Let’s be honest: finding a true ceramic foam filter manufacturers in India takes work. Sourcing foundry consumables brings its own headaches. You see online lists flooded with traders and middlemen. They all claim to be “leading manufacturers.” Yet, many don’t even own a factory.

So, we dug deeper for this guide. We looked past the fancy websites. We verified who really runs machines on the ground. Take S S Khardekar in Pune and their European ties. Or consider the huge exports from ASK Chemicals. The market here mixes local pros with global giants.

Maybe you cast ductile iron, aluminum, or steel. You still need to distinguish the maker from the reseller. We break down the top 10 foam filter players below. Check their real capacity and key materials. You get the details needed before signing that purchase order.

S S Khardekar India Pvt Ltd

S S Khardekar India Pvt Ltd is the only maker and supplier of Lanik Ceramic Foam Filters (VUKOPOR) in India. The company started in 2014. It got ISO 9001:2015 certified in 2017. This Pune-based maker works with Lanik Ceramic Foam Filters India Pvt Ltd and Keramtech s.r.o. They bring European ceramic filter technology to Indian foundries.

Company Credentials & Manufacturing Capability

SSKIPL makes about USD 3 million each year. The team has 13 skilled professionals. They work from the Sanaswadi facility in Pune, Maharashtra. The ISO 9001:2015 certification came in June 2017. This shows their focus on quality management. They make foundry consumables you can rely on.

Product Range Beyond Ceramic Filters

VUKOPOR ceramic foam filters are the main filtration line. But SSKIPL offers much more for foundries:

-

Feeding Systems: Insulating sleeves, exothermic sleeves, high-density sleeves, hot tops, direct pour systems

-

Refractory Products: Tundish boards, ladle boards, mould & core coatings

-

Metallurgical Additives: Alloy inoculants, FeSiMg (ferrosilicon magnesium), slag coagulant

-

Process Materials: Korestick, mould sealing rope, parting agents, chromite sand for chilling

Strategic Positioning

SSKIPL competes with big global brands. We focus on quality. Technical support matters. Customer satisfaction comes first. Cost-effective development is key. The partnership with Lanik/Keramtech gives access to proven European ceramic foam filter technology. Plus, local manufacturing brings real benefits. You get shorter lead times. Service responds faster. Pricing stays competitive for Indian foundries.

Contact Information:

– Location: Gat No. 994/1, Sanaswadi, Shirur Taluka, Pune – 412 208, Maharashtra

– Phone: +91 95525 28983

– CEO: Sonali Santosh Khardekar

Lanik Ceramic Foam Filters India Pvt Ltd

Lanik Ceramic Foam Filters India Private Limited is the Indian branch of Czech VUKOPOR technology. We’re based in Lonikand, Taluka Haveli, Pune, Maharashtra. Our company connects European ceramic technology with India’s growing foundry industry. We do two things: make advanced ceramic filters and import specialty foundry materials.

Material Options for Different Metals

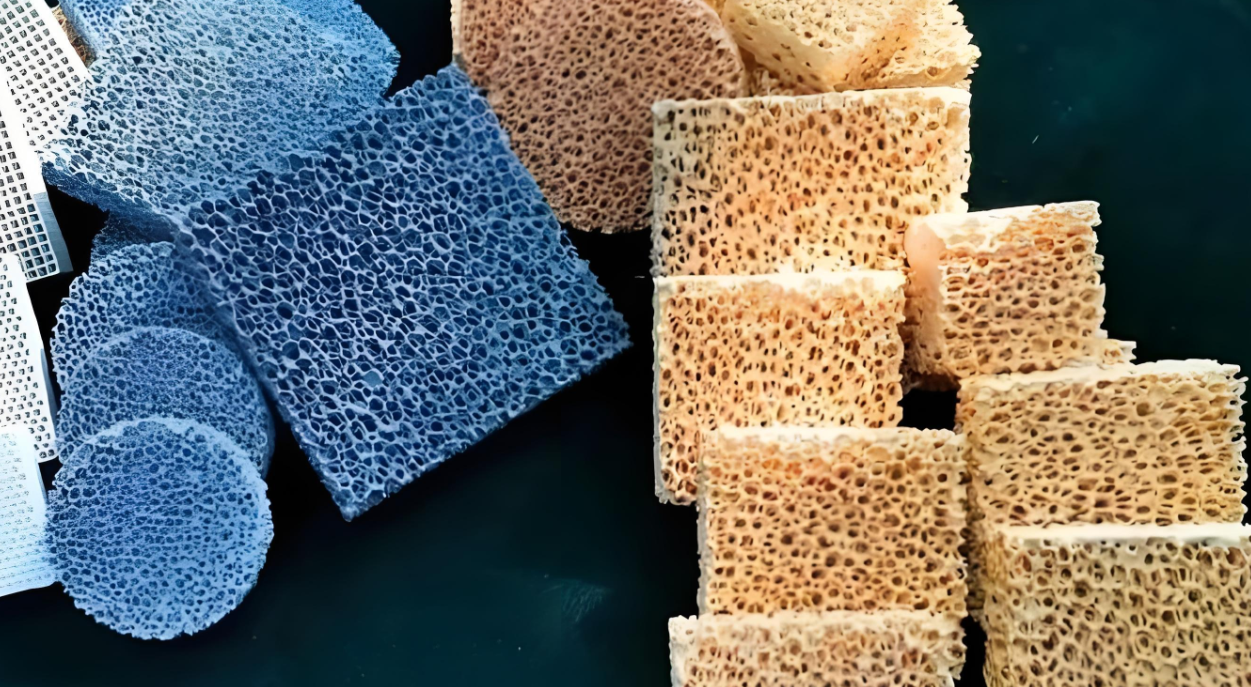

We offer three types of ceramic foam filters. Each one works for specific metal casting needs:

-

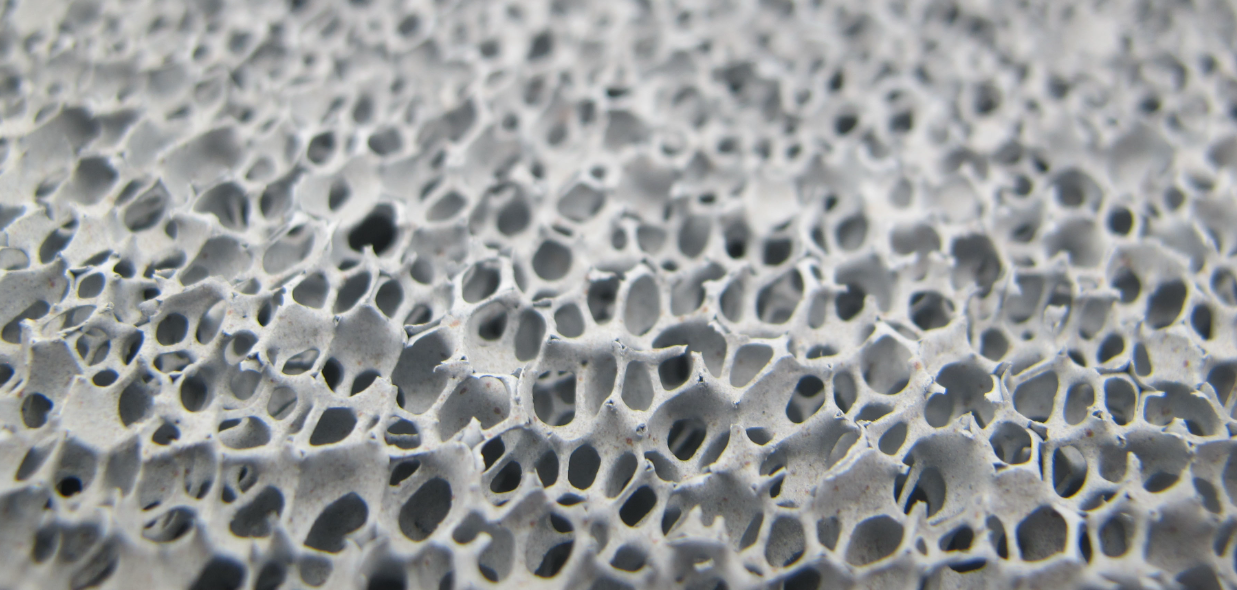

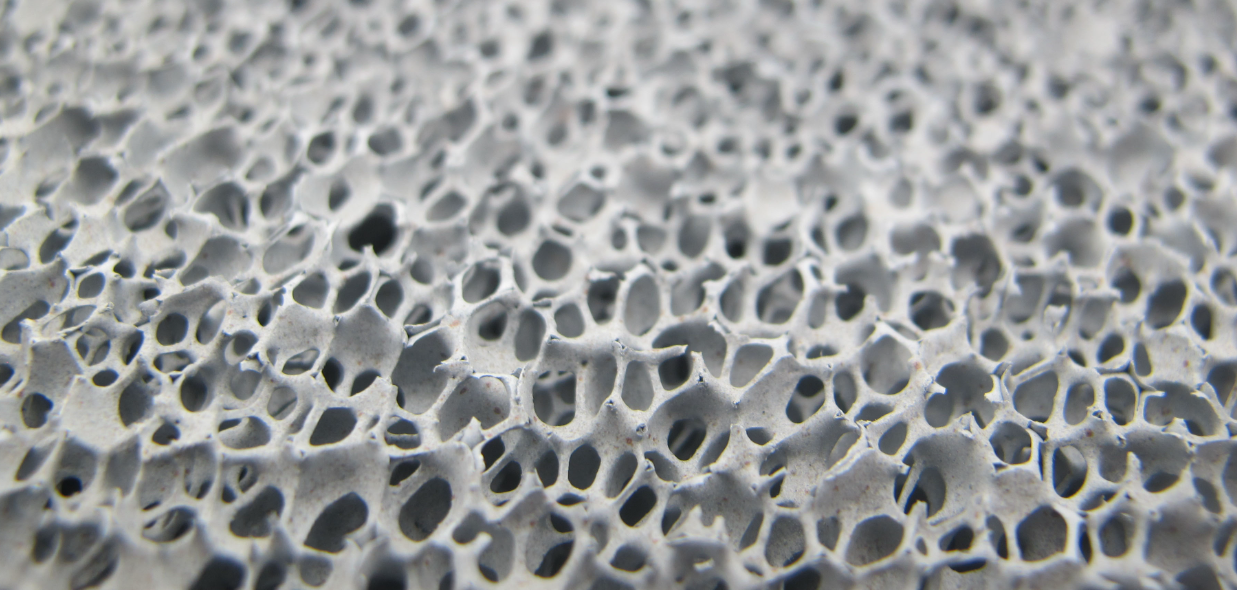

SiC (Silicon Carbide) Filters: These handle iron alloys and non-ferrous metals up to 1480°C. You get perfect results with ductile iron, grey iron, and copper alloys. Thermal shock resistance is key here.

-

Al₂O₃ (Alumina) Filters: Built for aluminum gravity die casting, sand casting, and permanent mold work. These cut down porosity and surface flaws in aluminum parts.

-

ZrO₂ (Zirconia) Filters: Made for alloyed steels and investment casting jobs that need top chemical purity and reliability.

All filters come in 10, 20, and 30 PPI (pores per inch) sizes. Foundries can match filter density to their inclusion size and metal flow needs.

Real Foundry Results

Casting plants using Lanik ceramic foam filters see clear gains. Better inclusion removal means stronger finished parts. Less scrap means you save more metal and spend less on re-melting energy. Smoother casting surfaces cut down CNC machining time. Plus, the filters protect refractory linings by stopping slag erosion in gating systems.

Coverage Across Casting Types

Lanik India works with all casting methods. We serve high-volume aluminum auto parts makers and precision aerospace casting shops. Continuous casting plants use our filters before metal turns solid into bars and rods.

Jagannath Company

Jagannath Company works as an export-import trader in India’s ceramic filter market. Eximpedia’s Indian customs data shows they work with 14 overseas buyers and 2 suppliers. This footprint points to a small to mid-scale global reach. They focus on linking global suppliers with local buyers.

Trade Activity Profile

The company runs both export and import operations. Customs records show shipment details. These include HS codes, product descriptions, quantities, and FOB/CIF values. Port and destination data show trade routes across many countries. Eximpedia’s analytics lets competitors check Jagannath Company’s market share at the HS-code level.

Data Transparency & Limits

Jagannath Company differs from integrated makers. Their public profile doesn’t show detailed tech specs. You won’t see data on filter sizes, PPI ranges (10/20/30/40/50), porosity rates, or chemical makeup. They don’t share ISO certifications. No foundry quality systems either. Application case studies from aluminum plants? Not available.

Sourcing Considerations

Procurement teams get flexibility from this trading model. You reach multiple supplier networks through one contact. That’s convenient.

But direct contact with makers might work better. You’d get stronger technical support. Customization options improve too. Traceability becomes clearer.

They don’t publish price lists or customer reviews. So buyers must request detailed quotes. Check supplier credentials on your own before placing orders. Do your homework first.

Ceratherm Technologies India Pvt Ltd

Ceratherm Technologies India Pvt Ltd got its manufacturing license in 2019. This Pune-based maker focuses on high-temperature ceramic parts for aluminum and metal processing. The company runs from Wagholi, Pune, Maharashtra. They make thermal systems and refractory products that protect molten metal equipment.

Product Specialization in Foundry Ceramics

Ceratherm’s products focus on thermal barriers and metal containment. They don’t make traditional foam filters.

-

Thermocouple Protection Tubes (TCPT): You get multiple lengths – 750mm, 900mm, and 1000mm options. These monitor temperature in harsh furnace conditions.

-

Ceramic Fiber Components: Tap-out cones, stalk tubes, and insulation products handle thermal cycling in aluminum melting furnaces.

-

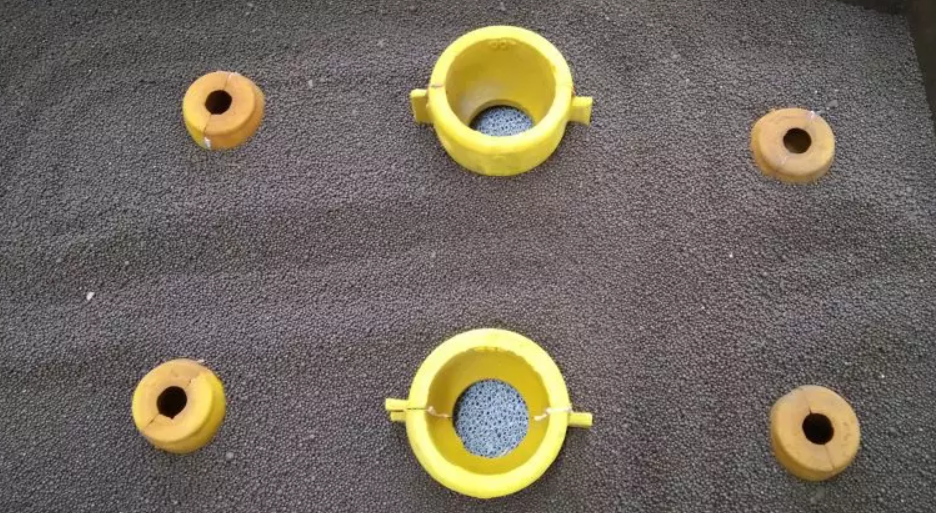

Molten Metal Filter Box Systems: Housing units work with filtration modules in casting lines.

-

High-Temperature Ceramic Castings: Custom-shaped refractory parts for ladle linings and furnace setup.

Filtration System Positioning

Ceratherm takes a different approach than dedicated foam filter makers. They work through systems integration. Their Molten Metal Filter Box serves as mounting structure for filter elements. Public specs don’t show ceramic foam filter details. No PPI ratings. No dimensions like 150mm thickness. No material breakdowns (Al₂O₃/SiC/ZrO₂). The company hasn’t shared porosity data, compression strength numbers, or pore structure analysis that foundries need.

Market Presence & Verification

TradeIndia lists Ceratherm as a “Manufacturer & Supplier” since 2019. The platform shows no customer reviews, sales records, or complaints. Looking for ceramic foam filters? Request detailed tech datasheets from them. Their catalog focuses on thermocouple tubes and refractory parts.

Contact Information:

– Location: Corporate Office in Wagholi, Pune, Maharashtra

– Established: 2019

– Business Type: Manufacturer & Supplier

SHIV Refractories

Public records show no verified company using the exact name “SHIV Refractories” in India’s ceramic foam filter industry. We searched company registries, trade platforms, and foundry supplier directories. No solid proof confirms this manufacturer exists or operates today.

Similar Named Entities – Not Confirmed Matches

Two Odisha-based companies have similar names. Neither shows a clear link to ceramic filtration:

-

Shiva Shiramon Refractories Private Limited: Started May 24, 1996 (CIN: U67120OR1996PTC004294). The company stays active after 29+ years. But no public catalogs connect it to foam filter production.

-

Shiva Refratech (India) Private Limited: Founded February 1, 2006 (CIN: U28999OR2006PTC008626). FY 2019-20 records show INR 1-100 crore revenue with +6.88% net worth growth. This company focuses on metal fabrication, not refractory ceramics.

Critical Data Gaps for Procurement Teams

Buyers looking for “SHIV Refractories” face serious verification problems:

-

Zero Product Documentation: No filter specs exist. We found no PPI density details, Al₂O₃/SiC/ZrO₂ material grades, or dimension charts on B2B platforms or at trade shows.

-

Pricing Claims Unverified: Many cite a ₹400/piece price point. This lacks real evidence. No tender documents, quotes, or distributor price lists back up this figure.

-

No Quality Certifications: ISO 9001, IATF 16949, or foundry OEM approvals are missing from public records.

Recommendation: Request full company registration proof before you engage with any supplier using the “SHIV Refractories” name. Get factory audit reports. Ask for third-party test certificates. These steps protect your procurement process.

Mighty Steel Links

Mighty Steel Links runs a retail business in Coimbatore. They sell industrial minerals and foundry raw materials. Ceramic foam filters aren’t their main product. This Tamil Nadu company stocks minerals for refractory work. These minerals work well with filtration systems in casting plants. You’ll find zircon products, olivine sand, and special silica materials in their stock. These materials go into mold coatings and refractory linings.

Zircon Product Line – Pricing & Specifications

The company stocks several zircon grades for refractory and coating work:

-

Zircon Sand-65/70/120: Brown crystal material at ₹180/kg. These grades come in bags. They work well for paints and coatings that need thermal stability.

-

Zircon Flour: Finer particles at ₹120/kg in 15 kg packages. This brown powder is good for foundry mold washes. It also works in investment casting slurries.

-

TRISIL-RC: Ultra-fine 200-mesh silica powder for refractory mixes. You can get it in 25 kg bags. Bulk users can order 1-ton jumbo bags.

Supporting Foundry Materials

They also stock other casting materials:

-

Olivine Sand: 87% pure gray sand in 1mm loose form. This magnesium-iron silicate handles thermal expansion well in green sand systems.

-

AFS 45-50 White Foundry Sand: 50 kg bags of white-grade sand. It meets American Foundry Society fineness standards. Good for precision mold work.

Positioning Note: Looking for ceramic foam filters? Contact Mighty Steel Links directly. Check if they stock filtration products or just focus on mineral supplies.

P. P. Ferro Alloys & Chemicals

P. P. Ferro Alloys & Chemicals has been a partnership firm in Ludhiana’s Focal Point industrial zone since 2006. The company handles manufacturing, importing, distribution, and export of ferro alloys, refractories, and foundry consumables. Partners Nipun Aggarwal and Pranav Goel run a team of 11–25 employees from Shop No. 14–17, C-39, Phase-II in Punjab.

Business Scale & Credentials

The company brings in USD 3 million each year. Their turnover sits between ₹25–100 crore. GST registration happened on July 1, 2017 (number: 03AAIFP7407Q1ZT). Import Export Code 3014008966 lets them trade across borders. They joined TradeIndia platform in 2012. Their main market covers northern India—Himachal Pradesh, Punjab, Haryana, Delhi, and Jammu & Kashmir.

Product Portfolio for Metal Casting

Their metal product line helps foundry work:

-

Ferro Alloys: Silico manganese lumps, calcium silicide lumps, and carbon raiser granules. These act as alloying and inoculant materials.

-

Silicon Carbide: You get it at ₹140/kg in 70 kg packs for metal work.

-

Refractory Castables: Insulyte-11/15 powder series and LC-45/60/85 low cement castables. These line furnaces.

-

Thermal Insulation: Fire clay bricks and ceramic fiber blankets (₹1,250/roll). They protect equipment that handles molten metal.

Positioning Note: P. P. Ferro Alloys works with refractory materials and metal additives. They don’t focus on ceramic foam filters. Need complete filtration systems? Check with them about ceramic filter stock.

G.S. Enterprises

Public databases show no verified records for G.S. Enterprises as a ceramic foam filter maker in Germany or India. Trade registries, B2B platforms, and foundry supplier directories reveal major data gaps. No company with this exact name links to ceramic filtration products like 7-inch, 10-inch, square, or round foam filters.

Found Companies – No Link to Ceramic Filtration

Two registered businesses use similar names but don’t make ceramic foam filters:

-

G. S. Enterprises Private Limited (India): Registered in Rajasthan since 1994 (CIN: U51101RJ1994PTC009059). Records show this is a wholesale trading business. Revenue ranges from INR 1-100 crore. FY 2018-19 had +1.74% EBITDA growth. NIC code U51101 means “wholesale trade agency” status. This is not ceramic manufacturing.

-

GS Enterprises, Inc. (USA): Located at 2540 S 88th St, Kansas City, Kansas. This media and internet services company has fewer than 25 employees. Annual revenue stays under USD 5 million. The company uses IM Creator, HostMonster, and Gorgias systems. No link to foundry supplies or refractory ceramics exists.

Major Procurement Warnings

Verify any supplier claiming the “G.S. Enterprises” name:

-

No Product Documentation: Ceramic foam filter specs don’t exist. PPI ratings, dimension charts, and Al₂O₃/SiC material grades are missing from trade databases.

-

Missing Quality Proof: No ISO 9001 exists. Foundry OEM approvals are absent. Third-party test reports don’t appear in public records.

-

No Customer References: Trade platforms show no reviews. Case studies are missing. Verified shipment records don’t exist.

Request complete company registration documents before doing business. Get factory audit reports. Ask for material test certificates. Do this before engaging with any business using this name.

Kel India Filters

Kel India Filters Pvt. Ltd. holds TÜV SÜD South Asia certification. They also won a national award for filtration solutions. This Ahmedabad-based company started in 2002. Over 20+ years, they built strong skills in industrial air filtration, dedusting systems, and liquid filtration for pollution control. Their work differs from ceramic foam filter makers. This Gujarat manufacturer focuses on industrial air quality and process filtration across factories and plants.

Core Filtration Technologies

Kel India works with cartridge-based and bag-type filtration systems:

-

Pleated Filter Cartridges: Dust collection units for industrial air systems. You get three-lug mounting designs. These work in top-loading and bottom-loading baghouse setups.

-

Liquid Filter Solutions: PP, PTFE, wound, carbon, and spun cartridge options. Polyester and PP filter bags handle process liquids.

-

HEPA & Pocket Bag Filters: Clean rooms and precision plants need these. Gas turbine cartridge filters and engine air filters protect rotating equipment.

-

Silo Top Dust Collectors: Bulk material plants use these to control dust emissions.

Technical Performance Data

Their cardboard panel pre-filters deliver 65–80% efficiency. Initial pressure drop is 10–25 Pa. Final pressure drop reaches 450 Pa before you replace them. The synthetic non-woven polyester media comes with wire support grid. Kraft liner beverage board frames resist 100% moisture. They handle 100°C temperatures. Standard sizes include 500/1000/1500mm lengths and 145–150mm OD for round models.

Metal panel PP foam filters use galvanized steel, aluminum, stainless steel, or powder-coated mild steel frames. Polyurethane foam media sits on expanded aluminum mesh. You get the same 65–80% efficiency and 450 Pa final pressure drop specs.

Industry Applications

Kel India’s pleated cartridges work in pigment and dye plants. These plants handle CPC blue, beta blue, green pigments, and copper phthalocyanide. The 100% spun-bonded polyester media pairs with GI/SS/PP filter cages and PU-molded or metal end caps. Many industries use these systems. This includes pharmaceutical plants, cement works, sugar mills, fertilizer factories, steel mills, powder coating lines, and shot blasting operations.

Paint booth operators use their paint arrestor paper filters to catch overspray. High strength prevents sagging and air bypass in exhaust systems. Sweeping machines and street cleaning trucks use special cartridges for mobile dust collection.

Procurement Details

Minimum order quantity starts at 10 pieces. Standard delivery takes 1–2 weeks for stocked items. Filter housings come in PP slim and big blue configurations. Panel filters, pre-filters, compact filters, and V-bank filters are also available. These support multi-stage air treatment systems.

Positioning Note: Kel India Filters serves air quality and liquid process filtration markets. They don’t make ceramic foam filters for molten metal casting. Foundries need special suppliers with Al₂O₃/SiC/ZrO₂ materials for high-temperature metal filtration.

ASK Chemicals India Pvt Ltd

ASK Chemicals India Private Limited is a fully-owned subsidiary of German parent ASK Chemicals GmbH. The parent group holds 100% of shares. Founded in 1973 under CIN U24231MH1973PTC016721, this Maharashtra-based company brings five decades of foundry chemistry know-how to Indian metal casting plants. The Pune facility connects to ASK Chemicals’ global manufacturing network. This network spans Europe, North America, South America, and Asia.

Explosive Growth in India Market

FY 2023 data shows strong expansion. ASK Chemicals India posted +64.57% revenue growth year-over-year. This shows rising demand for advanced foundry materials across India’s automotive, engineering, and steel casting sectors. The Indian operation adds to the parent group’s global revenue of €604.4 million (about $666 million in 2025). Asia regional volumes climbed +3% in Q1 2025. Indian market growth helped drive this increase.

Complete Foundry Solutions Portfolio

The company delivers full casting materials beyond ceramic foam filters:

-

Binder Systems: Organic and inorganic binders for sand molding

-

Mold & Core Coatings: Coatings that prevent metal penetration and improve surface finish

-

Feeding Systems: Heat-producing and insulating sleeves for controlled solidification

-

Metallurgical Products: Inoculants and grain refiners for structure control

-

Release Agents: Anti-sticking formulas for permanent mold casting

-

Industrial Resins: Group-level resin volumes surged +17% in Q1 2025, showing strong industrial use

Ceramic Foam Filter Export Leadership

ASK Chemicals India leads India’s ceramic foam filter export market. The company controls 61% of India’s total ceramic foam filter exports. This export strength shows product quality meets international foundry standards. Global parent ASK Chemicals invests in R&D regularly. Recent expansions in China and Mexico show group commitment to emerging markets. S&P Global forecasts +3% annual growth from 2025 onward for the ASK Chemicals group.

Global Backing, Local Execution

Parent group financial strength supports Indian operations. Q1 2025 Further Adjusted EBITDA reached €22.6 million worldwide. Last-twelve-months EBITDA jumped +17% to €91.9 million versus prior period’s €78.5 million. This financial strength funds technical support teams, quality labs, and just-in-time delivery systems across India’s foundry clusters.

The Reality: Which Supplier Fits Your Foundry?

We’ve looked at the market, and India’s ceramic filter choices get complicated. You see a mixed bag. The list includes genuine manufacturers, pure traders, and companies that simply shouldn’t sell filters.

Do you cast critical automotive or aerospace parts? Your choices narrow immediately. You need the technical backing established makers provide. Companies like S S Khardekar or ASK Chemicals offer consistent quality. They manage the entire process from raw material to firing. This reliability safeguards your high-stakes casting.

Maybe you handle smaller batches or standard commercial castings. Margins stay tight in these jobs. A responsive trader often works best here. They carry stock on hand. You get your order faster than waiting on a large factory with a four-week lead time.

Our final advice? Approach every supplier claim with skepticism. Never rely on a slick website or a directory label alone. Ask for fresh lab reports. Request a sample batch. Better still, video call their production floor. Verify the source to protect your scrap rate.