Ever stood in an auto store, staring at rows of air filters? I know I have. You wonder: is foam or cotton better for your ride? Both options sound good. But here’s the thing. Pick the wrong one and you get more dust in your engine. Or you spend extra time on cleaning.

People talk about air filtration and airflow all the time. But based on my experience, there’s one key factor most folks miss. It’s what really matters in air filter choice.

Filtration Efficiency

I’ve compared foam air filters and cotton air filters for filtration efficiency. The differences are clear. This is true when you need protection in harsh or dusty places.

Foam Air Filters: Superior Filtration in Dusty Conditions

Foam Filters achieve over 99% filtration efficiency for particles larger than 10 microns when you oil them well. They work well down to the 2–5 micron range.

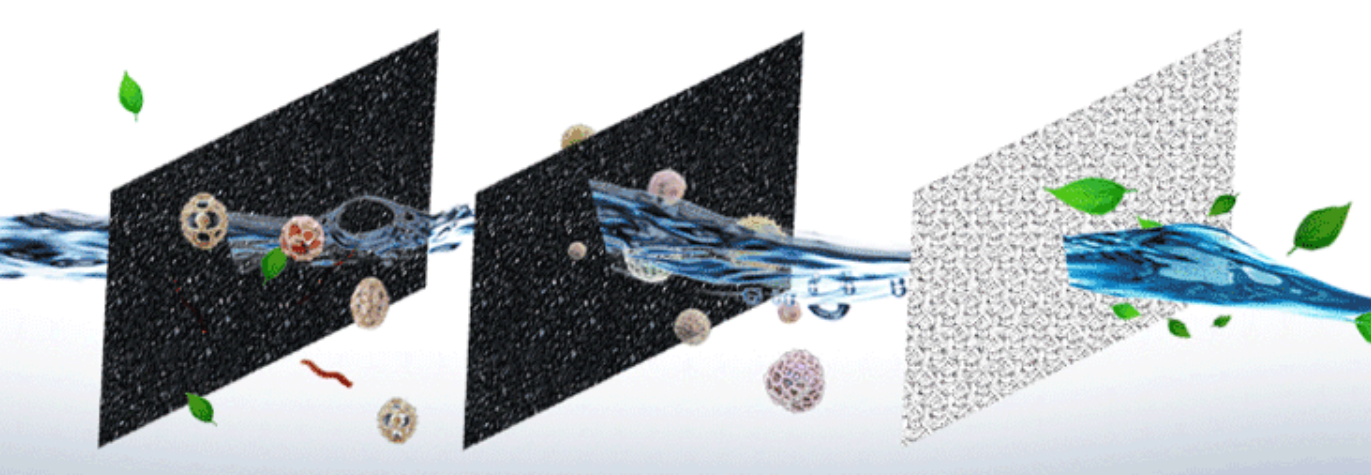

Their dense, multi-layered structure creates “depth filtration.” Particles get trapped through the entire thickness of the filter. This catches both large and fine debris, not just on the surface.

Foam’s design provides a high dust holding capacity. It absorbs much more dirt before airflow gets restricted. This means strong filtration and steady performance for longer periods. You clean them less often.

Foam material handles repeated washing and oiling. It offers lasting efficiency and durability.

Use Case: I recommend Foam filters for off-road motorsports and very dusty work settings. They handle both coarse dirt and tiny debris. Based on my experience, they are the best choice for engine protection where air quality matters.

Cotton Air Filters: Optimized Airflow with Moderate Filtration

Cotton Air Filters are made from oiled multi-layer cotton gauze. They are built for maximum airflow and engine performance. But they offer lower effectiveness for ultra-fine particles.

Cotton filters use a surface filtration approach. They trap debris on the outer layer. Their larger pores let more ultra-fine dust pass through. This is true as the filter gets dirty.

Efficiency depends on cleaning and oiling. Cotton filters work well when fresh. But they need frequent maintenance to avoid performance drops as dust builds up.

I like high-quality cotton filters in performance vehicles. They are favored where airflow matters more than blocking every particle.

Use Case: I suggest cotton gauze filters for high-performance street vehicles. They deliver strong engine response and good protection. You must clean and re-oil them often.

Key Comparative Data and Summary

Foam Air Filters:

They maintain strong filtration and consistent airflow. Less risk of clogging exists. Performance drops happen less often. They are durable. You clean them less often. Over 99% filtration for particles >10 microns (oiled).

Cotton Air Filters:

They maintain low airflow restriction. This boosts performance. They lose filtration efficiency for fine dust unless you keep them very clean. They need more regular cleaning and upkeep.

Airflow Performance

Let me compare foam air filters and cotton air filters for airflow performance. There are key differences you should know about.

Foam Air Filters: Consistent Airflow with Dirt Load

Foam air filters use a Tri-Foam layered structure. Air passes through winding channels. This design gives you optimized airflow with minimal pressure drop. You’ll notice this most when the filter is clean.

Industry tests prove their value. The SAE J726C procedure on AMSOIL foam filters shows these filters maintain up to 99%-100% filtration efficiency. Airflow stays steady, even as they get dirty. Their unique structure holds more dust. They won’t collapse or clog fast.

I see foam filters used in off-road, racing, and high-dust environments. People select them for consistent airflow over longer intervals. Performance stays stable as dirt builds up.

Comparison data shows that foam filters “can provide airflow as good as cotton gauze” filters in most direct tests.

Case Example: A MINI with an ITG Foam filter got better fuel economy. Power delivery became steadier after replacing a clogged paper filter. The foam’s surface flows more freely. It tolerates more dust.

Cotton Air Filters: Max Airflow for Performance

Cotton gauze air filters (like K&N) use a multi-layer, pleated, oiled design. This setup gives you maximum airflow. Intake restriction stays minimal when clean. Manufacturers claim some models provide at least 50% more airflow compared to traditional paper filters.

More airflow from cotton filters means real gains in horsepower and torque. I recommend them for high-performance street and track vehicles.

But there’s a trade-off. Their large pore structure and surface filtration mean efficiency drops if you don’t clean them often. Very fine particles may slip through.

Cotton filters work best where engine output and throttle response matter most.

Case Example:

A high-performance sports car running oiled cotton gauze filters showed more horsepower on the dyno. The improved airflow made the difference. But it needed consistent cleaning to maintain peak performance.

Key Data and Practical Insights

Foam filters:

- Airflow matches cotton gauze, based on test data.

- AMSOIL foam: Stays near 99%-100% filtration efficiency with almost no airflow drop (SAE-tested).

- Keeps airflow steady for longer service intervals—even as dirt builds up.

- Peak airflow is a bit less than cotton. But it filters fine particles much better.

Cotton filters:

- Up to 50% higher airflow than paper filters (manufacturer claim).

- Built for maximum engine performance.

- Must be cleaned and re-oiled often for best results.

My Take:

I recommend foam filters for motorsports and off-road use. Long-lasting balanced airflow matters there. Dust handling is critical. For high-performance street vehicles, I suggest cotton filters. They unlock real power gains and airflow. But you need to maintain them more often to keep that performance edge.

Durability and Longevity of Foam vs. Cotton Air Filters

Durability and longevity matter when you choose between foam and cotton air filters. Here’s how each type performs:

Foam Air Filters: Built for Tough Conditions

- Strong and durable: Foam filters use tough polyurethane material. They resist tears and punctures. They handle water exposure far better than cotton filters.

- Long service life: Foam filters last beyond 50,000–100,000 miles with proper care. You need to wash and oil them. Off-road riders and powersports users report multi-year use. Some run them across several racing seasons. They don’t lose efficiency or structure.

- Deep filtration benefit: Foam has a thick, multi-layer design. It traps large amounts of dirt before you need to clean it. Efficiency stays high even as dust builds up.

- Moisture and vibration resistance: Foam holds its shape in humid or wet conditions. It doesn’t collapse or bend. I recommend foam for harsh, muddy, or wet settings.

- Maintenance tips: After washing, dry the foam all the way through. This stops mold growth. It also ensures the filter oil soaks in for full protection. Long chemical exposure or poor care can cause aging. The foam may harden or seal poorly over time.

Cotton Air Filters: Longevity for Everyday Driving

- Reusable and long-lasting: Cotton filters use oiled cotton gauze. They can reach up to 150,000 miles. Some span the life of your vehicle. You must clean and oil them at regular intervals.

- Solid performance after cleaning: Cotton filters work great on-road and in mild conditions. They need more frequent care (every 5,000 miles or so). High-performance vehicles may need even sooner maintenance.

- Heat and chemical resistance: Cotton filters handle high temperatures well. They resist engine chemicals. Their layered build stays flexible. It holds form through many clean-and-oil cycles.

- Maintenance needs: Cotton filters last long in normal road situations. But they clog faster in dusty or wet environments. They drop in performance if you don’t service them on schedule.

Direct Comparison Table

| Feature | Foam Air Filter | Cotton Air Filter |

|---|---|---|

| Best Use Case | Off-road, dusty, wet, high-vibration | High-mileage, everyday driving, on-road |

| Water Resistance | Excellent (keeps structure) | Moderate (can get waterlogged, needs drying) |

| Lifespan | >50,000–100,000 miles, multi-year in harsh settings | Up to 150,000 miles, lifetime of vehicle possible |

| Maintenance Frequency | Less frequent in dust/extreme environments | Every ~5,000 miles, more if in high dust |

| Vulnerabilities | Can harden or tear if you neglect it | Fabric edges can fray, temporary waterlogging |

Both options outlast disposable filters. Each type shines in its own environment. Match your filter to your maintenance habits and driving conditions.

Water Resistance: Foam Air Filters vs. Cotton Air Filters

Foam air filters offer much better water resistance than cotton air filters. Polyurethane foam repels water by nature. It keeps its shape and filters well even in heavy rain or high humidity. Cotton air filters, particularly oiled cotton gauze types, have more trouble with moisture.

Foam Air Filters: Superior Water Resistance

- Reliable Protection: Foam filters block dirt and particles even when wet. They maintain airflow and structure.

- Fast Cleaning and Drying: Foam dries fast after water exposure. You can clean and re-oil it in no time. No long waits.

- Best for Tough Conditions: I recommend foam for off-road, powersports, and engines in wet or muddy places. The open-cell structure, when oiled, filters well and repels water.

- No Extra Gear Required: Foam filters stay water resistant on their own. You don’t need extra wraps.

Cotton Air Filters: Water Weaknesses

- Waterlogging Risk: Oiled cotton gauze soaks up water. It gets saturated. This cuts airflow until it dries out.

- Slower Maintenance: Cotton filters need complete drying after water exposure. Then you must re-oil them before use. The deep, pleated layers take much longer to dry.

- Extra Equipment Required: Some brands (like K&N) sell optional hydrophobic pre-filter wraps (e.g., DRYCHARGER®). These wraps cover the cotton filter to block water for up to 1–2 years. This proves cotton alone can’t handle tough, wet conditions.

- Reduced Filtration When Wet: Wet cotton loses efficiency. It may fail to protect your engine for a time.

Water Resistance Comparison Overview

Foam Air Filters:

- Repels water and works well in moist conditions.

- Cleans and dries fast; ready to use soon after exposure.

- Keeps filtering well even when wet.

Cotton Air Filters:

- Gets waterlogged, which reduces airflow and protection.

- Dries slower and needs extra steps like wraps and re-oiling.

- Not good for places with frequent water exposure.

Conclusion:

For moisture, splashing, or rain conditions, I suggest foam air filters. They win on water resistance. Their design and materials handle wet and tough environments better. Cotton filters need more maintenance and equipment to deal with water.

Maintenance Requirements for Foam vs. Cotton Air Filters

Foam and cotton air filters need different care. Understanding this helps you pick the right one. Each type has its own cleaning schedule and care routine.

Direct Comparison Table: Foam vs Cotton Filter Maintenance

| Key Requirement | Foam Air Filter | Cotton Air Filter |

|---|---|---|

| Cleaning Frequency | Every dirty ride, 1,500–2,500 miles | 30,000–50,000 miles |

| Cleaning Products | Grease-cutting cleaner, water, filter oil | Specialized kit, water, specific oil |

| Oiling | Saturate foam with filter oil | Use a light, even layer |

| Inspection | Check foam, edges, and glue for breakdown | Check gauze for tears and dirt buildup |

| Handling | Squeeze, never wring | Avoid harsh tools |

| Batch Maintenance | Common for frequent use | Not often needed |

Maintenance Time & Real-World Scenarios

Foam air filter service:

- Off-road: You may need to clean or swap it after every ride

- Typical cleaning task: 15–40 minutes

Cotton air filter service:

- Passenger car: It can go years between cleanings in normal conditions

- Typical cleaning: 20–45 minutes (plus drying time)

Summary:

Foam air filters need frequent cleaning, careful oiling, and routine checks. This is true in dirty or extreme conditions. Cotton filters need less frequent care. But proper oiling and gentle cleaning are still key for long-term use.

Based on my experience, I suggest choosing your filter type based on how much maintenance you can handle. Also think about the conditions where you drive.

Dust Holding Capacity: Foam vs. Cotton Air Filters

Dust holding capacity measures how much dust an air filter can trap before you need to service it. This impacts filter lifespan, performance, and how often you maintain it. This is true in dusty or off-road environments.

Foam Air Filters: Maximum Dust Retention for Harsh Conditions

High dust holding capacity comes from the thick, open-cell foam structure and large surface area. Oil-treated foam works well. It captures more dirt before airflow suffers. In off-road, motorsport, and dusty settings, I recommend foam filters. They go longer between cleanings.

User feedback and industry tests show foam has a huge surface area for dirt collection. This design keeps filtration strong. Airflow drops when the filter is heavily loaded. Oil-treated foam achieves up to 90% filtration efficiency for 10µm dust particles. It holds much more total dust than cotton before needing attention. Dry foam maintains 60–80% efficiency. Silicone-treated foam versions reach 85–95% filtration efficiency. They can retain up to 50–90g of dust before airflow becomes an issue.

Cotton Air Filters: Frequent Cleaning Needed in Dusty Environments

Lower dust holding capacity compared to foam. The oiled cotton gauze layers focus on airflow rather than maximum dirt retention.

Filter performance and airflow degrade faster as dust builds up. So more frequent cleaning is needed in dirty settings.

Oiled cotton gauze offers 70–85% efficiency for 10µm particles. It’s great for high-flow intake. But dust loads up the media fast.

In comparison charts:

- Typical cotton gauze (oiled): Dust holding capacity ~60g. Washable every 5,000–10,000 miles. Or more often in high-dust areas.

Side-by-Side Comparison and Key Insights

Foam filters beat cotton for total dust tolerance before airflow drops or cleaning is needed. I suggest foam for off-road, racing, and tough conditions. Cotton filters provide better initial airflow. But total dust they can hold is lower. Capacity falls fast in dusty conditions. So maintenance intervals are shorter.

For anyone facing heavy dust—off-roaders, dirt bikes, severe climates—I believe foam is the best choice for dust holding and longevity.

Example industry figures for context:

- Foam (oil-treated): Up to 90% efficiency for 10µm, slow to clog, longevity in harsh conditions.

- Cotton gauze (oiled): 70–85% efficiency, fast airflow, but faster decline as dust builds.

In summary: For anyone driving in extreme, dusty, or off-road environments, foam (oil- or silicone-treated) air filters offer better dust holding capacity than cotton gauze. For everyday road use, both work. But clean environments help cotton filters last longer between maintenance. If minimal downtime and long intervals between cleanings matter to you, I recommend foam. It’s the clear winner.

Cost Considerations: Foam vs. Cotton Air Filters

I want to compare foam air filters and cotton gauze air filters based on cost. This matters a lot to most buyers. Let me break down the pricing, ongoing expenses, and overall value for each type.

Maintenance Cost and Effort

Foam filters:

- Need cleaning from time to time. Easy to rinse and reuse.

- Less expensive to maintain in dusty or off-road environments.

Cotton filters:

- Ongoing cost of filter oil.

- You must maintain them well to protect the engine. This keeps efficiency high.

Cost Comparison Table

| Filter Type | Unit Price | Estimated Lifespan | Typical Cleanings & Use | Effective Cost-per-Use | Maintenance Required |

|---|---|---|---|---|---|

| Foam | $45–$70 | 18,000–30,000 km | 3–4 | $15–$23 | Wash & reinstall |

| Cotton Gauze | $110–$150 | Up to 150,000 miles | 5–6 (often more) | $20–$25 | Wash, oil, reinstall |

Foam filters offer a moderate upfront price. They become cost-effective with limited reusability. I suggest them for dirty environments.

Cotton gauze filters demand a higher initial spend. But they may be most economical over a vehicle’s life if you maintain them on schedule.

Your driving habits matter here. So does your maintenance diligence. Local conditions play a role too. Based on my experience, these factors determine which filter delivers better long-term value for you.

Application Recommendations for Foam vs. Cotton Air Filters

I suggest you think about your vehicle’s use, maintenance habits, and driving environment when choosing between foam air filters and cotton air filters. Here’s how I recommend deciding which filter fits your needs:

Best Use Cases and Recommended Applications

Foam Air Filters

I recommend foam filters for off-road vehicles, ATVs, dirt bikes, race cars, and utility vehicles operating in harsh, dusty, and dirty conditions. These work best in situations with high dust exposure and frequent debris. Think desert driving, racing events, or rural construction zones. I also like foam filters where water resistance and strong durability matter. They work well in wet, muddy, or snowy climates.

Example: Pipercross non-oiled foam filters work great for vehicles with Mass Air Flow (MAF) sensor sensitivity.

Cotton Air Filters

Based on my experience, cotton filters suit standard street cars, commuters, highway vehicles, and performance enthusiasts who want better airflow and engine performance. People often choose them for aftermarket upgrades in performance cars. Multi-layer, washable gauze designs are popular (e.g., S&B 8-layer Cotton Cleanable filter). I favor cotton filters for users seeking long service life (“fit and forget”). They shine in cleaner environments or where regular, simple maintenance is preferred.

Lifespan & Maintenance by Type

Foam Filters

- Maintenance: Clean after each dusty ride or at regular intervals. This is vital for peak filtration.

- Lifespan: Moderate—a few years with consistent care.

- Cost: Lower upfront. I find them economical for frequent filter swaps in extreme settings.

Cotton Filters

- Maintenance: Clean and re-oil every 10,000–30,000 miles depending on dust exposure.

- Lifespan: These can last your vehicle’s lifetime if you maintain them. Less frequent cleaning is needed in clean conditions.

- Cost: Higher purchase price. But I appreciate their substantial long-term value due to durability.

I suggest you choose based on your routine. Prioritize foam for rugged, dusty, or wet conditions. Go with cotton for commuter driveability and high performance on clean streets. Think about lifespan, maintenance, and total cost to match your usage and expectations.

Summary

Here’s my honest take after comparing foam and cotton filters: There’s no clear winner between them. Your best choice depends on where you drive and how you use your vehicle.

I prefer foam filters for dusty trails or off-road racing. They handle tough conditions better. For my everyday car, I choose cotton filters. They’re more convenient and last longer.

Don’t overthink this decision. Pick the industrial air filter that matches your driving style. Keep it well-maintained. Your engine will run strong for years.