A quick Google search for a reliable air filter foam supplier in the UK often misleads you. It is rarely straightforward. You typically find that many “suppliers” are just drop-shippers. They hold no real stock. Even worse, some companies look active online but stopped trading long ago. Perhaps you are an engineer sourcing reticulated foam for a new HVAC system. Or you might be a procurement manager needing custom-cut dust collection sheets. The wrong partner causes delays and quality issues. You deserve to avoid those headaches.

We handled the hard work for you. Our team didn’t just scrape a list of names. We dug into the details. This includes checking financial stability, manufacturing skills, and genuine stock levels. From seasoned converters in the West Midlands to specialist manufacturers in Kent, this guide gives you the facts. Check out the 10 best filter foam suppliers operating in the UK right now. We sort them by their actual strengths. This helps you pick the right match for your project.

Technical Foam Services (Technical Foam Services Ltd)

Technical Foam Services Limited (Company No. 02448832) built its reputation over 30 years as one of Europe’s most innovative foam converters. The company entered liquidation after decades of operation. Founded in 1990, this UK specialist earned strong recognition in the European foams industry. They focused on customer engineering and held a full ISO certification portfolio. They were the first UK foam converter to achieve all three core ISO standards, including ISO 9001 Quality Management System.

The company was a member of The Vita Group. This gave them access to hundreds of Vita-grade foams plus many global material options. They positioned themselves as a technical partner, not just a supplier. The company specialized in industrial rubber and foam conversion services. They cut, shaped, and processed materials for end-use applications. They didn’t produce raw foam. This converter model let them deliver engineered solutions across many sectors. These sectors needed breathable foam material and custom cut filter foam specifications.

Product Capabilities & Market Position

The company was a leading converter of polyurethane foams and industrial rubber products. But detailed technical specs for air filtration applications are limited in public records. Their Vita Group membership gave them access to materials suitable for HVAC foam filter media, automotive filter foam, and industrial air filtration foam projects. However, specific PPI ratings, reticulated foam grades, or fire-retardant certifications aren’t documented in public sources.

Important notice: Technical Foam Services Limited is in liquidation status. Accounts have been overdue since 2024. Check operational status and alternative suppliers before you start procurement talks. Kroll Advisory Ltd manages the company’s registered office at The Shard, London during liquidation.

Airclean Ltd

Airclean Limited makes HVAC foam filter media in Kent. They’ve done this for 36 years. The company started in April 1988 as Buckdales Limited. Three months later, they changed the name. They hold a stable spot in UK heating and ventilation filtration. Their work focuses on air filters and housings for commercial and industrial use. The business makes breathable foam material and assembles filters. This differs from just converting foam.

The company has 25 staff at Henwood House in Ashford, Kent (about 30km from Maidstone). Annual revenue hits around £2 million. The 3-year growth rate is 6% – a bit above the industry average of 5.2%. Steady demand exists for their industrial air filtration foam products. But the numbers show some challenges. Operating profit margin is just 0.2%. The sector average is 6.1%. Debt ratio stands at 60%. Revenue per employee averages £79,600 – less than half the industry benchmark of £176,000. Tight margins and capital limits are common in this type of manufacturing.

Globescan Limited owns 100% of the company. Net assets total £285,300 as of 2024. Total assets are £707,440 and liabilities are £422,140. Cash reserves dropped 7% year-over-year to £76,250. The accounts receivable period runs 52 days. This is close to the 56-day industry standard.

Product Range & Technical Positioning

Airclean makes low to medium-efficiency filters for HVAC systems. They target G2–G4 grade applications under EN 779 classifications. Their flagship Polyfoam Washable Air Filter Media uses open cell foam filtration technology. You can reuse these filters multiple times. Specific PPI foam ratings and ISO 16890 certifications aren’t listed online. Still, the product works as dust collection foam sheets for commercial ventilation pre-filtration. The washable feature means less frequent replacement. Disposable polyester foam filter options need changing more often. This saves costs for facility managers running multi-zone HVAC setups.

PAR Group (PAR Direct)

Plastic and Rubber Group Ltd (Company No. 7173176) trades as PAR Group and PAR Direct. The company runs two UK manufacturing sites. You’ll find the main production facility at Bridge House, Drumhead Road, in Chorley North Industrial Park (PR6 7BX). The registered office sits in Manchester city centre at One Express, George Leigh Street (M4 5DL). One site handles industrial manufacturing. The other manages commercial admin. Both operate across North West England.

The business employs 142 staff and pulls in around $22.6 million in annual revenue (roughly £18–20 million). We’ve served industrial markets for over 40 years. PAR Group holds ISO 9001 quality certification and ISO 14001 environmental management accreditation. These credentials show a quality focus plus strong environmental compliance. This matters to clients in regulated sectors like food, pharmaceutical, and aerospace.

Manufacturing Capabilities & Market Positioning

PAR Group runs in-house rubber moulding, CNC cutting, and plastic machining facilities. We extrude, cast, and fabricate plastics to exact customer specs. Core products include precision-cut gaskets, mouldings, extrusions, and flexible connectors. Materials include rubber, polyurethane, and fabric sheeting. The company stocks flexible hoses. We also keep an extensive range of rubber and plastic materials ready. This means quick turnaround on jobs.

Our customer base covers multinational blue-chip organisations down to sole traders. Key sectors include food & pharmaceutical, water treatment, chemical processing, brewing, mining & quarrying, aerospace, power generation, and packaging/recycling. PAR Group earned a reputation for solving “unusual and complex applications”. This points to custom engineering capability. We go beyond standard catalog items.

PAR Direct works as the stock-based e-commerce channel. It supplies off-the-shelf items through a B2B online ordering system powered by Prospect CRM. Custom engineered products go through the main par-group.co.uk site. Contact: +44 (0)1257 248369 | sales@par-group.co.uk

Foam Conversion Ltd

Foam Conversion (U.K.) Limited (Company No. 02434265) runs from a 24 Singer Way facility in the Woburn Road Industrial Estate, Kempston, Bedford. We started in October 1989. The company has been running for over 35 years with no breaks. Our registered office is in Bedfordshire (MK42 7AF). The team includes between 11 and 50 staff. This makes us an established SME in foam conversion.

Companies House shows our main work as SIC 22290 – Manufacture of other plastic products. NAICS codes (3262) confirm we make rubber products too. We file small company accounts with full exemption. Latest accounts run to 30 April 2024. We submitted these on 31 October 2024. The confirmation statement covers up to 19 October 2024. Next filing is due 2 November 2025. All legal filings are up to date.

Export Activity & OEM Supply Chain Position

Trade databases show Foam Conversion U K Ltd as an active exporter. Tendata has 28 export shipment records on file. Volza and Eximpedia track past exports from our Kempston site. Shipment records include “WINDSHIELD…” parts. This points to automotive OEM or Tier supplier work. The windscreen sector needs precision-cut custom filter foam and seals.

Export data proves we can ship finished or semi-finished foam parts across borders. Orders come back repeat. Our 35-year history plus proven export work shows we focus on specialist work. Not bulk commodity production.

Filters Direct

Filters Direct is a UK-based online distributor focused on HVAC air filtration products. The company’s website stocks panel filters, bag filters, pocket filters, HEPA filters, fan coil wire frame filters, and fume extraction systems. They serve commercial and industrial HVAC applications. You can select filters by type and size, then checkout through their online basket.

ZoomInfo shows the company’s annual revenue sits below US$5 million. The SIC code 35,356 – General Industrial Machinery & Equipment puts them in the industrial filtration supply chain. Do they make their own foam media or buy from third parties? That’s unclear. We found no public proof they produce reticulated polyester foam or open cell foam filtration materials in-house.

Product Range & Technical Transparency Gaps

Their catalog covers standard HVAC filter types. But you won’t find specific PPI foam ratings, pressure drop data (Pa), dust-holding capacity (g/m²), or ISO 16890/EN 779 test reports on product pages. There’s no proof they offer custom cut filter foam services with cutting tolerances or lead times listed. Washable foam filter durability claims—like max wash cycles or lifespan—are missing from public sources. They don’t show energy-efficiency certifications like Eurovent labels or ePM classifications. Customer reviews, repeat purchase rates, or third-party ratings? Not documented in public records.

Foam Factory

The Foam Factory runs foam conversion in North America and the UK. They operate under three names: Foam Factory, Inc., FoamByMail, and The Foam Factory (UK). The UK site works as an e-commerce foam converter. They don’t make raw foam. You’ll get cut-to-size polyurethane foams, polyethylene sheets, reticulated Quick Dry foam, and custom-shaped technical foams. These work for cushions, mattresses, packaging, and industrial uses.

The UK operation handles mixed orders in low-to-medium volumes. Their machines include CNC profile cutting, horizontal and vertical splitting, and die cutting tools. They can make complex seat profiles, packaging inserts, wedge shapes, and mattress toppers. Public records don’t list employee counts, yearly tonnage, or factory size. But their product range shows flexible job-shop production. They don’t do high-volume slabstock manufacturing.

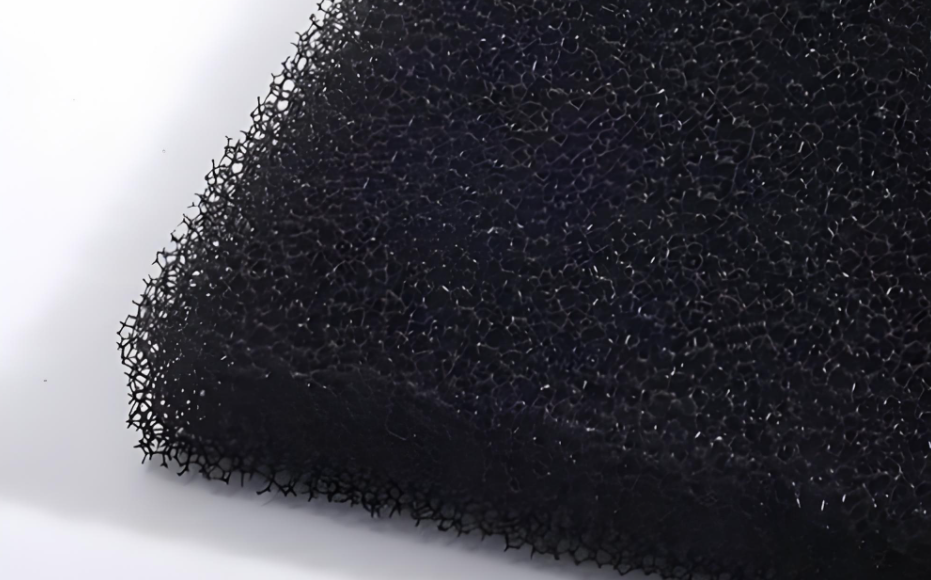

Quick Dry Reticulated Foam – Outdoor & Marine Applications

Their signature Quick Dry reticulated foam has >95% open-cell structure with connected pores. Typical grades run 10–30 pores per inch (PPI) and 24–32 kg/m³ density. Water drains through the full thickness in minutes to hours. This beats standard closed-cell foam by a wide margin. Airflow often hits 500 L/min at 200 Pa pressure in mid-PPI grades.

This breathable foam material works for outdoor patio cushions, yacht seating, marine cockpit pads, shower seats, and pool loungers. The open structure dries fast and lets air through. You’ll find firmness options in ILD ranges of 20–45 lb. You can also use it for drainage layers in ventilated mattresses. Plus, it works in special filtration pads that need high air flow with strong support.

Advanced Seals & Gaskets Ltd

Advanced Seals and Gaskets Limited (Company No. 03265619) runs a 30,000 sq ft production facility at Polymer Works, Hope Street, Dudley, West Midlands (DY2 8RS). We launched in October 1996 from a small 1,000 sq ft workshop. Our management team had over 10 years of rubber and plastics know-how before starting the business. By 1999, we moved to our current Dudley site. This is our own industrial property. It handles both fabrication and assembly work. The facility grew 30× from where we started. That’s close to three decades of steady growth in the UK seals and gaskets market.

Annual revenue hits £4.6 million as of March 2024. We employ 42 staff across production, engineering, and quality roles. Net assets stand at £4 million. Cash reserves reach £1.6 million—up 49% year-over-year (an increase of £535,000). This strong cash position lets us invest in equipment and stock materials for custom cut filter foam projects. Companies House lists us as a small-sized private limited company under SIC code 22190 – Manufacture of other rubber products. Our financial numbers show rare stability for a converter-class manufacturer.

ISO 9001 Quality Framework & Fabrication Capabilities

We’ve held ISO 9001:2015 certification since 2003. We upgraded to the 2015 standard by late 2016. Our quality system includes total quality management (TQM) principles. It also covers process improvement cycles and staff training programs. This certification is vital for clients in regulated sectors. They need documented tracking and batch control.

Our facility runs CNC cutting equipment, routing machines, milling tools, lathes, and automated production lines. These machines cut breathable foam material, solid rubber, and sponge rubber. We make gaskets, seals, anti-vibration mounts, insulation pads, sound absorption panels, and dust collection foam sheets. You can get production in “most formats at any size”. This includes custom filter foam seals with complex shapes for HVAC foam filter media housings. We also make automotive filter foam parts. We’re your “one approved supplier for all rubber and plastic needs”. You get multiple material types from a single quality-controlled source. Product lines include self-adhesive tapes, extrusions, moulded components, and multi-material builds with assembly work.

FoundryMax

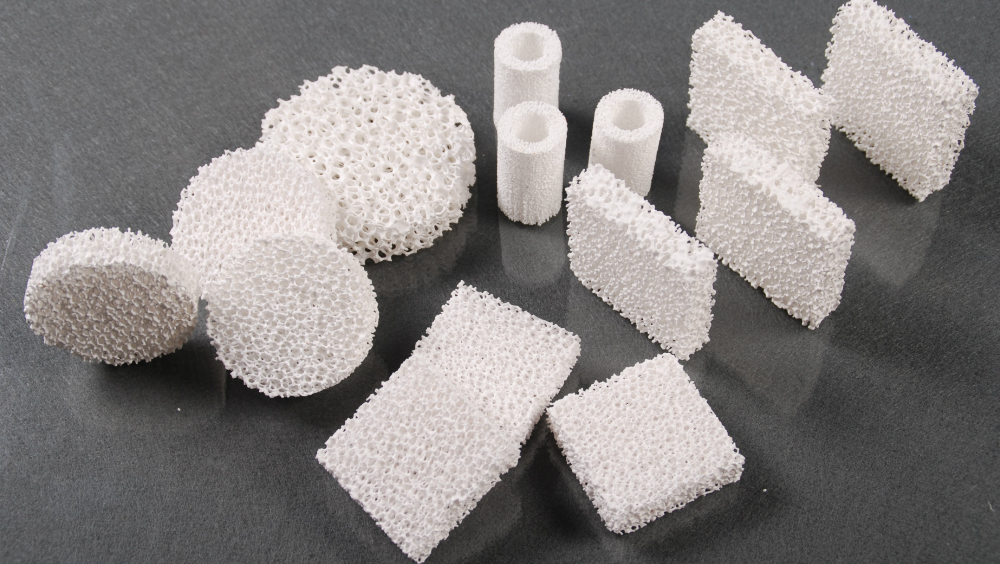

As we have seen, the innovation and application of air foam filter technology in the UK continues to drive global industrial standards toward higher efficiency and greater sustainability. Yet, whether in pioneering R&D or stable mass production, progress ultimately depends on core filtration components of uncompromising quality and reliability.

Within this global value chain, FoundryMax operates as a dedicated partner, providing core filtration solutions for high-end manufacturing and precision engineering. As a specialized manufacturer and supplier of ceramic foam filters, we understand how every pore and microstructure determines the final performance of the product. That’s why we not only offer a wide range of standard solutions but also focus on co-developing customized filtration systems with our clients—ensuring optimal efficiency and stability in every process, from molten metal purification to precision gas treatment.

If innovative design outlines the blueprint of filtration technology, then the high-performance ceramic foam filters provided by FoundryMax form the solid foundation that turns this blueprint into reality. We believe that through continuous material innovation and rigorous process control, we can help engineers and manufacturers worldwide translate theoretical performance metrics into tangible, quality-driven outcomes.

If you are looking for reliable filtration components to improve product yield and optimize process performance, we invite you to explore FoundryMax’s product portfolio and technical expertise. Let’s work together—starting with every bubble and every pore—to shape a purer, more efficient, and sustainable industrial future.

Final Thoughts: Making the Right Choice for Your Project

Sourcing industrial foam shouldn’t feel like a bet. However, the UK market is tricky. Big names like Technical Foam Services go bust. Plus, drop-shippers often fake being manufacturers. Don’t pick a supplier based on a flashy website or cheap prices. This often causes trouble when production deadlines hit.

The best supplier fits your specific needs. Maybe you run a high-volume production line. You need stock levels you can trust. Advanced Seals & Gaskets or Airclean Ltd work well here. They offer financial stability and ISO quality. This helps you sleep at night. They have the machines to handle complex, recurring orders. You won’t face constant delays.

Perhaps you just need a few custom sheets. This suits a prototype or a one-off repair. Huge industrial converters will likely ignore you. Smaller players like The Foam Factory or PAR Group’s online store are better choices. They serve as great alternatives. They handle small orders fast.

A quick tip: Always ask for a sample packet. Check their current ISO certificate too. Do this before you commit to a bulk order. It separates the real manufacturers from the middlemen. Good luck with your sourcing!