FM-07 Custom Fiberglass Mesh Filter for Metal Casting

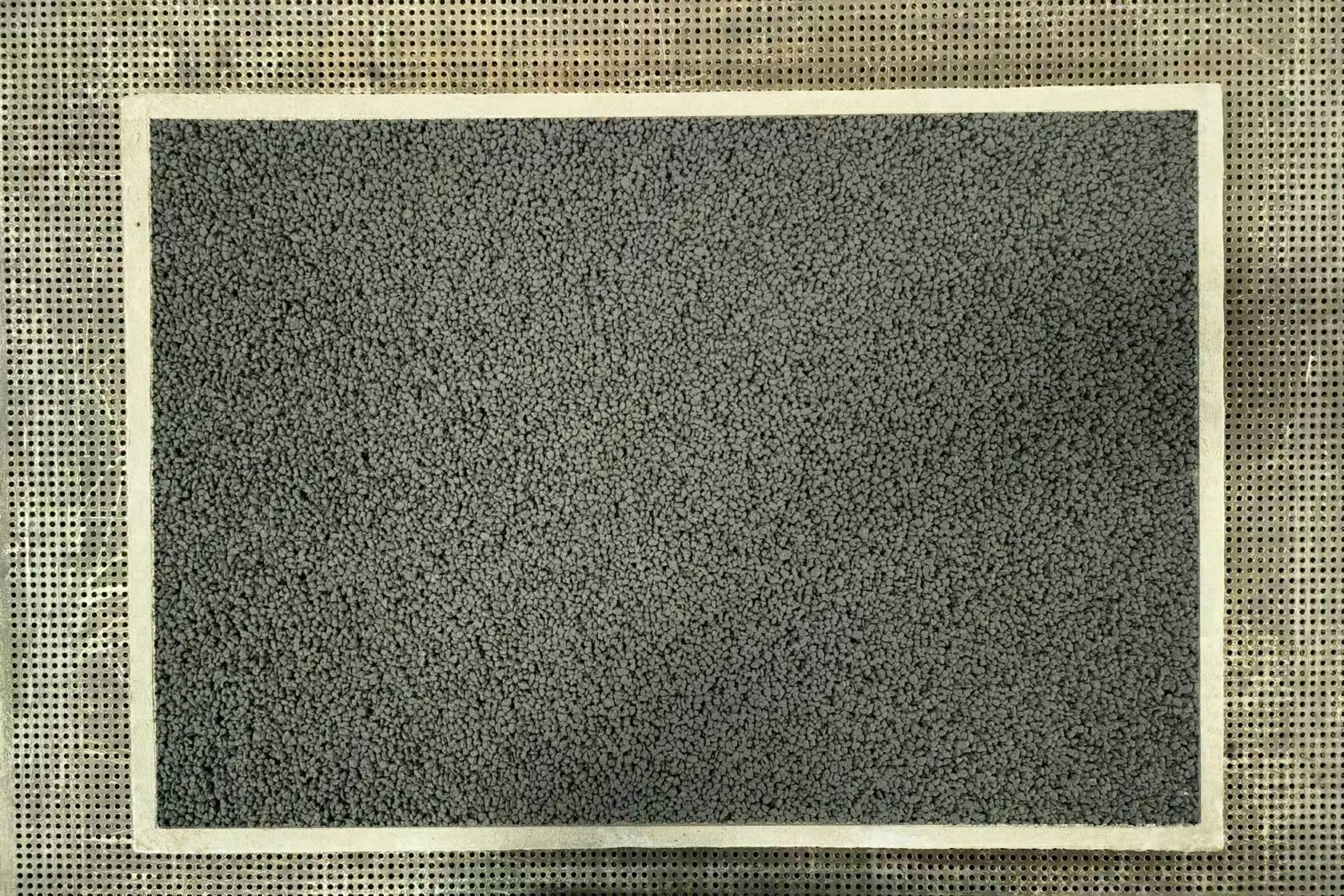

As a professional metal filtration products manufacturer, our company is committed to addressing key pain points in the metal casting industry. During the casting process, non-metallic inclusions in the molten metal can seriously affect casting quality, leading to defects such as reduced strength, porosity, and cracks. Our FM-07 series fiberglass mesh filter for casting, the screen filter, is crafted from special high temperature cloth materials such as high-silica glass fiber. It maintains structural stability in extremely high-temperature environments, and its precisely designed mesh structure effectively intercepts inclusions from the molten metal.

Compared to wire mesh filters, our fiberglass filters offer superior molten metal filtration performance and excellent high-temperature resistance. Using our filter products reduces casting defects, improves yield, and creates significant economic benefits for foundries.

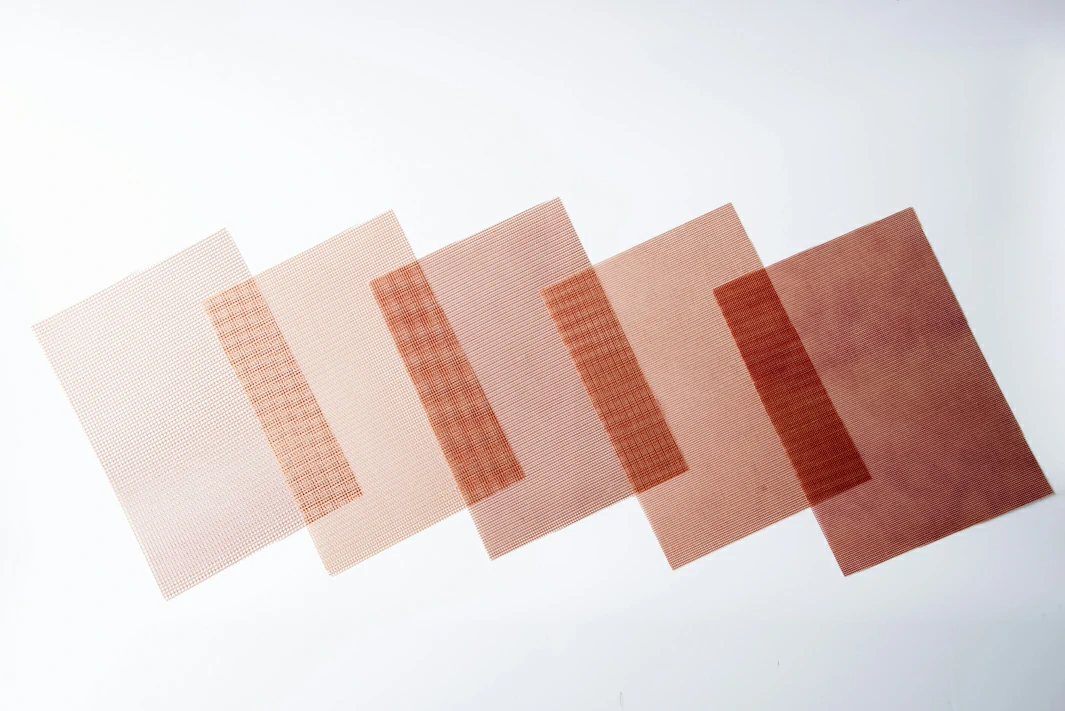

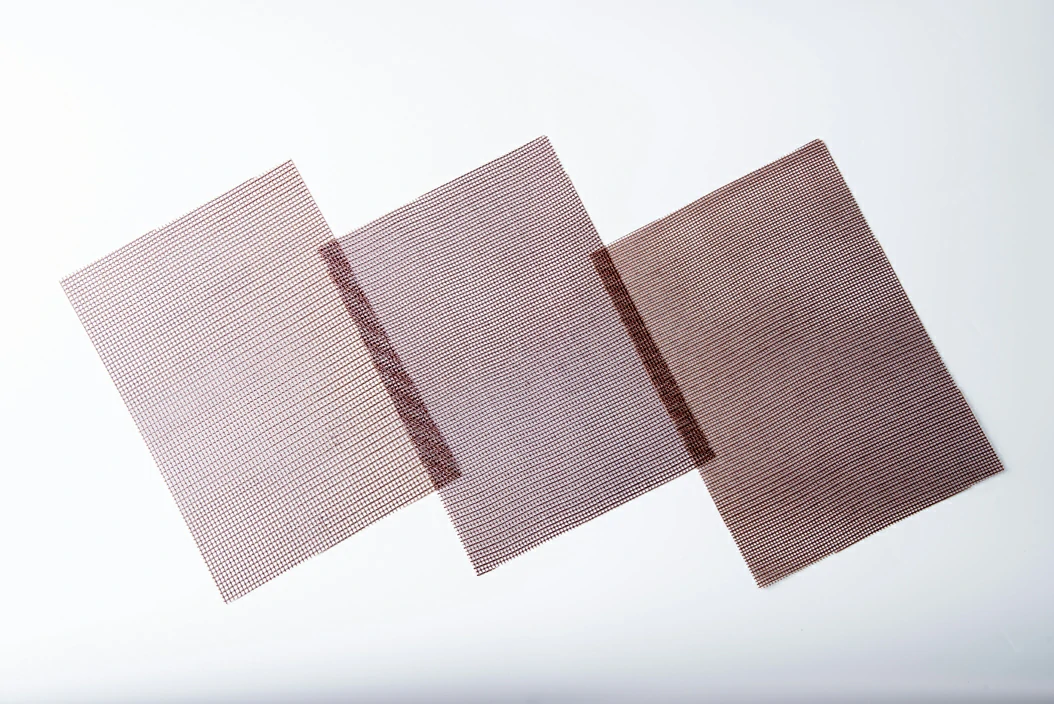

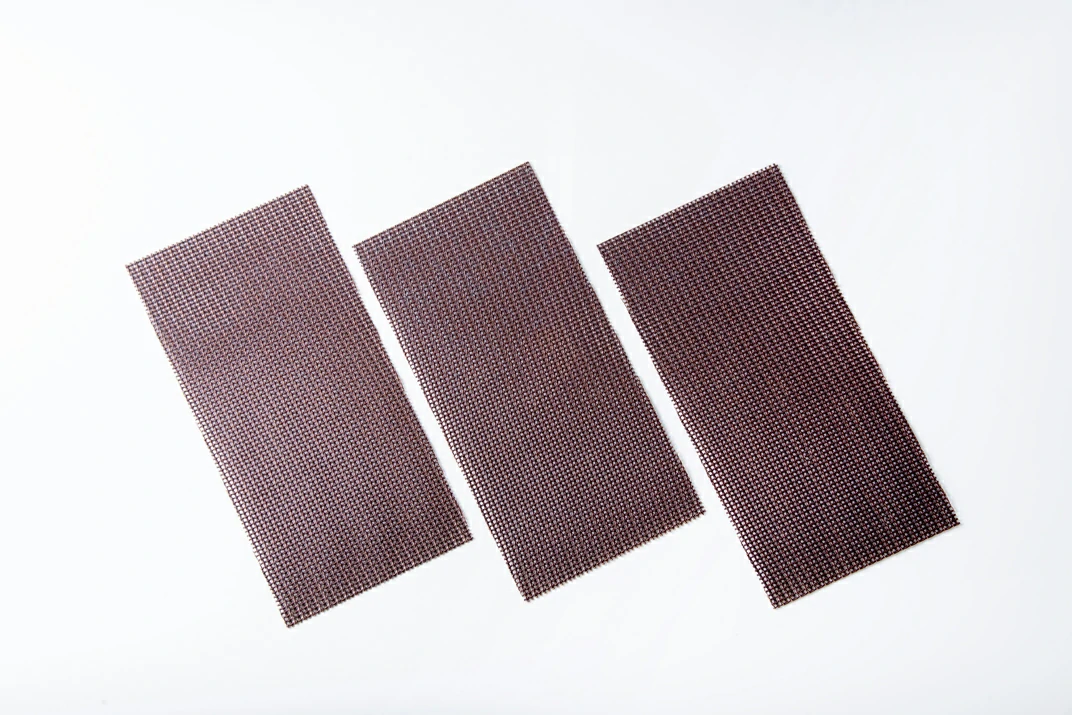

Available in Various Sizes

Mesh sizes range from 0.8×0.8mm to 2.5×2.5mm to meet diverse casting requirements.

Fully Custom Filter Service

Custom shapes, sizes, and thicknesses are available upon request.

Multi-Metal Compatibility

Suitable for various metal casting processes, including steel, iron, aluminum, and copper castings.

Easy Installation

Easily cut to desired shapes and installed in various locations, such as pouring cups and runners.

Molten Metal Filtration

High Temperature Filter Material Manufacturer

Our fiberglass filter is more than just a molten metal filtration product; it’s a comprehensive filtration solution for improving casting quality. Through superior filtration performance, flexible customization options, and comprehensive technical support, we help our customers significantly improve casting quality, reduce production costs, and ultimately enhance their market competitiveness. Compared to other metal filtration solutions, we offer higher cost-performance, a wider range of applications, and more comprehensive service support, making us the ideal choice for companies striving for superior casting quality.

Different Filter Types and Functions

We offer a comprehensive range of fiberglass mesh filters for foundries, optimized for various metal casting processes and temperature requirements. Each type undergoes a rigorous quality control process to ensure consistent filtration performance and reliable performance.

FM-07-AL Series (Aluminum Filter)

Designed for 700-800°C aluminum filtration, offers excellent corrosion resistance and filtration efficiency, making it particularly suitable for the production of high-quality aluminum castings such as automotive aluminum wheels and aluminum alloy structural parts. The filtration mesh primarily addresses alumina inclusions and porosity in aluminum melts, effectively improving the surface finish of castings.

FM-07-FE Series (Iron Filter)

Developed specifically for the temperatures of molten iron and copper, it features a reinforced filtration mesh structure, enhanced thermal and chemical stability, and is suitable for the production of gray cast iron, ductile iron, and various copper alloy castings. The high temperature filter effectively removes sand, slag, and non-metallic impurities from molten iron and copper, improving the mechanical properties and workability of cast iron parts.

FM-07-ST Series (Steel Filter)

Specially designed to withstand the high-temperature steel casting environment of 1500-1700°C. Coated with a special high-temperature-resistant material, it offers excellent thermal shock resistance and structural stability, making the mesh filter suitable for the production of various steel castings. It can effectively remove non-metallic inclusions from molten steel, significantly improving the mechanical properties and surface quality of steel castings.

Technical Specifications

| Parameters | FM-07-AL | FM-07-FE | FM-07-ST | FM-07-CU |

| Applicable Metals | Aluminum and Aluminum Alloys | Cast Iron | Steel and Steel Alloys | Copper and Copper Alloys |

| Working Temperature Range | 700-800°C | 1300-1450°C | 1500-1700°C | 1000-1200°C |

| Mesh Size | 0.8×0.8mm-2.5×2.5mm | 1.5×1.5mm-2.5×2.5mm | 1.5×1.5mm-2.5×2.5mm | 1.5×1.5mm-2.5×2.5mm |

| Applicable Castings | Automotive Parts, Aviation Castings | Machine Tool Castings, Valves, and Pipe Fittings | Precision Steel Castings, High-Temperature Components | Electrical Components, Art Castings |

Applicable Gating Systems

For sand casting, die casting, pressure die casting, precision casting, centrifugal casting, and other processes

Applicable Gating Systems

Compatible with various pouring cups, sprues, runners, and ingate designs

Applicable Metal Types

For carbon steel, stainless steel, gray cast iron, ductile iron, various aluminum alloys, copper alloys, and magnesium alloys

Applicable Casting Sizes

Suitable for small precision castings to large industrial castings

Fiber Glass Filter for Casting - Economically Effective Molten Metal Filtration Solutions

Made of special high-temperature fiberglass materials, it withstands extreme heat ranging from 700°C to 1700°C, making it suitable for all casting processes. The high temperature filter effectively removes non-metallic inclusions from molten metals such as cast steel, cast iron, cast aluminum, and cast copper, significantly improving casting quality and reducing scrap rates.

Fiberglass Filter Shapes

It is easy to install and cut to size. The filter design grid structure provides excellent filtration efficiency and smooth metal flow. Available in a variety of sizes to fit different metal types and casting processes. When used with a slag bag, it works even better for filtration performance at removing impurities.

Sheet Screen Filter

The filtration mesh can be cut to specific dimensions and easily installed in the gating system.

Custom Cap-type Filter

A pre-formed cap-shaped structure suitable for direct installation into a specific gate or runner shape.

Filter Application

Filter Screen in Casting System

Cap-type Filter in Traditional Sand Casting

Cap-type Filter in Investment Casting Pouring Cup

Mesh Filter in Aluminum Low-pressure Casting Equipment

Frequently Asked Questions

What are the advantages of fiber glass filters compared to ceramic filters?

Our fiber glass filters offer greater flexibility than ceramic filters and can be cut to various shapes and sizes.

Can the mesh filter be reusable?

Fiberglass mesh filters for casting are designed for single use. As the molten metal flows through them, the filter captures impurities and may partially carbonize, making them unusable. A new filter should be used for each casting to ensure optimal filtration.

What precautions should be taken when installing the filter?

Ensure that the filter completely covers the runner cross-section and can be cut as necessary. The installation location should take into account the metal flow path. It is generally recommended to install it inside the pouring cup or at the runner entrance.

Can you customize filters for special shapes?

Yes, we offer full customization services and can design filters in any shape to suit your gating system, including round, square, trapezoidal, or even custom shapes. Simply provide detailed dimensional drawings or samples, and we’ll manufacture them.

Is there a problem using the same filter model for different metals?

Different metal melts have different temperature, fluidity, and impurity characteristics. Using a filter designed for a specific metal will achieve the best results. For example, the FM-07-AL series, designed for aluminum, will quickly fail in a molten steel environment. We strongly recommend selecting the appropriate series for the metal type.

Related Casting Filter Materials for Molten Metal Filtration

Decades of experience in the foundry industry allow us to provide top-grade molten metal filter materials for superior casting performance

Discover Your Optimal Filtration Solution

Request a free consultation with our filtration specialists to identify the ideal industrial filter technology.

CONTACT US

Let's Connect

Our Engineers Will Analyze Your Needs & Offer the Perfect Filter Design – Contact Us Today.

Address

Guanting Industrial Park, Cangzhou City,

Hebei Province, China