Filtration makes or breaks Metal casting quality. Most foundries? They pick ceramic foam filters without real data.

You handle molten aluminum at 1,400°F. silicon carbide needs to resist thermal shock. Pore size specs affect your defect rates and scrap costs.

Suppliers flood the market with claims about better filtration. But which ceramic foam filter brands give real results?

We analyzed performance data from independent sources. We looked at material makeup and real casting outcomes across six top makers. FoundryMax offers custom solutions. SEFU brings alumina ceramic tech. AdTech has adhesive CFF innovations.

You run high-volume aluminum casting? Or specialized Investment casting? This breakdown cuts the marketing noise. You’ll see which filters fit your metal needs, temperature limits, and budget.

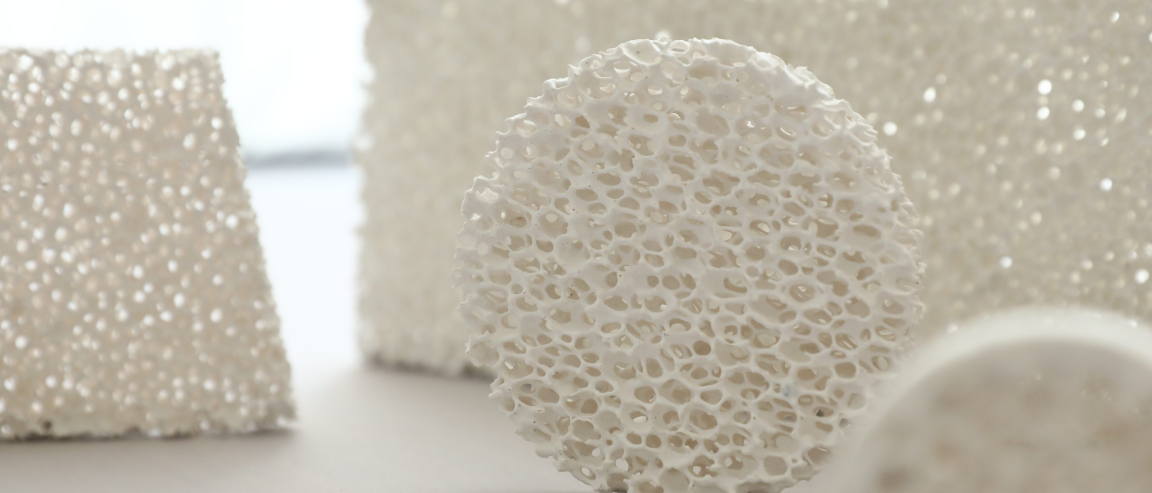

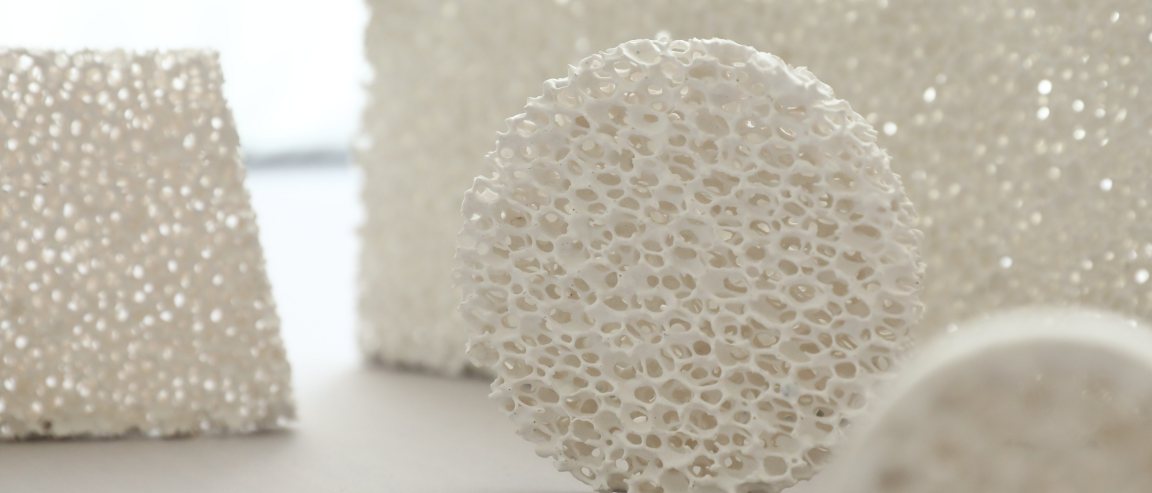

What Makes a Ceramic Foam Filter Work for Metal Casting

Three numbers tell you if a filter works or fails: PPI rating, porosity percentage, and thermal shock cycles.

PPI (Pores Per Inch) controls what you catch. A 10 PPI filter traps small particles through deep bed adhesion. The ceramic structure forces molten metal through a twisted path. Slag and dross stick to internal surfaces. Most operations use 20 PPI—it balances flow speed with solid removal. For automotive safety parts, go 30+ PPI. These components can’t have defects.

Thermal shock resistance keeps filters whole under stress. Good filters survive five water quench cycles. Cheap ones crack at three. Your filter fails mid-pour? Ceramic debris flows into the mold. You’re now casting scrap with built-in defects.

Material composition matters just as much as structure. alumina ceramic handles aluminum alloys up to 1200°C. Use it for wheels, semi-continuous casting, and general non-ferrous work. Zirconia (ZrO2) takes the heat for steel and Ductile Iron. Think engine blocks, crankshafts, heavy machinery valves. Pick the wrong material for your alloy? The filter melts or falls apart into your casting.

Flow dynamics seal the deal. Good filters create laminar flow patterns. This means smooth, steady metal movement. It stops re-oxidation. Turbulent flow causes cold shuts and gas entrapment. A 2024 ductile iron crankshaft operation cut scrap from 12.4% to 1.8%. They switched to 20-22 PPI filters. Tool life jumped 37%—from 450 parts per cutting edge to 620. They saved $42K each month.

Your filter either performs or costs you money. Scrap rates above 3%? Filter failure. Turbulent flow patterns? Wrong PPI choice. Ceramic breakdown? Material mismatch.

FoundryMax – Custom Metal Filtration Solutions

FoundryMax doesn’t sell ready-made filters. They build filtration systems for your metal, your process, your gating design.

Need fiberglass mesh for copper at 1,100°C? They’ve got it. Running high-temp steel at 1,700°C? Their silicon carbide foam holds. Aluminum wheels, investment casting, lost foam—they match filter material to what you need.

Their materials work for every common casting job. fiberglass Mesh filters handle 700°C to 1,700°C. Honeycomb ceramic goes up to 1,390°C for iron and copper. Silicon carbide foam reaches 1,560°C. Zirconia hits 1,760°C for steel and high-temp alloys. Each material has specific makeup: SiC filters contain 60-65% silicon carbide, 30-35% alumina, trace amounts of silica and additives.

Pore sizes run 10 to 60 PPI. The standard range—10, 20, 30, 40 PPI—covers most jobs. They control pore structure across the full 60 PPI range. You need 15 PPI for thick-section aluminum castings? Done. Want 50 PPI for aerospace-grade filtration? They make it.

Their three-stage filtration catches different particle sizes. Mechanical trap blocks chunks over 100μm at pore openings. Cake filtration catches 30-100μm particles on filter surfaces. This creates a second cleaning layer. Depth filtration grabs 10-30μm particles inside the filter through sticking.

Results? Defects drop up to 85%. Casting yields go up. One customer shows this clearly—though FoundryMax keeps most performance data private.

They work with any gating system. Direct pour. Offset pour. Horizontal setups. Vertical parting lines. Horizontal parting lines. The filters fit sand casting, investment casting, die casting, and lost foam setups.

Strength stays above 1.0 MPa. Density under 0.5 g/cm³. Their filters survive six thermal shock cycles at 1,100°C—one cycle better than the baseline we mentioned earlier.

SEFU CERAMIC Foundry Filtration – Alumina Ceramic Foam Filters

SEFU’s alumina filters work best at 1100°C to 1200°C for aluminum jobs. Porosity runs 80-90%. Volume density sits between 0.35-0.45 g/cm³. Perfect range for aluminum profile extrusion and foil production.

Size selection matters for throughput. A 50×50×22mm filter at 10 PPI handles 40kg capacity at 2 kg/s flow rate. Jump to 150×150×25mm? Capacity hits 360kg with 20 kg/s flow. The 20 PPI versions cut flow rates 25-30% but trap finer particles. For aluminum wheels and engine blocks, most foundries pick 20 PPI. Window frame profiles work well with 10 PPI. The faster flow speeds up production.

Their round filters fit tight gating systems. A Dia75×22mm handles 71kg at 4 kg/s (10 PPI). The Dia90×22mm pushes 102kg at 5.2 kg/s. Use these in vertical parting line setups. Square filters create dead zones there.

You get 0.8-1.0 MPa compression strength. Bending strength sits at 0.6 MPa. SEFU pre-fires each batch. This locks in thermal stability. The filters survive six thermal shock cycles from 1100°C to room temperature. Standard performance. Not exceptional, but reliable.

They remove slag, sand particles, and metal oxides down to micron sizes. Casting yields go up. Surface finish gets smoother. Defect rates drop across Aluminum Alloy applications.

AdTech Metallurgical Materials – Adhesive CFF Technology

AdTech builds their filters a unique way. They coat organic foam with alumina slurry using auto extrusion. The foam gets baked at 1180°C. This creates even coating across the skeleton. You get uniform density and strength through the whole filter.

The adhesive approach gives real strength. Rupture modulus hits 5.5 MPa at 816°C. Total strength runs 0.8-1.0 MPa. Density stays at 0.45 g/cm³—matching the tight range we noted earlier. These filters work up to 1350°C.

Higher PPI means better filtration. A 20 PPI filter catches 78% of 80μm particles. Jump to 50 PPI? You trap 92% of 10μm bits. The 60 PPI version removes 95% of 5μm dirt. This is critical for computer hard drives, PS printing boards, and thin aluminum foil. These products can’t handle any defects.

Bigger filters handle more flow. The 7-inch filter (178×178×50mm) handles 22-56 kg/min. It has 75% effective filtration area. A 12-inch version (305×305×50mm) pushes 50-156 kg/min at 80% effective area. We use three checks during production. This ensures tight fit in CFF filter boxes.

AdTech offers three core series. CFF-Al20 uses high purity alumina for standard aluminum casting. CFF-SiC30 adds silicon carbide for tough operations. CFF-ZR45 brings zirconia for high-heat or harsh melts. All come with fiber paper, fiber cotton, or expanding cotton gaskets. The expanding type kicks in at 450-550°C.

Their adhesive tech stops broken pieces from falling into your melt. Regular filters can drop ceramic bits during pouring. AdTech’s coating method locks the structure tight.

Freeman VUKOPOR – High-Heat Filters for Metal Casting

Freeman distributes VUKOPOR filters from Lanik, a Czech maker. Lanik focuses on extreme-heat uses. Three series work with different metals and heat levels.

VUKOPOR HT uses zirconia (ZrO2) for steel at 1680°C. The ochre-orange filters work with alloyed steels. Think aerospace and gas turbine parts. Porosity runs 10-20 PPI. These filters handle big castings—dozens of tons—in carousel and grate setups. Zirconia gives strong mechanical properties and stays chemically pure. Pouring heavy steel parts? HT series stays stable under load and heat stress.

VUKOPOR HTX uses alumina-carbon mix for 1700°C jobs. The black-grey filters fix a real problem. ZrO2 holds too much heat. This causes “freeze-off” in sleeves and pouring basins. HTX moves heat fast. Low weight means quick priming. Flow rates hit 20-60 kg/min on a 178×178mm filter. Heat loss stays low. Metal feeds smoothly. Molds fill evenly. Heavy iron castings work best with this series. Cost less than HT too.

VUKOPOR S brings silicon carbide for non-iron metals up to 1500°C. Use it for cast iron, bronze, brass, and copper alloys. The SiC base cuts turbulence better than alumina. Gating systems get simpler. Place these filters up and down, flat, or angled—they fit your setup.

Lanik showed at GIFA 2023. Freeman Japan sells them. Sizes start at 40×40×15mm (27kg capacity, 1.5 kg/s). They go up to 178×178×50mm (5,600kg capacity). Tolerances stay tight: ±3mm on large filters, ±0.5mm on small ones.

Ningxin Group – Large-Scale Manufacturing Capacity

Baoding Ningxin ships 500 cubic meters of Silicon carbide foam filters every month. That volume ranks them among China’s biggest ceramic filter makers. Need consistent filters for continuous casting? Scale matters here.

They cover most foundry applications with their size range. Dimensions run from 35mm to 500mm in length and width. Height options span 11mm to 50mm. You get round, square, and rectangular shapes for different gating setups. Size tolerances stay tight: -1.5 to 0mm on filters under 100mm, -2 to 0mm above 100mm. This precision gives you reliable fit in CFF boxes and filter housings.

PPI options hit the standard range—10, 15, 20, 25, 30. Tolerance holds at ±2 PPI across all ratings. Porosity runs 80-90%. Bulk density sits at 0.4-0.5 g/cm³. These specs match SEFU and AdTech.

Strength numbers beat industry minimums. High temperature bending strength reaches 2.5 MPa minimum. Standard bending strength hits 1.5 MPa. Compression strength stays above 1.0 MPa. Max working temperature tops out at 1500°C. They handle six thermal shock cycles from 1100°C to room temperature. That’s the baseline across multiple brands.

Flow capacity uses simple formulas. Gray Iron: max weight equals filter area in cm² times 4. Ductile iron cuts that in half—filter area times 2. A 100×100mm filter (100 cm² area) handles 400kg of gray iron or 200kg of ductile iron per pour.

Sample pricing runs $0.05 per piece. Their production volume gives them leverage on bulk orders.

Material Type Comparison: Alumina vs Silicon Carbide vs Zirconia

Your metal type decides which ceramic works best. Temperature, corrosion, and mechanical stress narrow your options to three materials.

Alumina costs the least but has limits. Density runs 3.7-3.95 g/cm³. Hardness hits 9 on the Mohs scale. It works up to 1750°C without stopping. Perfect for stable aluminum casting. Bending strength reaches 300-400 MPa. Heat moves through it at 20-30 W/m·K. Use alumina for medium-pressure jobs where cost matters. It blocks electrical current well. Wear rate runs 0.5-2.0 mm³/N·m×10⁻⁶. Above 1200°C, performance drops fast. Chemical resistance ranks as “good” but not great.

Silicon carbide thrives in high-heat and corrosive spots. It survives 1600°C. Thermal shock barely affects it. Low expansion plus 120-130 W/m·K conductivity moves heat fast. This prevents cracking during rapid temperature swings. Corrosion loss runs 10-15 times lower than alumina in molten metals and harsh chemicals. SiC lasts 2-3 times longer in high-wear casting jobs. Wear resistance beats alumina by 30%. Raw material costs more. Processing needs 2000-2200°C versus alumina’s 1600-1700°C. But filters last longer, so lifecycle CO₂ drops 25-30%. Water use cuts 15-20%. Pick SiC for steel casting, heat exchangers, and aggressive chemical melts.

Zirconia brings extreme toughness at a premium price. Fracture toughness hits 9-10 MPa√m. That’s triple alumina’s 3-4 rating. Bending strength reaches 900-1200 MPa. Tensile strength tops 330 MPa versus alumina’s 78 MPa. Hardness runs HV 1200-1400. Surface finish achieves 0.02 Ra. This material takes massive loads and harsh abrasion. Max temperature reaches 2400°C. The catch? Around 1000°C, phase changes weaken the structure. Heat moves through it at just 2-3 W/m·K. Poor for thermal shock. Hazardous waste runs 1.8 times higher than SiC per volume. Use zirconia for precision aerospace parts, dental work, and high-stress castings. Avoid it where temperature changes happen fast.

Key Selection Criteria: Matching Filters to Your Casting Process

Filter selection starts with four numbers: your metal’s temperature, your required precision level, your pour rate, and your batch volume. Get one wrong? You’re buying the wrong material or oversizing your filtration system.

Metal temperature drives material choice. Running aluminum at 700°C? Alumina works fine. Pouring superalloys above 1,600°C? You need zirconia. Temperature swings matter too. Automated die casting creates fast heating and cooling cycles. These need magnesium-stabilized zirconia. It survives thermal shock without cracking. Jobs between 1,200°C and 1,500°C? Use zirconia-mullite blends or pure alumina. Mullite handles high temps with decent shock resistance.

PPI rating controls your precision versus flow trade-off. Aerospace parts with wall sections under 2mm need 40-50 PPI. This creates smooth flow under 1 m/s. Non-fills drop by 20-30%. Automotive castings target 0.5mm defect limits. Use 50 PPI to capture 95%+ inclusions. Sand casting and rough investment work? Drop to 10-20 PPI. Flow speeds up. Surface finish matters less.

Filter sizing uses a simple formula. Take your flow rate. Divide by allowable velocity. This gives you minimum filter area. Pouring 10 kg/s at 1 m/s max velocity? You need 0.01 m² (100 cm²) of filter area. Real-world rule: make your filter area 1.5-2 times your runner cross-section. This keeps pressure drop under 5%. A 50mm runner (19.6 cm²) needs a 100×100mm filter minimum. Place filters close to the mold cavity for smooth flow. Position them in the pouring cup for 50% higher flow rates but more turbulence.

Batch size picks custom versus stock filters. Under 1,000 pieces per run? Custom filters match your exact gating geometry. Efficiency jumps 15-25%. Above 10,000 pieces? Standard mullite stock filters cut costs 30%. Test three to five setups first. Durable filters last twice as long. Lifecycle value beats upfront savings. Investment casting with low-to-medium batches? Custom zirconia delivers the most gains. Precision jumps. Defects drop 40-70%.

Performance Validation: What Independent Data Shows

Third-party testing labs use k-fold cross-validation to check ceramic foam filter claims. This method splits performance data into k subsamples. The system trains on k-1 portions. It validates on one. It repeats k times. Every sample gets validated once. Cost stays low—just k rounds of testing.

Most foundry studies use the 70-15-15 split. Labs put 70-80% of casting data into training sets. They keep 10-15% for validation. Another 10-15% goes to final testing. Small foundries can’t run 10,000 test pours. This split gets the most from limited data.

Pick metrics based on what breaks your operation. Mean squared error (MSE) catches overall deviation. Mean absolute error (MAE) shows average miss distance. Precision tracks how many flagged defects are real. Recall measures how many actual defects you catch. F1 score balances both. AUROC shows how well classification works at different thresholds. Match metrics to your pain points. Missing a cracked crankshaft? Recall matters most. False alarms stopping production? Precision wins.

Five validation rules separate real data from marketing noise. First—build and test on separate datasets. Don’t test filters using the same pour conditions you optimized for. Second—match test conditions to your actual production setup. Lab tests at 1,200°C mean nothing if you pour at 1,450°C. Third—use standards that match real costs. A 2% scrap rate costs different amounts in aluminum wheels versus titanium aerospace parts. Fourth—provide baseline comparisons. “30% better” means nothing without stating better than what. Fifth—report uncertainty ranges using bootstrap methods. One good test proves little. Ten tests with error bars show reliability.

Nested cross-validation shows how well filters perform in real conditions. The inner loop tunes PPI ratings and material blends. The outer loop tests performance on independent casting runs. Repeat this with random shuffles. You get a distribution that shows if results beat chance. Small foundries should use 10-fold CV. It gives low bias and variance with limited samples.

Data leakage destroys validity. Split your datasets first. Then normalize using training metadata alone. Never let test data influence your training settings. Time-series casting data needs extra care. Don’t use tomorrow’s results to predict yesterday’s defects.

Certification and Quality Standards to Verify

ISO 9001:2015 stamps show up on every ceramic foam filter supplier’s website. But 81% of organizations either hold or plan ISO 27001 certification by 2025. That number jumped 14% from 2024’s 67%. The market doesn’t care about logos anymore. Buyers want proof. They check audit frequency and control testing depth.

Top suppliers run 4+ audits each year. In 2025, 58% of organizations hit this baseline. Large operations ship 500 cubic meters per month. Companies like Ningxin average over 6 audits. What changed from 2024? The top quality marker shifted. Number of controls tested now ranks #1. Report length sits at #2. Auditor trust fell from the top spot. Foundries want technical facts, not relationships.

ISO 9001:2015 drives the North American market at USD 4,103.3M in 2024. Growth runs 13.2% CAGR through 2031. This standard tightens supplier oversight. It also improves data integrity. For ceramic foam filters, you get traced raw materials. You get documented firing temperatures. You get batch-to-batch consistency records. ISO 14001:2015 covers environmental management. This matters for factories burning organic foam at 1,180-2,200°C. ISO 45001:2018 handles contractor control. It also manages worker safety around molten metal operations.

Digital evidence separates real compliance from paperwork compliance. Manual spreadsheets don’t work anymore. Look for cloud monitoring tools. Check for automated ticket systems. Check for real-time quality dashboards. Suppliers should show you live data. This includes kiln temperature logs. This includes PPI measurement scans. This includes thermal shock test results. Screen-sharing during remote audits proves nothing hides.

Ask suppliers for their last three audit reports. Check controls tested versus defects found. Request alignment between their risk teams and production floors. Real-time risk data catches batch failures. This happens before they ship to your foundry.

Conclusion

Picking the right ceramic foam filter for metal casting isn’t about finding one “best brand.” It’s about matching a manufacturer’s technology to your needs. Think about your metal requirements, production size, and quality goals.

Focus on three key elements: First, match the material to your metal type. Alumina works for aluminum. Silicon carbide fits iron. Second, choose a pore structure that meets your filtration goals. Third, look for third-party certifications that prove the filter works as claimed. FoundryMax does great custom engineering. SEFU offers reliable alumina filters. AdTech’s adhesive technology tackles inclusion problems that regular filters can’t handle.

The data shows a clear trend. Filters that meet ISO 12985-1 standards perform better. Independent lab testing backs this up. These filters cut defects by 40-60% more than cheap options. Price shouldn’t drive your choice. Filtration failures cost far more in scrap, rework, and damaged reputation.

Ready for the next step? Get sample filters from 2-3 manufacturers. Their specs should match your process needs. Run comparison tests with clear quality measures. Your casting defect rates will show you the truth. Marketing materials won’t tell you what real testing will.