Open cell or closed cell foam for your filters? This choice goes beyond just picking a material. You need to know how cellular structure affects performance, efficiency, and how long your filter lasts.

Both foam types look alike at first. But their internal design creates very different filtration abilities. The wrong choice can make or break your application.

Air purification systems need the right foam. So do aquariums and industrial metal filtering processes. Pick the wrong type and you’ll waste money. Your efficiency drops. Your system might even fail completely.

This comparison clears up the confusion. We examine structural differences between open cell and closed cell foam filters. You’ll see real-world performance data. Plus, we cover which applications work best with each type.

Open Cell Foam Filters: Structure and Filtration Performance

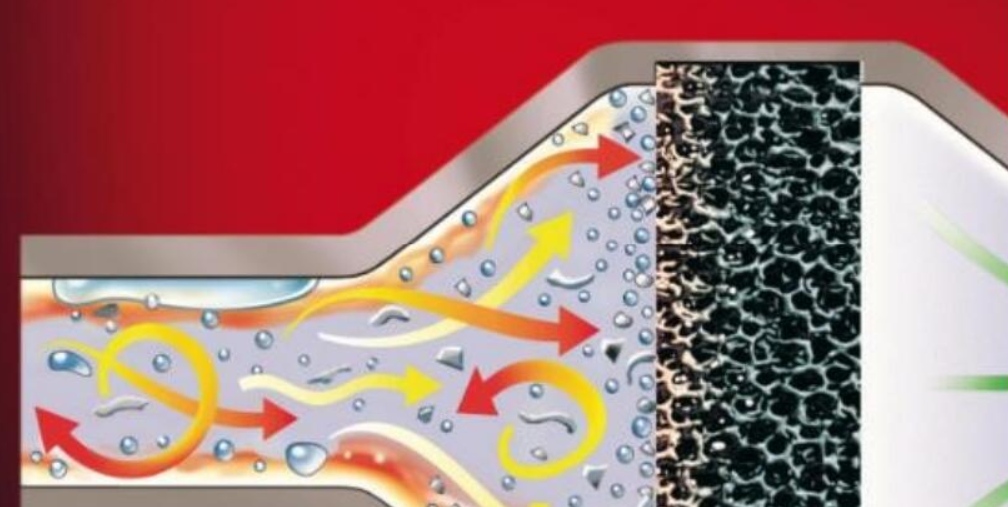

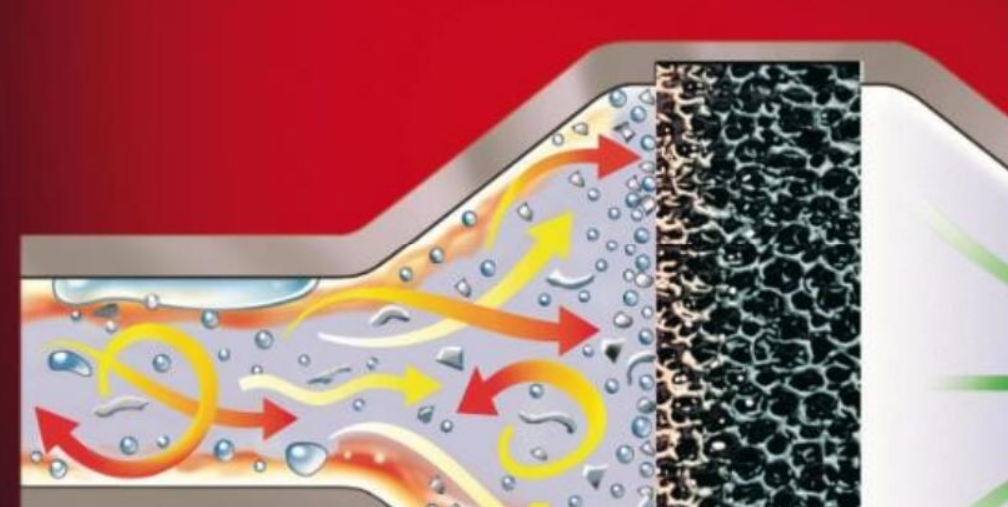

Open cell foam filters have a fully connected 3D skeletal structure. Every cell connects to its neighbors. This design creates a 97% void volume. It also reduces open channels that let contaminants slip through.

Cellular Architecture and Pore Specifications

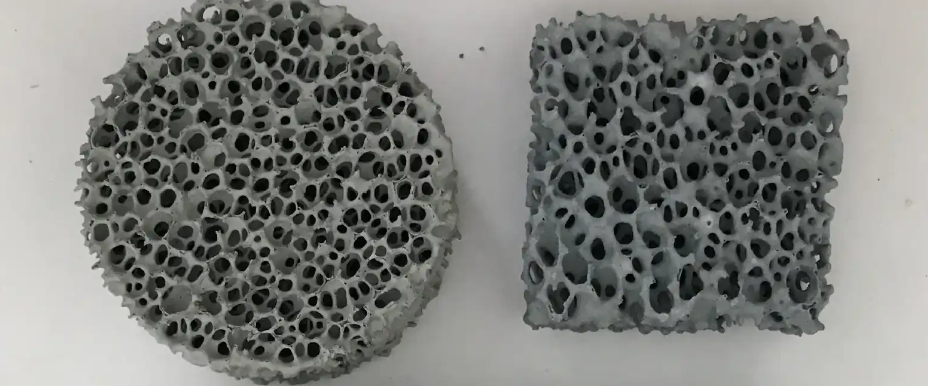

The foam’s skeletal strands form a continuous network throughout the material. Manufacturers measure pore density in pores per linear inch (ppi). Standard options range from 10 to 90 ppi. Common commercial grades include 10, 20, 45, 60, and 90 ppi configurations.

For metal melt filtration applications, engineers optimize porosity between 70-90%. They use geometric modifications to achieve this. Struts get elongated in an elliptical shape along the flow direction. Finger-like projections extend into pore cavities. Some windows are closed at key points. These changes improve the filtration coefficient. They also reduce hydraulic resistance, permeability, and the Forchheimer coefficient.

Measured Filtration Performance

Testing at 500 fpm air velocity (2000 cfm) shows clear performance differences across foam grades:

-

20 ppi foam delivers 69% average arrestance with 330 grams dust-holding capacity in 1/2″ × 24″ × 24″ test samples

-

Coarser grades show arrestance ranging from 63% to 82%, with dust capacity between 210-245 grams

-

Pressure drop links to pore density: 10 ppi foam maintains 0.1-10.0 inches H₂O across various flow rates, while finer ppi grades create higher resistance

Thickness and velocity show predictable patterns. At 10 ppi, filters from 0.125 to 2.0 inches thick handle 100-800 fpm at pressure drops of 0.1-0.5 inches H₂O. Filters at 45 and 60 ppi accommodate 100-700 fpm under similar conditions.

Core Performance Advantages

The large void volume gives exceptional dust-holding through depth loading, not surface buildup. High surface-area contact enables effective particle capture. The rigid skeletal structure prevents strand movement during use. Plus, these filters are washable and reusable. This cuts operational costs compared to disposable alternatives.

Closed Cell Foam: Why It’s Not Suitable as Filter Media

Closed cell foam works great for sealing and insulation. But filtration? Not so much. The cellular structure blocks particle capture and flow control.

Sealed Cells Block Flow Paths

Each cell in closed cell foam sits as a separate, gas-filled pocket. These cells measure 0.3–0.4 mm in typical polyethylene types. They don’t connect to nearby cells. A solid barrier runs through the material’s thickness.

No through-pores exist. So there’s no flow path. Air and liquids can’t pass through the foam depth like they do through open cell types. The foam works as insulation or a gasket—what it’s built for. Not as a flow-through medium.

Zero Filtration Performance Data

Makers list closed cell foam properties for sealing jobs. Data sheets show density (4–15 lb/ft³), compression deflection, and water uptake below 5% by volume. Micron ratings? You won’t find them. Same goes for arrestance percentages or efficiency curves. These filtration measures don’t exist for closed cell products.

Look at rigid depth cartridges. They give particle ratings from 2–190 µm. Real filter media show pressure drop versus flow rate specs for proper system sizing. Closed cell foam lacks this data—not by accident. The material was never built or tested for filtration work.

Fast Surface Plugging

Force closed cell foam into filtration service. It fails fast. Flow happens through manufacturing flaws, edge gaps, or broken cells. Particles pile up in a thin surface layer. Pressure jumps. Flow stops in minutes.

Open cell foam filters stay efficient across 50% of their service life through depth loading. Closed cell types have no dust-holding specs. They can’t hold dust inside their structure. The sealed design stops particles from entering the material depth. No entry means no capture and storage.

Material Properties Comparison: Filter-Critical Parameters

Engineers pick filter foam based on five key measurements. These numbers impact system performance. The metrics show if a filter catches particles well. They also show if the filter blocks airflow or raises energy costs.

Airflow Resistance and Pressure Drop

Airflow resistance (Δp) shows how hard your system works to push air through foam. Tests use 1 cm/s face velocity to compare products fairly. Lower resistance means better airflow. Plus, your fan uses less power.

Two things control resistance: fiber diameter and porosity percentage. More porosity creates more empty space. Pressure drop across the filter goes down. Open cell foam keeps 70-90% porosity in good designs. Closed cell foam has zero porosity. The sealed walls block all airflow.

Filtration Efficiency Metrics

Collection efficiency (η) shows the percentage of particles caught in one pass. Thinner fibers catch more particles. They work better at mechanical interception and diffusion.

Test data on PVA nanofiber filters (packing density α=0.052, thickness L=5.1 µm) shows clear patterns:

-

100nm fiber diameter: Catches the most particles across all sizes. Pressure drop goes up.

-

201nm fiber diameter: Reaches 88%+ efficiency for certain particle types.

-

306nm fiber diameter: Drops to 64% efficiency. Airflow resistance is lowest.

Filter Quality Factor

The filtering coefficient (q_F) balances efficiency against pressure penalty. The formula is: q_F = -ln(K)/Δp. This number shows which materials give maximum capture per unit of airflow resistance.

Thinner fibers produce higher q_F values. The performance edge stays strong even with higher pressure drop. Material differences between 1.1-1.7 don’t affect quality factor results much.

Critical Design Parameters

Packing density stays at 0.052 across standard tests. Filter thickness specs of 5.1 µm give the baseline for analysis. But fiber diameter stands out as the most important factor. Thinner fibers boost collection efficiency. They also raise quality factor performance. This double win separates top filter materials from poor ones.

Air Filtration Applications: Which Foam Works Best

Industrial air systems need different foam specs than home HVAC units. Your choice depends on three things: particle size targets, airflow needs, and where you’ll use it.

HVAC and Residential Air Purification

Ether-based polyurethane foam leads in home applications. This material handles moisture well. It has larger cells that keep air flowing smoothly. Standard 20-45 ppi grades catch common household stuff—dust, pollen, and pet dander—without blocking too much air.

Lab tests show polyurethane beats fiberglass at catching dust. The Philadelphia Post Office trial proved something useful: polyurethane roll filters lasted longer even though they held less total dust. Better dirty resistance means you replace filters less often. This cuts maintenance costs.

Reticulated foam is the premium choice for tough home systems. Porosity of 95-98% allows great airflow. It still catches particles well. This material fights off mildew and chemical damage. That matters in humid areas or homes using strong cleaners.

Specialized Air Filtration Systems

Activated carbon composite foams handle gas pollution. These materials soak up volatile organic compounds, odors, and chemical vapors. Standard filters miss these completely. You’ll find them in car cabin filters, pet air purifiers, and industrial gas scrubbers. Brand C carbon composites cost more ($$$). But they control odors so well the price makes sense.

Electrostatic foam filters use static electricity to grab fine particles. This tech matches MERV performance for submicron particles in HVAC systems and standalone purifiers. The electrical charge works with mechanical filtering. You get better efficiency without more pressure drop.

Industrial and High-Efficiency Applications

Catching fungal spores needs exact foam specs. Tests confirm 90 ppi foam at 15mm thickness works much better than 50 ppi options. The correlation coefficient (r²=0.8231) shows that ppi and thickness together predict performance well. Going from 15mm to 20mm with 90 ppi foam gives no extra efficiency. The 15mm setup is the sweet spot.

Rib thickness explains why performance differs. 90 ppi foam has 37.15 μm ribs. Compare that to 53.65 μm (SD 6.67) in 50 ppi material. Thinner ribs mean more capture points per volume. This improves how well you catch tough bioaerosol particles.

Water and Aquarium Filtration: Open Cell Foam Advantages

30 PPI open cell foam beats most static biomedia in aquarium systems. 90-day tests show it outperforms most alternatives except fluidized K1 media. K1 media shows 60% higher efficiency per cubic inch. This single spec—30 pores per inch—gives you the best balance between bacterial growth and water flow in home aquariums.

Bacterial Loading Capacity by PPI Grade

Open cell foam supports 2-10x more beneficial bacteria per cubic inch than competing filter media. Here’s what the numbers show:

-

20 PPI foam: Supports 74 metabolic grams of fish at full maturity. That equals eleven 2-inch fish in a stable bioload.

-

30 PPI foam: Handles 96 metabolic grams. That’s about fourteen 2-inch fish. This represents a 30% capacity increase over 20 PPI.

This bacterial advantage comes from 97% void volume in reticulated foam structure. Open cells take up 95-98% of total mass. This creates massive usable surface area for nitrifying bacteria colonies. The foam captures up to 90% of suspended solids while keeping flow rates strong. This supports toxin breakdown. The ammonia-to-nitrite-to-nitrate cycle runs nonstop without mechanical interruption.

PPI Selection: Performance Trade-offs

|

PPI |

Bacteria Surface |

Clogging Risk |

Flow Rate |

|---|---|---|---|

|

20 |

High capacity |

Low |

High |

|

30 |

Optimal balance |

Moderate |

Good |

|

40 |

Higher capacity |

High |

Lower |

30 PPI efficiency wins in ammonia oxidizing tests. The 15 cubic inch test samples over 90 days showed something clear. Surface area values (square feet per cubic foot) matched ammonia processing rates. Too coarse (20 PPI) means less bacterial real estate. Too fine (40 PPI) creates flow restriction and early clogging.

Tank-Specific Foam Specifications

Match foam thickness and pore density to your tank volume:

|

Tank Gallons |

Thickness (inches) |

Recommended PPI |

|---|---|---|

|

10-30 |

1-1.5 |

20-25 |

|

30-75 |

1.5-2 |

25-30 |

|

75+ |

2-3 |

30-35 |

Cleaning Schedule and Maintenance

Foam size sets your maintenance frequency:

|

Size (inches) |

Clean Frequency |

Tank Size (gallons) |

|---|---|---|

|

10×10 |

Every 2 weeks |

Up to 20 |

|

12×12 |

Every 3-4 weeks |

20-50 |

|

15×15 |

Every 5-6 weeks |

50+ |

Critical maintenance rule: Rinse with dechlorinated water. Don’t clean foam until flow restricts. That brown gunk buildup increases active bacterial surface area. Too much cleaning kills beneficial bacteria colonies you spent weeks growing.

Flow Rate Requirements

Standard turnover rates show why foam beats solid media:

-

Freshwater tanks: 2-4x tank volume per hour

-

Tropical systems: 4-6x volume per hour

At these rates, foam sieves debris 96 times daily. The lightweight structure and high strength handle this constant flow. You get no compression or breakdown. Foam keeps filtering even with partial clogs. Solid media fails once surface pores seal.

The ammonia-to-nitrate conversion cycle runs strong in correct-sized foam filters. This biological edge, plus debris capture and easy maintenance, makes open cell foam the practical choice for aquarium filtration at every skill level.

Metal Filtration Applications

Molten aluminum and magnesium casting need ceramic foam filters with exact pore structures. The metal industry uses open cell designs. Closed cell foam can’t handle temperatures above 1,300°F. Plus, it blocks metal flow.

Aluminum Foundry Requirements

Ceramic foam filters (CFF) remove oxide bits and dross from molten aluminum streams. The standard spec is 10-30 ppi for aluminum casting. This pore range balances filtration power against metal flow resistance at 1,380°F working temps.

Manufacturing data shows 20 ppi filters capture 85-92% of oxide particles above 50 microns. Finer 30 ppi grades push efficiency to 94%. But they increase pressure drop by 40%. Foundries with high-volume production lines use 20 ppi. This keeps throughput rates at 200-500 kg/hour per filter unit.

Filter thickness affects capture depth. 50mm (2-inch) filters give you the best time for particle settling. Thinner 25mm units work in low-dirt applications. But they sacrifice 15-20% removal power.

Magnesium Casting Specs

Magnesium filtration needs coarser 10-20 ppi ceramic foam. Magnesium has lower thickness at casting temp (1,202°F). The more fluid metal flows faster through filter structures. Too fine a pore grade creates rough flow. This pushes oxides back into the clean metal stream.

Zirconia-based ceramic foam handles magnesium’s chemical activity better than alumina types. Zirconia holds its structure through 50+ casting cycles. Alumina filters break down after 20-30 pours in magnesium service.

Filter Positioning and Metal Quality

Where you place the filter in the gating system controls how well it works. Inline bowl filters positioned before the runner achieve 88% removal. Pouring basin filters capture 65-70%. Rough filling disrupts particle settling.

Clean metal output from proper foam filtration cuts machining defects by 60-75% in aerospace aluminum parts. This quality boost justifies the $12-45 per filter cost in high-value casting operations.

Cost vs. Durability Trade-offs

Open cell foam filters cost $8-$25 per unit in standard HVAC sizes. Closed cell foam sealing products run $12-$40 for similar dimensions. But price tags tell half the story. The real cost difference shows up over the product’s life.

Upfront Cost vs Total Ownership

Open cell foam filters last 3-5 years with proper care. You buy once and clean each month. The washable, reusable design saves money. A $15 filter cleaned 40 times over four years costs $0.38 per month to run.

Disposable filters seem cheaper at $3-$6 each. Replace them each month and you spend $36-$72 per year. Over four years, that’s $144-$288 in filter purchases alone. The “cheaper” option costs 10-20 times more than washable foam.

Metal casting filters show even bigger gaps. Alumina filters cost $12-$18 and last 20-30 pours. Premium zirconia ceramic foam runs $35-$45 but survives 50+ casting cycles. Cost per casting drops from $0.60 (alumina) to $0.70-$0.90 (zirconia). The premium material costs more per use despite longer life. But it cuts machining defects by 60-75% in aerospace parts. Scrap reduction pays back the filter premium in 2-3 high-value castings.

Failure Risk and Maintenance

Aquarium foam life depends on pore density and how often you clean it. 20 PPI foam handles heavy bioloads with rinses every two weeks for 2+ years. 30 PPI grades need cleaning each week. They last 18-24 months before they compress and reduce flow. Skip cleanings and any grade clogs in 4-6 weeks. This kills helpful bacteria and crashes your nitrogen cycle. Tank restart costs $50-$150 in lost livestock and water chemistry products.

HVAC systems follow similar patterns. Ester-based polyurethane resists moisture but breaks down under UV exposure in 12-18 months. Ether-based grades cost 20% more but survive 3-4 years in the same conditions. The extra durability pays for itself by month 18.

Pressure drop tells you when to replace. Resistance climbs 50% above baseline? Efficiency drops fast. Keeping a filter too long raises fan energy costs by 15-30%. A $15 filter kept past its prime can waste $40-$60 in electricity over six months.

Selection Guide: Matching Foam Type to Filter Requirements

Four key factors decide which foam works for your filter job: particle size, efficiency needs, airflow limits, and your operating conditions. Miss one and your system fails or wears out fast.

Particle Size Decides PPI Range

Coarse dust and debris (above 100 µm) needs 10-30 PPI foam as a pre-filter. This pore size traps large particles. It won’t create too much pressure drop. Engine intake systems and powersports need 30-60 PPI grades. These catch road dust and debris. They still allow strong airflow to the combustion chamber.

Fine dust jobs need 60-100+ PPI foam. More pores mean more spots to catch particles per cubic inch. Well-oiled premium foam hits >99% efficiency on particles above 10 µm. It performs well down to 2-5 µm particle sizes. For HEPA-level sub-micron filtering, foam works as a pre-filter step. You’ll need synthetic or HEPA media after it for final capture.

Balancing Efficiency Against Pressure Drop

Higher PPI numbers and thicker foam boost capture efficiency and dust capacity. But they also raise pressure drop. Depth-loading foam design helps here. Restriction builds slowly over time. Surface filters clog fast.

Set your pressure drop budget first. Then pick the finest PPI grade that fits within limits. A 60 PPI foam at 25mm thickness might reach your efficiency goal. But pressure drop may exceed your fan’s power. Step down to 45 PPI at 30mm instead. The thicker section makes up for larger pores. Particles stay inside longer.

Picking Materials for Your Environment

High humidity or splash conditions need polyurethane foam. This material fights off water. It stays strong where paper filters fall apart. High-temperature jobs—molten metal filtering, hot gas streams—need ceramic foam like zirconia or alumina. These handle temperatures over 1,300°F. They won’t break down.

Corrosive chemical exposure limits you to PE foam, ceramic types, or chemical-resistant PU blends. Standard polyurethane fails under strong acids or solvents. For critical air filtering in medical or cleanroom spaces, verify your foam meets HEPA or equal performance standards. Get independent testing done.

Conclusion

Open cell foam wins for filter materials. It works across most industries. The connected pore structure gives you better airflow. You get excellent particle capture. This foam handles air purification, aquarium systems, industrial processes, and metal filtration.

Closed cell foam works well for insulation and flotation. But it fails as a filter medium. Its sealed structure blocks fluid passage. That’s the basic requirement any filtration system needs.

Your next step depends on what you need. Think about your filtration environment—air, water, or specialized applications. Check your required micron rating. Look at your budget and maintenance capabilities. Open cell foam in 10-60 PPI gives you the best balance. You get good filtration efficiency, durability, and cost-effectiveness.

Ready to pick the right filter foam? Match pore density to your particle size requirements. Don’t cut corners on quality. Your filtration performance depends on it. The better choice isn’t just open cell. It’s the right grade of open cell foam for what you’re doing.