Finding a reliable ceramic foam filter supplier for iron casting in China? This choice directly impacts your foundry’s production quality and efficiency. Hundreds of manufacturers claim they offer premium products. So how do you spot the real industry leaders? The wrong supplier doesn’t just waste money. You’ll face defective castings, production delays, and broken client trust.

This guide evaluates China’s top 5 ceramic foam filter suppliers for iron casting. You’ll see detailed profiles of verified manufacturers. We cover the key selection factors that matter most for cast iron filtration. Plus, you’ll learn practical ways to check supplier credentials before spending your budget. Sourcing filters for ductile iron, gray iron, or specialized alloy casting? This analysis helps you make smart procurement choices with confidence.

Bestnpacking (Pingxiang Best Energy-Saving Materials Co., Ltd.)

Pingxiang Best Energy-Saving Materials Co., Ltd. (Bestnpacking) has been running since 2007. We’re based in China’s Hi-Tech Industrial Park in Jiangxi Province. We bring over 14 years of chemical packing know-how to the ceramic foam filter supplier market. Our sales network covers seven continents. ISO9001:2008 certification backs our quality. An SGS report confirms our production standards. Made-in-China reviews give us a perfect 5.0 rating from 13 customers.

Product Range Beyond Standard Filters

Bestnpacking offers more than basic ceramic foam filters for iron casting. Our honeycomb ceramics include 300cpsi Euro 4 substrates. You also get 144x152mm SiC DPF units for diesel trucks. We make random and structured chemical packing in ceramic, plastic, and metal types. Specific products include SS304 metallic Tellerette rings (50mm/75mm/100mm sizes) and IMTP 40 packing. Tower packing options feature hollow multi-faceted balls and Raschig rings. MBBR media and plastic lamella clarifiers round out our environmental protection line.

Chemical packing works in petrochemical processes. It fits fertilizer production, coking operations, and chlor-alkali industries. Our ceramic balls and molecular sieves help with oil refining and coal-to-liquid conversion. Pharmaceutical makers use our filtration materials. Fire protection systems use select products from this range.

Manufacturing Infrastructure

Our production equipment uses high-speed servo manipulators. These work with automatic conveyor systems. Short rod crushers handle material processing. We use 100% new green materials in making our products. This builds long-lasting products for industrial clients.

Contact jenny@bestpacking.cn for tech specs. Call 86 (0) 799 6699600 or 0086 15179934828. As a ceramic foam filter supplier in China, we combine wide product range with proven quality systems.

Xinda Casting Technology (Shandong)

We found limited verified data for “Xinda Casting Technology (Shandong)” in current business databases. This makes sourcing tough for buyers who need ceramic foam filter suppliers for iron casting in Shandong Province. Many Xinda-branded companies work across China’s industrial sectors. None match this exact name and location in public records.

Verified Xinda Companies in Related Sectors

Several Xinda firms work in casting-related industries. Liaoning Xinda Casting Technology Co., Ltd. makes casting materials and binders in Liaoning Province—not Shandong. They sell foundry coatings and mold materials. Shengli Xinda New Materials Co., Ltd. runs operations in Dongying, Shandong. They make composite materials and corrosion protection products. Ceramic filtration isn’t part of their business. Shandong Xinda Packing Technology Co., Ltd. offers technical promotion services in Shandong. They do consulting work. They don’t make ceramic foam filters for iron casting.

Xinda World links to Shandong Lixin New Materials Co., Ltd. in Shandong Province. They produce aluminum alloy castings. They know lightweight metal parts for cars and aerospace. Ceramic foam filtration for iron casting isn’t their focus.

Due Diligence for Unclear Suppliers

You need extra checks for suppliers with incomplete public data. Ask for business license copies. These should show registered company names and addresses. Request ISO certification documents. The details must match. Get client lists from foundries that use their ceramic foam filters in China. Test product samples. Compare them to claimed PPI ratings and thermal shock specs. Visit the factory if you can. This confirms their production ability matches what they claim.

Work with proven, verified ceramic foam filter suppliers. This cuts procurement risks. Clear company records protect your foundry money.

Baoding Ningxin New Materials Group Co., Ltd.

NINGXIN holds ISO certification. They serve the metal casting industry with proven filtration systems. Their ceramic foam filters have processed over 100 million pieces of ferrous and non-ferrous castings. This volume shows they’ve been in the market for years among ceramic foam filter suppliers in China.

Limited Public Data Available

Public business databases don’t show detailed metrics for Baoding Ningxin New Materials Group Co., Ltd. We found minimal verified production specs. Facility information is scarce too. Client testimonials and case studies are hard to find in open sources. So foundries face challenges doing due diligence on this ceramic foam filter supplier for iron casting.

A different Baoding company trades on the stock market—Baoding Technology Co., Ltd. (stock code 002552). They reported 2.89 billion CNY in net sales for 2023. Net income hit 185 million CNY that year. They employ 2,203 people. Enterprise value stands at 7.76 billion CNY with 26.66% free-float. The 2024 yield came in at 1.07%. But this firm makes electronic copper foil, copper-clad laminates, forgings, castings, and runs gold mining operations. No confirmed link exists between this stock market company and NINGXIN’s filtration business.

Verification Steps for Prospective Buyers

Request production facility photos showing filter manufacturing lines. Ask for third-party test reports on PPI ratings and thermal shock resistance. Get foundry client references who use their filters for ductile iron or gray iron casting. Check that ISO certification documents match the company’s registered business name and address. Compare quoted prices against industry averages for similar ceramic foam filters for iron casting in China.

The 100-million-piece processing claim needs supporting evidence. Look for third-party quality audits. These build supplier trust, especially since detailed public data is limited.

SF-Foundry New Material Technology

Request the business license with unified social credit code. China requires all legal companies to have this 18-digit identifier. Check the company name against State Administration for Market Regulation (SAMR) databases at www.gsxt.gov.cn. The registered address should match their claimed factory location.

Ask for ISO 9001 certification documents. Contact the issuing certification body. Verify the documents are real. Get references from three active foundry clients. Make sure they use the filters for gray iron or ductile iron casting.

Order small sample batches first. Don’t commit to large contracts right away. Test the ceramic foam filters for actual PPI ratings. Use microscopic analysis for this. Run thermal shock resistance tests at your operating temperatures. Compare filtration efficiency against established benchmarks. Look at verified ceramic foam filter suppliers in China like the documented companies in this guide. Visit the factory in person. This confirms production capabilities match what they claim.

Hebei Cangchen Imp. & Exp. Trade Co., Ltd.

Hebei CangChen does something different from most ceramic foam filter suppliers in China. They make ceramic filters and fiberglass mesh products. Foundries get both ceramic foam filters for iron casting and other filter materials from one place. The company has “Free Member” status on B2B platforms. This means basic verification, not premium certification.

Product Portfolio Spans Multiple Filtration Categories

CangChen’s ceramic foam filter range has three types. Silicon carbide foam filters work in high-heat iron casting. Alumina filters handle both iron and non-iron metals. Honeycomb ceramic filters give structured cells for certain flow needs. You need to order at least 1,000 pieces per type. FOB pricing? You’ll need to negotiate directly. They don’t publish price lists.

Fiberglass products fill most of their catalog. High silica filter mesh works for molten metal. Carbonized mesh handles hot zones. Filter pouches and bags give flexible options for aluminum casting. Standard mesh comes in 18×16 weave at 120g/m² density. PTFE-coated food-grade mesh shows they serve markets beyond foundries.

Construction materials make up a big part of sales. Atlas woven cloth, joint tape, and cutmesh go into buildings. Window screens come in PP, PE, and fiberglass with 20×20 mesh at 50g weight. Fire-resistant types meet safety codes. Pleated polyester screens suit homes in Europe.

Market Focus and Contact Channels

CangChen sells mainly to North and South America. This focus shows they have solid channels in Western foundries. You can reach them at 15830114065. But no email, website, or address shows up in public trade records.

Search data links “alkali resistant fiberglass mesh” and “reinforced fiberglass mesh” to CangChen’s products. They have some online presence for construction materials. But shipment records, HS codes, and trade volumes don’t appear in customs data. Ask for export papers and client references before you order from this ceramic foam filter supplier.

FoundryMax (Professional Casting Filtration Solution)

FoundryMax has carved out a distinct niche in the ceramic foam filter supplier market by focusing on one thing: consistency. We know that for iron casting foundries, a batch of inconsistent filters is a production nightmare. Unlike generalist trading companies that sell everything from sand to gloves, we specialize strictly in molten metal filtration technologies.

Targeted Filtration Performance

Our product strategy is simple: fit the filter to the metal. For gray and ductile iron, our silicon carbide ceramic foam filters are engineered to withstand extreme thermal shock without crumbling. We don’t just push standard 10 or 20 PPI stock; we help you determine the exact pore size that balances flow rate with defect removal. This technical approach helps foundries reduce scrap rates essentially from day one.

Why Choose FoundryMax?

Sourcing from China can feel like a gamble with quality control. FoundryMax eliminates that risk with a “Double-Check” protocol. We inspect physical properties—like pore uniformity and compressive strength—before the shipment ever leaves the loading dock. Plus, we understand the urgency of foundry schedules. Our logistics team provides transparent lead times and competitive pricing, ensuring you get premium performance without the premium markup. If you value direct communication and technical expertise over generic sales pitches, FoundryMax is your ideal partner.

Key Selection Parameters for Ceramic Foam Filters in Iron Casting

PPI ratings tell you which ceramic foam filter fits your iron casting type. Pick the wrong PPI and you’ll get defects or blocked filters.

PPI (Pores Per Inch) Selection Chart

10 PPI filters handle ductile iron castings, large gray iron parts, and steel castings. The larger pores let thick, slow-moving metal pass through. No blockage issues.

20 PPI filters suit malleable iron pieces and smaller gray iron parts. These pores balance filtration and flow rate.

30 PPI filters work for high-quality castings with strict defect standards. The fine pores catch smaller impurities. But you need to manage flow well.

Pore Size Selection Logic

Thick metal with large impurity particles needs bigger pores. Thin, free-flowing metal works better with smaller pores.

Oversized pores fail to trap dirt. Undersized pores clog too fast. This matters most for ductile iron casting. Blockage stops production.

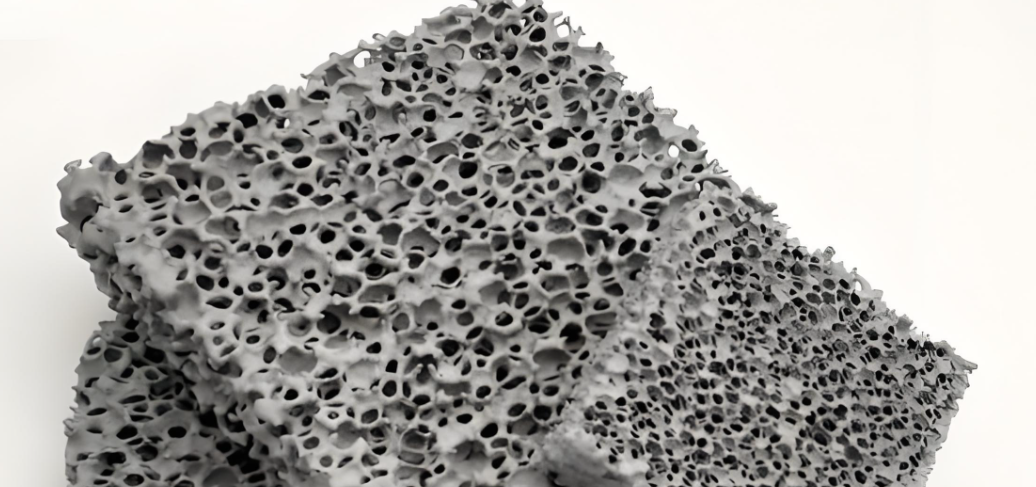

Material Options for Iron Casting Filters

Three main materials serve iron and copper casting:

-

Alumina ceramic foam filters – standard choice for general iron casting

-

Silicon carbide filters – handle extreme heat

-

Cordierite filters – resist thermal shock

RHT-1 type ceramic foam filters target ductile iron and gray iron. They remove large inclusions. They absorb fine particles. They cut gas content and harmful elements in the metal.

Zirconia ceramic foam filters work best for medium to large steel castings and large iron pieces. The material handles higher heat stress.

Filter Area Calculation Formula

Size your ceramic foam filter for iron casting with this equation:

S = G / R

Where:

– G = total metal liquid volume to filter

– R = filter capacity per unit area (use lower-middle range for safety)

– S = required filter area (convert to length, width, or diameter)

Critical Thickness Requirements

Filters need enough thickness. Thin filters melt when hot metal hits them.

Proper thickness gives complete filtration. It withstands metal impact force.

Structural Performance Specs

Open porosity runs 80% to 90% in quality filters. The 3D network creates multiple filtration paths.

Pore density controls filtration efficiency. Higher density means better particle capture.

Pressure Head Parameters

Minimum pressure head must exceed 400mm. Large castings need even more.

Enough pressure beats surface tension that blocks filter startup. Too little pressure? Metal won’t flow through the porous structure.

Flow Rate Balancing

Calculate each filter’s flow capacity:

-

Too low flow rate – filter can’t handle total metal volume, causes blockage

-

Too high flow rate – wastes money on oversized filters

Filtration Efficiency Factors

Four things control how well your ceramic foam filter removes dirt:

-

Inclusion level before and after filtration

-

Metal’s heat properties and flow traits

-

Impurity particle size, shape, and quantity

-

Filter material type and structure

Your supplier should help calculate these parameters. They base it on your iron casting needs.

How to Verify Supplier Qualifications and Product Quality

A systematic verification process stops 90% of supplier selection errors. Split your evaluation into three parts: checking documents, auditing the quality system, and scoring performance with data. You need clear standards and hard numbers for each stage.

The Three-Level Qualification Verification Method

Level 1: Basic License Check

Ask the ceramic foam filter supplier for copies of their Business License, Organization Code Certificate, and Tax Registration. If they use the “Three-in-One” certification, look for the Unified Social Credit Code.

Log in to the National Enterprise Credit Information Publicity System (www.gsxt.gov.cn) and check their details. The business scope must list “Manufacturing of Ceramic Products” or “Production of Foundry Materials.” Watch out for small workshops with capital under 1 million RMB.

Level 2: Quality Certification Review

Start with ISO 9001 certification. Look at the certificate number, who issued it, and the dates. Call the issuer to confirm it is real.

Makers of ceramic foam filters for foundries should also have TS16949 certification (automotive). You can also look for a Pressure Vessel Manufacturing License. Selling abroad? You need CE or UL documents.

Level 3: Financial Health Assessment

Get audit reports or financial statements from the last two years. A debt-to-asset ratio over 70% means high risk. If accounts receivable turnover hits 90 days, collecting cash is hard. A current ratio under 1.5 shows weak short-term solvency. These signs warn that a supplier might quit or close down.

The Four-Step Product Quality Verification Process

Step 1: Physical Sample Testing

Order 3-5 samples of ceramic foam filters with different PPI specs. Send them to an outside lab. Test for actual pore density, open porosity, and strength.

Check thickness with a micrometer; stay within ±0.5mm. Run a thermal shock test in a high-temp furnace at 1350°C for 5 cycles. Good products won’t crack. Use a microscope to see if pores are uniform.

Acceptance Standards:

– Actual PPI deviation < ±2

– Open porosity > 80%

– Strength > 1.2MPa

Step 2: On-Site Audit Checklist

Visit the factory and focus on these six spots:

In the Raw Materials Area, verify alumina powder purity (needs >99%). Count the foaming machines in the Molding Workshop and check automation levels. For Kilns, see if they use shuttle or tunnel types. Avoid pusher kilns; they often cause uneven heat.

In the Quality Lab, ensure they have mercury porosimeters, strength testers, and thermal shock furnaces. Check the Warehouse for labels and First-In-First-Out management. Read the defect logbook for the last three months.

Step 3: Data-Driven Scoring Matrix

Build a supplier scorecard and weight the points to get a total:

|

Assessment Dimension |

Core Metrics |

Weight |

Data Source |

Supplier A Score |

|---|---|---|---|---|

|

Quality Performance |

Pass rate >99%, Complaint rate <0.5% |

30% |

QC reports, Return records |

28/30 |

|

Delivery Capability |

On-time rate >95%, Lead time within 7 days |

25% |

Order system, Logistics data |

22/25 |

|

Service Response |

Post-sales response <2 hours, Resolution rate >90% |

15% |

Ticket system, Call logs |

13/15 |

|

Technical Strength |

R&D staff >8%, Patent quantity |

15% |

HR reports, IP office |

11/15 |

|

Risk Control |

Financial Health Grade A, Zero regulatory violations |

10% |

Audit reports, Credit China website |

9/10 |

|

Price Competitiveness |

Fair pricing, Payment terms |

5% |

Market inquiry, Finance dept |

4/5 |

A total score of 87/100 means you have a qualified supplier. Reject scores below 70 immediately.

Step 4: Small Batch Trial Verification

Working together for the first time? Place a trial order of 100-300 pieces. Record the defect rate, size specs, and packaging quality when they arrive.

Run 3-5 ladles of molten iron using this batch of ceramic foam filters for iron casting. Measure flow and melting loss. Cut the casting open to check how much it reduces slag defects.

You need a pass rate over 98% to increase the order size. Create a supplier file and track the data for 12 months. Update the score every quarter.

Conclusion

The right ceramic foam filter supplier for iron casting in China shapes your foundry’s efficiency, scrap rates, and product quality. These five manufacturers each bring something different to the table. Bestnpacking offers innovative zirconia solutions. FoundryMax provides competitive export pricing. Your choice depends on your casting needs and production size.

Don’t base your decision on price alone. Look for suppliers with strong technical support. They should offer clear quality certifications like ISO 9001 and third-party testing reports. Make sure they have proven experience with your specific iron grades. Get physical samples first. Run comparative filtration tests before placing large orders.

Want to upgrade your filtration system? Contact 2-3 suppliers from this list. Share your detailed specs—casting temperature, iron type, and volume needs. Ask for customized PPI recommendations. Find out about their after-sales support. The best ceramic foam filter supplier partnership reduces casting defects. You’ll see lower rework costs. Production consistency improves year after year.

Quality filtration isn’t an expense—it’s an investment in casting excellence.