Metal casting quality depends on one part that many foundry operators overlook: the ceramic foam filter. A poor filter does more than hurt your casting. It causes expensive rework, wastes material, and delays deliveries. All of this cuts into your profits. But finding reliable SIC ceramic foam filter manufacturers is hard. The market is scattered, and few deliver strong filtration every time.

We studied production capabilities, quality certifications, and real performance data. Our research covered manufacturers from three continents. This comparison highlights seven proven SiC ceramic foam filter manufacturers. You’ll find specialized Chinese producers that lead the Asian market. You’ll also see American precision manufacturers that serve demanding aerospace projects.

Are you sourcing filters for aluminum casting? Maybe iron or specialty alloy operations? Either way, you’ll learn which suppliers match your filtration needs. You’ll see who can handle your volume and meet your quality standards.

FoundryMax Ceramic Filter

FoundryMax built their business by working directly with small and mid-sized foundries. Big legacy suppliers often skip these shops. Their SIC ceramic foam filter business cuts out the middleman. You order from their tech team. Filters ship from regional centers in 72 hours.

Small-Batch Flexibility and Custom Solutions

Most makers require 500-1,000 pieces minimum. FoundryMax starts at 50 filters. Testing new alloy mixes? Running short production cycles? You don’t need to fill a warehouse for a prototype run.

Their silicon carbide ceramic foam filter gets customized from your metal data. Send them casting temperature, flow rate, and inclusion size targets. Their engineers figure out the best PPI range and filter size in 24 hours.

Stock filters ship in 5-7 business days. Custom specs add 10-15 days to make. Filters come in sizes from 20mm to 250mm diameter. Square ones go up to 300×300mm. Thickness runs 15mm to 60mm based on your metal pressure needs. Their premium SiC formula handles up to 1650°C.

Technical Support Structure

Each account gets a filtration specialist. Not a sales rep who handles ten different products. Real engineers who review your casting defect reports. They look at inclusion patterns in failed parts. Then they tweak filter placement, PPI choice, or preheating steps.

You get metal-specific install guides. Filtration capacity charts match your pouring speed. Thermal shock data tells you how many heat cycles each grade lasts. Call their tech desk for filter performance estimates. They base it on your scrap rate and rework costs.

DTYR Filters (China)

Shanxi DTYR runs two plants in Houma Economic Development Zone. Both focus on silicon carbide ceramic foam filters for metal casting. The facility handles Ductile Iron, grey iron, vermicular cast iron, plus copper and aluminum alloys. You’ll find their products under DTYR Casting Filters and DINGTAI brands.

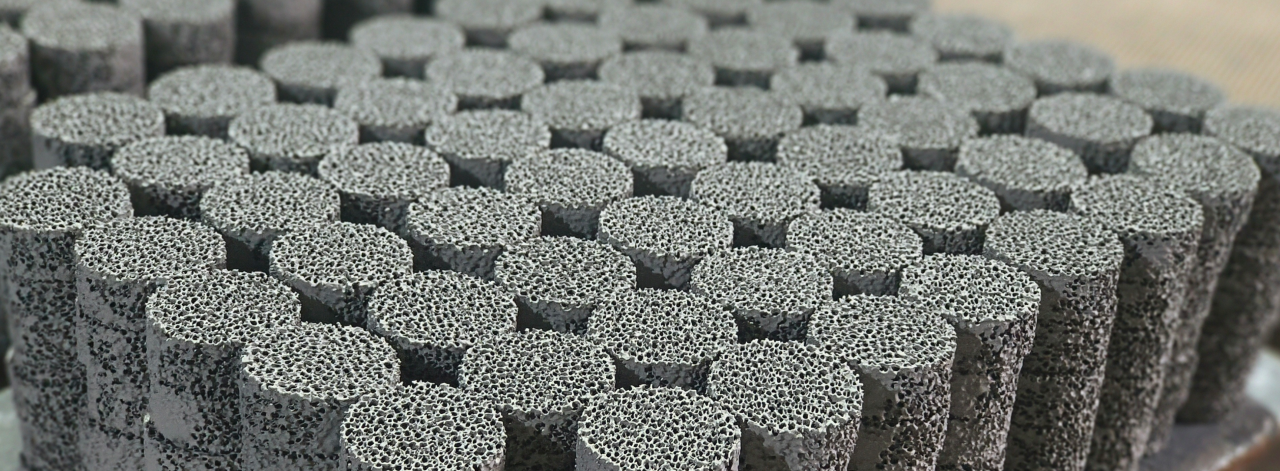

Their SIC ceramic foam filter production starts with high-purity silicon carbide powder. The process builds a mesh-like structure. Porosity stays controlled between 80-90%. This range creates smooth metal flow. At the same time, the filters hold up under high heat.

Technical Specifications and Product Range

DTYR makes filters in 10, 15, 20, 25, and 30 PPI sizes with ±2 PPI tolerance. Standard round filters range from 30mm to 100mm diameter. Square filters go from 40×40mm up to 200×200mm. Each filter has a bulk density of 0.4-0.5 g/cm³. They work at temperatures up to 1600°C.

Need custom sizes? Length and diameter can reach 300mm. Thickness goes from 11-50mm. For filters under 100mm, DTYR keeps diameter within -1.5mm to +0.5mm. Thickness stays at -1mm to +0.5mm. Larger filters get -2mm to +0.5mm tolerances.

Compressive strength tops 1.0 MPa across all products. Round filters go through compression tests. Square and rectangular ones get bending strength checks in their lab.

Quality Control Process

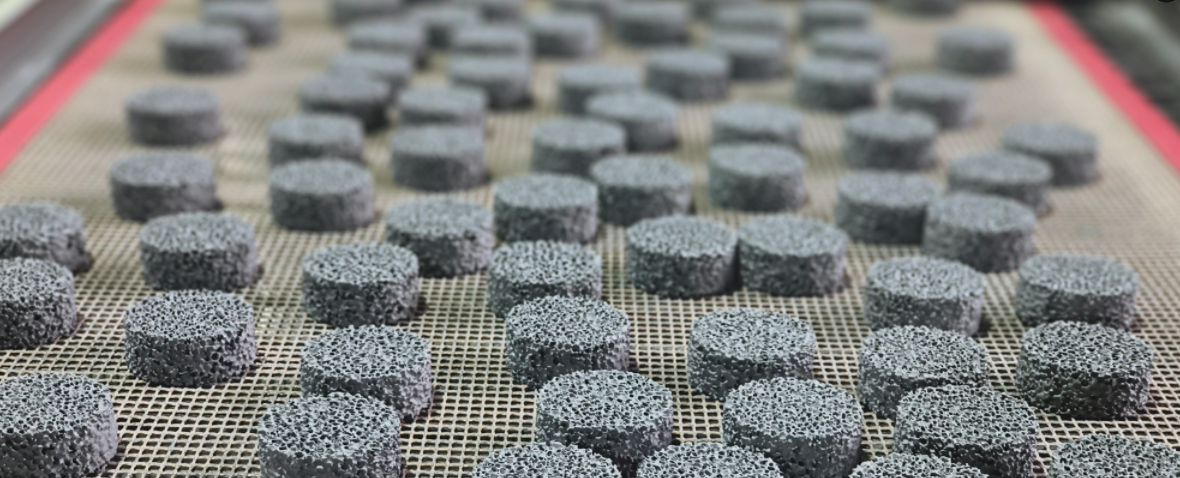

DTYR uses seven quality checks during production. First, they test slurry thickness while making the filters. Every batch gets measured and recorded. They run thermal shock tests to check how filters handle fast temperature shifts. Before packing, they inspect each filter to remove any debris.

DTYR also makes Zirconia ceramic foam filters for steel casting. Plus alumina types, Extruded ceramic filters, and fiberglass Mesh filters. Foundries can get all their filter types from one supplier.

Products ship with three-layer protection. Each filter gets individual wrapping. Then carton packing for safe transport. Bulk orders go on pallets.

Baoding Ningxin Group (China)

Baoding Ningxin Group runs a 50,000 m² production facility in Hebei Province’s Baqie Industrial Zone. They started in 2002. The company combines R&D, production, and sales under one roof. They hold 23 patents for their technical work. More than 3,000 partners worldwide use their SIC Ceramic foam filters and filtration products.

Their silicon carbide ceramic foam filter line works for many casting types. You’ll find filters for stainless steel, high manganese steel, ductile iron, and Gray Iron. They also make filters for specialty alloys. These include titanium, high nickel, aluminum, and copper castings. This wide range makes them different from other makers who focus on just one area.

Product Range and Pricing

Ningxin makes four main ceramic filter types. silicon carbide filters top their list. They also offer alumina, zirconia, and oxide series filters. The product line includes high silicon-oxygen glass fiber filters too. You can get alkaline glass fiber filters and fiberglass mesh filters for aluminum die casting.

A standard 40×22mm SIC ceramic foam filter costs USD 0.085-0.1 per piece. This price is for wholesale buyers. It works for Sand casting and general foundry use. They make precision filters for aerospace applications. These handle complex thin-walled parts. Their main customers include military, auto, wind power, railway, and heavy machinery foundries.

Manufacturing Infrastructure

They use medium frequency electric furnace systems for production. The furnaces maintain steady temperatures during casting. Automatic sand screen equipment preps the materials. A push rod heat treatment line processes the finished filters. Their R&D center and quality checks back up 21 years of making these products.

Delivery time depends on the season. Off-season orders ship in 15 working days. Peak season takes up to one month. They ship to nine global regions. These span North America, Western Europe, Southeast Asia, and the Middle East. Ningxin works with eight Incoterms (FOB, CIF, EXW, and more). They accept six payment types: LC, T/T, PayPal, and others.

You can visit their factory to check their work. They provide OEM/ODM services. Free samples are available. Call them at 13383626300. Or find them on Made-in-China.com as a Diamond Member.

SEFU Ceramic Filters

SEFU started its automatic production lines in 2010 at Guanting Industrial Park, Cangzhou City. The ISO9001-certified facility makes four types of products: ceramic foam filters, Honeycomb filters, thermocouples, and ceramic fiber products. The R&D team works on custom formulas and OEM projects. This helps foundries that need filters beyond standard specs.

The company backs all SIC ceramic foam filter sizes with a 0% crack rate guarantee. Every filter gets pre-fired before shipping. This heat treatment sets the dimensions in place. Each batch goes through lab tests. These check porosity, compression strength, and chemical resistance. A filter ships only after it passes six thermal shock cycles. These cycles run between 1100°C and room temperature.

High-Temperature Filtration Systems

SEFU’s Model SF-ZCF silicon carbide ceramic foam filter works with steel casting up to 1700°C. The ZrO2/SiO2 mix gives it a compression strength of ≥1.2 MPa. Bulk density sits at 0.8-0.9 g/cm³. Most competitors’ filters are less dense. More density means better structure under molten metal pressure.

A 100×100×25mm filter handles 190kg of carbon steel at 7kg/s flow rate. Use alloyed steel, and the same filter manages 10kg/s. The 150×150×30mm size reaches 420kg capacity. Flow rates hit 17-22kg/s based on alloy type. Round filters are also available. A 75mm diameter version processes 85kg at 4-5.5kg/s.

Aluminum Casting Solutions

SEFU makes Alumina-based filters for aluminum and alloys under 1100°C. Porosity stays at 80-90%, just like the steel filters. Compression strength goes down to ≥0.8 MPa. Aluminum needs less structural support than steel. The alumina filters come in six PPI grades: 10, 20, 30, 40, 50, and 60.

A 50×50×22mm alumina filter at 10PPI processes 40kg of aluminum at 2kg/s. The 20PPI version in the same size handles 30kg at 1.5kg/s. Larger formats go up to 360kg capacity. For aluminum bars, SEFU suggests 10-30PPI. For semi-continuous casting, use 30-50PPI. Profiles and plates work best with 40-60PPI.

Filters come in sizes up to 660×660×50mm. Thickness ranges from 12mm to 50mm. Contact the Cangzhou facility for metal-specific filtration plans. They’ll provide delivery schedules and bulk pricing on custom sizes.

Carpenter Brothers, Inc. (USA)

Carpenter Brothers built its reputation over a century of hands-on foundry work—not flashy marketing campaigns. The Mequon, Wisconsin company runs 11 warehouses and 8 transloading sites across North America. This network reaches foundries from Alaska to Ontario. Their $9.4 million operation employs 39 specialists who know metal casting equipment inside out.

The company stocks foundry products across six categories. Metals and alloys, melting systems, mold making, casting operations, surface finishing, and environmental gear. SIC ceramic Foam Filters sit within their melt quality product line. You won’t find detailed PPI specs or pricing on their website. Carpenter Brothers works as distributors, not direct filter makers. They match filters to your specific casting setup.

Full-Service Distribution Model

Call (414) 354-6555 and you get a foundry equipment specialist. Not a sales rep reading from a script. They ask about your alloy type, pouring temperature, and production volume. Then they source the right silicon carbide ceramic foam filter from their supplier network. This approach works for foundries running mixed operations. One order can include filters, Refractory materials, and finishing equipment.

Their warehouse system cuts lead times for Midwest foundries. Stock ships from Milwaukee within 24-48 hours. West Coast orders route through their transloading sites. East Coast foundries get service from Baltimore, Allentown, or Essex locations. Need die casting supplies too? Carpenter Brothers handles that equipment line as well. Contact CEO John E. Carpenter’s team at 7100 W Donges Bay Rd for product availability and delivered pricing to your facility.

Midvale Industries (USA)

Midvale Industries doesn’t advertise its 120-year track record. The St. Louis operation has outlasted competitors since 1901. Their Knox Industrial Drive facility stocks ceramic foam filters for grey iron, ductile iron, aluminum, magnesium, and brass casting. The 11-50 employee team serves foundries across the Midwest. They operate from two locations—St. Louis headquarters and a Tulsa, Oklahoma office.

Filter Specifications and Selection

Their SIC ceramic foam filter line runs from 10 to 40 PPI. Most foundries order 20-40 PPI sizes. This range balances casting speed with filtration efficiency. Below 20 PPI? You catch bulk oxides and large particles. Cell size drops mean better removal. Metal slows inside the filter, and efficiency climbs.

Standard sizes include 7″, 9″, 12″, 15″, 17″, 20″, and 23″ formats. Shapes come in square, round, and cylinder options. Custom cuts are available. Midvale’s technical staff checks density, roundness, and wall thickness on every batch. High-volume production needs this consistency.

Technical Support Structure

Sales reps train through American Foundry Society programs, Cast Metal Institute courses, and hands-on field work. Need process testing? Their Finishing Technologies Inc. (FTI) facility in Tulsa runs contract jobs. They test different abrasives, chemicals, and media mixes off-site. You see which process works. Then you change your production line.

One customer cut prep time to one-tenth using their blast cabinet. Another foundry slashed paint costs after switching coating equipment. Call the St. Louis office at 6310 Knox Industrial Dr for filter availability. Get technical specs that match your alloy chemistry.

Precise Ceramic/Advanced Ceramic Materials (ACM)

advanced ceramic materials makes products where materials science meets real industrial needs. The global advanced ceramics market hit USD 76.50 billion in 2024. It should reach USD 327.15 billion by 2035. ACM makes Silicon carbide ceramic foam filters that meet specs most foundries never see in standard catalogs.

Their SC2325 SiC foam filter series targets operations that can’t afford filtration failures. Aerospace castings. Medical device parts. High-performance auto parts. These need consistent pore control and heat stability beyond what standard filters offer. ACM uses nanostructured ceramic technology—grain sizes below 100 nanometers. This boosts strength by 200-400% versus regular Ceramic filters. Toughness jumps 50-150% too.

Manufacturing Process and Cost Structure

ACM uses spark plasma sintering (SPS) and flash sintering methods. These cut energy use by 50-80% versus traditional kiln processes. Sintering time drops from hours to minutes. The company uses 3D printing for prototype filters and small custom orders. This reduces tooling costs by 30-60%. Lead times shrink from months to weeks.

Raw material costs stay high. High-purity silicon carbide powder and exact sintering control drive expenses up. ACM has set up ceramic recycling protocols that recover 70-90% of production scrap. This cuts material costs by 30-50% versus buying new powder for every batch.

Technical Specs and Applications

Standard filters handle temps up to 1650°C. Their ultra-high temperature ceramic (UHTC) composites push working limits to 3,900°C. These use hafnium carbide (HfC) and tantalum carbide (TaC) bases. You’ll find these filters in hypersonic part casting and nuclear material processing. Most suppliers won’t touch these jobs.

ACM serves the electrical and electronics sector (28% of advanced ceramics demand), automotive casting operations (22% market share), and machinery tooling (18%). Their filter line covers energy and power uses (14%) and medical device making (10%).

Contact ACM’s technical team for metal-specific filter tips. They’ll match ceramic matrix makeup to your alloy chemistry and casting temp range.

Conclusion

Your choice of SiC ceramic foam filter manufacturer affects your casting quality, production efficiency, and profits. DTYR offers cost-effective solutions. Baoding Ningxin provides industrial-scale capacity. Carpenter Brothers delivers American-made reliability. Each manufacturer has its own strengths.

The smartest move? Don’t rely on just one supplier. Get sample filters from 2-3 manufacturers that match your metal type, filtering needs, and budget. Test them in your actual production setup. The results will tell you more than any sales pitch.

Your next step: Contact at least two manufacturers from this list within 48 hours. Ask about their material certifications. Request technical data sheets. Check about trial quantities. The best SiC ceramic foam filter manufacturers prove themselves through performance, not promises.

Superior filtration isn’t an expense. It’s an investment that cuts scrap rates, boosts mechanical properties, and builds your reputation for quality castings. Choose carefully and test well. Your rejection rates will drop.