The right ceramic foam filter supplier affects your sand casting efficiency and product quality. Get it wrong, and you’ll see the impact fast.

India’s foundry industry has a problem. Precision casting demand keeps growing. But the supplier market is scattered. You’ll find export-focused manufacturers in Kolhapur. Ludhiana has regional distributors. This fragmented setup leads to expensive mistakes through trial and error.

Maybe you’re stuck choosing between alumina and silicon carbide matrices. Or you can’t match PPI specifications to your melt temperature. Perhaps conflicting supplier claims on IndiaMART have left you confused.

We’ve done the research for you. Our team analyzed technical certifications from India’s top ceramic foam filter factories. We studied material composition trade-offs. We gathered real-world ROI data from three leading manufacturers. This data helps you make a smart sourcing choice. Your scrap rates depend on it. So does your casting yield.

Jagannath Company – Top Supplier for Sand Casting Needs

Jagannath Company joined India’s foundry chemicals market in 2015. They’ve built a strong name in aluminum extrusion and foundry solutions.

What Makes Them Different

Their facility uses automated production lines. Quality checks happen at every step. The company does more than sell materials. They run in-house nitriding plants and heat treatment tech. This setup gives them better control over product quality.

Core products:

– Magnesium master alloys for alloy changes

– Foundry chemical compounds

– Aluminum extrusion materials

– Heat treatment services

Team and Setup

Jagannath has a skilled team in three areas: R&D, making products, and tech support. Their Turkey site handles global shipping. Local support teams help foundries solve specific problems.

The company has grown steadily since it started. This stability counts for a lot. You want a reliable partner for the long haul.

Hard-to-Find Info

Details about their sand casting products aren’t online. Production capacity? Not shared. Client names and certifications? You have to ask them.

Need ceramic foam filter specs? Want PPI options or bulk prices? Contact their tech team. They’ll suggest the right products for your melt temp and metal type.

Jagannath operates in India’s 12 million MT annual casting industry. This shows solid market reach. But their exact market share? They haven’t said.

FoundryMax – Global Standard Ceramic Filtration Partners

We discussed local Indian giants. Now, take a look at FoundryMax. They mix high-grade manufacturing with consulting. Indian foundries needing consistency go here.

Bridging the Quality Gap

Many local distributors just re-label imports. FoundryMax takes a unique path. They are a specialized manufacturer. They focus only on ceramic foam technology. You pay no “middleman markup” here. Order a Silicon Carbide filter from FoundryMax. You get a controlled chain, not just a consumable.

They fix the biggest problem in India: Batch Consistency. One batch won’t crumble at 1450℃ while the next survives 1500℃. Automated kilns give every filter the exact same thermal shock resistance.

Technical Transparency

Getting technical data from some competitors is hard work. FoundryMax puts the specs right in front of you. They know a foundry engineer needs more than just the price.

What they bring to the table:

-

Custom PPI Solutions: You can get standard 10 PPI for heavy iron casting. Or go for 60 PPI for aerospace-grade aluminum.

-

Advanced Materials: Look beyond standard Alumina and SiC. They provide Zirconia filters for high-heat steel. Regional traders often miss these.

-

Defect Analysis: Their team doesn’t just ship boxes. They help analyze why your casting failed. Then, they identify which filter geometry fixes it.

Why Consider Them for Your Supply Chain?

Running a busy foundry in Pune or Coimbatore? You can’t afford trial and error. FoundryMax gives you the reliability of European brands like VUKOPOR. But the price fits the Indian market. Logistics is a strong point too. They handle the hard import/export paperwork that slows down smaller suppliers.

Exporting your castings to Europe or the US? Use a certified filter brand like FoundryMax. It adds quality assurance to your final product.

S S Khardekar India Pvt Ltd – Lanik/VUKOPOR Exclusive Distributor

S S Khardekar India Pvt Ltd (SSKIPL) is the sole distributor for Lanik VUKOPOR® ceramic foam filters in India. The company started in 2014. They teamed up with Lanik Ceramic Foam Filters India Pvt Ltd and Czech Republic’s Keramtech s.r.o. Their goal? Bring European filter technology to Indian foundries.

ISO Certification and Factory Location

SSKIPL got ISO 9001:2008 certification on June 10, 2015. By June 11, 2017, they upgraded to ISO 9001:2015. You’ll find their factory at Gat No. 994/1, Sanaswadi, Tal – Shirur, near Nareshwar Temple Road in Pune-412 208.

Lanik India runs from a different spot: Gat No 399, Balaji Warehousing, Taluka Haveli, Lonikand-412216, Pune.

VUKOPOR® Filter Technology

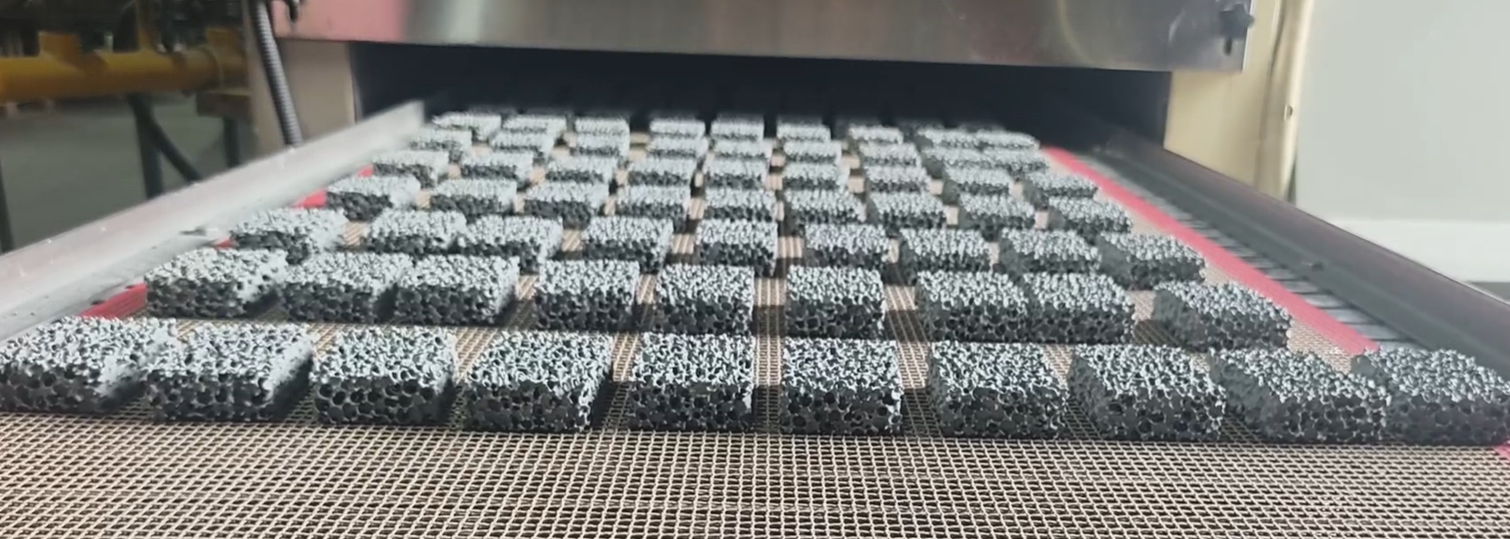

VUKOPOR® filters use pure alumina (Al2O3) or silicon carbide (SiC). The open-cell pore design does two things. It lets molten metal flow through. It traps dirt and debris.

VUKOPOR® S series works at high heat. Use it for cast iron, bronze, brass, and copper-alloys. These filters fit many casting styles: investment casting, continuous casting, and regular sand casting.

Metal uses:

– Steel and iron filtering

– Non-ferrous alloys (aluminum, copper, bronze)

– Special copper-based alloys

Real Performance Results

VUKOPOR® filters give you clear benefits. Casting yield goes up. Less waste, fewer flaws. You get lower rejection rates at quality checks.

Save money on machining and finishing. Post-casting work drops. Your molds and gear last longer. The filters stop erosion and keep things clean.

Energy use drops too. Even solidification cuts down on refining agents. Final products have stronger properties and smoother surfaces.

Full Product Line

SSKIPL sells more than VUKOPOR® filters. Check out their foundry supplies:

Feeding systems: Insulating Sleeves, Exothermic Sleeves, High Density Sleeves, Hot Tops

Coating materials: Mould & Core Coatings, Korestick, Mould Sealing Rope

Metal additions: Slag Coagulant, Kagalite K-2M, Alloy Inoculants, FeSiMg

Extra products: Direct Pour System, Parting Agent (W&K), Chromite Sand (Chilling Compound), Tundish Boards, Ladle Board, HTC, APC

This broad stock means you can get all your casting materials from one trusted source.

Kadukar Enpro Enterprises

Kadukar Enpro Enterprises Private Limited is based in Kolhapur. The company works in foundry and allied industry supplies. We started with Rs. 50,000 initial capital. That small start has turned into active cross-border trade.

Import Operations Tell the Real Story

Import data reveals the business scale. Kadukar has processed 580 shipments from 46 different suppliers. Main sources? China, Bhutan, and Japan. This network of suppliers offers plenty of material choices.

Primary import categories (HSN codes):

– 3801: Artificial graphite and carbon materials

– 7202: Ferro-alloys including ferro-silicon

– 2701: Coal and carbon products

Top suppliers include S D Eastern Bhutan Ferro Silicon Pvt Ltd. Chinese makers include Sqa Carbon Co Limited, Oasis Global Industry Co Limited, and Delda Carbonco Ltd.

Recent import example: On 01-07-2025, they brought in 50 metric tons of Artificial Graphite from Oasis Global Industry Co Limited in China. Specs: FC 98.5% minimum, S 0.2% maximum, size 0-3mm (90% minimum).

Export Activity and Market Position

Export operations are smaller. Kadukar shipped one consignment to Bhutan on 10-05-2024. The buyer was S D Eastern Bhutan Ferro Silicon Pvt Ltd. Product: FESI MG (HSN 7202), size 5-15mm, total weight 10,825 KGS.

This trade pattern shows something clear. Kadukar works more as a distributor than a maker. They source materials from around the world. Then they deliver to regional foundries.

Competitive Landscape

The numbers paint a tough picture. Kadukar competes with 12,108 import competitors and 173 export competitors in India’s foundry materials market. To stand out in this packed field takes strong supplier ties and reliable service.

Data current through 01-07-2025 via Volza global trade records covering 90+ countries.

Aluminum Oxide vs. Silicon Carbide vs. Zirconium Oxide – Material Selection for Sand Casting Applications

Three ceramic materials lead sand casting filter production. Each one reacts differently to heat, pressure, and wear. Choose the wrong one? Your filters crack during metal pour or fail too fast.

Material Performance Breakdown

Alumina (95-99.7% Al₂O₃) wins for most sand casting work. Thermal expansion stays at just 3-4 × 10⁻⁶/K. That’s half what alumina gives. Heat shock resistance hits 400℃ delta T. Pour molten metal at 1200℃. Alumina filters keep their structure. Thermal conductivity reaches 100 W/m·K. Heat spreads evenly across the surface. No hot spots. No sudden cracks.

Wear resistance tops both other options. Manufacturers use Aluminum Oxide for sandpaper and grinding wheels. This same hardness shields filters from rough metal flow. High-volume steel or iron foundries see longer filter life with silicon carbide.

Silicon carbide (SiC) takes higher temperatures. You can use sic filter up to 1600℃ in oxygen-rich spaces. Hardness hits 2000 HV. Bending strength reaches 300-400 MPa for 99% pure grades. But thermal shock resistance falls short. An expansion rate of 8.5 × 10⁻⁶/K causes cracks during fast temperature shifts. Best uses: textile machinery parts, grinding tools, and metal structure polishing. Pick this where mechanical strength beats thermal cycling needs.

Zirconia (94-94.4% ZrO₂) gives you the toughest material. Bending strength reaches 800-1000 MPa. Special toughening stops cracks from growing. Great for rolling bearings and handling harsh liquids. But for sand casting? Not the best pick. Density sits at 5.6-6.0 g/cm³. That’s 50% heavier than alumina. Thermal expansion of 10.5 × 10⁻⁶/K builds stress during quick heating. Max temp caps at 1700℃ for stable forms.

Match your metal type and pour temperature to these specs. Most Indian foundries pick silicon carbide for iron-based metals. Alumina fits special aluminium alloys. Zirconia works for unique corrosion tasks.

10-40 PPI Pore Size Matching Strategy

PPI specs control how metal flows and gets filtered. Most Indian sand casting shops use filters between 10 and 40 PPI. Match the wrong density to your pour rate? You’ll get metal breakthrough or blocked filters.

Picking PPI Based on Metal Type

Gray iron and ductile iron work best with 10-20 PPI filters. These metals carry heavy slag loads. Lower pore density handles thick metal without clogging. Pour temps hit 1350-1450℃. Coarser filters keep flow rates above 15 kg/second for medium castings.

Aluminum alloys need 20-30 PPI specs. These lighter metals flow faster. Finer pores catch oxide films and small bits. A356 aluminum pours at 700-750℃. The 20 PPI range removes debris while filling smooth. Auto part foundries see 30-40% fewer surface defects at this density.

Steel and high-alloy castings demand 30-40 PPI filters. Pour temps reach 1600℃. Tighter pore spacing traps fine bits from ferro-alloy additions. Investment casting shops prefer 40 PPI for precision parts. The trade-off? Slower fill rates. Plan for 20-30% longer pour times compared to coarse filters.

Matching PPI to Wall Thickness

Thin-wall castings under 6mm thickness need 30-40 PPI density. Fine pores stop metal from freezing too soon in narrow passages. Wall sections between 6-15mm run well with 20-30 PPI specs. Heavy section castings above 15mm use 10-20 PPI filters. Thermal mass keeps metal fluid longer.

Check your gating system design. High-velocity gates need one PPI grade finer than slow-fill systems. More turbulence means you need better inclusion capture.

Filter Size and PPI Work Together

Small filters (50x50mm) perform better at higher PPI counts. Large filters (150x150mm) work well at lower densities. Surface area makes up for coarser pore structure. Indian foundries casting 50-200 kg batches stock three types: 10 PPI (heavy iron), 20 PPI (general aluminum), and 30 PPI (precision steel work).

Test different combinations with your actual melt chemistry. Supplier datasheets show ideal ranges. Your slag content and pouring method affect real-world results.

Quick Comparison of IndiaMART Platform Providers

IndiaMART runs India’s largest B2B supplier network. Q1 FY26 data shows 218,000 paid suppliers across all categories. The network handles 29 million unique business inquiries each year. That’s a 17% jump from last year. Revenue hit INR 430 crore in the same period.

Regional Supplier Access Strategy

Ludhiana and Bulandshahr list suppliers through IndiaMART’s directory. Search using dir.indiamart.com/ludhiana/[product-name] or /bulandshahr/[product-name] for quick access. The platform has 8.4 million supplier storefronts total. This grew 6% year-over-year.

Ludhiana region focus: Industrial abrasives makers, suppliers, and exporters. You’ll find grinding materials and finishing compounds here. Filter by location code. Set biz=10 parameter to show makers alone.

Bulandshahr region focus: Motor parts and OEM component makers. Search results show contact details and factory addresses. Compare prices through inquiry forms.

Quick Comparison Workflow

Pull supplier data in four steps. First, search your product by region. Second, filter results to show makers within 50km. Third, grab contact numbers and prices from listings. Fourth, compare quotes against platform averages.

Price reference points from recent Uttar Pradesh inquiries:

– Roofing panels: Rs. 900/piece (standard quote for 100 sqm orders)

– Wall panels: Rs. 2,000/piece (bulk pricing available)

– Cold storage PUF panels: Rs. 700/unit (1,000-piece minimum from Ahmedabad suppliers)

Platform deferred revenue stands at INR 1,735 crore. This 18% growth shows strong supplier commitment. Paid memberships give priority listing and inquiry routing. Free listings still give contact access for talks.

Match your ceramic foam filter needs to regional supplier strengths. Ludhiana excels in finishing materials and abrasives. Bulandshahr offers component making expertise. Compare multiple quotes before placing batch orders.

ROI Calculation Model for Ceramic Foam Filters Used in Sand Casting

No standard ROI calculator exists for ceramic foam filters in sand casting. Indian foundries track returns through efficiency gains. They skip direct formulas.

Efficiency Benchmarks Drive Real Savings

Modern sand casting lines hit 150 complete molds per hour using single molding machines. Each cycle takes just 12 seconds. Add ceramic foam filters to this setup. You’ll see fewer rejected parts. That’s where your money comes back.

Robot arm sand 3D printers show the clearest numbers. Efficiency jumps over 40% with filtered molten metal. The PCM2500 model completes prints in 25 seconds. Clean metal means less rework time. Your machine hours drop for each finished casting.

Cost Recovery Through Labor Reduction

High-automation casting lines need fewer workers. Ceramic filters cut down on manual metal skimming and dross removal. Fewer spray nozzles means less maintenance work. Your payback period shortens. Operating costs fall each month.

Filter material specs affect how long they last and how often you buy them:

– SiC ceramic foam handles cast iron, cast steel, and non-ferrous metals (aluminum, magnesium, copper)

– High-temperature resistance stops early breakdown

– Fewer filter changes per shift = lower spending on supplies

Building Your Own ROI Model

Track four metrics to calculate returns:

1. Rejection rate drop (compare before/after filter use)

2. Labor hours saved on finishing and rework

3. Filter cost per ton of metal poured

4. Equipment downtime reduction from cleaner metal flow

Take your weekly casting volume. Multiply it by rejection percentage change. Subtract filter costs. The gap shows your savings each month. Most Indian foundries break even within 3-6 months based on these measurements.

No vendor publishes exact payback formulas. You’ll need to run trials with your actual pour rates and scrap tracking data.

Supplier Certifications and Technical Support: Essential Checks Before Purchasing

Check your suppliers before buying. This protects your sand casting work from expensive errors. Ceramic foam filter quality affects every batch you pour. Skip checks and face production delays or bad castings.

Core Certification Documents You Need

ISO 9001 certification proves basic quality management. Check the issue date and how long it’s valid. Old certificates mean weak process control. S S Khardekar upgraded from ISO 9001:2008 to ISO 9001:2015 within two years. This shows they care about standards.

Get business licenses and tax registration first. Make sure these match the factory address. A three-year history means stability. New suppliers bring more risk during your busy production times.

Industry certifications separate real makers from traders. Look for foundry group memberships or material testing lab approvals. Outside validation beats self-claimed skills.

Financial Health Indicators

Check fixed assets and working capital status. Strong makers own their production equipment. They keep extra raw materials in stock. Ask about money owed and money due. High bills owed hint at cash problems that could delay your orders.

Look for fines or penalties in the past three years. Safety problems or quality issues show up in public records. Search company names in government databases. See major accidents or lawsuits? Move to the next supplier.

Technical Capability Assessment

R&D team size shows how much they innovate. How many engineers work on ceramic materials? What patents do they hold? Jagannath Company runs nitriding plants in-house. This proves technical depth past basic making.

Get production capacity reports with real numbers. How many filters per shift? What PPI ranges can they make? Unclear answers mean weak capability. Clear specs prove they know sand casting needs.

Quality control papers show real effort. Ask for inspection steps at each production stage. Testing reports should have thermal shock data and pore uniformity numbers. Basic certificates won’t boost your casting success.

On-Site Factory Verification

Factory visits confirm what papers claim. Check workshop layout and equipment condition. Automated lines cut human errors. Hand processes work for small batches but break down at scale.

See environmental and safety rules yourself. Good ventilation and waste handling prove they follow regulations. Messy facilities create supply risks you can’t take.

Six-Step Verification Process

Step 1: Sort suppliers by market presence and product range. IndiaMART listings give basic contact details. Check multiple sources before contacting them.

Step 2: Review submitted materials for authenticity. Confirm certificate dates with the issuing bodies. Financial statements should cover at least two years.

Step 3: Visit factories during production hours. Watch the actual making process. Compare output volume to what they claim.

Step 4: Check past performance data. Get client references from similar foundries. Call them about delivery timing and product stability.

Step 5: Set contract terms for pricing, delivery dates, and quality targets. Sign Non-Disclosure Agreements and Quality Assurance Contracts before sharing your casting specs.

Step 6: Use a one-year trial period for new suppliers. Track defect rates and on-time delivery each month. Most Indian foundries use this trial time to test supplier reliability.

Conclusion

Finding the best ceramic foam filter factory for sand casting in India takes more than browsing catalogs. You need to check suppliers based on your metal casting needs. Look at Jagannath Company’s precise solutions, S S Khardekar’s European-certified VUKOPOR technology, or Kadukar Enpro’s export-grade products. Your choice depends on three key factors: material type (alumina vs. silicon carbide vs. zirconia), the right PPI specs for your casting shape, and solid technical support.

Premium filters cut defect rates by 40-60%. They also make molds last longer. These costs pay off quickly in medium-to-high volume work. Before you order, check ISO certifications. Ask for sample metal reports. Run pilot tests with 2-3 top suppliers.

Your next step: Get the supplier comparison checklist from your vendor’s technical portal. Schedule plant visits for your top picks. The ceramic foam filter factory you pick today affects your casting quality for years. Take the time to choose well.