FM-05 Alumina Ceramic Foam Filters for Casthouse

FM-05 alumina ceramic foam filters for aluminum casthouse remove solid inclusions from molten aluminum that can impact product quality and production efficiency. The filter’s three-dimensional mesh structure features a tortuous path that effectively captures inclusions through mechanical filtration and adhesion mechanisms.

Aluminum casthouse using our filtration technology report a reduction in inclusion-related defects, significantly improved metal cleanliness levels, and enhanced aluminum alloy performance in applications such as foil production, extrusion, and high-precision component manufacturing. The economic benefits include reduced scrap, increased yields, and consistent product quality to meet the demands of automotive, aerospace, and high-performance industrial applications.

Our alumina ceramic foam filters deliver immediate and measurable benefits to your casthouse operation:

Reduced inclusion defects

Improved surface quality of finished aluminum alloy products

Improved mechanical properties of critical components

Extended mold life and reduced maintenance costs

Constant filtration performance throughout the aluminum filtration

As a trusted supplier to aluminum producers worldwide, our ceramic filters are engineered for reliability, consistency, and superior performance.

Fiber Paper

Fiber Cotton

Expandable Cotton

Alumina Filtration Technology for Superior Aluminum Casthouse

Designed specifically for aluminum casthouse operations, our FM-05 alumina ceramic filters delivers unmatched filtration performance, combining superior inclusion removal efficiency with exceptional thermal stability up to 1250°C. By implementing our advanced ceramic filtration technology, aluminum manufacturers achieve measurable improvements in metal cleanliness, product quality, and operational efficiency, translating directly into higher yields, reduced waste, and enhanced competitiveness.

Superior Aluminum Filtration Technical Specifications

| Item | Index |

| Porosity (%) | 80~90% |

| Working Temperature | ≤1250°C |

| Bending Strength (MPa) | 0.6 |

| Compression Strength (MPa) | 0.8 |

| Thermal Shock Resistance | 1100°C—room temperature 6 times |

| Volume Density | 0.35-0.45 g/cm3 |

Thermal Stability

Made from high-purity alumina ceramic, it quickly adapts to sudden temperature changes and resists cracking

Pore Size Range

Precisely pore structure control from 10 ppi to 60 ppi to target specific inclusion types in the aluminum melt

Corrosion Resistance

High-purity alumina is chemically inert and has excellent resistance to molten aluminum attack

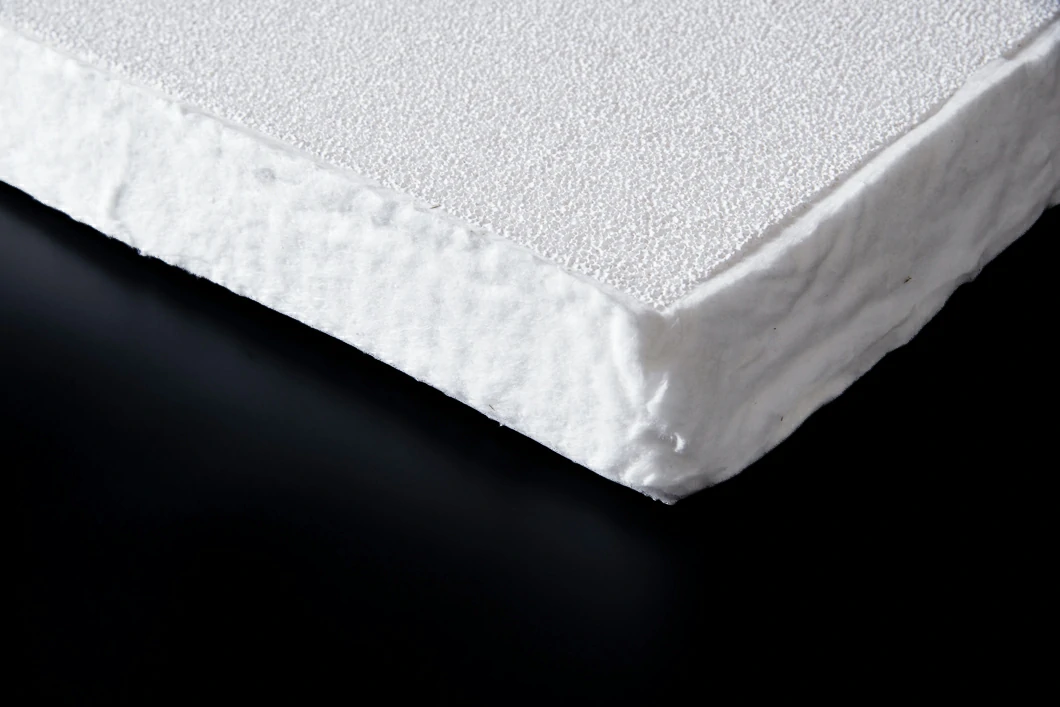

Gasket Options

Fiber paper, fiber cotton, and expandable cotton for optimal sealing in various filtration box designs

Alumina Ceramic Foam Filters for Metal Filtration

High-performance alumina filters (10-60ppi) for molten aluminum filtration. Operating at 1250°C with proven inclusion removal for superior aluminum alloy products.

More Filter Production Scenarios

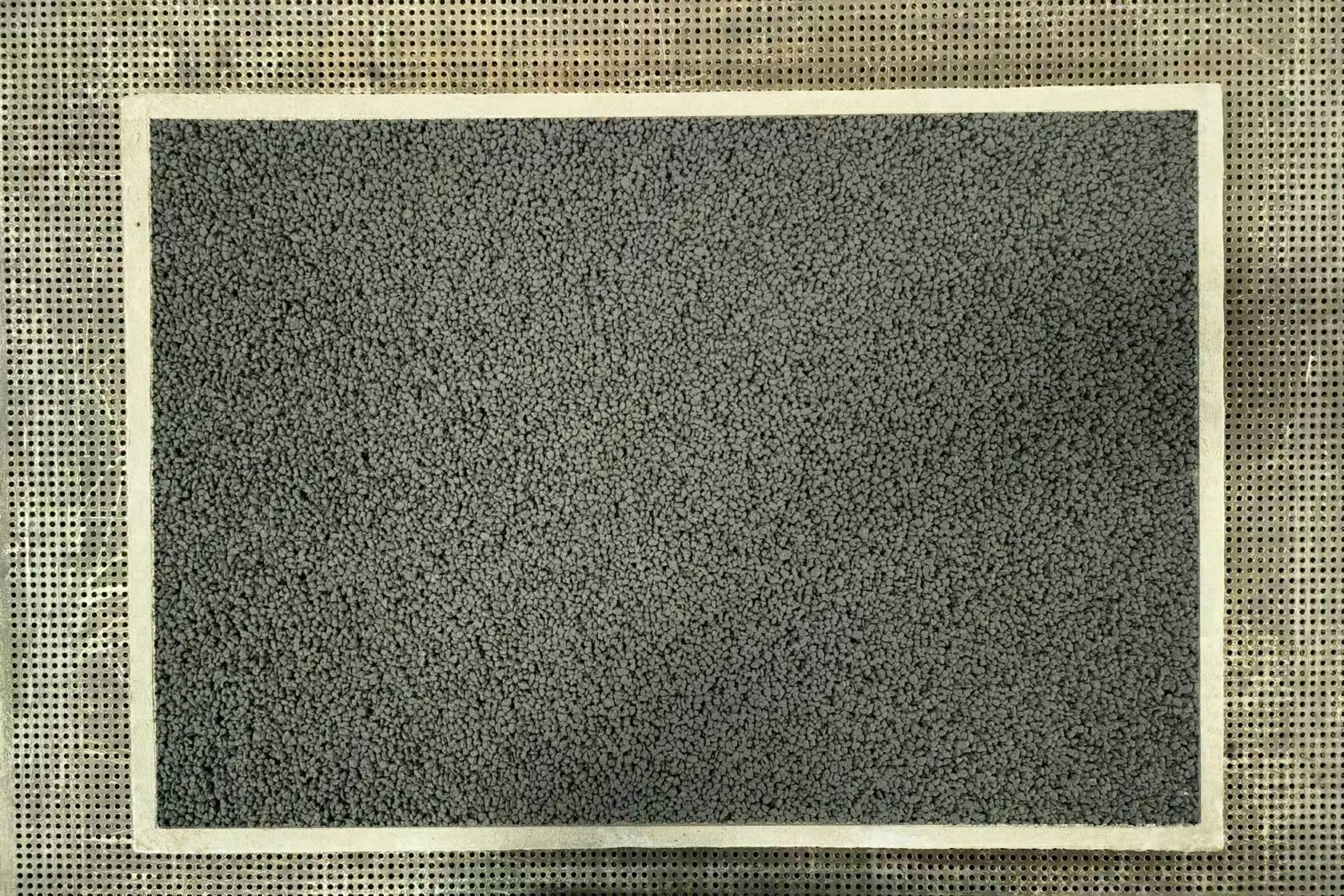

In our modern production facility, alumina ceramic foam filter plates are precision-manufactured to provide efficient filtration solutions for the aluminum casting industry. High-quality alumina powder is uniformly mixed with a special binder, then formed into a three-dimensional porous structure through advanced processes. This structure is then sintered at high temperatures to ensure high strength, high-temperature resistance, and excellent chemical stability.

Each alumina foam filter plate undergoes rigorous quality inspection. Its uniform pore structure effectively traps impurities, slag inclusions, and bubbles in the aluminum melt, significantly improving the purity and mechanical properties of castings. Our alumina foam filter plates are widely used in aluminum alloy casting, automotive parts, aerospace, and other fields, helping customers achieve high-quality aluminum castings with their superior filtration efficiency and reliability.

Request a comprehensive technical consultation with our aluminum filtration experts to determine the appropriate FM-05 ceramic filter specifications for your specific foundry.

Frequently Asked Questions

Are your filters compatible with our existing filtration systems?

FM-05 filters are designed for compatibility with all standard filtration box systems. We offer multiple size options (7″-26″) and provide suitable sealing solutions for different box designs. Our technical team can review your current foundry system specifications to confirm compatibility or recommend minor modifications for optimal performance.

What sealing options are available? How do I choose the right one?

We offer three main sealing options: fiber paper, fiber cotton, and expanded cotton. Selection depends on your filter box design, gasket seating conditions, and operating parameters. Our technical consulting service includes gasket recommendations based on your specific filtration system.

Do you offer custom filter designs for unique applications?

Yes, we offer custom filter services for specialized applications, including non-standard sizes and unique shapes. Our engineering team works directly with your technical staff to develop challenging aluminum filtration solutions that exceed standard specifications.

More Foundry Filters

FoundryMax offers multiple foundry filters to address specific metal filtration requirements across various casting operations.

Discover Your Optimal Filtration Solution

Request a free consultation with our filtration specialists to identify the ideal industrial filter technology.

CONTACT US

Let's Connect

Our Engineers Will Analyze Your Needs & Offer the Perfect Filter Design – Contact Us Today.

Address

Guanting Industrial Park, Cangzhou City,

Hebei Province, China