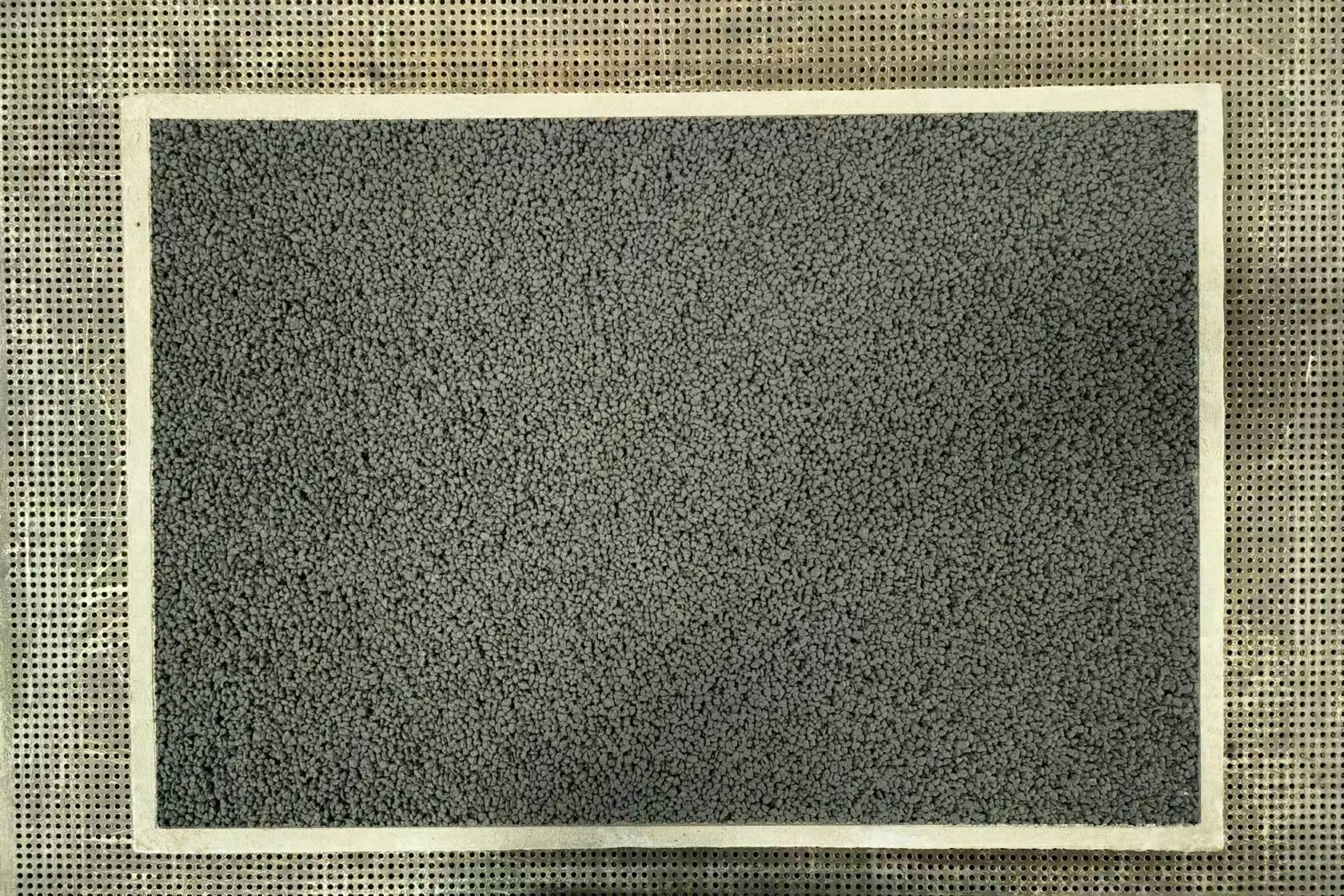

Fiberglass Mesh Filter for Aluminum Casting FM-07

Our FM-07 fiberglass mesh filter delivers exceptional filtration performance for aluminum and non-ferrous metal casting applications. Engineered with high-temperature resistant glass fibers, this cost-effective filtration cloth removes inclusions and impurities efficiently, reducing scrap rates while offering 60% cost savings compared to traditional ceramic filters. Trusted by leading foundries worldwide for consistent, high-quality castings.

-

Placement: The filter screen is typically placed in the runner system or at the sprue base to ensure all metal passes through it.

-

Compatibility: This type of filter is specifically designed for aluminum and its alloys (e.g., A356, 380). It is not suitable for metals with higher melting points, such as iron or steel.

High-Performance Glass Fiber Filter Mesh - Superior Aluminum Melt Filtration at Lower Cost

Our clients in automotive and aerospace sectors have achieved consistent quality improvements while significantly reducing their per-casting filtration expenses. The screen’s lightweight design also simplifies handling and reduces labor requirements during filter changes.

Superior Aluminum Casting Filter Screen Technical Specifications

| Parameter / Category | Technical Specifications & Typical Values |

|---|---|

| Material Composition | High-silica glass fiber (SiO₂ content >96%) or amorphous fiberglass |

| Working Temperature | Continuous use: 700°C – 800°C (1292°F – 1472°F) Peak short-term: Up to 850°C (1562°F) |

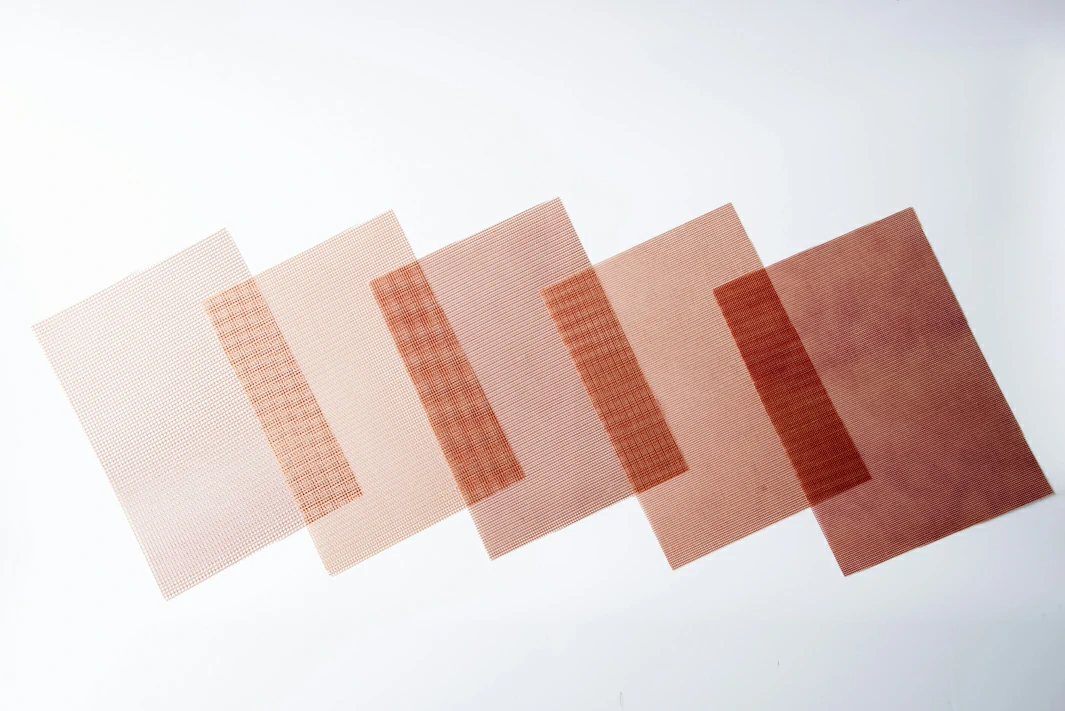

| Mesh Size (Aperture) | Common sizes: 0.8×0.8mm, 1.0×1.0mm, 1.2×1.2mm, 1.5×1.5mm, 2.0×2.0mm, 2.5×2.5mm (Mesh size selection depends on the required fineness of filtration) |

| Standard Sheet Size | Common: 100mm x 100mm, 150mm x 150mm, 200mm x 200mm (Custom sizes and shapes (e.g., round, cap) are available) |

| Filtration Efficiency | Effectively removes oxides (Al₂O₃), slag, and non-metallic inclusions larger than the mesh aperture. |

| Chemical Compatibility | Chemically inert, does not alter the composition of aluminum alloys. |

| Handling & Installation | Can be easily cut with scissors or a knife to fit gating systems. |

| Typical Duration in Molten Metal | Sufficient for the duration of pouring a single mold; not designed for prolonged holding. |

| Primary Advantages | Cost-effective, easy to use, does not affect alloy chemistry |

Compatible Casting Processes

Gravity die casting / Permanent mold casting

Sand casting (green sand, resin-bonded, shell molding)

Investment casting / Lost wax casting

Low-pressure die casting

Lost foam casting

Continuous casting (ingot, billet)

Compatible Foundry Equipment

Ladle transfer systems (all capacities)

Pouring basins and sprue systems

Gating systems (in-gate, runner filters)

Degassing and refining equipment

Holding furnaces with filtration chambers

Foundry Filter Mesh for Metal Filtration

Bespoke filtration mesh designed in collaboration with your technical team to address unique foundry challenges. We customize mesh density, fiber composition, dimensions, and layering configurations based on your specific alloy chemistry, pouring temperature, and quality requirements. Our engineering team provides comprehensive filtration analysis and ongoing optimization support.

Filter Screen Production Scenarios

Metal casting foundries face a persistent challenge: slag, oxides, and non-metallic inclusions contaminate molten aluminum, leading to porosity, surface defects, and mechanical weakness in finished castings. Traditional ceramic filters, while effective, are expensive, fragile during handling, and require careful storage. Many manufacturers struggle with high operational costs.

Our Fiberglass Mesh Filter delivers a superior solution. Constructed from specialized high-temperature glass fibers with proprietary weaving techniques, this filtration cloth creates a filtration network that captures impurities. The flexible, durable mesh withstands thermal shock and mechanical stress during pouring operations, maintaining structural integrity throughout the filtration process.

Request a comprehensive technical consultation with our aluminum filtration experts to determine the appropriate FM-07 mesh filter specifications for your specific aluminum foundry.

Frequently Asked Questions

Can I cut the filter mesh to custom sizes for different mold configurations?

Yes, absolutely. Our fiberglass filter mesh is designed for easy customization. You can cut it to any shape using sharp scissors or utility knife without compromising filtration performance. The flexible mesh conforms to irregular shapes and curved surfaces, unlike rigid ceramic filters. For complex geometries, we recommend making cardboard templates first, then cutting mesh to match. Leave 10-15mm overlap at edges for secure positioning. Many customers maintain a few standard sizes in inventory and cut custom shapes as needed, reducing inventory complexity.

What is the maximum temperature this filter can withstand?

Our Standard Series withstands continuous operation up to 800°C (1472°F), suitable for most aluminum casting applications (typical pouring temperatures 680-750°C). The High-Temperature Premium Series extends resistance to 1000°C (1832°F) for specialized applications including aerospace aluminum-lithium alloys and extended holding times. Short-duration temperature spikes 50-75°C above rating are tolerable, but sustained operation above maximum rated temperature will cause fiber degradation and reduced filtration efficiency. Always select the appropriate series based on your actual pouring temperature plus 50-75°C safety margin.

Will fiberglass filter material contaminate my aluminum castings?

No. Our fiberglass is manufactured from E-glass composition specifically selected for chemical compatibility with molten aluminum. The glass fibers do not dissolve, react with, or contaminate aluminum alloys. Extensive testing including spectrographic analysis of filtered metal shows zero increase in silicon, calcium, or other glass components. The fiber surface treatment is non-reactive and thermally stable.

Can I use this filter for metals other than aluminum?

Yes, with temperature considerations. The filter works excellently for magnesium alloys (similar temperatures to aluminum), zinc alloys (lower temperatures, very safe), and lower-temperature copper alloys like bronze and brass (verify specific alloy temperature). For higher-temperature metals like cast iron (1200-1400°C) or steel (1500-1600°C), our fiberglass mesh exceeds safe operating temperature. For ferrous metals, we recommend our specialized ceramic-based filtration products. Contact our technical team with your specific alloy and temperature; we’ll confirm compatibility or recommend appropriate alternative.

More Foundry Filters

FoundryMax offers multiple foundry filters to address specific metal filtration requirements across various casting operations.

Discover Your Optimal Filtration Solution

Request a free consultation with our filtration specialists to identify the ideal industrial filter technology.

CONTACT US

Let's Connect

Our Engineers Will Analyze Your Needs & Offer the Perfect Filter Design – Contact Us Today.

Address

Guanting Industrial Park, Cangzhou City,

Hebei Province, China