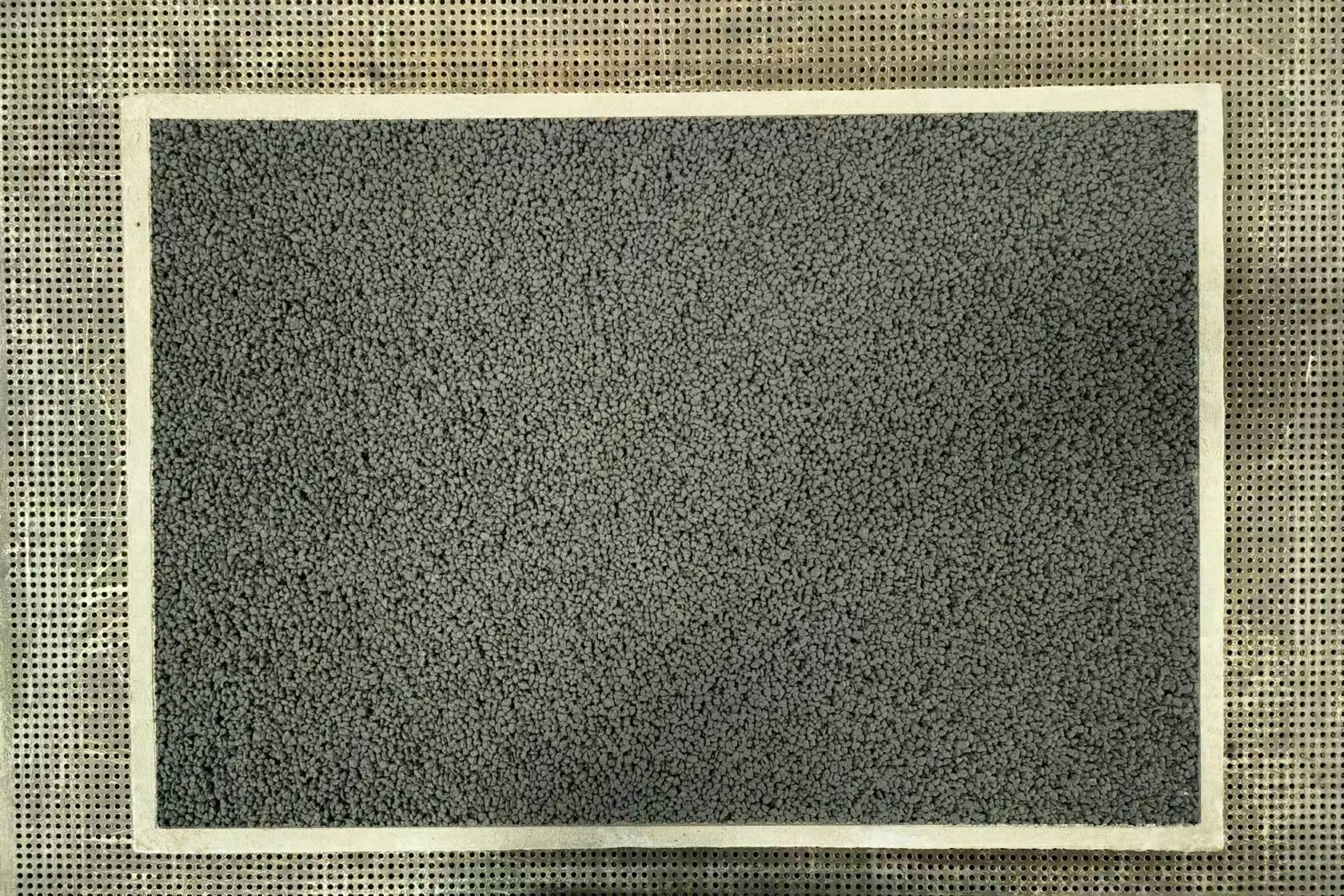

Fiberglass Mesh Filter for Molten Iron Filtration FM-07

Specially designed fiberglass mesh filter for molten iron filtration, made from high-temperature resistant glass fiber material, withstands temperatures up to 1450°C. Effectively filters oxides, slag inclusions, and impurities in molten iron, ensuring casting surface smoothness and internal density. Suitable for gray iron, ductile iron, vermicular graphite iron, and various casting processes, helping foundries significantly reduce defect rates and improve product qualification rates.

- Ultra-High Temperature Resistance – Withstands 1450°C, suitable for all cast iron melting processes

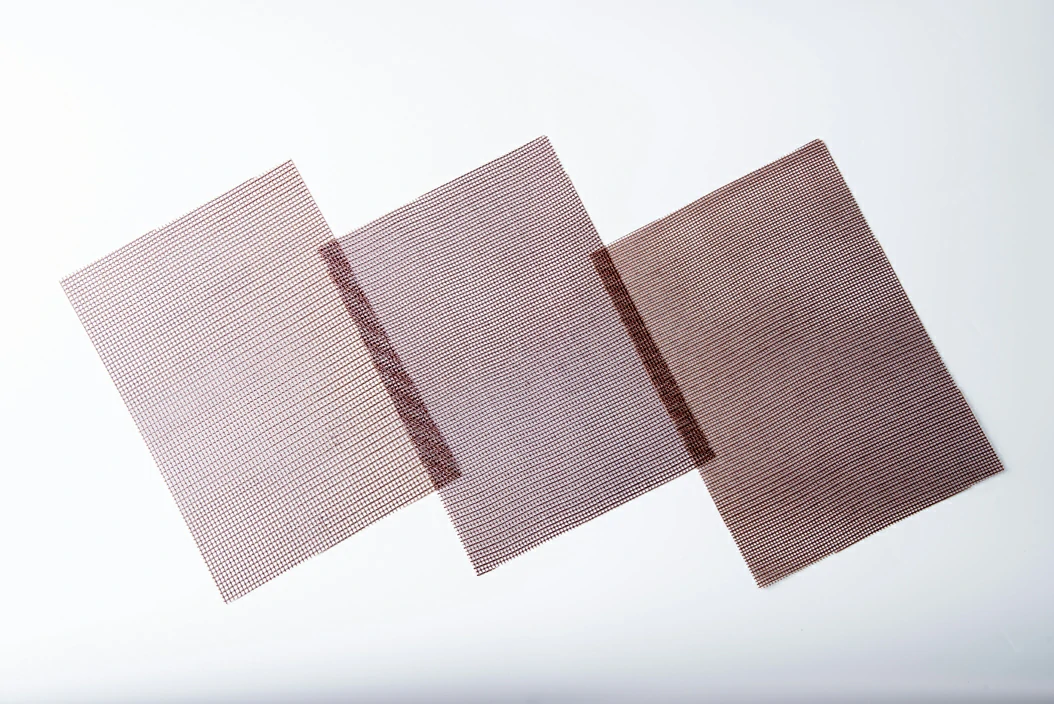

- Flexible Customization – Available in different mesh sizes, supports customization to meet different casting process requirements

Enhanced product developed for high-temperature casting processes, made from high-silica glass fiber material, stable and reliable performance, heat-resistant up to 1450°C, specifically designed for ultra-high temperature molten iron filtration needs. Particularly suitable for gray iron, ductile iron casting, vermicular graphite iron, and other high-requirement casting scenarios.

This series offers the best cost-performance ratio, ideal for small and medium iron foundries for bulk procurement. Reinforced fiber weaving structure maintains structural integrity at extreme temperatures without softening or shrinking.

Application scenarios include automotive parts casting, pipe castings, mechanical components, wind power castings, automotive engine cylinder blocks, and other conventional casting production.

Industrial High-Temperature Fiberglass Filter Mesh - Improve Casting Quality, Reduce Scrap Rate

Professional manufacturer supplies high-temperature fiberglass mesh filters for cast iron filtration, heat-resistant up to 1450°C, OEM customization available, wholesale pricing, exported to 50+ countries worldwide.

Technical Data Sheet: Molten Iron Filtration Fiberglass Filter

This datasheet outlines the key specifications of high-silica fiberglass filters designed specifically for the filtration of molten iron (including ductile iron and gray iron) in foundry gating systems.

| Parameter Category | Specification | Details / Note |

|---|---|---|

| Product Identification | Primary Application | Filtration of Molten Iron (Ductile Iron, Gray Iron) |

| Filter Type | Woven High-Silica Fiberglass Mesh | |

| Thermal Properties | Continuous Working Temperature | 1400°C – 1450°C |

| Softening Point | ~1700°C | |

| Effective Contact Time | Approx. 10 minutes in molten iron. Optimal filtration is achieved within the initial moments of pouring. | |

| Filtration Performance | Primary Function | Removes non-metallic inclusions (slag, oxides, refractories), promotes laminar flow, reduces turbulence. |

| Standard Mesh Sizes (Hole x Hole) | 1.5 x 1.5 mm, 2.0 x 2.0 mm, 2.5 x 2.5 mm | |

| Product Form & Handling | Standard Sheet Dimensions | Customizable. Common sizes: 300mm x 300mm, 400mm x 400mm |

| Handling | Can be easily cut with scissors or a knife to fit any gating system. |

Compatible Casting Materials

Gray Iron

Ductile Iron

Vermicular Graphite Iron

High-Strength Cast Iron

Wear-Resistant Cast Iron

Special Alloy Cast Iron

Compatible Casting Processes

Sand Casting

Lost Foam Casting

Shell Mold Casting

Permanent Mold Casting

Centrifugal Casting

Continuous Casting

Foundry Filter Mesh for Metal Filtration

Foundry enterprises commonly face high scrap rates due to slag inclusion defects in castings. Traditional ceramic filters, while somewhat effective, are fragile, and increase production costs. Our FM-07 Series Fiberglass Molten Iron Filter Mesh utilizes patented high-silica glass fiber technology, effectively intercepts oxide inclusions, sand particles, and slag in molten iron. The special fiber weaving process maintains structural stability at temperatures up to 1450°C without melting or deformation.

Compared to ceramic filters, fiberglass filter mesh is lighter, easier to install, and due to its flexibility. The product has passed ISO 9001 quality certification, exported to over 50 countries including Turkey, USA, and India, serving more than 800 foundry manufacturers.

Foundry Industry

- Automotive parts casting (engine blocks, cylinder heads, crankshafts)

- Machinery manufacturing castings (pump bodies, valves, gearboxes, hydraulic cylinders)

- Construction hardware castings (manhole covers, pipe fittings, brackets)

Energy Equipment Industry

- Wind power equipment castings (hubs, bases, gearbox housings, main shafts)

- Hydroelectric equipment castings (turbine blades, guide vanes, spiral casings)

- Thermal power equipment castings (turbine components, boiler parts)

Marine & Offshore Engineering

- Marine castings (propellers, rudders, anchors, valves)

- Offshore platform castings (connectors, support structures)

- Marine engine castings (cylinder blocks, cylinder heads, crankshafts)

Our Core Value Proposition

As a professional fiberglass filter mesh manufacturer and exporter, we provide global foundry enterprises not just filtration products, but a complete casting quality improvement solution. By adopting our FM-07 Series high-temperature fiberglass filter mesh, foundry enterprises can:

In quality – it reduces casting scrap rates, surface defects, and internal porosity, achieving a significant leap in casting quality and meeting the stringent requirements of high-end markets such as automotive, energy, and precision machinery.

In cost – the overall operating cost is lower than traditional ceramic filters, significantly improving enterprise profitability and market competitiveness.

In service – it provides comprehensive services from filtration solution design and product customization to after-sales support. A professional technical team is available 24/7 to respond to customer needs, helping customers solve various casting challenges and becoming a trusted long-term partner.

We promise: higher filtration efficiency, longer service life, lower overall costs, and superior technical services to help casting enterprises achieve high-quality development.

Are you facing problems such as casting inclusion defects, high scrap rates, and excessively high filter prices? Let our fiberglass filters help you!

More Foundry Filters

FoundryMax offers multiple foundry filters to address specific metal filtration requirements across various casting operations.

Discover Your Optimal Filtration Solution

Request a free consultation with our filtration specialists to identify the ideal industrial filter technology.

CONTACT US

Let's Connect

Our Engineers Will Analyze Your Needs & Offer the Perfect Filter Design – Contact Us Today.

Address

Guanting Industrial Park, Cangzhou City,

Hebei Province, China