my experience, always check data points.

- Don’t rely on marketing claims alone.

Application Areas of Filter Foam

Filter foam works in many industries. Its flexible structure, strong particle retention, and versatility make it popular. Here is a breakdown of the major application areas, practical examples, and performance data.

Automotive Filter Foam Applications

- Air Intake, Fuel, and Cabin Air Filters: Foam captures dust, pollen, and fine particles. This protects the engine. It also improves air quality inside vehicles.

- Oil and Fuel Residue Absorbers: Foam absorbs unwanted residues. This extends maintenance intervals.

Example: High-density reticulated foam in cabin air filters doubles the filter’s lifespan. It goes from 12 months to over 24 months.

HVAC & Air Filtration

Home and Commercial Heating, Ventilation, and Air Conditioning: Foam filters remove dust, lint, allergens, and microorganisms. I recommend them for air purifiers and vacuum cleaners.

Material: I suggest polyurethane foam for its durability and high dust capacity.

Performance Data: HEPA-grade foam panels filter out up to 99.97% of airborne particles larger than 0.3 microns.

Medical Devices and Healthcare

Wound Care and Respiratory Devices: Foam is used in wound dressings, CPAP machines, and surgical instruments. It ensures sterility. It also enables breathability and filtration.

Other Uses: Foams appear in cleaning wipes, surgical padding, and protective sponges for delicate procedures.

Water Filtration & Aquatic Systems

Aquariums, Ponds, Pools: Foam filters trap organic debris. They enable surface colonization by beneficial bacteria. These bacteria support biological filtration. This creates stable aquatic environments.

Material Selection: Polyether-based foam is chosen for its strong water and chemical resistance.

Example: 30–45 PPI foam in aquarium filters offers over 1,000 cm² of surface area for bacteria growth per liter of foam.

Industrial & Manufacturing

Oil, Chemical, and Wastewater Filtration: Filter foam removes solids, chemical residues, and smaller particles from process streams.

Structural and Protective Uses: Foam is formed into gaskets, seals, pads, and insulation components. It provides vibration resistance, temperature stability, and dust exclusion.

Application Areas: Electronics, construction, and heavy equipment benefit from foam’s flexible properties.

Aerospace Applications

Critical Air and Liquid Filtration: Reticulated foam is used in air and fluid filtration systems on aircraft and spacecraft. It maintains cabin air quality. It also maintains mechanical reliability under demanding conditions.

Consumer Products & Miscellaneous Uses

Everyday Items: Filter foam is found in face masks, speaker grills, humidifier pads, scrubbers, and tobacco or inkjet filters. Its structure allows for dust, smoke, or particle capture. It can be shaped for various uses.

Customization: Based on my experience, foam is offered in thicknesses from 2–30 mm, porosity from 10 to 100 PPI, and formats such as sheets, rolls, or custom-molded shapes.

Performance Data Summary

Filtration Efficiency: Open-cell foams remove particles down to 5–20 microns in air filters. They achieve high removal rates in water purification.

Durability: Most foams are washable and reusable. This extends their usable lifetime and reduces costs.

Material Choice: Polyurethane dominates air and general industrial filtration. Polyether foam excels in water and chemical settings. This is due to its degradation resistance.

Common Filter Foam Applications List

- Air filters (HVAC, purifiers, car engines)

- Water filters (aquarium, pond, pool, drinking systems)

- Medical devices (CPAP machines, surgical tools, wound care)

- Gaskets and seals (auto and industrial)

- Speaker grills, face masks, scrubbers

- Tobacco and ink filters

- Padding and protection (electronics, packaging, construction)

- Oil and chemical filtration (industrial processes)

Selection Tip: I recommend you match the foam’s type, porosity, density, and format to your filtration goal. Consider environmental exposure and efficiency needs. This ensures the best results.

Summary

Filter foam is more than an industrial product. It’s a precise tool that solves real problems when you choose it right. I’ve seen how matching the right PPI, material, and structure transforms filtration results. This matters whether you’re filtering air, water, or molten metal.

Understanding these basics puts you in control. I suggest you start with your specific needs. Compare the data. Don’t settle for generic solutions.