The right foam filter material supplier can make or break your filtration project. This applies whether you manage industrial air quality systems, design automotive parts, or maintain aquatic setups.

Countless manufacturers claim they’re the best. So how do you find partners who deliver real quality, customization, and reliable service?

The U.S. market has excellent foam filter material suppliers. Each one brings special skills to different industries and uses. These companies have built strong reputations through engineering quality and customer support. You’ll find everything from reticulated polyurethane foam to advanced filtration media.

Duraflow Industries – Top Aftermarket & OEM Foam Filter Specialist

Duraflow Industries does two things well. They keep aftermarket filters ready to ship. They also make custom OEM foam solutions built to your exact specs. Their open-cell foam rolls have MERV 4 ratings (untested). These catch dust, lint, pollen, and pet hair in HVAC systems, mobile homes, RVs, and air scrubbers.

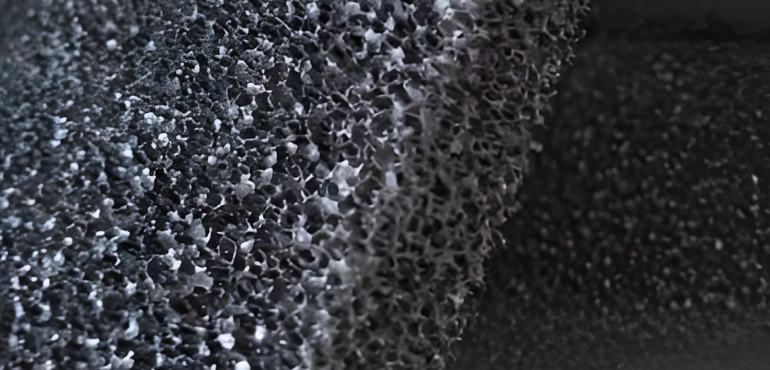

The foam has thousands of small chambers inside. Large cells on the intake side get smaller near the exhaust. This design grabs more particles in furnaces, AC units, and static systems. You can adjust the pore size. This works for rough pre-filtering or fine high-grade jobs.

Material Advantages:

|

Feature |

Benefit |

|---|---|

|

Washable/Reusable |

Lower long-term costs vs. disposable paper |

|

High Dirt Retention |

Extended service intervals |

|

Moisture/Chemical Resistant |

Lasts longer in tough conditions |

|

Non-allergenic/Non-toxic |

Safe for hospitals, labs, food processing |

Duraflow uses just-in-time (JIT) production. This means quick turnaround times. No minimum order quantities needed. So bulk OEM buyers and small aftermarket customers both get what they need.

Reilly Foam Corporation – 40+ Years in Engineered Filtration Foam

Reilly Foam Corporation runs four manufacturing sites across the United States. Their production space covers 450,000 square feet. All of it focuses on engineered filtration foam. Over 40 years, they’ve become the trusted partner for reticulated polyurethane foam solutions.

Reticulation Technology:

Their special process dissolves cell walls inside polyurethane foam. This creates an open-cell structure with lots of tiny holes. You get better filtration for air, water, fuels, gases, and steam. Reilly controls the hole size with precision. No guessing. Just reliable filtering power that fits your fluid metering needs.

Specialized Foam Portfolio:

-

Reticulated polyurethane – Main filtration foam for engines, HVAC, and industrial liquids

-

Cellulose foam – Large surface area traps more particles in air and liquid systems

-

Aerofonic® foam – Felted foam that absorbs sound in aircraft, diesel engines, computers, and high-speed rail

Medical-Grade Filtration:

Biocompatible foam runs in wound care dressings, NPWT (negative pressure wound therapy) devices, dental products, and ECG pads. The open-cell design soaks up fluids. It also fights bacterial growth. This keeps patients safe.

Speed Matters:

Reilly ships orders in 3-5 business days. They handle die-cutting, convoluting, and lamination in-house. No waiting on outside vendors. You get custom shapes, densities, and thicknesses fast.

Amcon Foam – Industrial Custom Filter Foam Solutions

Amcon Foam brings 40+ years of engineering know-how to filter production at two advanced U.S. facilities. Their open-cell polyurethane foam reaches 100 PPI (pores per inch). That’s some of the finest filter density you’ll find in American manufacturing. The tiny pores trap particles smaller than a micron. You see this in electronics cabinets, industrial engines, and liquid systems that need exact filtration.

Material Selection by Application:

-

Open-cell polyester foam – Most used for air and liquid filters. High porosity catches dust, lint, and debris

-

Reticulated polyurethane – Strong and resists chemicals. Built for tough industrial settings

-

Closed-cell foams – Neoprene, cross-linked polyethylene, and low-porosity types for gaskets and mixed filters

-

Polyethylene densities – 1.2 to 9 lb/ft³ range. Comes with anti-static, military-spec, and fire-resistant options

Compliance & Performance Standards:

All foams meet MVSS302 and UL94 certifications. Amcon sets up materials for HEPA-grade performance. This works in HVAC air/liquid filtering, medical devices, and factory air systems. Their design team helps you pick materials and set up your application. They make sure you hit your exact filtration goals.

Custom Manufacturing Capabilities:

Die-cutting and waterjet-cutting work with any shape, size, or quantity. Fast prototypes move straight to production. No delays. The inventory systems hold millions of pieces for ongoing contracts. One popular option: Amcon 7294/30PPI-77967 – a 30 PPI open-cell polyurethane foam air filter. It removes dust and debris in electronics boxes and engine areas.

Specialized Product Lines:

|

Application |

Foam Type |

Key Feature |

|---|---|---|

|

HVAC filters |

Open-cell polyester/polyurethane |

Any porosity for air/liquid |

|

Gaskets |

Open/closed-cell with PSA options |

Flexible movement in pumps/piping |

|

Sound abatement |

High/low frequency damping foam |

OSHA compliance for industrial noise |

|

Marine/chemical |

Closed-cell neoprene |

Heat/flame/chemical resistance |

New England Foam – Polyurethane Filter Foam Fabrication Specialist

New England Foam stocks filter foam blocks and sheets. You get a full 10-90 PPI porosity range. They carry both polyester and polyether base materials. Standard colors are charcoal (black) and white. Need custom porosities, colors, or densities? They ship those on request.

Material Chemistry Matters:

Charcoal (black) foam uses a polyester base. This works for gas filtration—oxygen, nitrogen, CO₂ systems. White foam runs on polyether chemistry. Use this for water-based solutions. Cell structure makes the difference. Polyester has closed cells. These prevent air flow but seal gases tight. Polyether has open cells. These handle liquids well.

UL94/HF-1 Certified Options:

Fire-rated foam meets strict safety codes. They add flame retardant additives during thermal reticulation (hydrogen explosion process). You can get this on polyester (2.0 pcf S82N in 54″x108″ sheets; 4.0 pcf 4.0N in 54″x72″). Also available on polyether (0.9 pcf 1034; 4.0 pcf 4.0 SEN). Need outdoor protection? We ship a UV coating version too.

Stocked Inventory:

|

Foam Type |

PPI |

Density (pcf) |

25% CFD (psi) |

Sheet Size |

Base Material |

|---|---|---|---|---|---|

|

S-10 (Polyester) |

10 |

1.9 |

0.45 |

Custom |

Polyester |

|

S-20 (Polyester) |

20 |

1.9 |

0.5 |

Custom |

Polyester |

|

T-20 (Polyether) |

20 |

1.4 |

0.5 |

54″x82″ |

Polyether |

|

T-40 (Polyether) |

40 |

1.4 |

0.55 |

82″x108″ |

Polyether |

|

T-50 (Polyether) |

50 |

1.4 |

0.55 |

82″x108″ |

Polyether |

Polyester filter foam ships in 10-100 PPI. Densities range from 2-4 pcf. Polyether spans 1-4 pcf across multiple PPI ratings. General polyurethane stocks run 1-6 pcf. Sheet sizes go from 48″x72″ up to 82″x108″. Rebond options hit 4-6 pcf.

Custom Fabrication Services:

Our die-cutting and waterjet systems produce any shape or profile. They offer anti-static, ESD, flame-retardant, and antimicrobial treatments. These add extra function to your foam. The dodecahedron cell structure creates 95-98% void space. Picture twelve-sided struts of polyurethane, polyether, or polyester. This design maximizes surface area. Plus, it keeps structural integrity strong.

RoboVent – Manufacturing & Metalworking Clean Air Filtration Expert

RoboVent builds filtration systems for manufacturing plants with robotic welding stations and metalworking operations. Their Spire Series handles heavy weld fume loads. The MLS-02-06 setup pushes 3300 CFM through six filter cartridges. It runs on a 10 HP motor at 480V/14 Amps. Size measures 46.5″D x 52″W x 127.5″H. Weight hits 2308 lbs.

PleatLock Filter Technology:

RoboVent’s A15 PleatLock filters pack 35% more usable media than standard pleated designs. The extra surface area captures more weld fume, grinding dust, and metal bits. This happens before pressure drop forces a change. Pulse-cleaning dislodges dust along the full pleat length. Service life gets longer. You replace filters less often.

Portable Room Cleaner (PRC) Options:

The PRC-1200 moves 1200 CFM through a 1.5 HP motor on standard 110V/20A power. Compact size (36″H x 20″L x 39″D, 275 lbs) lets you roll it between work zones. Filter choices include:

-

HEPA H13 – 170 sq ft media, removes >99.95% of particles above 0.3 microns (P100-level protection)

-

HEPA E11 – 170 sq ft, >95% efficiency (N95-comparable performance)

-

Nanofiber MERV15 – 254 sq ft media area for general dust and fume control

Air Change Rate Calculation:

Divide your room volume by CFM rating. You get minutes per air change. Then divide 60 by that number. This shows changes per hour. A 1200 CFM unit cycles a 10,000 cubic foot space 7.2 times per hour (10,000 ÷ 1200 = 8.3 minutes; 60 ÷ 8.3 = 7.2).

Energy Efficiency & Smart Controls:

RoboVent’s eDrive VFD (variable frequency drive) adjusts motor RPM as filters load with dust. This cuts energy use 20-30%. Filter life extends up to 30%. The SafeSensor system spots filter bypass or leaks in real time. You catch problems before dirty air escapes back into your shop.

Vortex Series Airflow Design:

Vortex units skip straight-line suction. They create circular airflow patterns across the facility. Adjustable punkah louvers direct air to collection points. Multiple units work together. They pull dirt away from workers. RoboVent’s VentMapping service uses CFD (computational fluid dynamics) modeling. This finds the best system placement for your facility layout.

Endurex RMO Filters:

Reinforced Media Optimization gives you filter media for your specific job. Choose cellulose for general dust. Pick NanoFiber for fine particles. Grab PTFE for sticky or oily fumes. Dust collects in 15-gallon bins (Spire) or 14-gallon pull-out trays. You empty them easily without stopping production.

Clean Liquid Systems – Custom Air & Liquid Filter Fast-Turnaround Provider

Clean Liquid Systems makes filtration equipment for air and liquid streams. Our engineering team builds custom housings. These accept multiple cartridge setups. We focus on high-purity standards and quick delivery.

Liquid Filter Series Specs:

Four micron ratings handle different fuel and oil types:

|

Series |

Micron Rating |

Typical Use |

Water Removal |

|---|---|---|---|

|

25 series |

25 micron |

Diesel/heating oils |

25 ppm |

|

5 series |

5 micron |

Tighter filtration |

10 ppm |

|

2 series |

2 micron |

Kerosene/gasoline/naphtha |

<5 ppm |

|

1 series |

0.5-1 micron |

Max coalescing/particulate |

<5 ppm |

Activated Carbon Air Filters:

Carbon bed depth runs 26-28mm with virgin pellets. You’ll find sizes like 145x450mm, 145x600mm, 145mm diameter, and 160mm diameter. Honeycomb V-cell setups come in 20mm, 25mm, 45mm, and 95mm depths. Pre-filter sets last 1.5-3 years under normal use.

Performance Test Data (VGT/HEPA Models):

|

Parameter |

Value |

|---|---|

|

Final Resistance (Recommended) |

2.4″ W.G. |

|

Final Resistance (Max) |

3.2″ W.G. |

|

Continuous Temp |

160°F |

|

Max Humidity |

≥100% |

|

Static Burst (New) |

20″ W.G. |

|

Dynamic Burst (New) |

20″ W.G. |

Materials:

Housings use 316/316L stainless steel on all wetted surfaces. Media mixes 100% synthetic fibers with activated carbon or alumina. Pleated V-setups sit in ABS frames. You can burn all parts. Carbon types include granulated and large surface area forms. These meet MERV13/F7 (EN 779:2012) standards.

Custom Fit Uses:

We build air, liquid, and fume filters to match your equipment. Single-round and multi-round housings fit existing pipes or ducts. Our production methods keep dirt out during build and testing. This keeps purity high.

Clean Air Technology Solutions – Multi-Industry Air Filter Design & Support

Clean Air Technology Solutions builds filtration systems for industrial ventilation, data centers, compressed air lines, and HVAC applications. The engineering process starts with a detailed filter specification procedure.

Measure the opening (length, width, thickness). Calculate face velocity by dividing airflow by filter area. For example: 200 CFM ÷ 0.50 sq ft = 400 feet per minute (FPM). Pick disposable or washable media based on your maintenance budget. Check that initial resistance stays ≤0.10″ water gauge (wg).

Match media thickness to frame depth. UFM-50 media fits 0.30-0.50″ frames. Quadrafoam™ 0.25″ works in 0.30-0.43″ housings. The 0.50″ versions fit 0.50″ frames.

Air ducted into clean rooms must meet ≥T1/10 class. Recirculation air needs the same performance or better. Pre-filters ahead of heat recovery systems also require ≥T1/10 ratings. The G4-F8 filter grades (EN779) match T5/10 through T0.5/10 at the 10% penetration threshold.

Compressed Air Filtration Portfolio:

|

Housing Type |

Flow Range (l/s) |

Flow Range (CFM) |

Grades Available |

Size Options |

Pressure Range |

|---|---|---|---|---|---|

|

Cast aluminum |

9-550 |

19-1,200 |

6 |

13 |

20-350 bar |

|

Welded steel |

550-8,000 |

1,200-17,000 |

6 |

12 |

20-350 bar |

|

Tower design |

20-1,800 |

42-3,814 |

1 |

14 |

20-350 bar |

|

Threaded |

15-944 |

32-2,000 |

5 |

9 |

20-350 bar |

All compressed air filters meet ISO 8573-2:2007 (particle and oil removal) and ISO 12500-1:2007 (performance testing protocols). HEPA ISO 35 E units deliver 99.95% efficiency at MPPS (most penetrating particle size). This matches H13-grade performance. Fiber density optimization balances high capture rates against acceptable pressure drop.

Frame Construction Standards:

Housings use aluminum, galvanized steel, or engineered plastics. These materials resist temperature swings, humidity, and chemical exposure. Gasket seals prevent bypass leakage.

For data centers, frames meet Class E fire ratings per EN 13501. This stops flame spread in sensitive electronic environments.

Filter Product Lines:

They stock disposable 2-inch width standard filters, high-capacity bag filters, and multipocket rigid-frame units. Pre-filter layers extend main filter life. This cuts replacement costs 30-40% in dusty facilities.

ASHRAE recommends ≥MERV 8 for acceptable indoor air quality. Industrial dust collectors follow OSHA PEL limits (permissible exposure levels) for worker safety.

Their design teams look at your application type, required airflow rates, and acceptable pressure drops. Then they select the right filter class and housing configuration. You get molecular contaminant removal for data centers. Plus, you get particulate control for general HVAC—all from one engineering partner.

Hengst Air Filtration – High-Performance Automotive & Industrial Foam Filters

Hengst Air Filtration builds filtration systems that meet strict ISO 16889 multipass standards. Their PWR1 series hits ß5(c) ≥ 1000 performance. Just one particle in 1,000 gets through at the 5-micron level. The H-series gives you scalable ratings: H1XL filters at 4.5 µm, H6XL at 7 µm, and H20XL at 20 µm. Each grade delivers ß(c) ≥ 200 efficiency. You can pick the exact micron level for your hydraulic systems or air quality needs.

Automotive Cabin Air Performance:

Hengst cabin filters remove 95% of 2.5 µm particles (PM2.5). Multi-layer designs boost total efficiency to 99–99.9% using melt-blown media. Add activated carbon layers and PM2.5 capture jumps to 99%. Cellulose/polyester blends deliver 97–99% total filtration. These ratings shield passengers from pollen, exhaust fumes, and fine dust.

Pressure & Temperature Specs:

Filters start with low pressure drop—0.2 bar maximum for the Aquasorb line. Swap out elements at 2.2 bar differential pressure. Multi-layer glass fiber media keeps ISO 10/6/4 cleanliness per ISO 4406 standards. NBR seals work from –20 to +65°C in humidity up to 65%. Need extreme heat resistance? FKM seals (V-code designation) handle higher temps. Check Hengst catalogs for exact high-temp filter models.

Material & Chemical Compatibility:

Hengst offers glass fiber (3-layer build), cellulose/polyester blends, melt-blown synthetics, and activated carbon layers. Aquasorb filters work with non-mineral oils and HLP/HEES hydraulic fluids. Cellulose treatment stops humidity swelling. Stainless steel mesh gets epoxy coating for chemical resistance. F1 flame-retardant media hits >99.95% efficiency without curing agents.

Application-Specific Use Cases:

-

Automotive cabin filters – 95–99% PM2.5 removal for passenger protection

-

Heavy equipment hydraulic systems – Reach 20/19/14 to 22/21/16 ISO 4406 cleanliness codes

-

Industrial cleanrooms – HEPA/ULPA-grade HVAC filters keep controlled environments clean

-

Hydraulic vent filters – BFSK series handles max airflow per equipment type

Pentair AES – Fish-Grade Reticulated Filter Foam Supplier

Pentair AES makes reticulated foam for aquaculture and koi pond filters. Their fish-grade material has zero fire retardants, germicides, or dyes. This keeps your aquatic life safe. Many cheap air filter foams use toxic additives. These harm fish. Pentair’s formula skips these chemicals entirely.

Biological & Mechanical Filtration Performance:

The 15 PPI structure gives you high surface area. Bacteria colonize here to convert ammonia and nitrite. The open-cell design traps solid waste. Water flows through without resistance. You can rinse the foam clean fast. Clogging won’t happen over time.

Application Coverage:

This foam works in commercial fish farms and hobbyist koi ponds. The Fish Farm™ II setup uses this media to support 300 lbs of fish production. Gravity-fed systems get low-pressure drop benefits. The foam lasts long. This cuts how often you replace it and lowers your operating costs.

FoundryMax Foam Filter

Metal casting needs filters that handle extreme heat. These filters also catch tiny impurities. Foundry-grade ceramic foam filters work at temperatures up to 1700°C. They remove slag, oxides, and inclusions that damage casting quality.

Core Material Composition:

These filters mix silicon carbide powder (50-60%), aluminum oxide (20-30%), and magnesium oxide (>10%). The ceramic structure forms a rigid 3D lattice. It catches contaminants without breaking down under molten metal flow. Yellow zirconia foam filter types work up to 1700°C. Gray-black SiC types handle standard foundry jobs at 1480-1500°C.

Porosity & Strength Specifications:

|

Property |

Standard Range |

High-Performance |

|---|---|---|

|

Porosity |

80-90% |

80-92% |

|

PPI Range |

8-30 (±2 tolerance) |

50-60 (precision casting) |

|

Compression Strength |

≥1.0 MPa |

≥2.0 MPa (room temp) |

|

Bending Strength |

0.8 MPa |

≥2.5 MPa (high temp) |

|

Bulk Density |

0.36-0.5 g/cm³ |

0.4-0.5 g/cm³ |

Pick Your PPI Based on Use:

-

10-25 PPI – General casting (aluminum, iron, steel alloys)

-

30-60 PPI – Semi-continuous operations and higher-grade ingots

-

50-60 PPI – Continuous rolling and precision aerospace parts

Flow Capacity by Size:

A 100x100x22 mm square filter handles 16 kg/s for ductile iron. For grey cast iron, it processes 24 kg/s. Maximum filtration weight hits 200 kg (ductile) or 400 kg (grey). Scale up to 150×150 mm filters for 450-900 kg batches. Round Φ100×22 mm units process 140-280 kg. This depends on alloy type.

Heat Shock Resistance:

Filters survive six cycles from 1100-1200°C down to room temperature. No cracking occurs. This toughness means longer service life in busy foundries. Keep a buffer height of 1.5H to 2.5H (H = filter thickness) above the filter spot. This gives you balanced flow across multiple filters in large casting setups.

Conclusion

The right foam filter material supplier makes a big difference. Your equipment performs better. Costs drop. Maintenance gets easier.

You might need industrial filters for manufacturing. Or precision automotive foam filters. Maybe specialized aquatic filtration solutions. The top 10 best foam filter material suppliers in the USA in this guide have proven skills across all these areas.

Duraflow excels at OEM precision. Reilly Foam brings four decades of engineering know-how. RoboVent specializes in metalworking air quality. GreatWave uses German Poret foam technology. Each supplier has unique strengths. Match your needs with their core skills, certifications, and custom options.

Ready to upgrade your filtration system? Check your exact needs first:

– Material density

– Chemical compatibility

– Flow rate requirements

– Industry certifications

Contact 2-3 suppliers from this list. Get detailed consultations. Request sample testing. The right partner solves today’s filtration problems. Plus, it protects your future operations with scalable, reliable solutions. You’ll see clear ROI.

Your perfect foam filter material supplier is out there. Make the smart choice today.