Every metal caster knows this moment: a good casting comes out of the mold. Then you see rough surface defects. The structure looks weak. Or worse—the entire part is scrap.Many of these failures have one persistent cause. Slag inclusion in casting costs the industry...

Metal Casting

What Is The Difference Between Pressurized And Unpressurized Gating System

A gating system is a controlled pathway. It directs molten metal from the pouring basin into the mold cavity during casting.The key difference between pressurized and unpressurized systems? It's about metal flow control. Plus, where you place the choke area - the...

What Is Gating System? 5 Key Components in Metal Casting

What Is Gating System?A gating system is a network of channels and passages. It guides molten metal from the pouring ladle into the mold cavity during casting. This pathway acts as the metal's route map. It ensures metal reaches every corner of the mold the right...

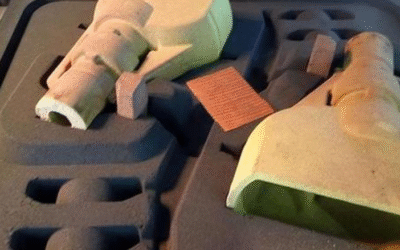

5 Common Types of Sand Used in Sand Casting

Overview of Sand Casting Sands Sand casting uses different types of molding sands. Each type has unique properties. You select them based on what your project needs. The main types are green sand, resin-coated sand, sodium silicate sand, core sand, and facing sand. I...

Which Metal Is Most Frequently Used In The Casting Process

Ever wondered why some metals show up everywhere in cast machinery and car parts? Gray Iron stands out as the go-to choice in the casting world. It offers strength, low cost, and shapes with ease. You'll find it behind most engine blocks and heavy parts. Based on...

What Metal Has The Lowest Melting Point Besides Mercury

Introduction to Low Melting Point Metals Some metals turn from solid to liquid at low temperatures. This makes them useful in many industries, science labs, and tech products. Mercury stays liquid at room temperature, but other metals and alloys also melt at very low...