Metal casting quality depends on one key choice: picking the right filter system. This decision can save or cost you thousands in scrap and rework. Ceramic foam filters and honeycomb filters both promise cleaner castings and fewer defects. But they work in completely different ways. Pick the wrong one? Your yield rates take a hit.

Most foundries just use what their equipment supplier recommends. This leaves money on the table. The truth? Each filter type works best in certain situations. Flow patterns, alloy types, heat resistance, and total costs vary greatly based on what you produce. Running high-volume aluminum alloys? Or casting superalloys with tight tolerances? Either way, you need to know how ceramic foam filters compare to honeycomb filters in real conditions. This knowledge helps you stop defects, improve metal flow, and choose a filter that truly pays for itself.

What Are Ceramic Foam Filters and How Do They Work

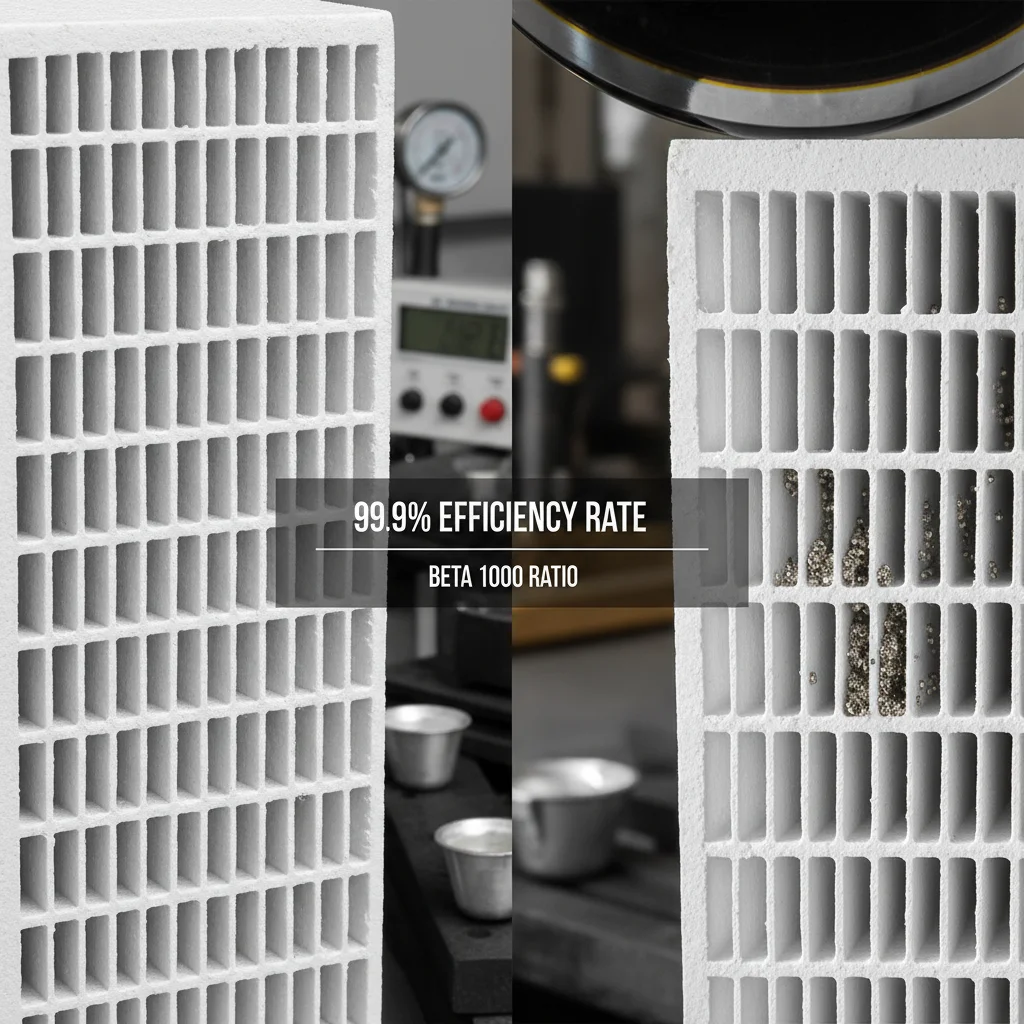

Ceramic foam filters use a 3D open-cell network. Think of it as a maze of connected struts. These struts copy the structure of polyurethane foam templates. The struts form the core of the filtration system. They create winding pathways that control metal flow. At the same time, they trap unwanted particles.

Structure and Pore Density Options

The filters come in pore densities ranging from 10 to 60 PPI (pores per inch). Your casting application determines which density works best:

-

10-20 PPI: Large ingots where low head loss matters more than ultra-fine filtration

-

20-30 PPI: Billet casting needs balanced particle capture and flow rates

-

30-45 PPI: Thin-section castings need finer particle removal

-

Above 45 PPI: Finishing work where you’ll accept higher pressure drops for maximum purity

Material Composition and Temperature Performance

Three main ceramic materials work best for foundry use:

Alumina (Al₂O₃) gives you the best balance of cost and stability. It sinters at 1100-1600°C. Plus, it offers high chemical stability against molten aluminum. Most operations rely on this workhorse material.

Silicon carbide (SiC) handles thermal shock better. High thermal conductivity makes this possible. Rapid temperature changes can damage filters. This material protects against that.

Zirconia-based materials (ZrO₂ or Zr₂SiO₄) deliver extreme toughness at high sintering temperatures. But cracking can happen. You need to optimize processing parameters to avoid this.

How the Filtration Happens

Metal enters the open-cell network. Right away it hits strut deflection points. These struts are 0.5-2mm thick. They force the molten metal through winding paths. This reduces velocity. It also controls turbulence.

Particles larger than 5-50 microns hit the struts. This happens through inertial impact. They stick to the ceramic surface through adsorption. The result? Over 90% efficiency for capturing oxides and unwanted particles. Just match PPI to your application.

Particles build up over time. They form a filter cake. This cake improves capture rates. But head loss can become a problem.

What Are Honeycomb Filters and How Do They Work

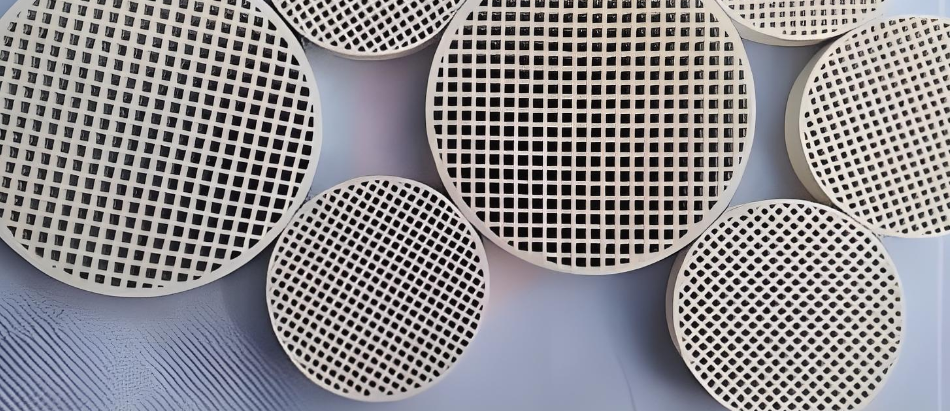

Honeycomb filters replace the random maze with precision geometry. Thousands of straight parallel channels run through them in hexagonal or square patterns. Thin ceramic walls separate each channel. This design packs huge surface area into a small space.

Channel Density and Wall Specifications

Cell density runs from 100 to 900 CPSI (cells per square inch). Higher counts give you more filtration area. Wall thickness matters just as much: 0.005 to 0.020 inches (about 0.15-0.50 mm). Thinner walls reduce pressure drop. Thicker walls boost structural strength. Your application determines the right balance.

Manufacturing and Material Choices

Extrusion creates these channels. A die presses wet ceramic paste into the honeycomb shape. After drying, sintering locks everything in place. Four materials dominate foundry use:

-

Cordierite: Low thermal expansion prevents cracking up to 1000°C+

-

Mullite: Strong at high temperatures, perfect for extreme pouring temps

The Straight-Channel Filtration Process

Metal enters open channels and flows straight through. No winding paths exist. Particles hit the thin porous walls. Some get trapped on the surface (surface filtration). Others stick inside wall pores (depth filtration). Clean metal exits through nearby channels in wall-flow designs.

Pressure drop starts low—50-70% open area makes this possible. Particles build up over time. Resistance grows as they do. But filtration efficiency still exceeds 95% for particulate matter. Flow rates stay steady even with heavy inclusion loads.

Structural Strength Under Thermal Shock

Foam struts measure 0.5-2mm thick. Junction points create stress points. Fast temperature swings (>200°C/minute) can crack these junctions. Silicon carbide foam handles this better than alumina. But the random structure makes it hard to predict where failure will happen.

Honeycomb walls use uniform thickness. Thermal stress spreads across the entire structure. Cordierite honeycomb handles thermal shock cycles 3-4x better than alumina foam. Failure happens slowly through tiny cracks—not sudden collapse.

Flow Characteristics and Metal Flow Control

Metal speed controls everything. Too fast? Turbulence pulls oxides into the metal and creates flow marks. Too slow? The metal cools before it fills the mold. Your filter choice controls this balance. It works through pressure drop and channel shape.

Pressure Loss at Different Flow Rates

Foam filters push metal through twisted paths. This creates friction. Honeycomb channels run straight. You get less friction. But surface roughness changes how this works.

Darcy friction factor sets pressure loss in laminar flow (Reynolds number Re_D < 2000): f = 64/Re_D. Clean channels follow this formula. Surface roughness doesn’t matter much here.

Transitional flow (2000 < Re_D < 10000) changes things. Roughness starts to interfere. Friction goes up but stays easy to predict.

Turbulent flow (Re_D > 10000) shows the real difference. Ceramic foam filters show sand-grain roughness over 40 μm. That’s rougher than machined metal parts. Honeycomb extruded channels measure smoother at 7-15 μm. Sintering quality affects this range.

Turbulence and Flow Uniformity

Small diameter channels stay laminar longer. Large channels with high length-to-diameter ratios (L/D) turn turbulent fast. Ceramic foam has random pore structure. This creates different Reynolds numbers across flow paths. Some metal takes a short route. Other metal gets trapped in dead zones. This creates uneven speed distribution.

Honeycomb designs give uniform Re_D across all parallel channels. Every channel has the same diameter. Every wall thickness matches. Flow distribution stays within ±5% from channel to channel. Surface roughness still affects performance. Higher ε/D increases friction losses and temperature drop. But you get better predictability.

Impact on Casting Quality and Alloy Systems

Uneven flow causes defects. High friction losses raise temperature drop during mold filling. Metal cools too fast. Flow marks form where speed changes. Europe’s flat steel sector reported 32% liquid metal loss to scrap in 2013. 60% came from process problems including flow control issues. Thin-gauge galvanized steel (used most in cars) suffers worst from filling defects.

Aluminum alloys need low turbulence. This prevents oxide entrainment. Foam filters work well at 10-20 PPI for ingots. Higher PPI ratings create too much pressure drop. Cast iron and steel handle higher friction. But they need thermal stability. Zirconia foam handles 1700°C pour temperatures. Pressure stays steady across long production runs.

Temperature Resistance and Thermal Stability

Ceramic foam filters work up to 1700°C. That’s hot enough for superalloy casting and high-carbon steel pours. Silicon carbide and zirconia make this happen. They stay solid when aluminum turns to vapor. Honeycomb filters max out around 1000-1500°C. The exact number depends on what material you pick. Cordierite honeycomb handles most aluminum jobs. Mullite and silicon carbide honeycomb work better for iron casting.

Thermal Expansion Control

CTE (thermal expansion rate) shows how well a filter resists cracks. Materials grow at different rates across 20-1000°C ranges. Different growth rates create stress. Stress leads to failure. Cordierite honeycomb has low CTE—around 1.0-2.5 × 10⁻⁶/°C. This stops cracks during fast heating. Alumina foam runs higher at 7-8 × 10⁻⁶/°C. Silicon carbide sits in the middle at 4-5 × 10⁻⁶/°C.

Chemical Stability Against Molten Metal

Active alloys eat away at filter materials. Magnesium breaks down standard alumina. Titanium eats through silicon carbide over time. Zirconia-based foams fight off chemical damage better. They just cost more. Match your filter to your alloy type. Pick wrong and your filter dies early. Plus, it pollutes your metal.

Application Suitability for Different Metal Types

Filter choice changes with each metal type. Different alloys present their own challenges. Melting points vary. Oxide behaviors differ. Chemical reactions happen at different rates. Flow properties change too.

The filter that works for aluminum casting won’t work in titanium shops. Metal-specific requirements matter. They decide if you get clean castings or expensive scrap.

Aluminum Alloys: Speed and Oxide Control

Aluminum melts at low temperatures. Common casting alloys melt at 660-720°C. Both ceramic foam and honeycomb filters work at these temperatures.

But aluminum oxidizes fast. A thin oxide film forms right away. This happens the moment metal touches air. Turbulent flow folds these oxide films into the melt. These inclusions ruin mechanical properties.

Ceramic foam filters at 10-30 PPI handle most aluminum gravity casting work. The twisting flow paths slow metal velocity. Turbulence drops. Fewer oxide films get dragged into the melt stream.

Automotive parts benefit from this. So do aerospace components. Electronics housings use this too. Aluminum’s light weight and corrosion resistance make it the top choice in these sectors.

Low-pressure casting systems use honeycomb filters. Controlled fill rates reduce turbulence risk. Cordierite honeycomb at 100-200 CPSI provides good filtration. Pressure drop stays minimal. The straight channels keep flow smooth. Temperature works fine since aluminum stays well below cordierite’s 1000°C+ limit.

Cast Iron and Steel: Extreme Heat Endurance

High carbon steel needs filters that survive 1450-1600°C pour temperatures. Alloy steel does too. Standard alumina foam cracks under this stress.

Silicon carbide foam filters (20-30 PPI) became the industry standard. SiC handles thermal shock cycles. It fights off chemical attack from iron oxide. It stays strong through multiple heats.

Steel’s strength and impact resistance serve many uses. Tools. Springs. Automotive components. Structural elements. These critical applications can’t have inclusion defects. A single oxide particle in tool steel starts a crack. The part breaks under load.

Honeycomb filters at 200-400 CPSI works for continuous steel casting. Thin walls (0.008-0.012 inches) keep pressure drop low. Higher cell density catches fine particles that foam might miss. The uniform channel shape stops dead zones. Particles can’t build up and release later.

Cast iron runs cooler (1150-1400°C). But it makes more slag and dross. Foam filters trap these contaminants through inertial impact. Pumps need this cleanliness. So do bearings. Gears depend on it too.

Copper, Bronze, and Brass: Conductivity Requirements

Copper’s electrical and thermal conductivity drives 44.12% of base metals revenue. Power grids need ultra-pure copper. Electric vehicles need it. Renewable energy systems need it.

Tiny inclusions hurt conductivity. A 0.1% impurity level drops electrical performance by 5-8%.

Bronze (copper-tin alloys) and brass (copper-zinc alloys) serve different uses. Bronze fights corrosion better. Aerospace landing gear uses this durability. Marine components use it. Industrial bearings use it.

Brass machines easier. Plumbing fixtures use it. Musical instruments use it. Decorative hardware uses it.

Alumina foam filters at 30-40 PPI work well for copper alloys. Pour temperatures stay moderate. Bronze pours at 1050-1150°C. Brass pours at 900-1000°C. The higher PPI rating catches smaller oxide particles. This protects the electrical properties that make copper valuable.

Honeycomb filters see less use here. The extra cost doesn’t help most copper casting operations.

Titanium and Specialty Alloys: Ultimate Purity Demands

Titanium’s strength-to-weight ratio can’t be replaced. Neither can its corrosion resistance. Aerospace uses it. Medical implants use it. Chemical processing equipment uses it.

But titanium reacts with everything. Oxygen contaminates titanium melts. Nitrogen does too. Carbon does too. Ceramic filters face chemical attack during long contact.

Zirconia-based foam filters handle titanium’s harsh chemistry. Zirconia resists reaction with molten titanium up to 1700°C. Medical device makers can’t accept any contamination. A hip implant with oxide inclusions creates stress points. The implant fails inside the patient.

Specialty filters for titanium use yttria-stabilized zirconia (YSZ) at low PPI (10-20). Higher densities create too much pressure drop. They also increase metal-ceramic contact time. More contact time means more chance for chemical reaction.

Honeycomb filters don’t appear much in titanium foundries. The thin walls can’t resist titanium’s reactivity over production runs.

Installation, and Handling Requirements

Proper installation makes or breaks filter performance. A misaligned filter creates bypass channels. Metal flows around the edges. Your filtration efficiency drops to zero. Damage during handling cracks ceramic structures before they see molten metal. Your maintenance schedule decides if filters work through their full life or quit halfway through production.

Pre-Installation Preparation and Positioning

Store ceramic foam filters in dry, room-temperature conditions. Moisture weakens the ceramic. Use sealed containers. Keep humidity below 60%. Preheat filters to 150-300°C before installation. The temperature depends on your alloy type. Aluminum casting needs the lower range. Steel needs higher temps. This stops thermal shock from the hot metal hitting cold ceramic.

Honeycomb filters come with protective end caps. Take caps off at installation time. Position honeycombs so channels run perpendicular to metal flow direction. Parallel setup causes uneven loading. The filter clogs faster. Use spring-loaded holders or refractory gaskets. These keep the seal tight during thermal expansion. A 0.5mm gap around the filter edge creates 15-20% bypass flow. Your filtration rate drops from 95% to 75%.

Handling Protocols That Prevent Damage

Foam filters break at corners and edges. Manual handling causes 8-12% damage rates. Workers drop units. They chip edges loading them into filter boxes. Train staff to use two-handed support. Grab the filter body—never the edges. Check each unit before use. Hairline cracks grow under thermal stress. One broken strut creates a weak point. The whole section can collapse during metal pour.

Honeycomb structures handle impact better. Rigid construction gives more strength. But thin walls (0.008-0.012 inches) still crack under point loads. Use padded containers for transport. Stack honeycombs vertically—not flat. Flat stacking puts weight on fragile channel walls. Damage rates drop to 2-3% with proper handling systems.

Performance Monitoring and KPIs

56% of facilities track PM completion as their top KPI. Use this approach for filter systems. Log every installation. Write down metal grade, pour temperature, and tonnage processed. Figure out mean time between filter failures (MTBF). Target MTBF should beat 98% of designed life. Less than that means installation errors or wrong filter choice.

Predictive maintenance boosts staff output by 55%. Sensor-based maintenance reaches 45% of facilities. Put pressure sensors upstream and downstream of filter systems. Real-time pressure readings show you filter cake buildup starting. This data goes into your CMMS (52% of foundries use CMMS). Schedule filter changes during planned downtime. Stop dealing with random failures during production runs.

Industry-Specific Recommendations and Selection Criteria

Your casting operation doesn’t exist in a vacuum. Metal type matters. Production volume matters. Quality standards matter most of all. The filter that saves money in automotive work burns cash in aerospace jobs. Construction hardware needs different solutions than turbine blades. Match your filter to what your industry actually requires—not generic sales pitches.

Automotive Casting: Speed Meets Consistency

Engine blocks and transmission housings demand defect rates below 1%. Casting flaws cost $3,000-8,000 per vehicle in warranty claims, recalls, and repairs. Your filter choice impacts this number.

Aluminum cylinder heads need ceramic foam filters at 20-30 PPI. Target 25-40μm particle capture to stop oxide films from reaching the mold. These filters cut inclusion defects 40-60% in real production data. Flow rate requirements: 5-15 cm/min through the filter bed during 1000kg pours. Pressure drop should stay under 0.5-1.0 MPa to maintain fill speed.

Iron engine blocks run hotter. Pour temperatures hit 1450-1550°C. Switch to alumina-based foam at 20 PPI or honeycomb at 200-300 CPSI. The honeycomb’s straight channels keep flow even across high-volume production. One automotive supplier cut rework costs 30%—saving $50,000 per year per casting line—after upgrading from 10 PPI foam to 25 PPI ratings.

Filter cost runs $2-5 per kilogram of melt. High-volume lines processing 10,000+ units each month hit payback in under 12 months. ROI exceeds 25% as scrap reduction combines with faster cycle times.

Aerospace: Zero-Defect Mandate

Turbine blades can’t have porosity. Structural castings can’t have inclusions. AMS 2175 Class A standards allow fewer than 10 defects per cm². Miss this target and the part gets scrapped. Titanium aerospace castings cost $800-2,400 per kilogram. One bad pour destroys thousands in material value.

Fine mesh filtration at 15-25μm becomes mandatory. Use 45-60 PPI zirconia foam for titanium and superalloy work. Capture efficiency must reach 99% for particles above 20μm. Lower ratings don’t meet aerospace quality gates.

Temperature needs exceed automotive work. Superalloys pour at 1600-1700°C. Zirconia-based filters are the only option that survives this. Silicon carbide works for some nickel alloys but fails against titanium’s chemical attack.

NADCAP certification requires documented filter performance. Track lot numbers, installation dates, and metal tonnage processed. Risk assessment scores must stay below 2 out of 10 for critical flight hardware.

One aerospace manufacturer documented 25% efficiency gains and $75 million in savings over 18 months by switching to premium zirconia filters. Defect-free pours cut out expensive rework loops. The upfront filter cost—$25-40 per unit—paid back through first-pass yield improvements.

Industry Benchmark Comparison

|

Criteria |

Automotive |

Construction |

Aerospace |

|---|---|---|---|

|

Primary Weight |

Quality (25%) |

Cost (40%) |

Compliance (30%) |

|

Target ROI |

25% |

15% |

30% |

|

Payback Period |

12 months |

6 months |

18 months |

|

Defect Reduction |

40% |

20% |

60% |

|

Filter Cost/kg |

$2-5 |

$1-2 |

$5-10 |

|

Required Mesh Size |

25-40μm |

50-100μm |

15-25μm |

Real operations using this framework saw clear gains. Manufacturing facilities improved project success rates 40% while cutting timelines 25%. Technology platforms achieved 25% ROI above industry average by weighting feasibility at 30% and resources at 20% in their selection models.

Your industry sets your filter type. Your production volume sets the budget. Your quality standards define the minimum performance. Match all three right and choosing between ceramic foam filters and honeycomb filters becomes an easy choice—not a gamble.

Conclusion

There’s no universal winner between ceramic foam filters and honeycomb filters. You need to match the right filter to your casting operation.

Ceramic foam filters work best for aluminum and magnesium applications. They capture inclusions well and reduce turbulence in complex shapes. Honeycomb filters offer strong thermal stability and cost savings. Iron and steel foundries with high-volume production lines benefit most from them.

Here’s how to decide: Check your primary metal type. Look at your cleanliness standards. Consider your production volume and budget. Match these factors with each filter’s strengths. A small-batch aluminum aerospace parts maker will pick a different filter than a large ductile iron automotive foundry.

Your next step? Pull up your last quarter’s rejection rates. Trace them back to filter performance. This data shows whether you need ceramic foam’s deep-bed filtration or honeycomb’s simple design. Make ceramic foam filters vs. honeycomb filters a data-driven choice, not a guess. Your casting quality goes up. Scrap costs drop.

Your filter choice today determines your profit tomorrow.