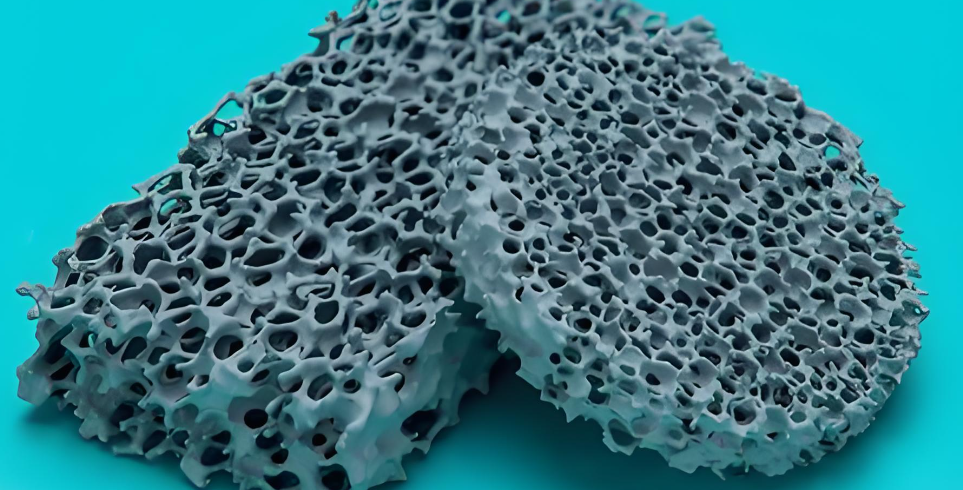

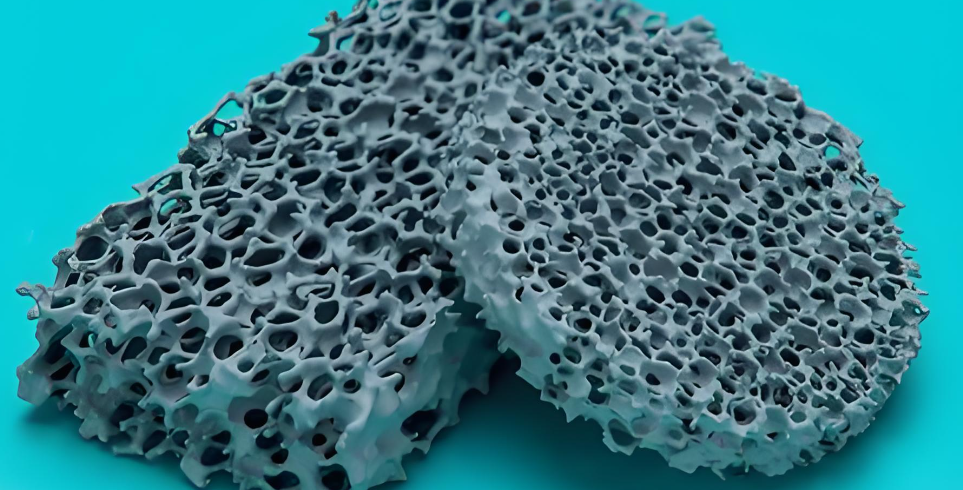

Sourcing reticulated foam filters from China can cut your costs by 40-60% compared to Western suppliers. But you need to know where to look. First-time buyers often fall into traps that waste time and money.

The Chinese market has options for everyone. You’ll find precision-engineered filters for aerospace applications. You’ll also find budget-friendly choices for basic industrial use. The challenge? Manufacturers, trading companies, and B2B platforms create a complex landscape. Success requires insider knowledge.

Many buyers face common struggles. PPI specifications confuse people. Quality consistency raises concerns. Pricing structures shift with every inquiry. This guide shows you the exact sourcing strategies that procurement professionals use to find reliable suppliers.

Direct Manufacturer Sources vs Trading Companies

Chinese foam filter suppliers come in two types. Each type works better for different buying needs.

Price Structure Reality

Buying direct from factories cuts out middleman costs. You pay the factory price with no extra markup. Large orders give you big cost savings. Trading companies can’t match these savings.

Trading companies add their profit margin on top of the factory price. Here’s what surprises most buyers: China’s low costs keep these markups small. Some traders work on margins as slim as 0.05%. Rent and running costs stay very low. These traders buy in bulk from factories. This gets them discounts that cover their fees. Some order sizes? Trader prices beat what manufacturers quote.

|

Supplier Type |

Typical Fees/Markup |

Key Consideration |

|---|---|---|

|

Manufacturer |

Lowest (direct ex-factory) |

High upfront investment required |

|

Trading Company |

Variable markups above factory cost |

Bulk buying reduces effective pricing |

|

Purchasing Agent |

5-10% commission on ex-factory cost |

Optimizes logistics for additional savings |

Order Quantity Flexibility

Manufacturers require high minimum order quantities. These amounts match their full production runs. Small buyers face a problem. They either can’t afford the minimum or must order more than they need.

Trading companies keep stock on hand. They work with many factories. This setup lets them take smaller orders. Want 50 filters instead of 5,000? Traders fill these orders all the time. Manufacturers say no.

Service and Communication Gap

Trading companies focus on customer service. You get quick responses, English-speaking staff, and complete logistics help. They manage customs, shipping, and any issues that come up. Your business matters to them.

Manufacturers put their resources into making products, not serving customers. Limited staff means emails take longer to answer. You get less help through the buying steps. Language problems happen more often with factory teams.

Product Range Options

One trading company works with dozens of factories. This gives you wide choices. Their catalogs cover many filter types, PPI ratings, and materials. One contact gets you everything you need for your product line.

Manufacturers focus on specific products they know well. They go deep into their specialty instead of broad. Need custom specs or unique requirements? The production team gives these closer attention.

B2B Online Platforms: Alibaba vs Made-in-China vs Global Sources

Three major B2B platforms lead China’s reticulated foam filter market. Each one connects buyers with suppliers differently.

Alibaba: Volume and Variety Leader

Alibaba runs the largest B2B marketplace worldwide. The platform has over 2 million suppliers. They serve 726 million active buyers across 200+ countries. You’ll find the widest selection of reticulated foam filters here.

Bulk purchasing? Alibaba excels at it. Small buyers face no minimum order limits. Discount coupons come out each week to cut costs. Free shipping pops up often. Trade Assurance guards your payments until you confirm receipt and quality.

Buyers give Alibaba 4.66 stars based on 10,012 reviews. Look for Gold Supplier and Verified Manufacturer badges. These help you spot reliable sellers. Filter suppliers list 43,254 private label products ready for your branding.

Price negotiation thrives on Alibaba. Most buyers get 10-30% discounts by talking directly with suppliers. The platform lets you run dropshipping models. No special licenses needed.

Made-in-China: Export Factory Focus

Made-in-China serves 279 million customers. The focus? Export-ready manufacturers. You get detailed supplier checks and company backgrounds.

Minimum orders run higher here. Most foam filter suppliers want 500 pieces minimum. Prices sit a bit above Alibaba. But you get better supplier quality in return. Export factories fill most of the listings.

The platform lists 92,862 private label products for custom branding. Dropshipping? You’ll need proper licenses and certificates. Supplier info runs deeper than competitors. You see production capacity, certifications, and export history.

Customer ratings sit at 1.29 stars from 7 reviews. The low rating shows strict quality demands from pro buyers. It’s not about poor service.

Global Sources: Premium Verification Standard

Global Sources curates its suppliers carefully. Staff verify each manufacturer through hands-on inspections. Electronics and technical products get the closest look.

Pricing catches many buyers off guard. Some categories cost 30-50% less than Alibaba for domestic deals. The smaller, vetted supplier pool means less competition. You build better factory relationships.

Trade show connections make Global Sources different. Suppliers show up at physical events. You get face-to-face checks. Compliance papers meet international standards. Think ISO 9001, BSCI, and SA8000 certifications.

This platform fits buyers who put quality first. Filter makers here supply aerospace, medical, and precision industrial fields.

Making Your Platform Choice

Pick Alibaba for maximum options and flexible order sizes. Go with Made-in-China for verified export factories with full backgrounds. Choose Global Sources for premium filters that need strict compliance.

All three platforms take PayPal and secure payments. Check supplier response rates, years in business, and customer reviews first. Get samples no matter which platform you pick.

Minimum Order Quantities & Pricing Structures

Chinese foam filter factories base their minimums on production costs. These aren’t random numbers. A typical reticulated foam filter supplier needs 500-1,000 units per order. This covers machine setup, material waste during setup, and labor costs. Smaller runs? Your per-unit cost jumps 40-60%.

How Suppliers Calculate MOQ

The math starts with break-even analysis. A factory makes custom 30 PPI polyurethane filters at $8 per unit. This includes materials, labor, and overhead. They sell at $15 per unit. Setup wastes 50 units worth of material. Machine time takes 4 hours at $200.

Total fixed costs reach $600 before the first sellable filter comes off the line. At 100 units, the factory loses money. At 500 units, they break even. Profits start around 600-800 units. This is why most Chinese manufacturers avoid orders below 500 pieces.

|

Order Size |

Per-Unit Cost |

Your Total |

Factory Margin |

|---|---|---|---|

|

100 units |

$21 |

$2,100 |

-$100 (loss) |

|

500 units |

$16 |

$8,000 |

5% profit |

|

1,000 units |

$14 |

$14,000 |

12% profit |

|

5,000 units |

$11 |

$55,000 |

18% profit |

Volume-Based Price Breaks

Bulk orders get you big discounts. A 10 PPI filter costs $12 at 500 units. Double your order to 1,000 units? Price drops to $10.20. That’s 15% savings. Jump to 5,000 units and you pay $8.40 per filter. That’s 30% off the base price.

The savings come from three sources. Setup costs spread across more units. Material suppliers give discounts on larger raw foam purchases. Production runs get more efficient with fewer changeovers.

Trading companies sometimes beat manufacturer pricing on small orders. They combine orders from multiple buyers. A trader buying 10,000 filters each month gets factory rates 20% below what you’d pay for 500 units. They add a 5-8% markup. But they still deliver lower final costs than going direct.

Negotiating Lower Minimums

Factories adjust MOQ rules for the right reasons. Commit to bi-monthly orders totaling 2,000+ units each year. Suppliers often cut single-order minimums from 1,000 to 400 units. Your steady orders let them plan production better.

Payment terms matter in negotiation too. Offer 50% deposit, 50% before shipment instead of the standard 30% deposit. Better cash flow makes smaller orders work. One Guangdong supplier dropped MOQ from 800 to 500 units after a buyer switched to this payment plan.

Extended lead times give you leverage. Accept 8-week delivery instead of 4 weeks. The factory fits your order into gaps between larger jobs. They use machines better without needing special setup time.

Show concrete growth plans. Give sales data that proves you’ll grow from 500 to 2,000+ units within 12 months. Smart suppliers bet on the relationship. They’ll take early losses because future volume pays off.

Price Structure Components

Base pricing has five cost layers. Raw polyurethane foam makes up 35-40% of total cost. Reticulation processing (chemical or thermal) adds another 25-30%. Labor and machine time takes 15-20%. Quality testing and packaging runs 5-10%. Factory overhead and profit margin fills the remaining 10-15%.

Custom specs raise these costs. Need 80 PPI medical-grade filters with antimicrobial treatment? Add 25-35% to standard pricing. Special materials like conductive foam or flame-retardant grades push costs up 40-60%.

Shipping weight affects your landed cost a lot. Reticulated foam ships light but takes up space. A 1,000-unit order might fill a 40-foot container but weigh just 800kg. You pay for volume, not weight. Sea freight runs $1,200-2,000 per container to major ports. This adds $1.20-2.00 per unit no matter the filter price.

Risk Management with MOQ

Overordering eats up capital fast. You order 400 foam filters at $12 each ($4,800 total) to meet a 400-unit MOQ. Sales reach just 250 units in six months. Those 150 unsold filters take warehouse space. They freeze $1,800 in working capital. Storage fees add another $50-100 each month.

Start small with standard industry numbers. Most buyers begin at 500-800 units for first orders. Test market demand before jumping to 5,000-unit orders. Low-margin, high-volume products work with higher MOQs. Premium specialty filters do better with smaller, regular restocking.

Split orders across multiple PPI ratings to cut risk. Instead of 1,000 units of one spec, order 300 units each of 20 PPI, 30 PPI, and 45 PPI grades. You hit the 900-unit combined MOQ. Plus, you test which density your market likes best. Suppliers take mixed orders at 10-15% price premium over single-spec runs.

Quality Verification & Standards Compliance

China’s reticulated foam filter industry runs strict audit protocols. Skip these checks? You’ll face product failures, shipment rejections, and expensive rework. Audit frequency jumped in 2025. 58% of organizations ran 4 or more audits during the year. 35% of enterprises conducted over 6 audits on average. Quality controls got much tighter across all manufacturing sectors.

ISO Certification Requirements

ISO 9001 certification is now the baseline for foam filter suppliers. 81% of organizations report current or planned ISO 27001 certification in 2025. That’s up 14% from 67% in 2024. Buyers want documented quality systems. The numbers prove it.

ISO 9001:2026 brings big changes. The updated standard focuses on new risks and opportunities, sustainability practices, and how fast you adapt. Annual audits are out. Continuous monitoring systems are in. You get real-time compliance visibility. No more waiting for annual reviews.

Look for suppliers at “managing” or “optimizing” maturity levels. 57% of compliance programs reach these stages. These factories run mature processes. They prevent issues. They don’t just react to failures.

Supplier Recommendations for Your Specific Needs

AI matching tools help you find the right foam filter supplier in China quickly. These systems check performance data from hundreds of factories. They rank suppliers based on financial health, delivery records, and compliance ratings. You get a list that fits your exact needs.

Scoring Suppliers Based on Performance

Ranking systems changed how buyers find reticulated foam filter suppliers. The scoring looks at several factors. Financial stability shows which factories can weather tough markets. Delivery records tell you who ships on time and who doesn’t. Compliance certificates separate real manufacturers from unreliable ones.

Manufacturing buyers using AI supplier selection saw 25% fewer supplier risks. Efficiency jumped 30% in one case study. Retail procurement teams cut costs 20% through better supplier matching. These gains are significant.

Location affects pricing. Suppliers in Guangdong province charge different rates than Zhejiang factories. Payment terms differ too. Some suppliers offer net-60 terms. Others ask for 50% deposits. Scoring systems show these differences right away.

Filtering Criteria for Different Applications

Medical-grade foam filter buyers need different suppliers than industrial buyers. Market tools gather financial reports, quality certificates, and delivery data for each type. DEI and ESG certificates now appear in supplier profiles. You can filter for green credentials before you reach out.

Custom recommendations focus on what matters most to you. Need the lowest price? The system shows cost-friendly suppliers first. Tight deadlines? You see suppliers with quick turnaround times. Quality matters most? Certified makers appear at the top.

Benchmark data from 466 companies with $1.4 trillion total procurement spend runs these tools. Average diverse supplier spend sits at 17.8%. Community patterns show which suppliers excel at specific foam filter work.

Spotting Risks Early

Pattern recognition catches problems before they happen. Suppliers with slow communication show 40% higher chances of delivery issues. Recent transaction data flags inactive suppliers who may lack capacity. The system steers you away from risky options.

Compliance tracking monitors purchase order processes. You see bypass cases and turnaround times for each supplier. This data stops quality issues before they start.

How to Set It Up

Connect your procurement system through supplier portals, EDI integration, or APIs. Make data formats the same across all sources. Units, structures, and codes need to match. Clean data helps the AI give you better recommendations.

Payment term checks show regional gaps. A Shenzhen foam filter supplier might offer better terms than a Shanghai rival for the same specs. Price trend checks show seasonal shifts. Time your orders to save the most money.

Savings reports show planned versus actual cost cuts. Supplier reports break down by type, preferences, and risk scores. This feedback helps you pick better suppliers next time.

Red Flags & Supplier Selection Mistakes to Avoid

Production rejection rates above 2% show serious process control failures at foam filter factories. This marks the line between normal variation and real quality problems. High rejection rates eat into your margins. They damage your brand reputation. They trigger disputes with your customers.

Critical Warning Signs During Supplier Evaluation

Fluctuating Cp/Cpk values show unstable manufacturing controls. A supplier shows Cp values of 1.33 one month and 0.98 the next. This means they lack process stability. Reticulated foam needs consistent cell structure. Capability indices that swing around mean the factory can’t maintain PPI specs under different production conditions. Temperature changes cause these swings. So do material batch variations and equipment drift.

Late shipments destroy your planning cycles. Suppliers who push delivery dates create expedited freight costs you didn’t budget for. A Guangdong foam filter maker might promise 30-day lead times during talks. Then shipments arrive 45-60 days later. You end up paying $800-1,500 extra for air freight to meet your deadlines.

Missing production data blocks your ability to verify compliance. Request inspection reports, SPC charts, and batch records during supplier screening. Factories that can’t provide this hide quality issues. You’re buying blind. Medical-grade or aerospace applications? This gap creates regulatory risks you can’t afford.

Dangerous Cost-Cutting Mistakes

Chasing the lowest price without calculating Total Cost of Ownership (TCO) creates hidden losses. A supplier quotes $9.50 per filter versus a competitor’s $11.00. Looks like a 13.6% savings. But that cheap supplier delivers 4% defect rates. You spend $2,800 on rework for a 1,000-unit order. The “savings” turned into a loss.

TCO includes defect costs, rework labor, freight variances, and inventory carrying costs. Run the full calculation before you commit. A $1.50 cheaper unit price means nothing. Quality failures cost you $3.00 per unit in handling.

Skip financial stability checks and you get supplier failures mid-contract. Pull Creditsafe or Graydon credit reports on potential vendors. Check their balance sheets. High debt-to-equity ratios above 2:1 signal cash flow problems. These suppliers may cut corners on materials to stay afloat. They might disappear during economic downturns.

Process Control and Transparency Gaps

No Statistical Process Control (SPC) charts means the supplier can’t track variation trends. SPC dashboards show what’s happening with foam density or PPI measurements. They alert you before measurements drift toward spec limits. Without these tools, the factory catches problems after defects appear. You get bad product in your shipment.

Weak batch traceability systems create recall nightmares. Handwritten labels on foam bales? That’s a red flag. Modern suppliers use barcode or RFID tracking with digital lot records. A quality issue hits and you need to trace affected batches within hours. Manual systems take days or weeks. Your entire inventory sits in limbo during that time.

Misapplied AQL sampling gives false confidence. Some suppliers claim “AQL 2.5 inspection” without following proper sample sizes or acceptance criteria. Request their actual sampling plans. Check if sample sizes match ANSI/ASQ Z1.4 tables for your lot quantities. Uncalibrated measurement tools make this problem worse. A supplier might show passing PPI measurements using equipment that’s 15% out of calibration.

Hidden Chain Vulnerabilities

Zero visibility into 4th-party sub-suppliers creates single-source risks. Your direct supplier might source raw polyurethane foam from one chemical plant. That plant shuts down for maintenance? Your entire chain stops. Ask suppliers for sub-supplier disclosure covering critical raw materials. Map dependencies before you sign contracts.

Constant price changes between quotes show poor cost controls. You request pricing in January. Get a quote. Follow up in March for an order. The price jumped 18%. Legitimate raw material cost changes happen. But frequent, unexplained price swings show the supplier lacks stable sourcing and margin management. Perform a Bill of Materials (BOM) teardown to verify costs against industry averages.

Essential Screening Evidence

Centralize all supplier data in one system. Track on-time delivery rates, lead-time variance, defect percentages, and capability indices for every vendor. Run KPI reviews every 90 days comparing actual performance to commitments. Suppliers slipping below 95% on-time delivery need immediate escalation.

Financial checks go beyond credit scores. Review audited financial statements for the past two years. Look for declining revenues or shrinking margins. Check for bankruptcy filings in their jurisdiction. CDP or EcoVadis scores show environmental and social compliance levels for ESG-focused buyers.

High-risk orders require site audits before production starts. Send inspectors to verify equipment, processes, and quality systems match supplier claims. Kraljic segmentation helps you decide which suppliers deserve deeper checks. Strategic suppliers and bottleneck items get the most scrutiny.

Conclusion

Sourcing reticulated foam filters in China is simpler than you think. Pick your path: go direct to manufacturers for custom options and better prices, or use verified B2B platforms for more supplier choices and buyer protection.

Three factors drive your success. First, match technical specs (PPI density, foam chemistry) to your exact needs. Second, check quality certifications upfront. This prevents expensive mistakes later. Third, calculate the true landed cost—don’t just look at FOB prices.

You might filter molten metal in foundries. Or maybe you purify water systems. China’s manufacturing ecosystem has solutions for every scale.

Start by listing your technical requirements. Request samples from 3-5 suppliers on your shortlist. Don’t skip the factory audit—virtual visits work too.