Trying to pick between diecast and metal? I’ve handled both many times.

You know that feeling when you hold a model car and think, “Wow, this feels solid”? Or when you look at a shiny coin in a collection? I bet you’ve wondered what makes each one special.

The answer isn’t just “metal is stronger.” There’s a surprising detail that could change what you think is best. Have you thought about what sets them apart?

What is Diecast?

Diecast is a metalworking process. Molten metal is injected under high pressure into a custom steel mold (we call it a die). I recommend this method for producing metal parts with high precision and complex details.

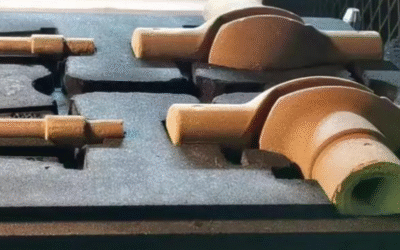

Diecasting Manufacturing Process

- Mold Design: We design custom molds using CAD software. CNC machining creates exact shapes and ensures durability.

- Metal Selection: Common metals include aluminum, zinc, magnesium, copper, pewter, and tin-based alloys. These are non-ferrous metals.

- Injection: We push the molten metal into the mold at pressures from 1,500 to over 25,000 psi (10–170 MPa). This creates sharp, accurate forms.

- Cooling: We cool molds with water or air. Parts solidify fast.

- Ejection: Ejector pins release the solidified part from the mold.

- Trimming and Finishing: We trim away excess metal. Surfaces can be coated or polished based on your needs.

Key Advantages of Diecasting

- High Speed and Productivity: Diecasting machines produce hundreds of shots per hour. Some setups generate thousands of finished parts in just a few hours.

- Dimensional Accuracy: We achieve tight tolerances, as precise as ±0.001 inches (0.025 mm) for small components.

- Excellent Surface Finish: Surfaces are smooth with roughness values as low as 1–2 microns Ra.

- Complex and Thin Designs: This process supports wall thickness down to 0.020 inches (0.5 mm). I find it ideal for intricate parts.

- Efficient Material Usage: More than 90% of materials are utilized. We remelt and reuse scrap.

Applications and Example Products

- Automotive: Engine blocks, transmission cases, brackets, valve covers

- Aerospace: Seatbelt hardware, housings for mechanical parts

- Consumer Electronics: Enclosures, connectors

- Everyday Use: Door handles, hardware, decorative pieces, toy model cars

Historical and Market Notes

Diecasting is the most popular Casting process across the globe. Its origins date back to 1838 for printing type. Commercial diecasting grew from the late 19th century. Manufacturers produce parts ranging from miniature toys to heavy-duty engine blocks.

Based on my experience, diecast manufacturing stands out for its speed, precision, and durability. It can mass-produce complex, high-quality metal products.

What is Metal (in Collectibles Context)?

In collectibles, metal means the material used to make coins, figurines, and special memorabilia. Makers use different metals. Some are precious, like gold, silver, and platinum. Others are semi-precious, such as bronze and brass. Some use industrial metals like iron.

Key Features of Metal Collectibles

- Material Variety: Collectibles use precious metals (gold, silver, platinum), semi-precious metals (bronze, brass), and iron. Each metal creates different effects and values.

- Durability: Metals resist corrosion well. They last for generations. Precious metals last the longest. I recommend precious metals if you want items that stand the test of time.

- Aesthetic and Artistic Appeal: Metals enable detailed designs, unique textures, and rich patinas. These features attract collectors and artists. Based on my experience, this is why metal collectibles feel so special.

- Intrinsic Value: Items made with precious metals have baseline worth. This worth ties to current metal prices. It impacts their market value beyond their artistry.

In summary, collectors prize metal collectibles for more than durability or raw value. They serve as mediums for creativity, rarity, and cultural storytelling. I like how metal collectibles blend artistry with lasting value.

Durability Comparison: Diecast vs. Metal Alloys

I’ve compared diecast materials with various metal alloys used in collectibles and industrial parts. Several key differences stand out. These differences can affect your choice as a collector or manufacturer.

Diecast Durability Advantages

Diecast models made with zinc resist wear and damage from rough handling much better than plastic. I recommend zinc diecast for its superior impact resistance. It outperforms both magnesium and some aluminum alloys in tough environments.

Aluminum diecast offers an impressive strength-to-weight ratio. It resists high temperatures. This makes it suitable for automotive parts, aerospace components, and electronics housings. These applications need both durability and precision.

Thicker paint coatings on diecast items help prevent fading and scratching. This maintains both aesthetic quality and long-term collectability. Premium diecast models often hold value for decades. I’ve seen collectors treasure them for years.

Diecast magnesium stands out for being lightweight and strong. But it is softer and less stable than aluminum or zinc under stress.

Durability Table: Diecast Metal vs. Plastic

| Feature | Diecast (Metal) | Plastic (Regular) |

|---|---|---|

| Durability | Durable; resists falls and rough handling | Prone to breakage; wears fast |

| Paint/Finish | Thick, resistant to scratches and fading | Easy to scratch, color often fades |

| Collectability | Retains value and appeal for collectors | Low resale or collection potential |

Example: Diecast model cars hold their condition and value. They fetch high prices among collectors even after years of use. Plastic toys often show damage in a few months of play.

Weight and Feel: Diecast Metal vs. Other Metals

I find that weight and tactile feel matter most for manufacturers and collectors comparing diecast metals. The metal you choose—zinc, aluminum, or magnesium—changes how premium a product feels in your hand.

Density and Tactile Sensation

Zinc die cast alloy has a density between 6.6–7.0 g/cm³. It’s one of the heavier diecasting options. I like how this higher density creates a solid, substantial presence. Many collectors and users link this quality with high value and durability.

Aluminum alloys have a density of about 2.7 g/cm³. Parts cast from aluminum are much lighter. They work best where portability or easy handling matters more than weight.

Zinc die castings are up to 2.5 times heavier than aluminum castings of identical size and design. This weight difference creates a unique user experience.

Magnesium alloys are the lightest among diecast metals. They’re even lighter than aluminum. I recommend them for situations needing ultra-low weight, like aerospace components or portable electronic casings.

Application Preferences Based on Weight

Zinc diecasting: I suggest this option for a heavy feel. It works well for collectibles, high-impact hardware, or decorative objects. Buyers often see these heavier items as more durable and well-made.

Aluminum diecasting: This is best for parts where light weight and easy movement are key. You’ll find it in automotive engine components, power tools, and bikes. Reducing overall mass improves performance.

Magnesium diecasting: I recommend this for applications where minimal weight is required. Think aerospace products or ultra-light consumer electronics.

Cost Comparison: Die Casting vs. Metal Manufacturing

I want to compare the costs of Die casting with other metal making methods like fabrication and machining. Many factors affect which process gives you better value.

Die Casting Costs: Upfront Investment and Volume Efficiency

Die casting needs expensive molds (dies) and special machinery. The initial setup can cost from $10,000 to over $100,000 per mold. Complex items like automotive cylinder heads cost even more. Once you make the tooling, die casting works great for high-volume production. Automated processes let factories produce thousands of parts each day. The cost per part drops as you make more units. You spread the large upfront cost across many units. This makes die casting more economical for manufacturing runs of thousands or millions.

Fabrication and Machining: Lower Setup, Higher Per-Part Cost

Fabrication and machining need little to no expensive tooling. So the initial investment is much less. These methods need more hands-on work. This increases labor costs. Machining also wastes more raw material. Complex designs in fabrication can increase overall expense. Material waste and manual processes drive up costs. Per-part pricing does not decrease much with higher volume. So small batches or custom pieces cost less with these methods.

Direct Cost Comparison: Which Method Wins

Die casting is 30% cheaper than metal injection molding for many parts. It needs lower post-processing. Compared to Sand casting, die casting has a higher tooling cost. But it becomes the cheaper option for large production runs. For low quantities of complex parts (such as a few high-precision gears), I recommend machining or fabrication. They cost less. But for thousands of complex parts, die casting’s lower unit cost makes it the winner.

In summary:

Based on my experience, die casting is the best choice for high-volume, complex metal parts. It offers lower per-unit costs once you spread mold expenses across a large run.

For small batches, prototypes, or simple parts, I like traditional metal fabrication or machining. They provide better value. Lower startup costs and flexibility make them ideal for these applications.

Common Applications of Diecast and Metal: Industry Examples and Benefits

Diecast and metal parts are important in many industries. They offer unique performance benefits. You need to pick the right alloy—zinc, aluminum, or magnesium. Your choice depends on what you need: strength, weight, detail, or cost.

Automotive Industry

Key Uses: Engine blocks, transmission cases, steering wheels, seat frames

Magnesium and aluminum diecast parts are popular here. I recommend magnesium components for engine blocks. They are up to 50% lighter than cast iron. This improves vehicle fuel efficiency. Aluminum works best for structural parts. It balances strength and lightness. Zinc alloys fit well for carburetors, precision fittings, and gear assemblies. They offer high dimensional accuracy.

Electronics & Technology

Key Uses: Laptop and tablet frames, smartphone bodies, camera housings, connectors

I like magnesium diecast cases for electronics. They are light and strong. They dampen vibration well. This supports thinner, lighter device designs. Aluminum works great for frames and covers too. For small, complex connectors and electronic parts, zinc is the best choice. It’s stable and easy to form.

Consumer Goods and Home Products

Key Uses: Door handles, locks, appliance parts, decorative hardware, toys, model cars

Zinc and aluminum diecastings are common in household items. Zinc is excellent for fine detail work. It’s easy to finish and polish. I suggest it for fancy handles, locks, or decorative pieces. Toys and model cars use Zamak 3 or Zamak 5 zinc alloys. These are strong and easy to machine.

Aerospace and Aviation

Key Uses: Aircraft seat frames, housings, brackets, lightweight structural members

Diecast aluminum (like A380 and Al-Si alloys) and magnesium (such as AZ91D) cut weight while keeping strength. This is critical for fuel savings and better performance in aerospace. Based on my experience, these materials are essential for modern aircraft design.

Material and Alloy Choices I Recommend

- Aluminum A380: Common in automotive gears, power tools, and kitchenware. It resists corrosion and machines easily.

- Aluminum AC 46500: Used in electrical and automotive parts that need flexibility and high strength.

- Zinc Zamak 3: Popular for gears, electrical fittings, toys, and precision parts. It’s stable and affordable.

- Zinc Zamak 5: Chosen for parts that need impact strength and durability.

- Magnesium AZ91D: Used in electronics and automotive for lightweight structures. It casts easily and holds up well.

In summary:

Each diecast alloy has special strengths. Zinc works best for detailed, durable small parts. Aluminum gives you lightness with strength. Magnesium offers extreme weight reduction. I recommend choosing based on your specific needs. These materials have proven themselves in automotive, electronics, home products, aerospace, and collectibles. They deliver real performance, efficiency, and quality. Their use reflects decades of smart, tested choices.

Pros and Cons of Diecast Models

Advantages of Diecast Models

-

Strong and Durable: Diecast models use sturdy metal construction. They resist everyday bumps, falls, and rough handling. I recommend them for collectors who want long-term preservation.

-

Real Weight and Feel: Diecast models have noticeable heft. This gives them a realistic “metal feel.” The weight mirrors the real item. It creates a sense of premium quality that plastic or resin models lack.

-

Pre-painted with Fine Details: Most diecast models arrive with detailed, factory-applied paint and markings. You’ll find intricate logos, realistic textures, and precise decals already applied. No extra painting or building needed.

-

Working Parts: Many premium diecast pieces have working doors, hoods, steering, or suspension systems. These moving parts boost display value. They also add to play and collector enjoyment.

-

Ready to Display: Diecast models require no building. They arrive pre-built. You can display them right out of the box.

-

High Collectible and Investment Value: Limited-edition or well-preserved diecast models can rise in worth. I’m talking about those tied to popular classic cars, aircraft, or franchises. Rare vintage models have sold for $5,000–$10,000 USD at auction.

-

Smooth Surface and Fine Accuracy: Die casting technology achieves a very smooth surface and fine details. Wall thickness can be as low as 0.3 mm for zinc and 0.5 mm for aluminum components. This supports intricate and realistic design work.

Disadvantages of Diecast Models

-

Hard to Customize: Diecast models come pre-assembled and pre-painted. There’s little room for modification. Hobbyists can’t easily customize them.

-

Higher Costs: Diecast models cost 20–50% more than similar plastic or resin models. This reflects metal materials, complex production, and higher finishing standards. Premium 1:18 scale cars retail for $120–$400 USD.

-

Heavy Weight Issues: The added mass of diecast models can make large collections hard to store or transport. This is true with bigger models or multiple pieces.

-

Material and Finish Problems: Over time, diecast models may develop stippling (small paint dots caused by metal changes). They can also experience metal fatigue leading to crumbling. This happens if you store them poorly or if they’re made from inferior alloys.

-

Scale or Detail Flaws: Some design elements must be exaggerated or simplified. Metal casting has limitations. This may result in minor scale errors. I’ve noticed this for very small or detailed parts.

-

Metal Aging Concerns: Certain diecast alloys break down with age. Poor storage conditions speed up issues. This leads to structural failures or the infamous “zinc pest.”

-

Production Scale Dependency: Diecasting works best for large production runs. Small batches or one-off pieces become expensive. High steel mold costs are the reason.

I believe diecast models deliver unmatched realism and durability. But they come at a higher price. They also offer less custom flexibility. I suggest them for collectors and enthusiasts who value authenticity, premium finish, and long-term investment value. Diecast is the clear winner with rare, limited, or vintage editions. Think about the weight, cost, and potential aging concerns before building a large collection.

Pros and Cons of Other Metal Types

I recommend considering several metal manufacturing methods besides die casting. These include Metal Injection Molding (MIM), sand casting, metal extrusion, and powder metallurgy. Each method works best for different needs. Think about precision, cost, and how many parts you plan to make.

Metal Injection Molding (MIM)

Advantages: MIM creates intricate shapes and internal channels. It handles fine details that traditional casting cannot make. This process achieves 95–99% material yield. I suggest it for expensive materials where waste matters. MIM delivers consistent tolerances of around ±0.1% in large runs. You get the same quality every time.

Disadvantages: This method becomes cost-effective above 10,000 pieces. For smaller runs, I recommend other options. Steps like debinding and sintering add time. Based on my experience, MIM doesn’t work well for prototyping. It’s also not ideal if you change designs often. Molds last for hundreds of thousands of cycles. Die casting molds can run up to a million cycles.

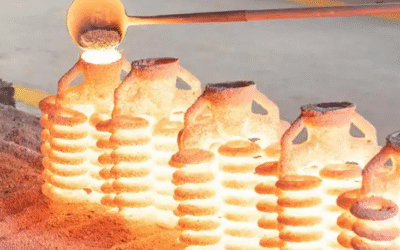

Sand Casting

Advantages: Sand casting offers flexibility. It’s affordable for small batches or large custom pieces. This method handles very large jobs. It also works well for repairs.

Disadvantages: Dimensional accuracy is weaker. The surface finish comes out rough. You’ll need machining or finishing afterward. Sand molds work one time each. This limits speed. I recommend sand casting for custom, low-volume runs. Sand-cast parts are weaker than die-cast metal. The structure doesn’t hold up as well.

In sand casting, ceramic foam filters are typically placed in the runners of the gating system. Their main function is to efficiently remove non-metallic inclusions from the molten metal, such as slag particles, refractory fragments, and oxides. As the molten metal flows through its three-dimensional network of pores, these impurities are effectively mechanically intercepted and adsorbed, thus significantly purifying the molten metal. This greatly improves the internal quality of the casting, effectively preventing casting defects such as porosity and slag inclusions caused by inclusions. It not only increases the yield, mechanical properties, and density of the casting but also makes the surface of the casting smoother. Therefore, it has become an indispensable process in the production of modern high-quality castings.

Metal Extrusion

Advantages: Extrusion works well for rods, tubes, and long, straight profiles. It keeps the cross-section consistent. I like this method for projects that don’t need complex features.

Disadvantages: You can’t produce closed or intricate shapes. Complex designs won’t work. Extruded parts bend more easily. They’re less stiff than die-cast alternatives.

Powder Metallurgy

Advantages: Every cycle produces precise parts. Material use is excellent. You get the same results batch after batch. This makes components from materials with very high melting points. Think tungsten or titanium—metals too hot for conventional casting.

Disadvantages: Cycle throughput is low. Mass production costs more than die casting. I recommend this for small, intricate, specialty pieces. Large parts don’t work well.

Summary Table: Other Metal Methods vs Die Cast

| Method | Key Pros | Key Cons | Best For |

|---|---|---|---|

| Metal Injection Molding | Complex, precise, high material yield | High setup cost, long lead time, short mold life | Small, intricate, high-volume |

| Sand Casting | Low cost for small runs, large parts possible | Rough finish, less strength, slow production | Large, low-volume or repairs |

| Metal Extrusion | Cost-effective profiles, long straight shapes | Simple shapes, less stiffness | Rods, tubes, simple profiles |

| Powder Metallurgy | Consistent parts, works with refractory metals | Limited size, high cost for high volume | Small, intricate, specialty |

Which is Better? Diecast vs Metal Manufacturing Methods

I’ve worked with both diecast and metal manufacturing methods for years. Your best choice depends on several key factors: material type, complexity, mechanical needs, volume, surface finish, and cost. Here’s a clear comparison based on my experience to help you decide.

Material Flexibility

Die casting works with non-ferrous metals—aluminum, zinc, and magnesium. These metals are perfect for lightweight, detailed, and corrosion-resistant parts. Other metalworking methods (like forging and stamping) handle a broader range. This includes steel, iron, and titanium. Do you need ultra-strong, load-bearing, or heat-resistant parts? I recommend these options.

Complexity & Precision

Diecasting excels at making complex shapes, fine details, and thin walls. Typical tolerances reach ±0.1 mm. Forged or stamped parts have simpler designs. But they deliver unbeatable strength and fatigue resistance.

Production Volume & Speed

Diecasting works best for high-volume runs—up to 1 million parts per mold. Manufacturing cycles are fast (as little as one minute per part). Stamping, forging, and MIM suit lower to medium production volumes. Molds or tools last for a couple hundred thousand cycles. Speed slows down for very large or complex items.

Surface Finish & Detailing

Diecast parts leave the mold with a smooth, fine surface finish (often <2 μm Ra). This cuts post-finishing costs. Forging and stamping often need machining or finishing. Only then can you achieve similar quality.

Cost Analysis

Diecasting involves a higher up-front investment ($10,000–$80,000 molds). But it lowers per-part costs at scale. For high-volume parts (thousands+), unit price drops fast—under $1/unit in automotive examples. Based on my experience, this is where diecasting shines.

Stamping, forging, and MIM may be more cost-effective for small batches. They also work well for custom features or frequent design changes. Setup costs are lower.

Mechanical Strength & Use Cases

Forged metal is stronger. It has better grain structure and fatigue resistance. I suggest this for hand tools, engine components under stress, and aircraft landing gear. Diecast is optimal for electronics housings, decorative parts, and detailed models. Precision beats raw strength here.

Application Examples

Diecast parts: Automotive engine blocks, consumer electronics chassis, detailed collectibles.

Forged, stamped, or MIM parts: Aircraft landing gear, high-performance machinery, structural auto parts, hand tools.

Summary:

– I recommend diecasting for intricate, lightweight, non-ferrous parts. This is true if you need tens of thousands or more with fine surfaces and lower unit costs.

– I suggest forging, stamping, or MIM for maximum strength or critical safety parts. Choose these where steel, iron, or titanium are required. You might sacrifice surface finish or pay more per part for small runs.

Which is “better”? It depends on what matters most to you: strength, weight, detail, volume, or budget.