Foundry operators make a key choice every day: mesh filters or foam filters. This choice affects casting quality, production costs, and defect rates.

Both filters promise cleaner metal and fewer inclusions. But their performance gaps are huge. You either meet quality standards or scrap expensive batches.

The mesh filter vs foam filter debate goes beyond specs. You need to know which filter fits your casting needs, metal alloys, and budget.

This comparison shows how these two systems perform in real foundries. You’ll learn about their structural differences and filtration efficiency. We cover cost-per-casting and give you a practical decision framework. This helps you pick the right filter for your production needs. Plus, we explore hybrid solutions that blend the best of both technologies.

Mesh Filter Structure

Mesh filters use woven fiber structures to trap metal impurities. The core material controls heat resistance and filtration precision.

Aperture and Mesh Density Design

The mesh has precise pore sizes between 1.5-2.5mm. This size blocks sand particles and inclusions larger than 1.5mm. It works through basic mechanical sieving.

The grid density uses a voxel volume of 1cm³ (0.01f × 0.01f × 0.01f). Point cloud downsampling reduces width and height by 50-70%.

Foam Filter Structure and Working Principle

Ceramic foam filters use a 3D connected network for their performance. This skeleton creates continuous pore channels. These channels form maze-like twisted paths through the material. The complex routing makes the melt flow longer distances. It also stays inside the filter longer. This design strengthens how the filter catches and holds inclusions.

Open-Cell Foam Structures and PPI Specifications

The open-cell foam structure is what defines ceramic foam filters. Each cell connects fully to its neighbors. This design lets liquid and gas pass through easily. At the same time, it filters deeply through the whole filter volume.

Two structural features drive how well filtration works:

High surface-area-to-volume ratio gives more chances for inclusions to hit filter walls. More contact points mean you capture more particles.

High porosity creates multi-stage twisted channels. It also keeps a large cross-section for flow. This combo holds more slag without slowing down throughput.

PPI (pores per inch) measures how dense the pores are. The 10-30 PPI range works for most aluminum and alloy melt filtration:

-

10-15 PPI: Maximum flow with minimal pressure drop. Removes large particle inclusions well. Best choice for speed over fine filtering.

-

20 PPI: The industry standard. Balances precision and flow rate. Handles general quality needs across most casting jobs.

-

25-30 PPI: Catches fine inclusions better. The tighter pores trap smaller particles. But pressure drop goes up. Higher pouring temps and greater static head are needed to keep flow rates steady.

The maze structure creates expansion-contraction cavities and recirculation zones at certain points. Melt speed drops fast in these areas. Some spots barely move. Inclusions separate from the main flow due to gravity, inertia, and surface forces. They settle or stick to skeletal surfaces. Once trapped in these “dead zones,” inclusions almost never get back into the melt stream. High PPI filters boost this passive capture effect.

Collaborative Filtering Mechanism

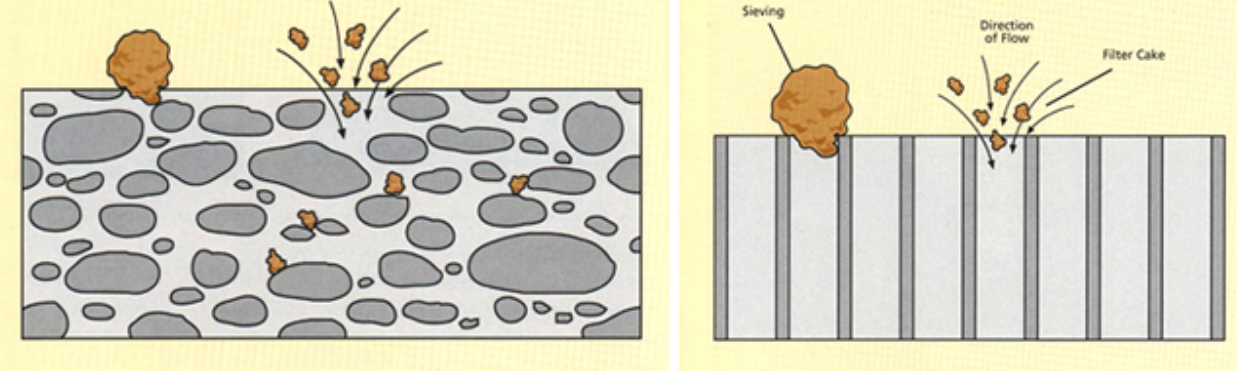

Mechanical screening is the first filtration stage. Melt flows through connected channels. Pore throat diameters get smaller than some inclusion sizes. Direct size sieving happens. Large particles get blocked at entrance points or internal throats. The honeycomb network cuts down on internal and external shrinkage cavities. Surface defects drop noticeably. Casting density and yield rates go up.

Filter cake formation adds a second filtration layer over time:

Initial stage: Mechanical blocking and surface sticking trap inclusions on foam ceramic entrance surfaces and front-layer pore walls.

Progressive buildup: A dense filter cake builds up on the upstream side. This piled-up slag layer has much smaller pores than the original foam. It acts as a secondary filter with finer screening power.

The filter cake holds micro-inclusions better. It uses Brownian diffusion, blocking, and inertial collision together. But pressure drop rises at the same time. You need enough metal static head and filtration area to keep flow going.

Surface adsorption and wetting finish the filtration system. Melt flows across foam skeleton surfaces. This triggers surface reactions. Oxide inclusions and non-metal particles stick strongly to ceramic oxide surfaces. This “like attracts like” surface chemistry pulls particles from the melt stream. Capillary action and surface tension help pull small particles to pore walls. They hold them there.

Comparison of Filtration Performance: Inclusion Removal Efficiency

Particle size decides the winner. The 5-50μm range splits good castings from scrap metal.

Mesh Filter vs Foam Filter: Particle Removal Data Comparison

Mesh filters use mechanical screening. They catch particles bigger than their pore openings (1.5-2.5mm). Anything below 50μm passes straight through. Deep adsorption doesn’t happen. The filter blocks what can’t fit. Everything else flows into your casting.

Foam ceramic filters work across the full particle range:

Particles above 50μm get removed at 100% efficiency. The maze structure traps every large piece through blocking and filter cake buildup.

The 20-50μm range shows foam’s real strength. Deep adsorption starts working. Large surface area grabs mid-sized particles that mesh filters miss. Surface chemistry pulls oxide bits to ceramic walls. They stick and stay there.

Particles below 20μm still get removed well. The 3D network creates slow-flow zones. Brownian motion and surface forces pull tiny particles from the melt stream. Mesh filters catch nothing at this scale.

Actual Filtration Performance of Different Metals

Steel melt filtration shows clear differences:

Pulse current treatment (4×10⁷ A/m² density) removes all particles above 5μm. Even 2μm particles drop by over 50%. Run it for just 30 seconds. You eliminate 100% of 10μm+ inclusions and over 70% of 5μm particles.

Standard mesh filters can’t compete at these tiny sizes. They depend on pore diameter. Steel bits smaller than 1.5mm sail through untouched.

Molten iron works better with mesh systems through chemistry. SiC oxidizes to SiO₂ at high temps. This creates a soft layer that grabs inclusions. Chemical help boosts what screening misses. But sub-50μm particles stay hard to catch.

Aluminum melt shows foam ceramic’s best results. Deep adsorption does the heavy lifting. The skeletal network catches particles across all sizes. Electromagnetic stirring speeds up capture even more. Foam filters cut gas holes, slag bits, and oxide flaws better than fiber mesh. Mesh stops surface particles. Foam traps them through its full volume.

Magnesium alloys benefit most from pulse current methods. Treatment removes all particles above 50μm plus high rates of smaller ones. The current density breaks up particle clusters. Electromagnetic forces pull particles from the melt fast.

Quantitative Comparison of Casting Defect Reduction

Foam ceramic filters cut more defect types than mesh options. The deep adsorption targets three key problems:

Gas porosity drops a lot. Trapped bits can’t become spots where gas bubbles form. Cleaner metal means fewer holes in final castings.

Slag inclusions decrease through filter cake buildup over time. The second filtration layer catches what first foam layers miss.

Oxide film defects fall due to surface chemistry. Ceramic pulls in and holds oxide particles. Mesh filters let oxide films flow through if particles are small enough.

Pulse current adds another plus for steel casting. Nozzle deposit thickness drops 55.5%. Deposit density increases 48.5%. This stops clogs that cause pour stops and surface flaws.

|

Filter Method |

5μm Removal |

20-50μm Removal |

Best Metal Match |

|---|---|---|---|

|

Pulse Current |

>70% (30s) |

100% |

Steel/Al/Mg |

|

Foam Ceramic |

High adsorption |

Excellent |

Aluminum/Universal |

|

Mesh/Fiber |

Low |

Above pore size |

Iron |

|

Gas Stirring |

Limited |

High |

Steel |

The data shows foam ceramic filters beat mesh systems for fine particle removal. Mesh filters work if inclusions are bigger than pore size. But modern quality needs sub-50μm filtration. Foam structure gives you real, measured gains here.

Production Efficiency and Cost Analysis

Filter choice impacts your foundry’s profit. Upfront price tells part of the story. Track throughput capacity, replacement cycles, labor hours, and energy waste.

Flow Capacity and Back Pressure Differences

Mesh filters keep flow rates high during continuous operation. The open grid design creates little flow resistance. Melt passes through with less pressure drop. Pouring speed stays steady during high-volume runs.

The woven structure causes complete blockage rarely. Particles larger than mesh openings get trapped on the surface. Liquid flow continues around blocked zones. You don’t see sudden throughput crashes during a single pour cycle.

Foam ceramic filters work with different flow patterns. The maze-like pore network creates natural resistance. Melt takes longer twisted paths through the 3D structure. Pressure drop starts 15%-30% higher than mesh systems.

Filter cake buildup changes flow over time. Trapped particles form dense layers on the upstream face. This secondary filter catches more particles. But backpressure increases steadily. Static head needs grow as the filter loads with slag.

Higher PPI ratings boost this effect. 25-30 PPI foam needs higher pouring temperatures and metal head height to keep flow rates up. 10-15 PPI options reduce pressure penalty but catch fewer fine particles.

Equipment capacity plays a key role here. Foundries with adequate static head systems handle foam filter backpressure well. Operations with marginal metal head height struggle to keep throughput up. Flow rate can drop 10%-20% below target with thick filter cake buildup.

Single-Use Cost and Replacement Frequency

Foam ceramic filters cost more upfront but function in a different way. Standard 20 PPI units cost $25-45 each based on size and quality grade. Premium 25-30 PPI options reach $50-75 per filter.

The key difference: foam filters are single-use consumables. You replace them after each pour or after a set tonnage limit. Filter cake buildup makes cleaning hard. Most foundries throw away loaded filters rather than try to clean them.

Typical usage rates:

-

One filter per 500-800 kg of aluminum melt for 20 PPI.

-

One filter per 300-500 kg for 25-30 PPI higher-precision work.

-

Cost per ton: $0.06-0.15 based on metal type and quality needs.

The math shifts with scrap reduction. Foam filters cutting defect rates by 8%-12% can offset their higher cost. One prevented scrap batch often pays for dozens of filters.

Labor Costs and Operational Complexity

Mesh filter installation needs little training. Workers position the filter in the runner system. Secure it with refractory cement or mechanical clips. No special skills needed. Setup time: 3-5 minutes per filter.

Checking during operation stays simple. Visual inspection shows if metal flow looks normal. No complicated mid-pour adjustments needed. Workers replace filters based on cycle count or visual wear signs.

Foam ceramic handling needs more operator attention. Filters arrive dry and must stay that way until use. Moisture absorption ruins filtration performance. Storage needs climate control in humid places.

Pre-heating adds steps. Foam filters need gradual temperature ramp-up to avoid thermal shock cracking. Here’s the procedure:

-

Preheat to 200-300°C in separate oven.

-

Hold for 15-30 minutes to drive off any absorbed moisture.

-

Transfer to pouring position while keeping temperature.

This adds 20-30 minutes to setup time compared to mesh systems. Rushed pre-heating causes 15%-25% filter failure rates from thermal cracking.

Positioning precision matters more with foam. The filter must seal tight against the filter box walls. Any gap lets unfiltered metal bypass the ceramic. Workers need proper training to avoid bypass flow. Installation time: 8-12 minutes including pre-heat and positioning.

Digital cost analysis tools show labor impact with clear data. Foundries using automated filter handling systems cut setup time 40%-50%. Robotic pre-heating and positioning stop human error. But capital investment costs $80,000-150,000 for integrated systems.

Companies tracking worker hours report real savings. One mid-size aluminum foundry switched from manual foam handling to semi-automated mesh systems. Here’s what happened:

-

Filter setup labor dropped 10% total.

-

Training time for new workers dropped from 7 days to 2 hours.

-

Installation error rates fell 18%.

The efficiency gains build across shifts. BI+AI analytics applied to filter operations show production efficiency gains averaging 27.8% with other digital manufacturing tools.

Applicability to Different Casting Scenarios

Sand casting leads ferrous metal production. The numbers back this up. Over 80% of all steel and iron castings rely on sand mold processes. This method works with different sizes, materials, and batch volumes. No expensive tooling changes needed.

Selection of Filters for Ferrous Metal Casting

Mesh filters fit steel foundry economics well. Sand casting keeps costs down with flexible equipment. You can switch between engine blocks, transmission housings, and chassis parts on the same line. Mesh filters handle this shift easily.

Aluminum Alloys and High-Purity Casting Requirements

Aluminum alloy precision work calls for a fresh approach. Product designs grow more detailed. Material specs get tighter. Foam ceramic filters remove complex inclusions better.

Vacuum chamber tech keeps the supply chain stable for high-purity aluminum. Proper filtration pushes conversion efficiency to 27.5% theoretical max. Heat exchangers and pump housings need this purity. Standard mesh falls short.

Forecasts show aluminum vacuum chamber value hitting 640 million yuan by 2025. Foam filters cost more per unit. But they stop scrap in premium uses. The 8%-12% defect drop makes the higher cost worthwhile for valuable castings.

Key Selection Factors and Decision Matrix

Your foundry needs a clear system to pick filters. A decision matrix helps you sort through conflicting specs and vendor claims. You get scored comparisons instead of guesswork.

Build your matrix with three core parts:

Rows list your filter options. Add different PPI ratings, materials, brands, and price levels. A typical aluminum foundry might compare:

– 20 PPI foam ceramic (standard grade)

– 30 PPI foam ceramic (premium)

– 1.5mm mesh filter (carbonized glass)

– 50 PPI foam ceramic (high-end aerospace)

Columns show selection factors. Give each factor a weight based on what matters in your production. All weights must add up to 100%:

-

Inclusion size match: 25%

-

Filtration efficiency: 20%

-

Pressure drop tolerance: 15%

-

Temperature compatibility: 15%

-

Thermal shock resistance: 10%

-

Cost per casting: 10%

-

Overall quality rating: 5%

Scoring uses a 1-10 scale. Rate each filter on each factor. Take the score and apply the weight. Add up all weighted scores. The highest total is your winner.

The Thermal Conductivity Advantages of Graphite Foam Filter

Graphite foam filters shift how heat flows through the filtration system. Thermal conductivity hits 80-150 W/m·K in-plane and 20-60 W/m·K through-thickness. That’s 5-20 times higher than ceramic foam.

The structure stays light even with better performance. Porosity runs 75-95% by volume. Relative density sits at 0.1-0.3 (0.2-0.6 g/cm³ absolute). Specific surface area stays high across 10-80 PPI ratings.

Temperature control benefits appear in pour quality:

Metal local overheating drops. Temperature spreads evenly across the filter volume. This cuts thermal cracking risk in the casting.

Viscosity control gets better with uniform melt temperature. Inclusions float or get trapped more reliably. One aluminum foundry measured 30-50% less temperature drop versus ceramic foam at equal flow rates.

High thermal conductivity speeds up preheating too. Graphite foam hits working temperature faster than ceramic options. Setup time drops. Energy waste during heat-up goes down.

Conclusion

Mesh filters vs foam filters? There’s no universal winner here. Match the right tech to your casting needs.

Mesh filters work great for high-volume jobs. They handle thin, fast-flowing melts well. Plus, they cost less per unit.

Foam filters use a three-dimensional structure. This removes more inclusions than mesh. They cost more per unit. But for quality-critical work, they’re worth it.

Smart foundries optimize instead of picking sides. Look at your alloy type. Check your inclusion levels. Count your production volume. Know your quality standards.

Many operations use both filter types. Hybrid systems work well. Or use different filters for different product lines. This approach gives you the best value.

Want to upgrade your filtration? Check your current defect rates first. Calculate what scrap actually costs you. Compare that to filter costs.

The right filter choice cuts rejection rates by 30-50%. Casting quality improves too.

Your next step is simple. Review your last 100 castings. Find where better filtration would pay off most.